Soybean milk machine provided with turbulent flow tube

A spoiler tube and soybean milk machine technology, which is applied in household appliances, kitchen appliances, milk substitutes, etc., can solve the problem of not being able to effectively reduce the fluid speed of the cutter, so as to improve the crushing effect, increase the thickness of the blade, and have a good crushing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

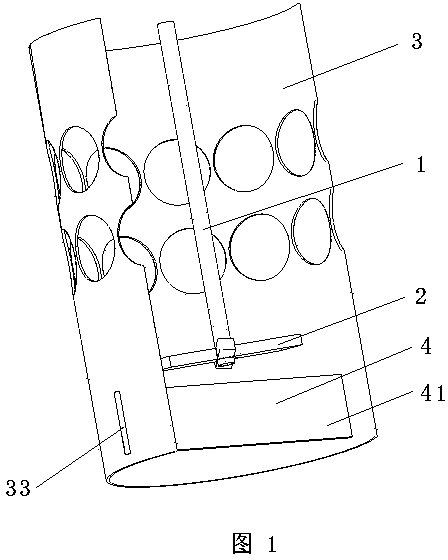

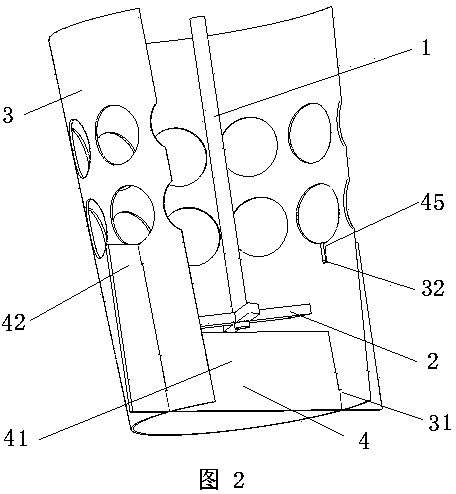

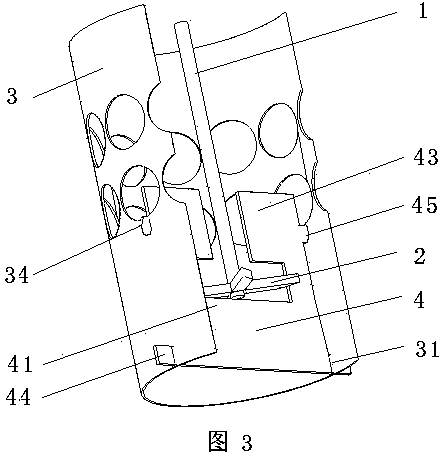

[0045] figure 1 It is the first embodiment of the present invention. The thin-walled tube 3 of this embodiment is connected to the machine head. There are holes on the thin-walled tube 3. The cutter shaft 1 and the cutter 2 are inserted into the thin-walled tube 3. The whole piece of turbulence The in-tube horizontal portion 41 of the sheet 4 straddles the inside of the thin-walled tube 3 and is fitted in front of the cutter 2, that is, on the lower surface. The fitting structure of the thin-walled tube 3 is a pair of axial grooves 33 on the tube wall, and the two ends of the spoiler 4 are embedded in the grooves 33 .

[0046] During assembly, pressure can be applied to cause elastic deformation of the thin-walled tube 3 or the spoiler 4, and the spoiler 4 is inserted upward from the lower end of the thin-walled tube 3. After reaching the fitting position, the pressure is released to make the thin-walled tube 3 or the spoiler 4 The elastic deformation of the tape-outs 4 rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com