Automatic food processor

A food processing machine and automatic technology, which is applied in home appliances, applications, kitchen appliances, etc., can solve problems such as increased noise, accelerated motor vibration, and reduced consumer experience, so as to achieve the effect of improving crushing efficiency and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

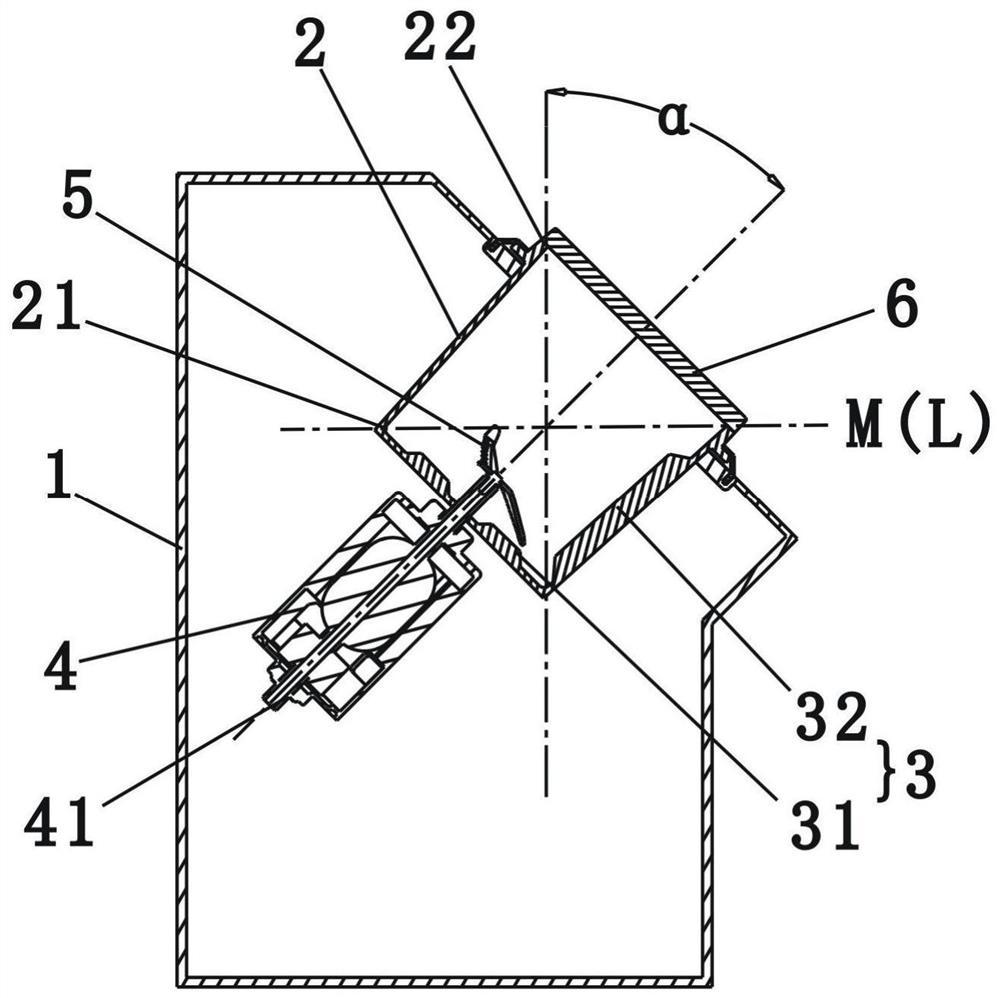

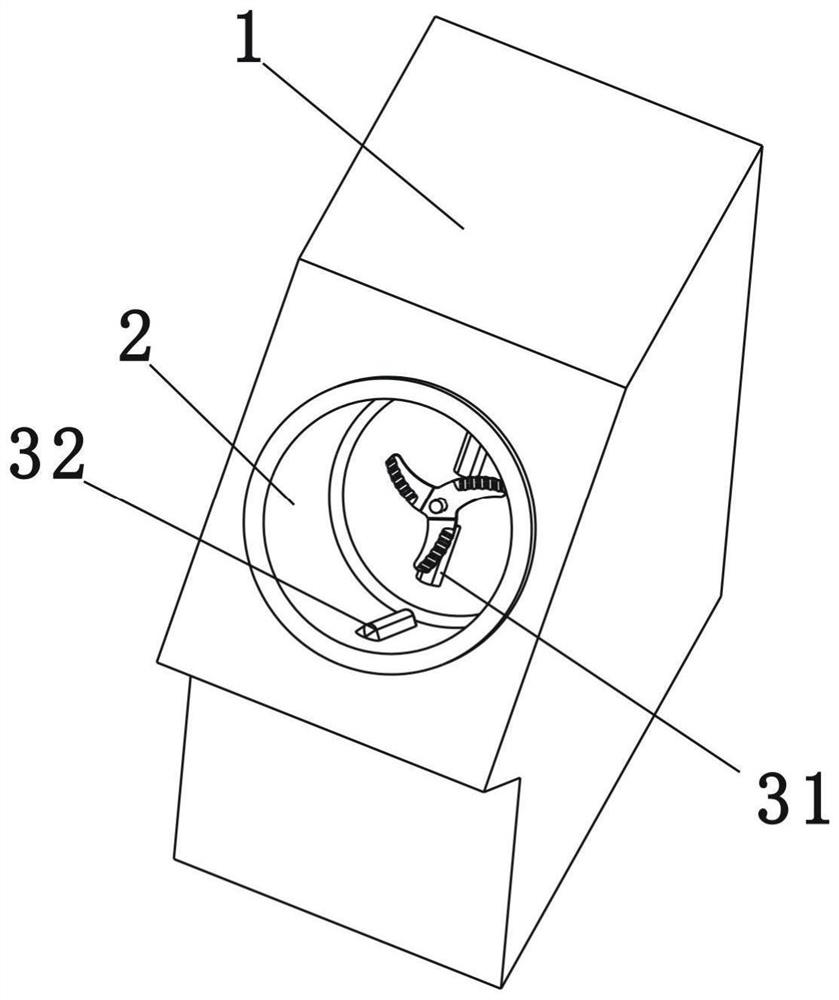

[0032] Such as figure 1 , figure 2 Shown is a schematic structural diagram of the first embodiment of the present invention. A food processor comprising:

[0033] body 1;

[0034] A crushing cup 2, the crushing cup 2 is a barrel-shaped structure with a depth greater than the inner diameter, and the crushing cup 2 is obliquely installed in the body 1, and the inner wall of the crushing cup 2 is provided with an inwardly protruding spoiler rib 3;

[0035] The motor 4 is located outside the crushing cup 2, and the rotating shaft 41 driven by the motor 4 penetrates the cup wall of the crushing cup 2 and extends into the crushing cup 2;

[0036] The crushing blade 5 is located in the crushing cup 2 and is mounted on the end of the rotating shaft 41;

[0037] The peripheral wall of the crushing cup 2 is connected to the bottom through a transition part 21. In this embodiment, the transition part 21 is a rounded corner. After the crushing cup 2 is tilted, the highest point of th...

Embodiment 2

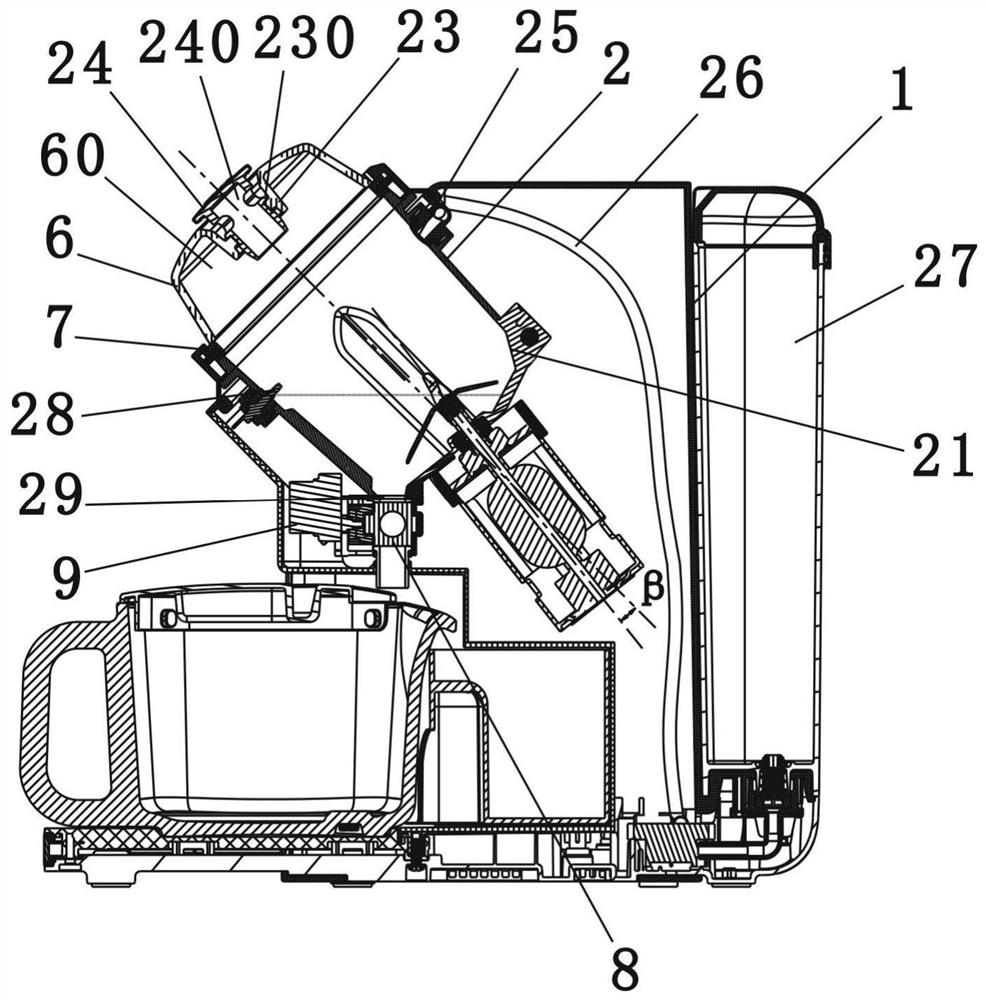

[0046] Such as image 3 Shown is a schematic structural diagram of the second embodiment of the present invention. The difference between this embodiment and the first embodiment is that in this embodiment, a sealing member 7 is installed between the cup cover 6 and the cup mouth, and the sealing member 7 is clamped and fixed by the cup cover 6 and the cup mouth, so as to realize the alignment of the cup. Mouth seal.

[0047] At the same time, in this embodiment, the cup cover 6 has an upwardly recessed auxiliary cavity 60, and the inner surface of the cup cover 6 is provided with a flow blocking portion 23 protruding into the crushing cup 2, and the flow blocking portion 23 is provided with a There is an installation hole 230 that runs through the top wall of the cup cover 6, and a vent plug 24 is installed at the installation hole 230, wherein the vent plug 24 is provided with a vent channel 240 that communicates the space in the crushing cup 2 with the atmosphere. And, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com