Centrifugal labyrinth type oil-gas separator with jet smashing function

A technology of oil and gas separator and oil and gas separation chamber, which is applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of insufficient oil and gas separation, and achieve the effects of eliminating difficult condensation, accelerating condensation rate, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

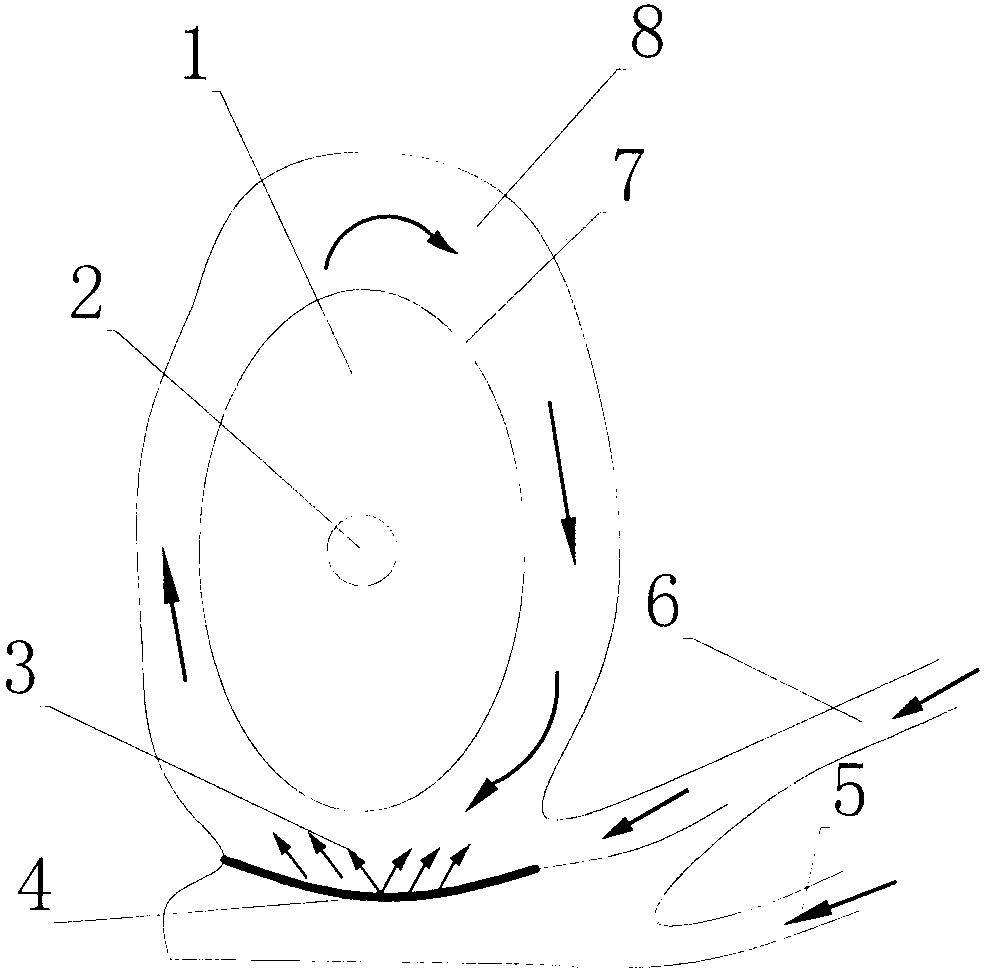

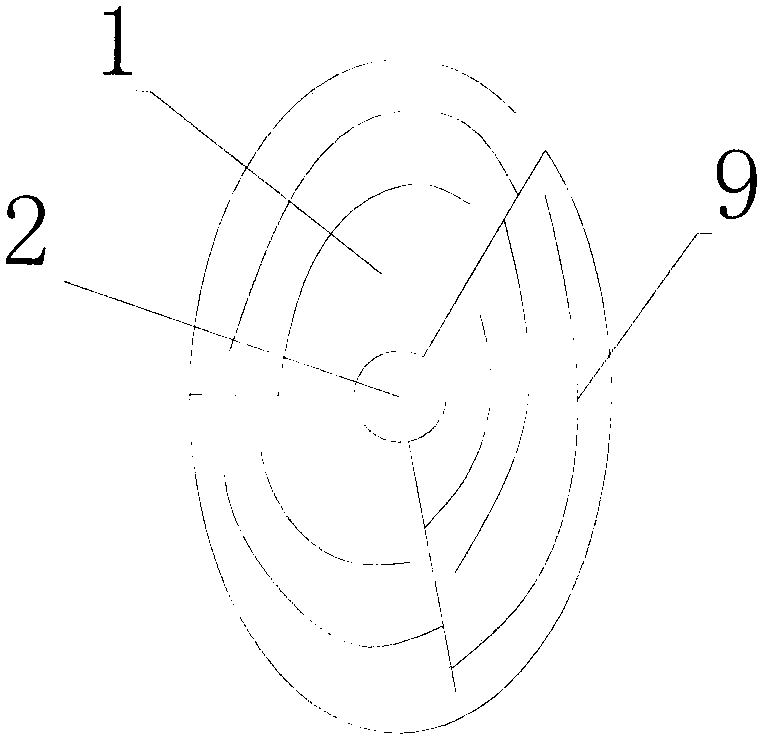

[0020] The structure of a centrifugal labyrinth oil-gas separator with the function of jet crushing mainly includes 1, a centrifugal labyrinth chamber 3, a crushing chamber 8, and a ring track, which spray compressed gas into the oil-gas mixture, and collide with the compressed gas and oil droplets, Friction and so on achieve pulverization, through the annular labyrinth track, due to the centrifugal force and the baffle effect, the probability of oil particles colliding with the wall is increased, the oil particles are accelerated to condense and merge, and are recovered from the oil return tank.

[0021] The mixed oil and gas from the crankcase enters the pulverizing chamber 3 at the bottom of the annular track 8 of the oil and gas separator through the first mixed oil and gas input port 6 . The compressed gas in the crushing chamber 3 is injected into the first mixed oil and gas, and the oil particles in the mixed oil and gas are accelerated and become turbulent. The pulveri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com