MBR sewage processing facility and method

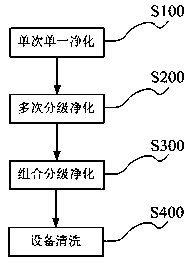

A technology of sewage treatment equipment and sewage treatment methods, applied in biological water/sewage treatment, water/sludge/sewage treatment, special treatment targets, etc., can solve the problems of single purification effect, long cleaning cycle, difficult operation, etc. The effect of improving the purification effect and shortening the purification cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. In addition, the examples are illustrative, and are only for explaining the present invention, and should not be construed as limiting the present invention.

[0067] Structural analysis of the present invention:

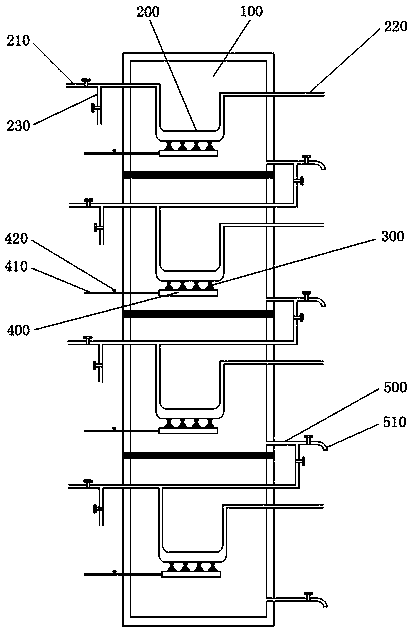

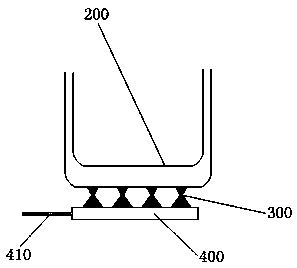

[0068] In one aspect, the present invention discloses a MBR sewage treatment equipment. According to an embodiment of the present invention, the equipment is provided with a purification tank, such as figure 1 and figure 2 As shown, the accommodating chamber of the purification tank separates multiple purification chambers (100), and the purification chambers (100) are all equipped with U-shaped MBR membrane tubes (200), sewage pipes (300), and sewage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com