Supported chromium and metallocene bimetallic catalyst, preparation method and applications thereof

A bimetallic catalyst, supported technology, applied in the production of bulk chemicals, etc., can solve the problems of unsatisfactory reduction effect of chromium active center and reduced activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

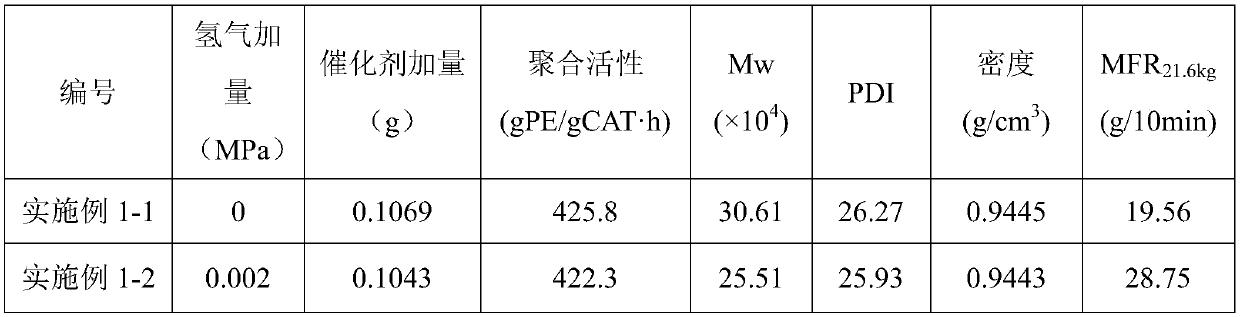

Embodiment 1-1

[0065] The preparation method of described loaded type chromium and alocene bimetallic catalyst is as follows:

[0066] Preparation of titanium-loaded silica gel: select commercially available Davison955 silica gel as an inorganic carrier, immerse in n-hexane solution of tetra-n-butyl titanate (titanium loading is 2wt%), stir continuously for 4 hours, then dry in an oil bath at 80°C for 4 hours, Then use vacuum drying for 2 hours to further remove the solvent in the pores of the silica gel carrier, transfer to a blast drying oven for 8 hours at 80°C and dry for 8 hours; then, roast and activate the dried samples in a fluidized bed, maintain the low temperature section at 120°C for 2 hours, and The temperature was kept at 600°C for 4 hours under pure air, and the silica gel was finally cooled naturally under nitrogen to obtain titanium dioxide modified silica gel prepared by the impregnation method.

[0067] Dissolve 0.11g of chromium acetate in 36ml of distilled water at 60°C ...

Embodiment 1-2

[0071] The catalyst of Example 1-1 was used to carry out the hydrogen modulation polymerization test according to the gas phase polymerization mode, except that 0.002 MPa hydrogen gas was added during the polymerization.

Embodiment 1-3

[0073] This embodiment is the same as Embodiment 1-2, except that the amount of hydrogen added is 0.004MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com