Anti-freezing plate heat exchanger

A plate heat exchanger and anti-freezing technology, which is applied in the field of brazed heat exchangers and anti-freezing plate heat exchangers, can solve problems such as prone to freezing, and achieve the effects of avoiding freezing, reducing dead angles of radiation, and eliminating crystal nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

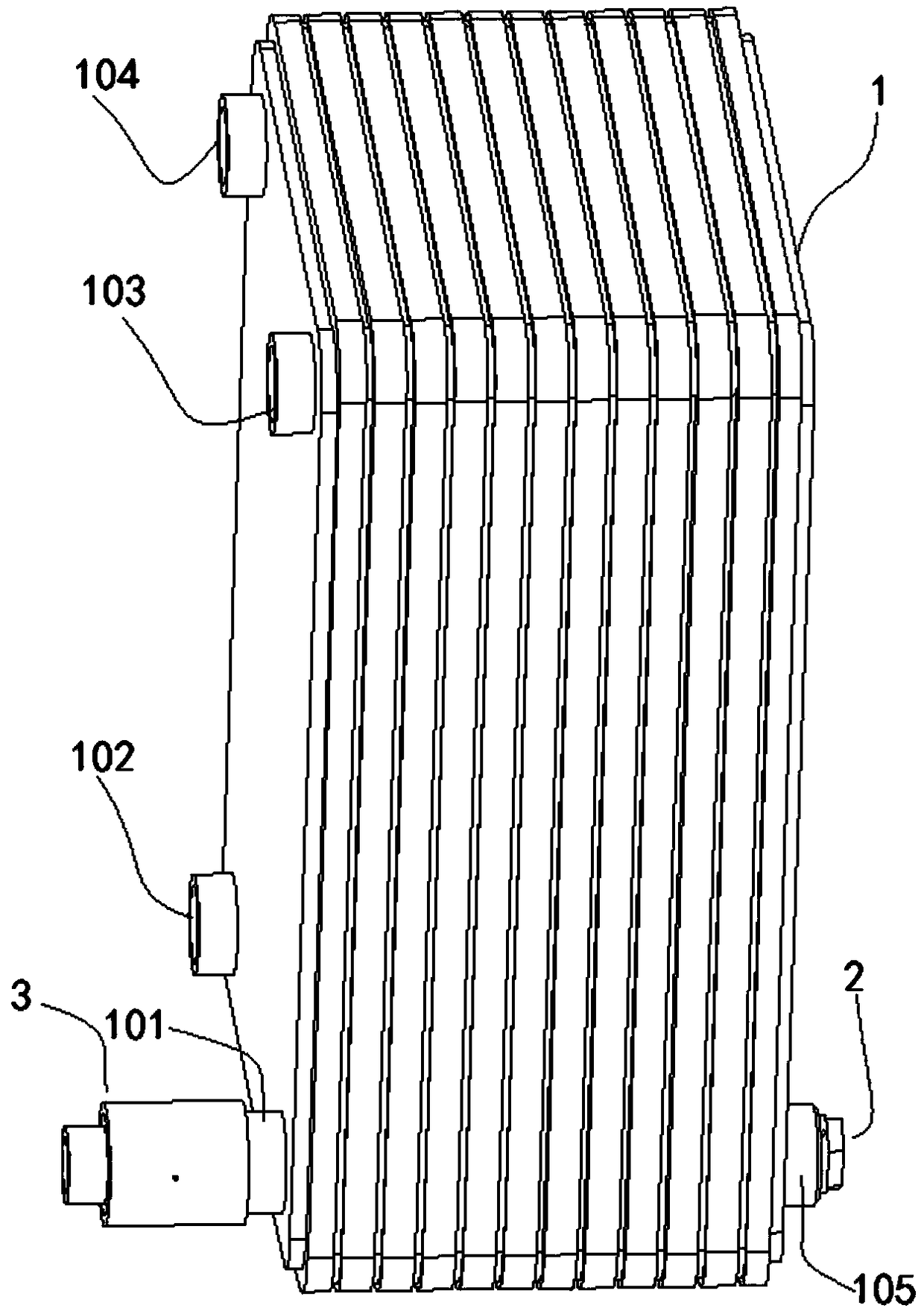

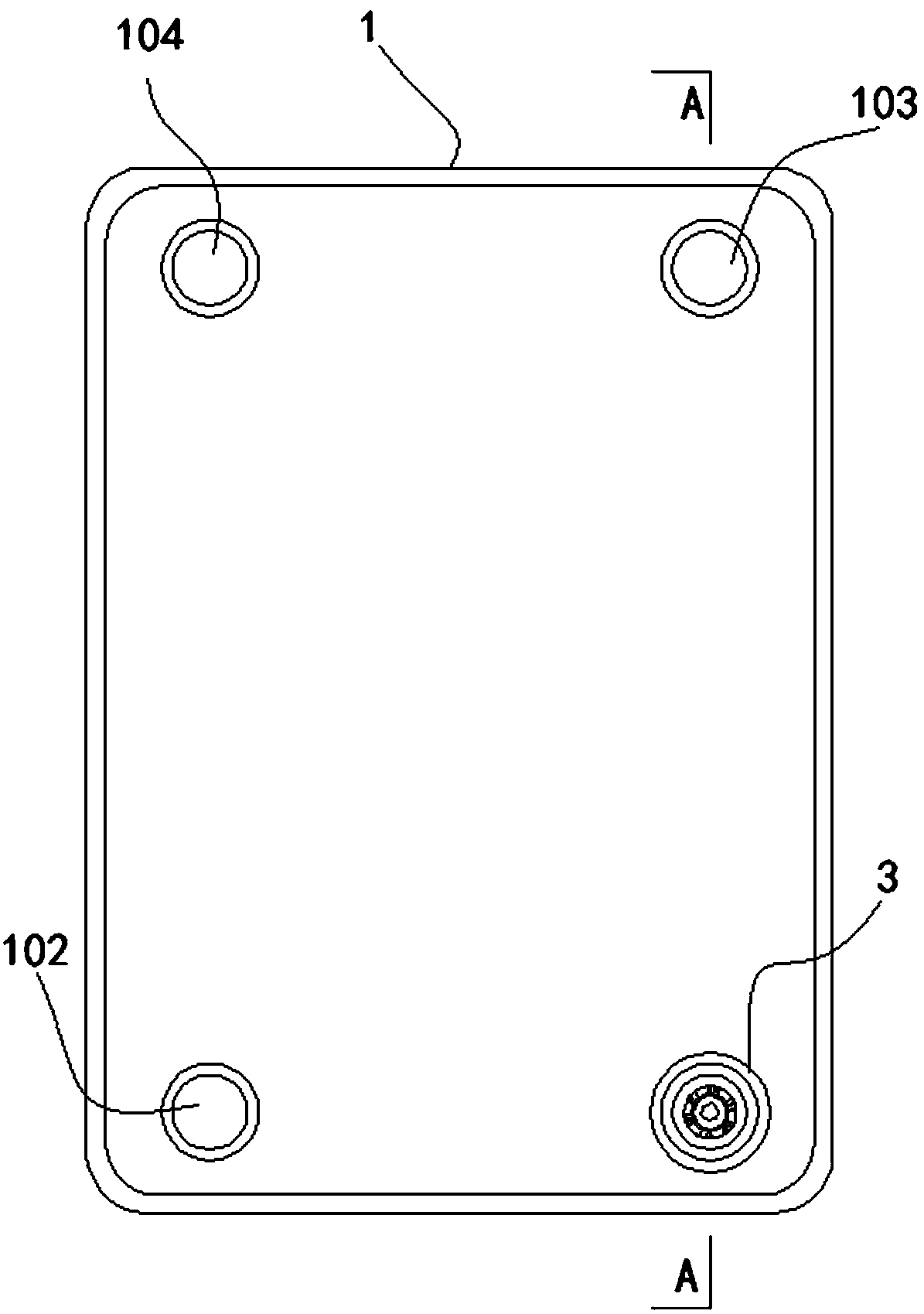

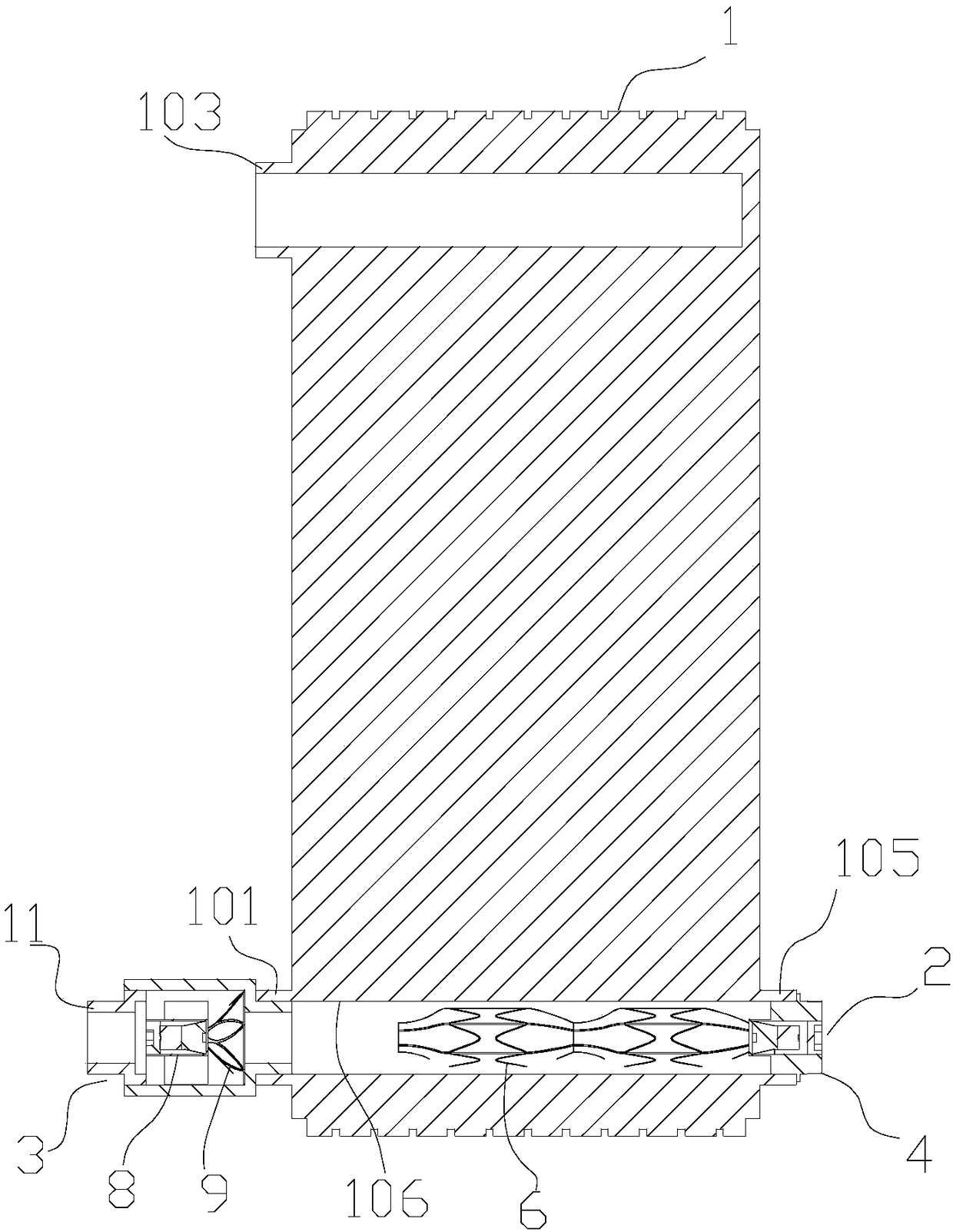

[0027] see Figure 1-5 As shown, this embodiment relates to an anti-freezing plate heat exchanger, including a plate heat exchanger body 1 with a liquid inlet channel and a liquid outlet channel 106 on the plate heat exchanger body 1, and a fixed clamping plate for the plate heat exchanger body 1 One surface is provided with a cold medium inlet interface 102 , a heat medium inlet interface 103 and a cold medium outlet interface 104 . The heat exchange medium enters the plate heat exchanger body 1 to exchange heat with the cooling medium and then discharges from the liquid outlet channel. A front end interface 105 connected with the liquid outlet channel 106 is provided on the fixed clamping plate, and the front end interface 105 is threadedly connected with a The agitation component 2 is in the liquid outlet channel 106 . A liquid outlet por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com