A wide-range horizontal high-efficiency oil-gas separator for a screw compressor test system

A technology of screw compressor and oil and gas separator, which is applied in the direction of machine/engine, mechanical equipment, liquid fuel engine, etc., can solve the problems such as the wide range, high efficiency and low cost of the power screw compressor test system, and achieve oil removal. Good effect, increase the probability of impact, improve the effect of oil removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

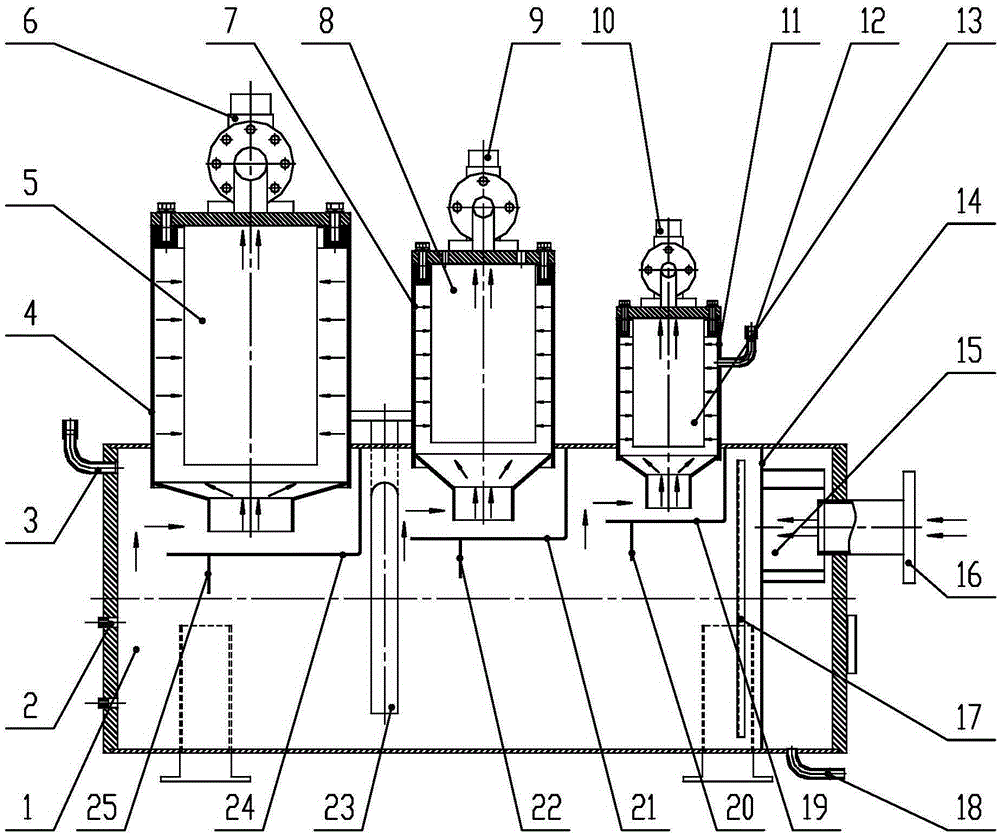

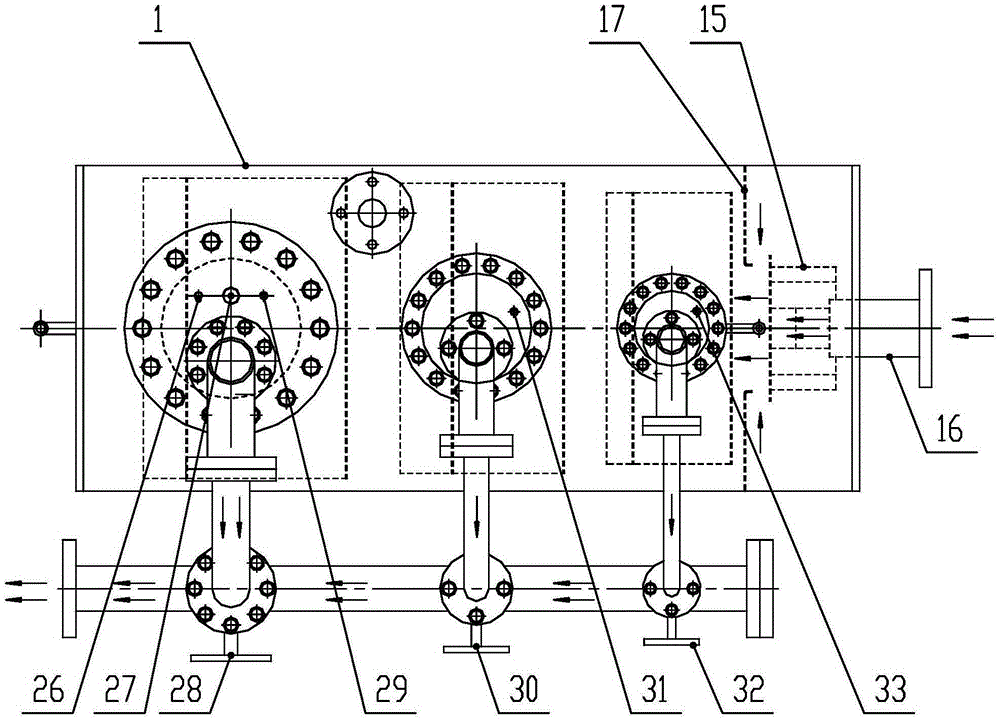

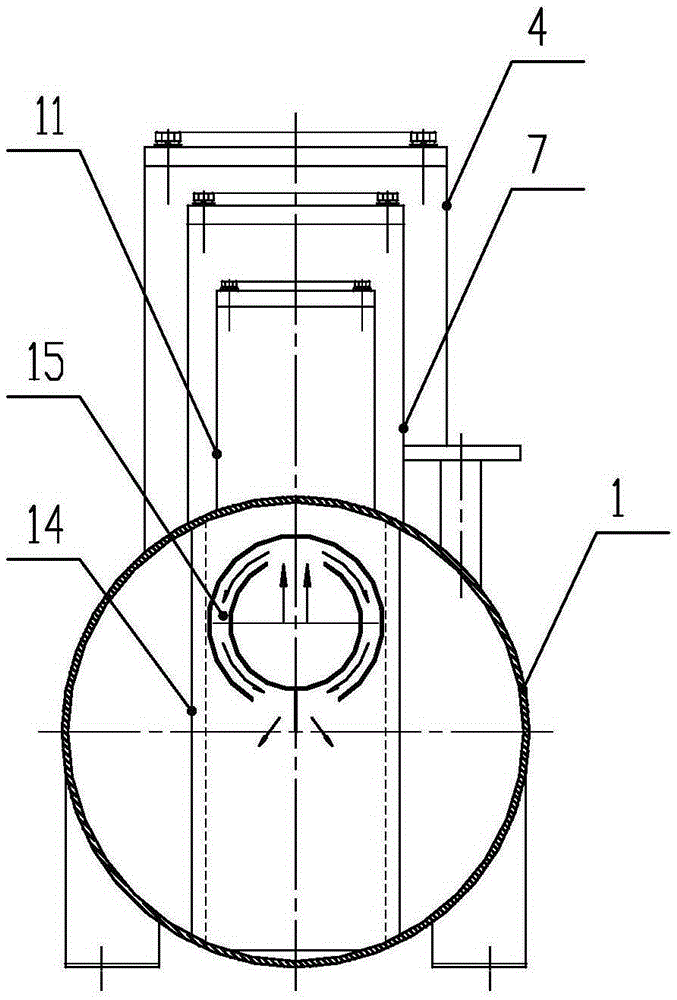

[0042] The present invention will be further described below in conjunction with accompanying drawing, appended Figure 1~4 The arrow in is the flow direction of the oil-gas mixture.

[0043] Such as Figure 1~4 As shown, the barrel 1 of the oil-gas separator is provided with a feed pipe 16 for conveying the oil-gas mixture, a circulating lubricating oil outlet pipe 23 for connecting with the oil pump, and an exhaust piping system for discharging gaseous separated materials. The body 1 is provided with a centrifugal degreasing unit 15, a labyrinth type degreasing unit, a three-row filtering degreasing unit and an exhaust piping system in sequence from the feeding pipe 16 to the exhaust piping system.

[0044] Such as figure 1 , 2 As shown, one end of the feed pipe 16 is inserted into the first centrifugal oil removal pipe 15a of the centrifugal oil removal unit 15, and the oil-air mixture enters the first centrifugal oil removal pipe 15a from the feed pipe 16, and is passed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com