Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Increase structural rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet (UV)-hardened primer

InactiveCN102660188AIncrease structural rigidityGood flexibilityPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyAcrylic resin

The invention discloses a kind of ultraviolet (UV)-hardened primer, which comprises the following ingredients by weight percent: 50 to 65 percent of 100% UV resin, 0.1 to 0.3 percent of defoaming agent, 0.2 to 0.4 percent of dispersing agent, 6 to 10 percent of stuffing, 2.5 to 4 percent of initiator, 0.3 to 0.7 percent of anti-settling agent and the balance of monomer; the 100% UV-resin is quadri-functional polyurethane acrylic resin, tri-functional modified epoxy acrylic resin or mixture of the quadric-functional polyurethane acrylic resin and the tri-functional modified epoxy acrylic resin; the monomer is acrylate, modified acrylate or mixture of the acrylate and the modified acrylate; and the stuffing is the organism modified high-pure and high-hardness glass powder or quartz powder. The paint has good flexibility, has high hardness and good flexibility, also has certain tensile strength and can improve the hardness of furniture, floor or soft lumber so as to form durable protection for the surface of the wooden furniture and the floor board and to prolong the service life.

Owner:JIANGSU HIMONIA TECH

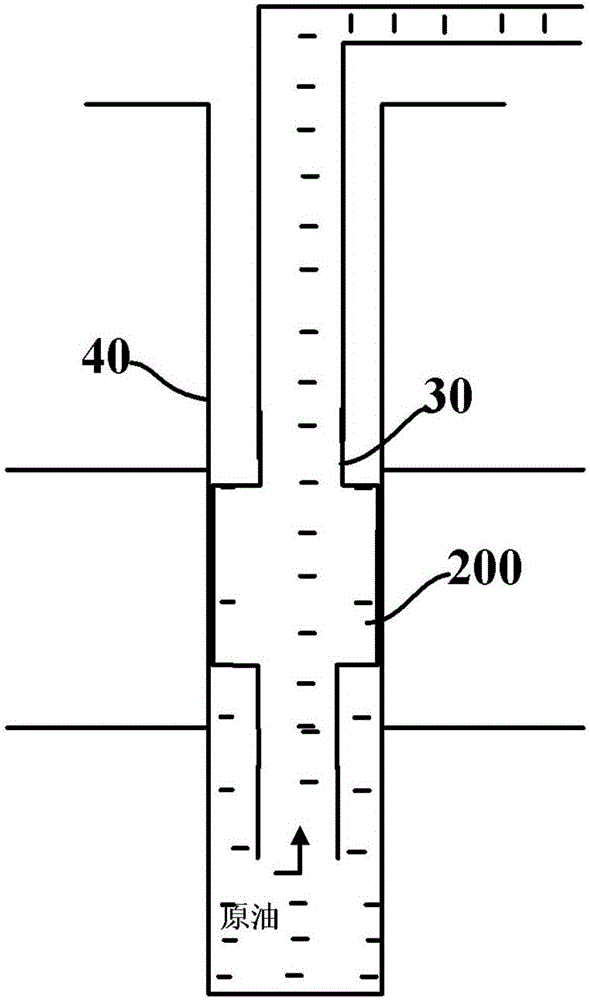

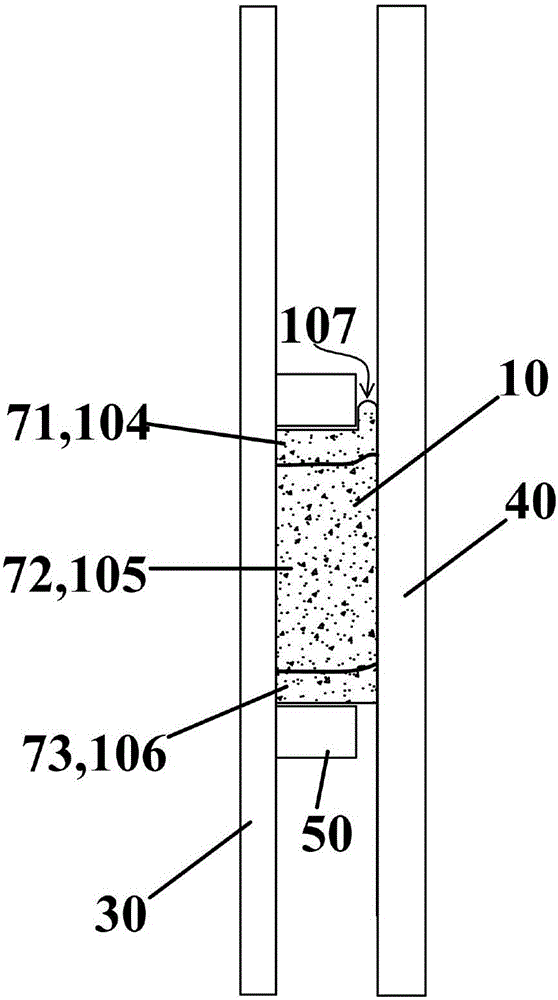

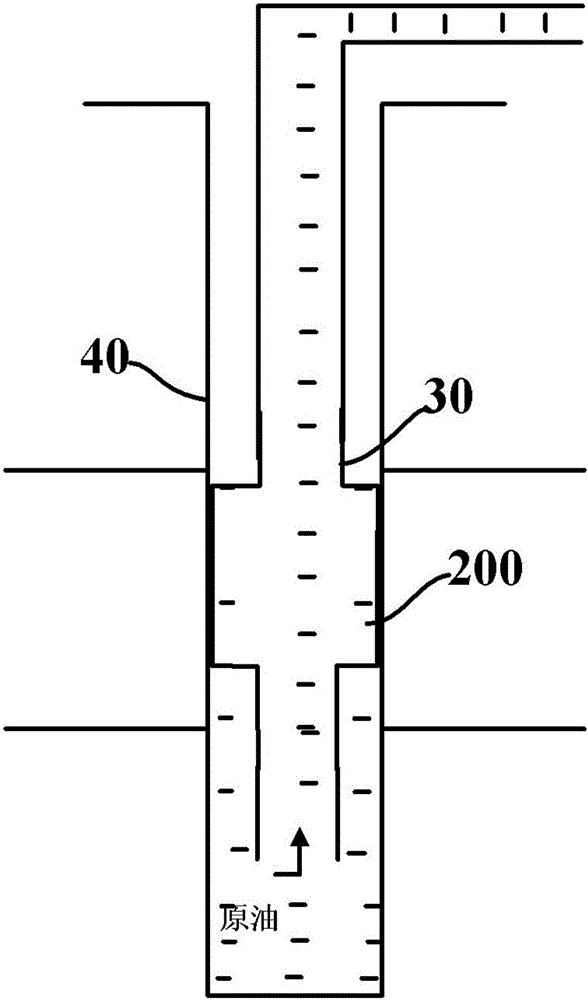

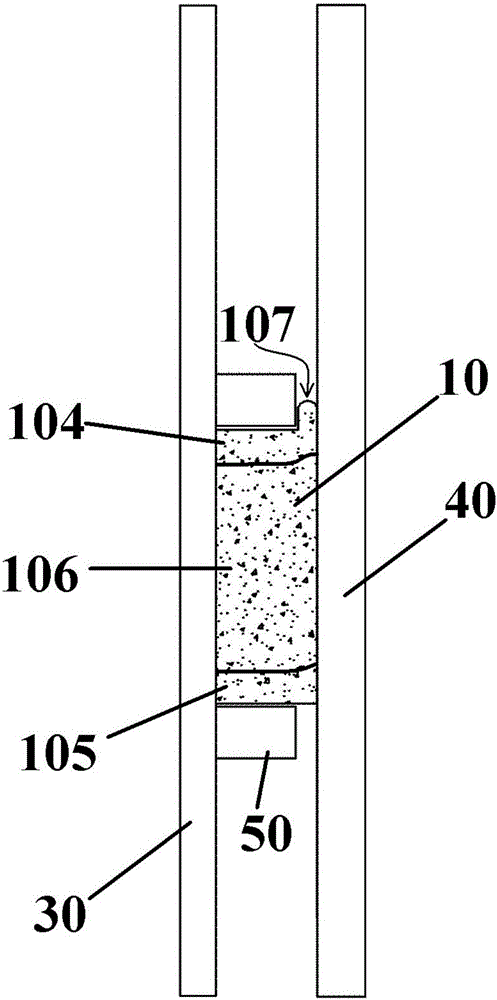

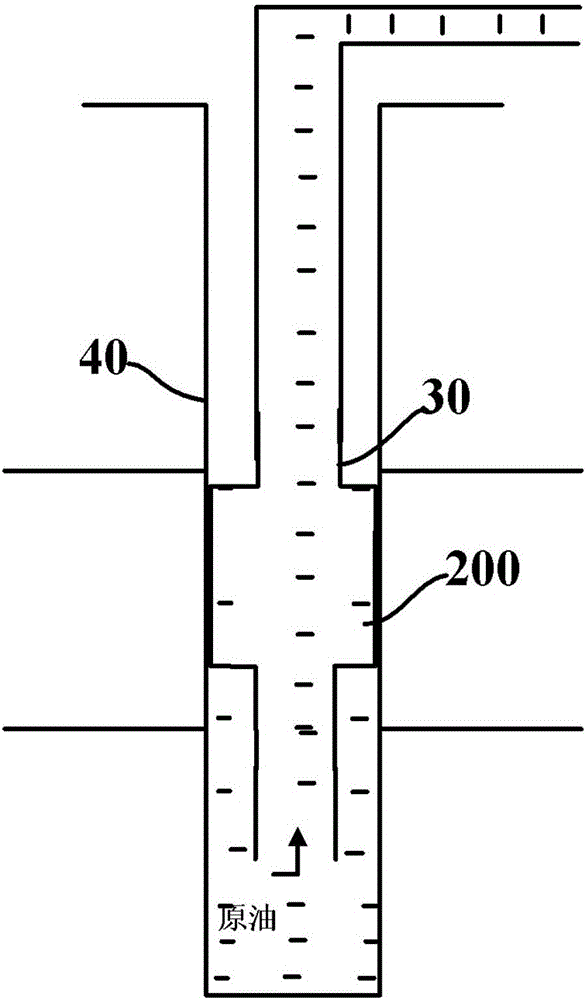

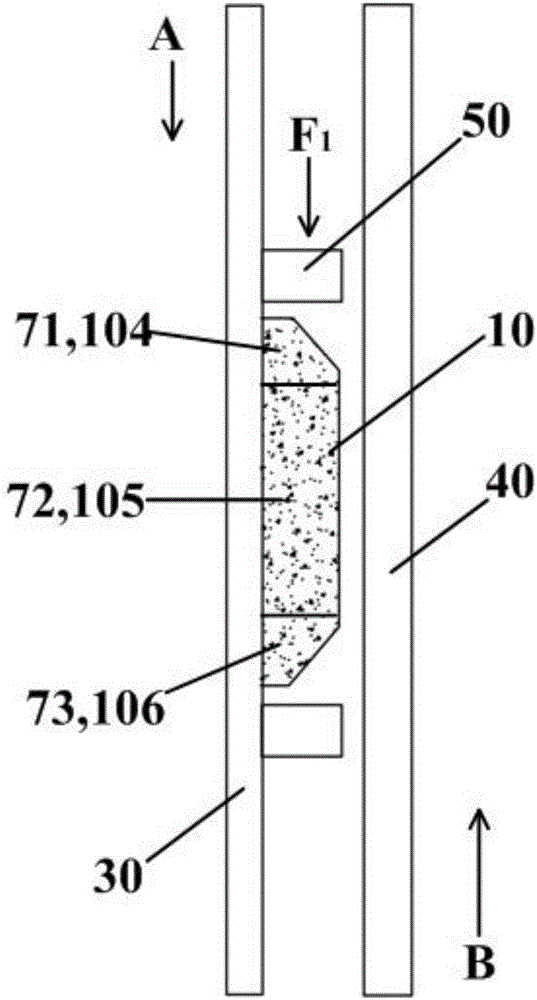

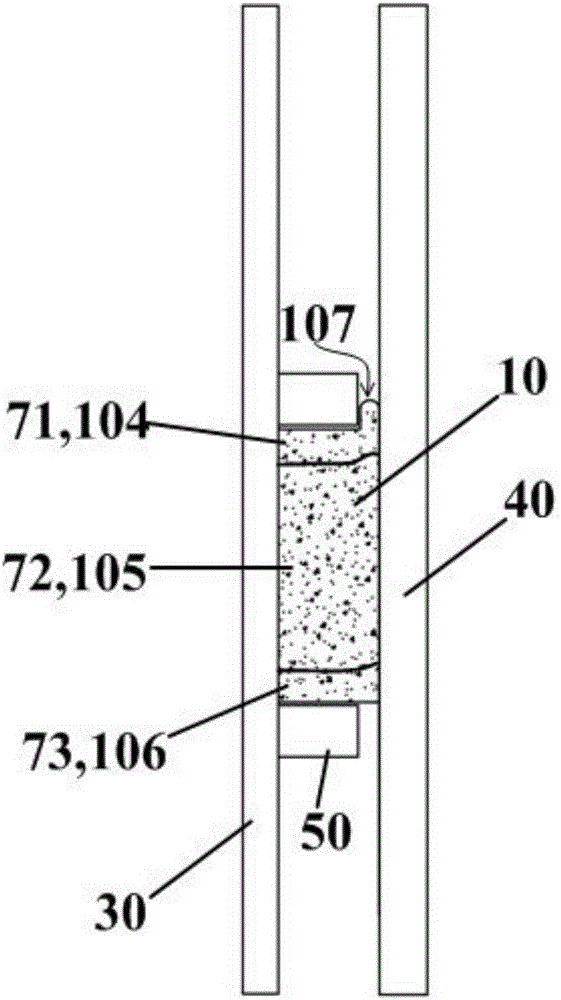

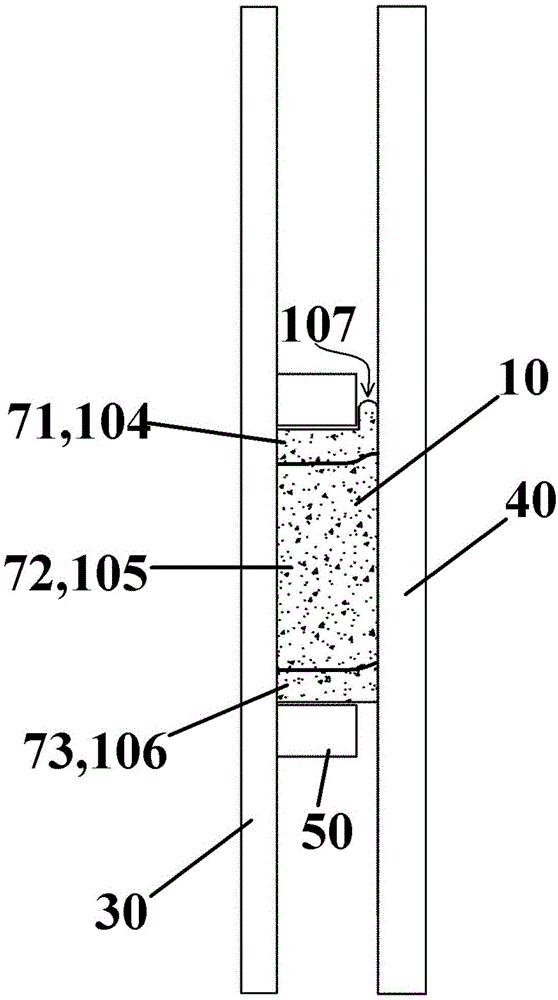

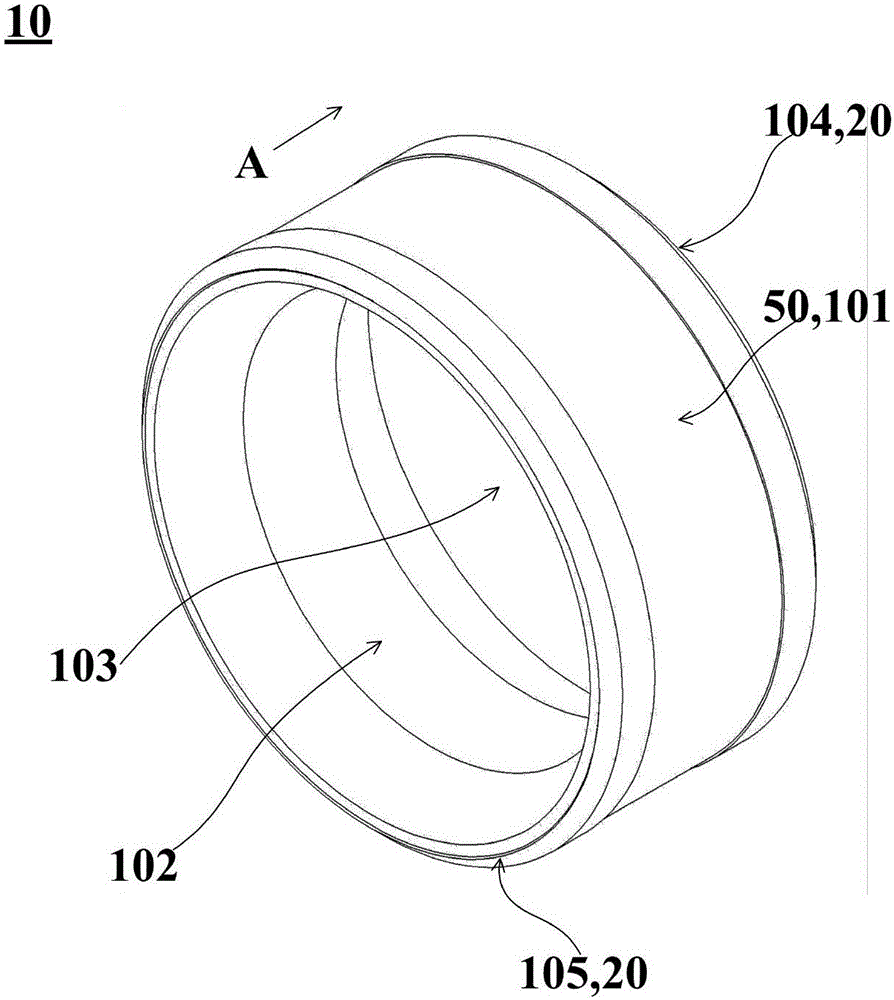

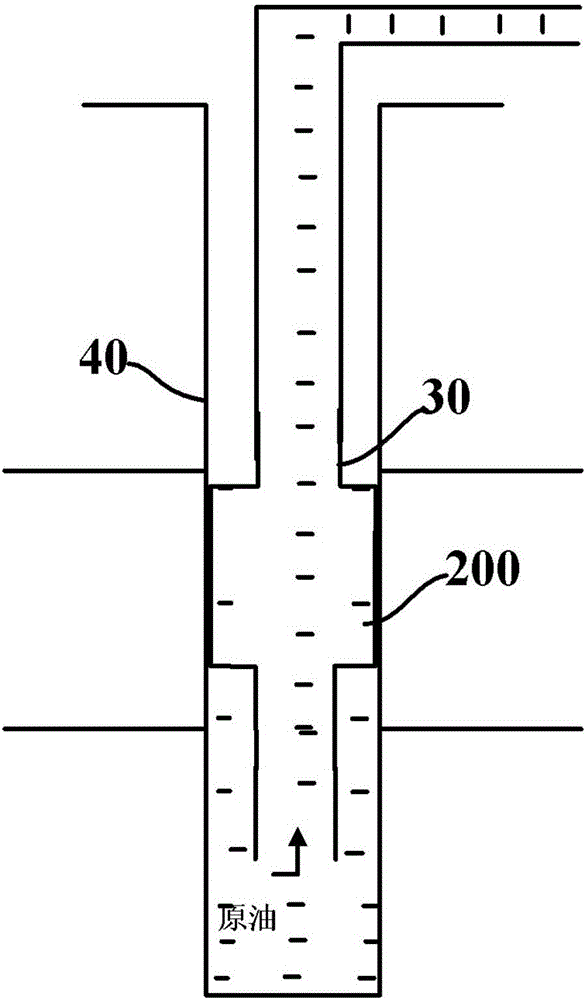

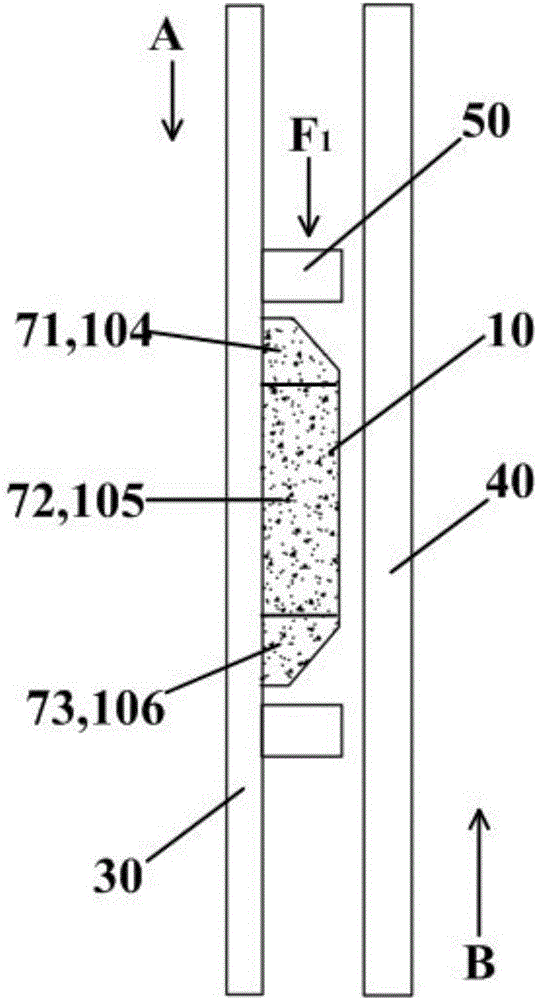

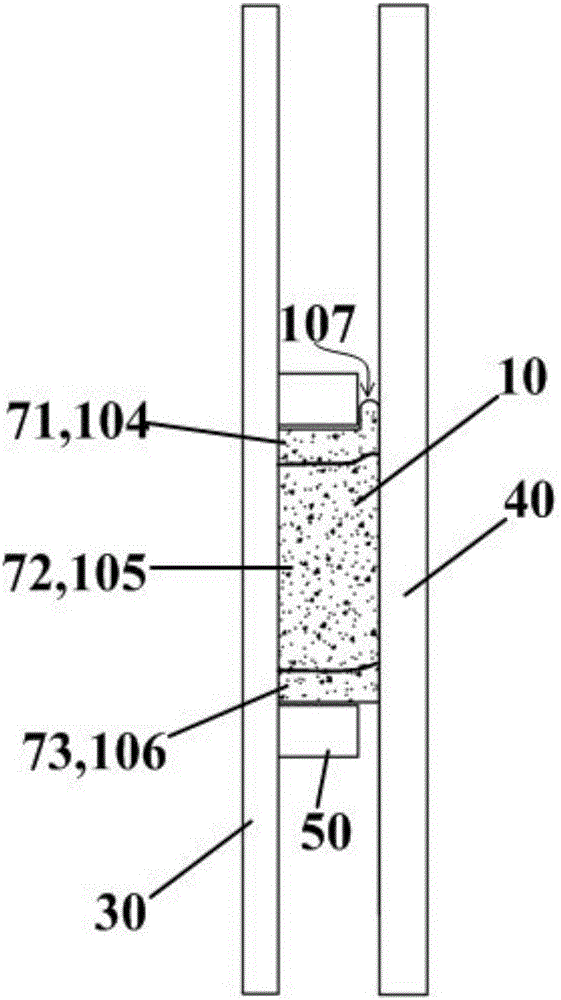

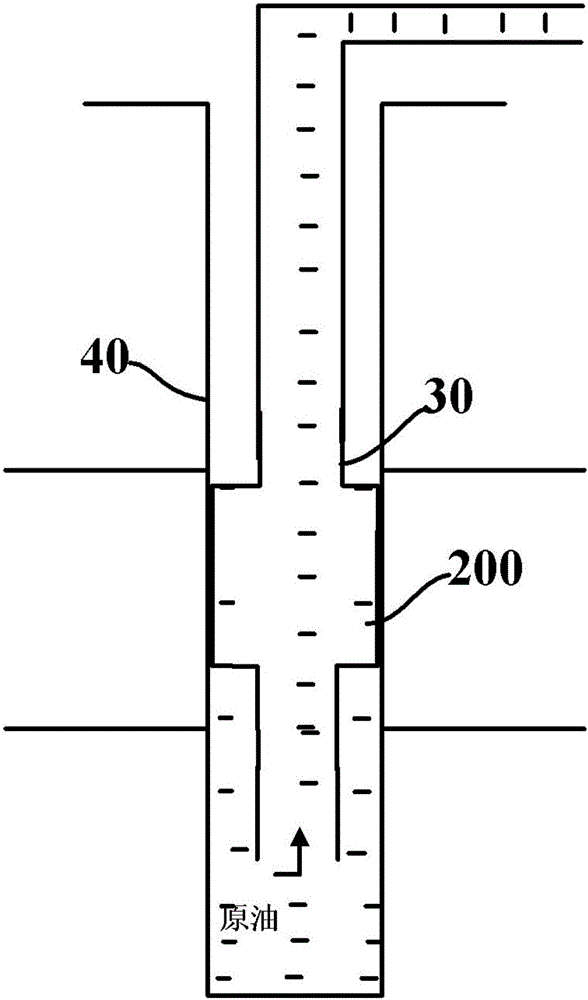

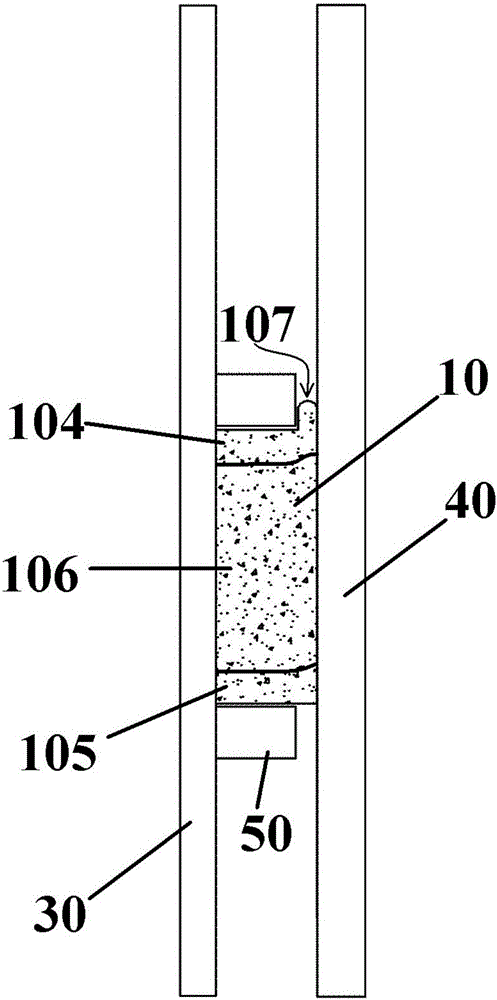

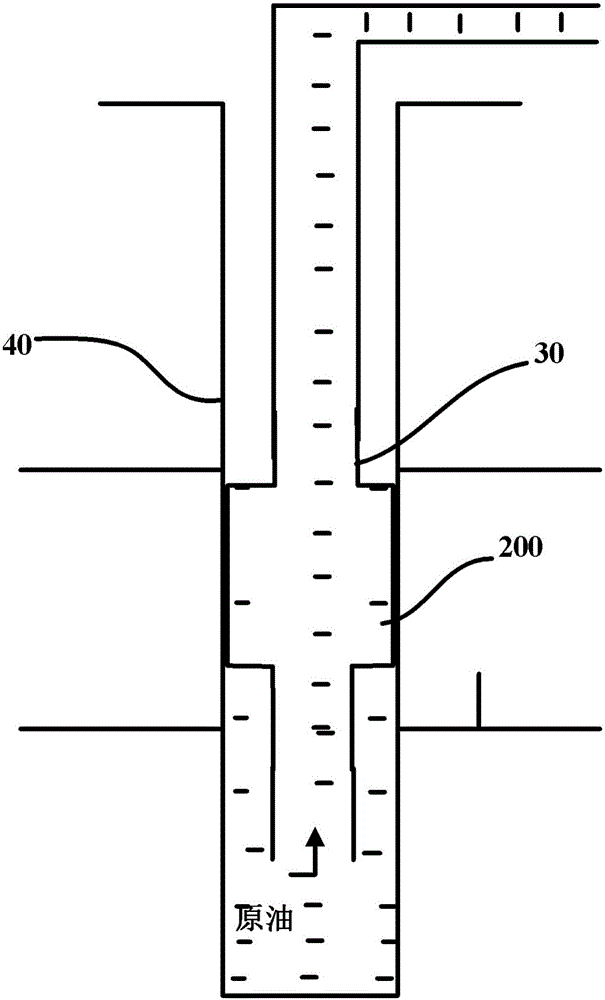

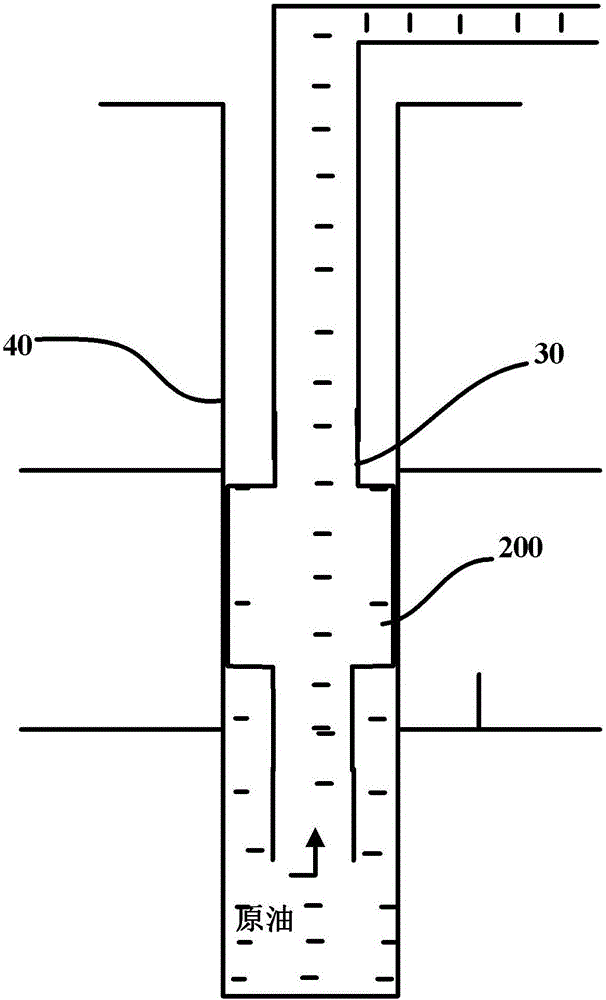

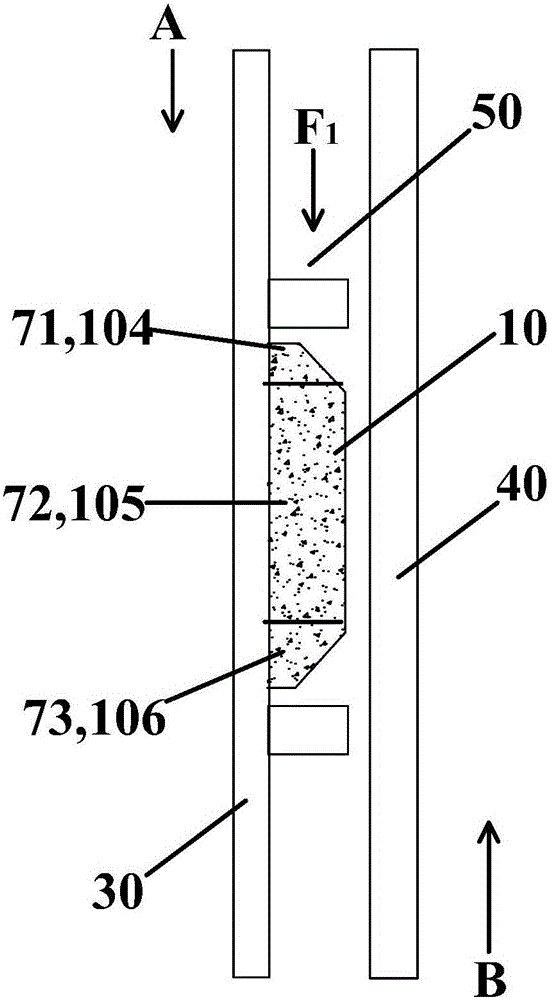

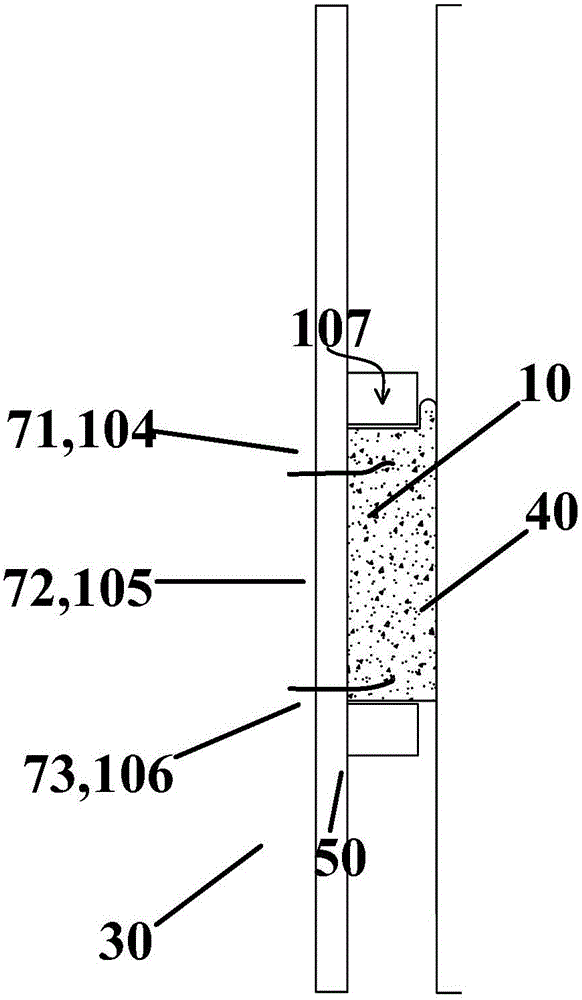

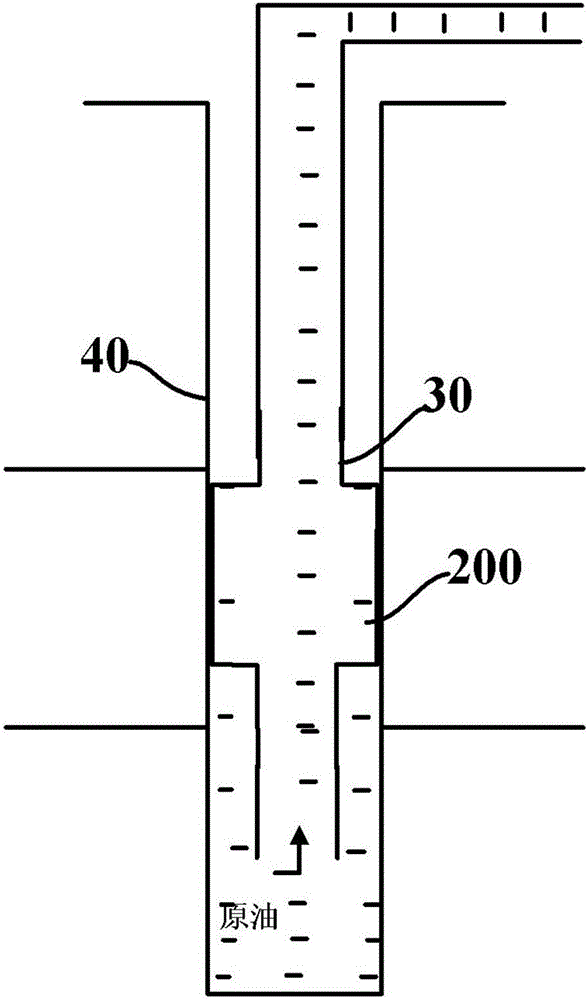

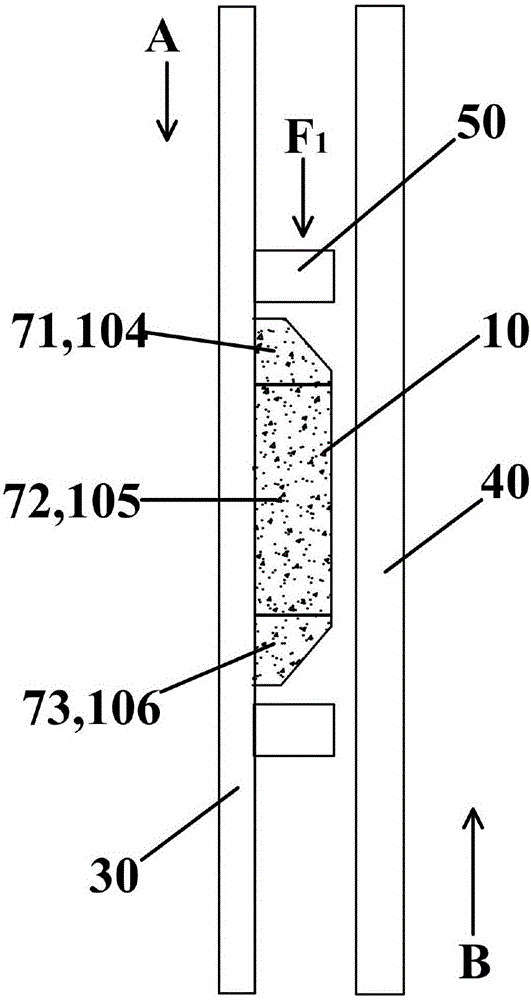

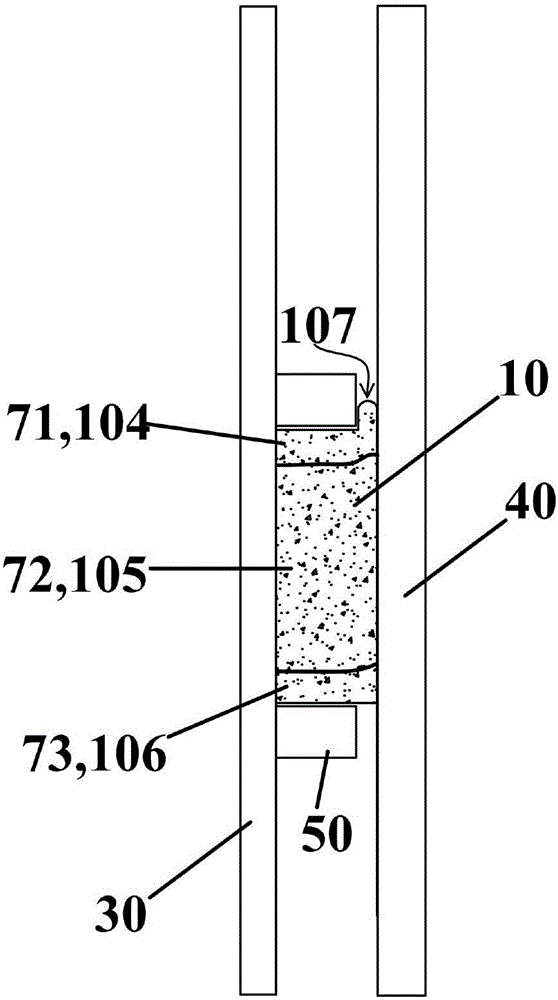

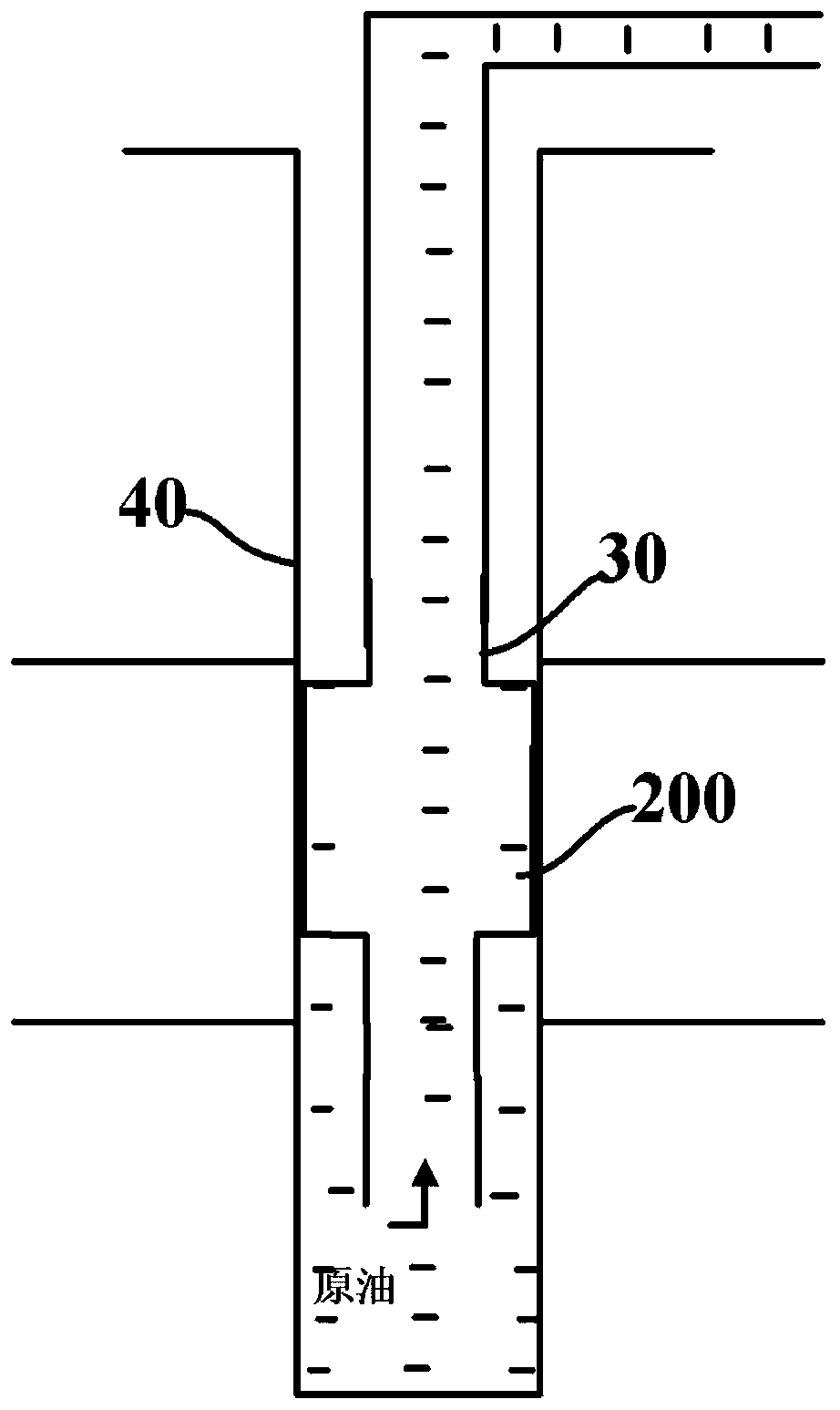

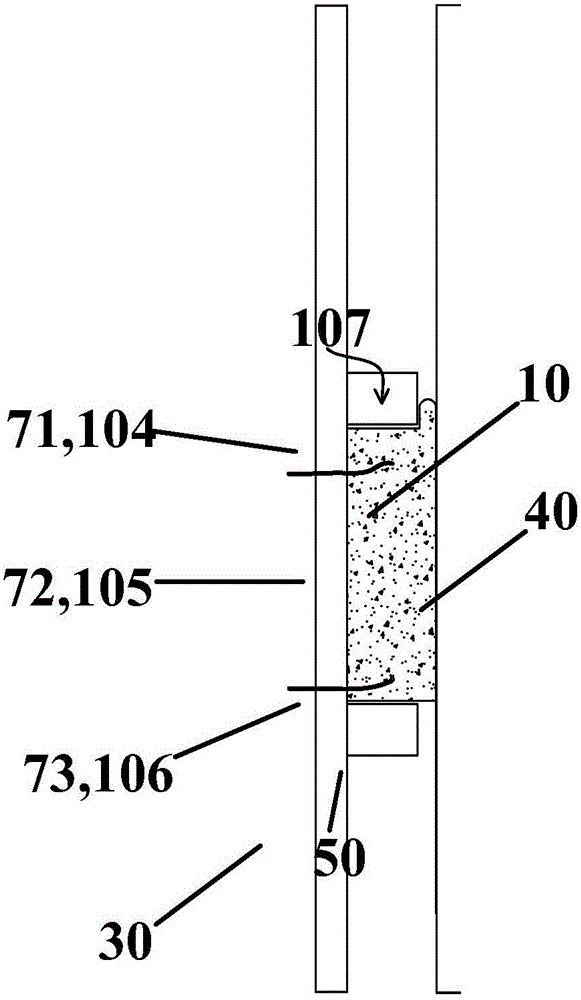

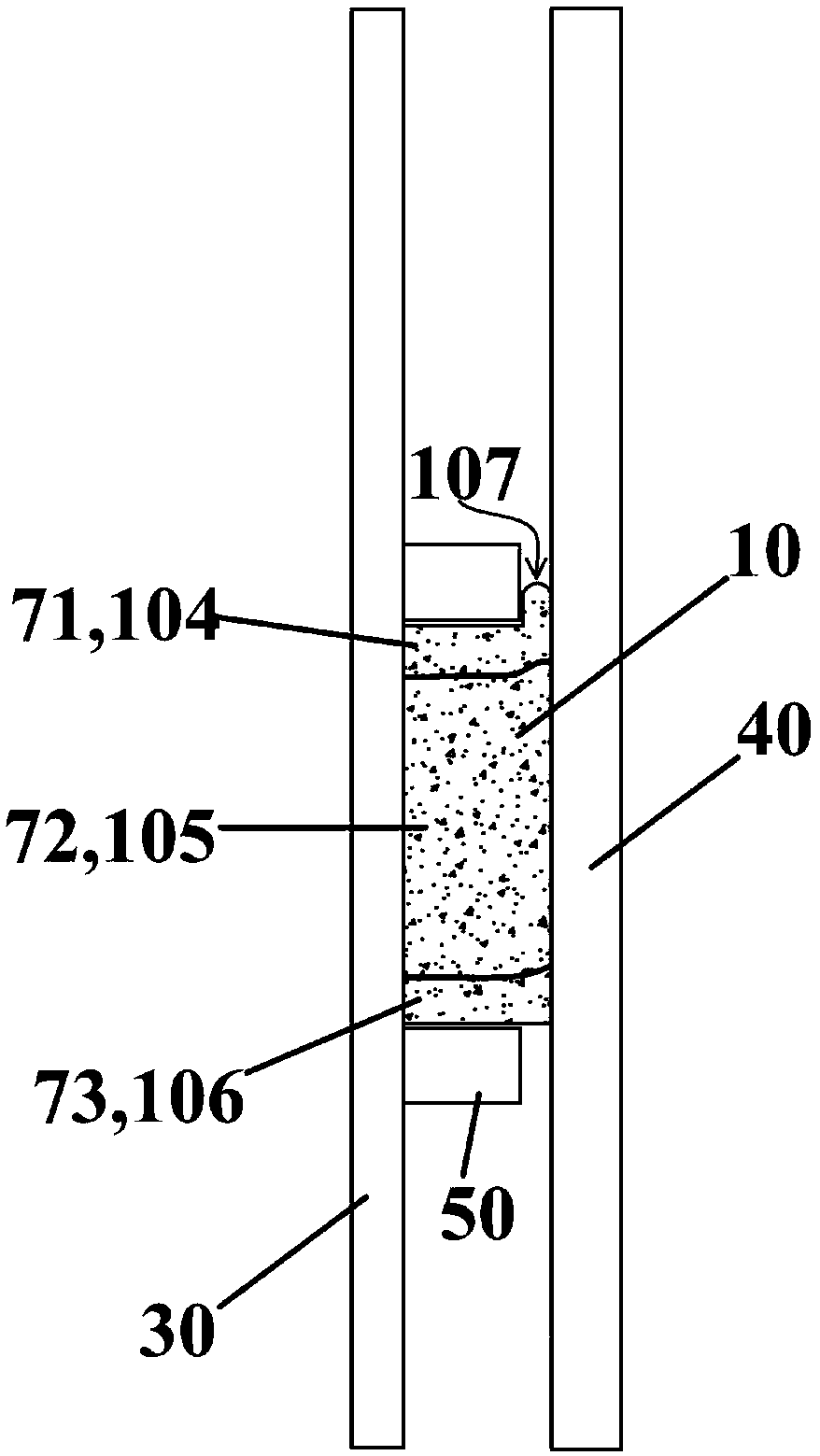

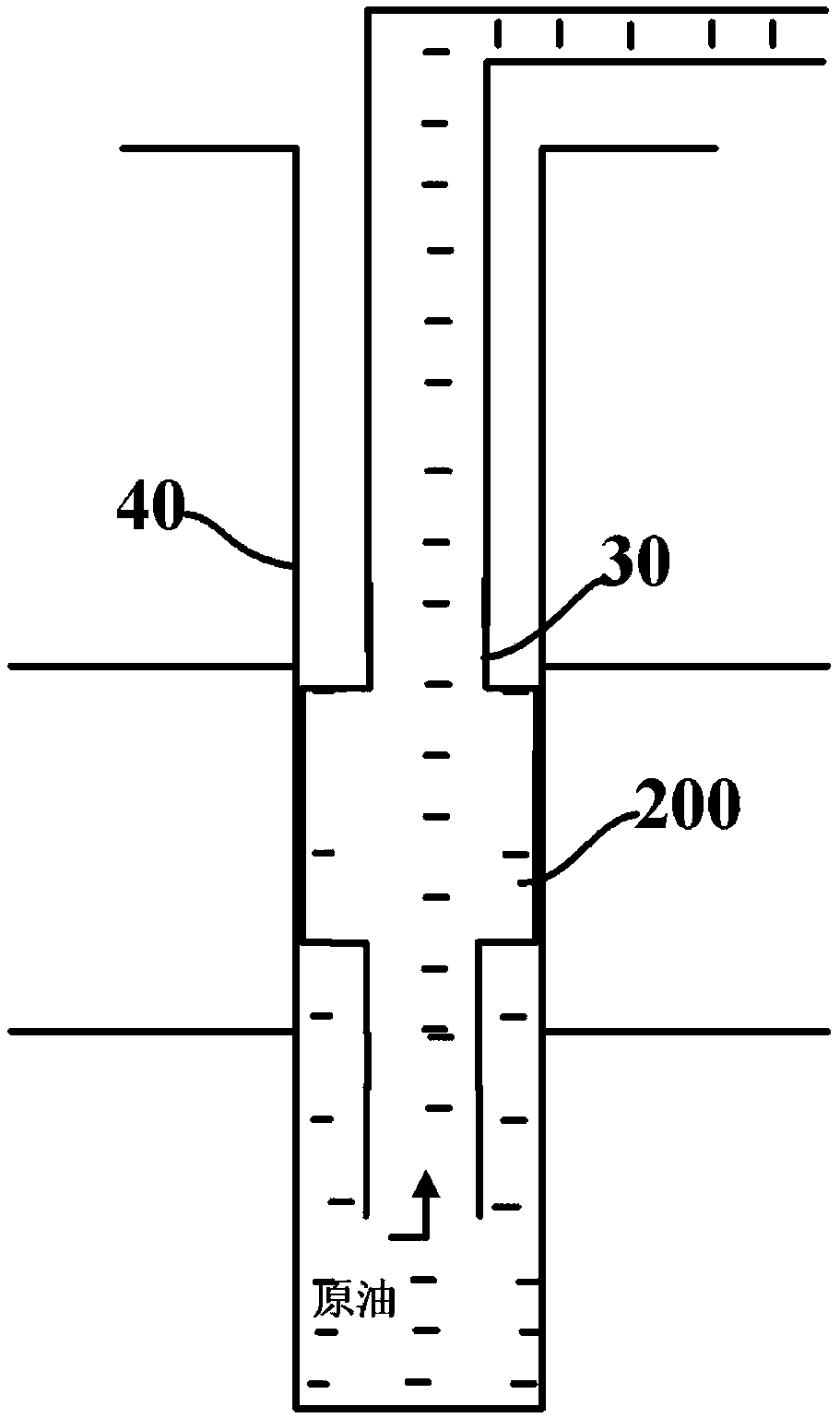

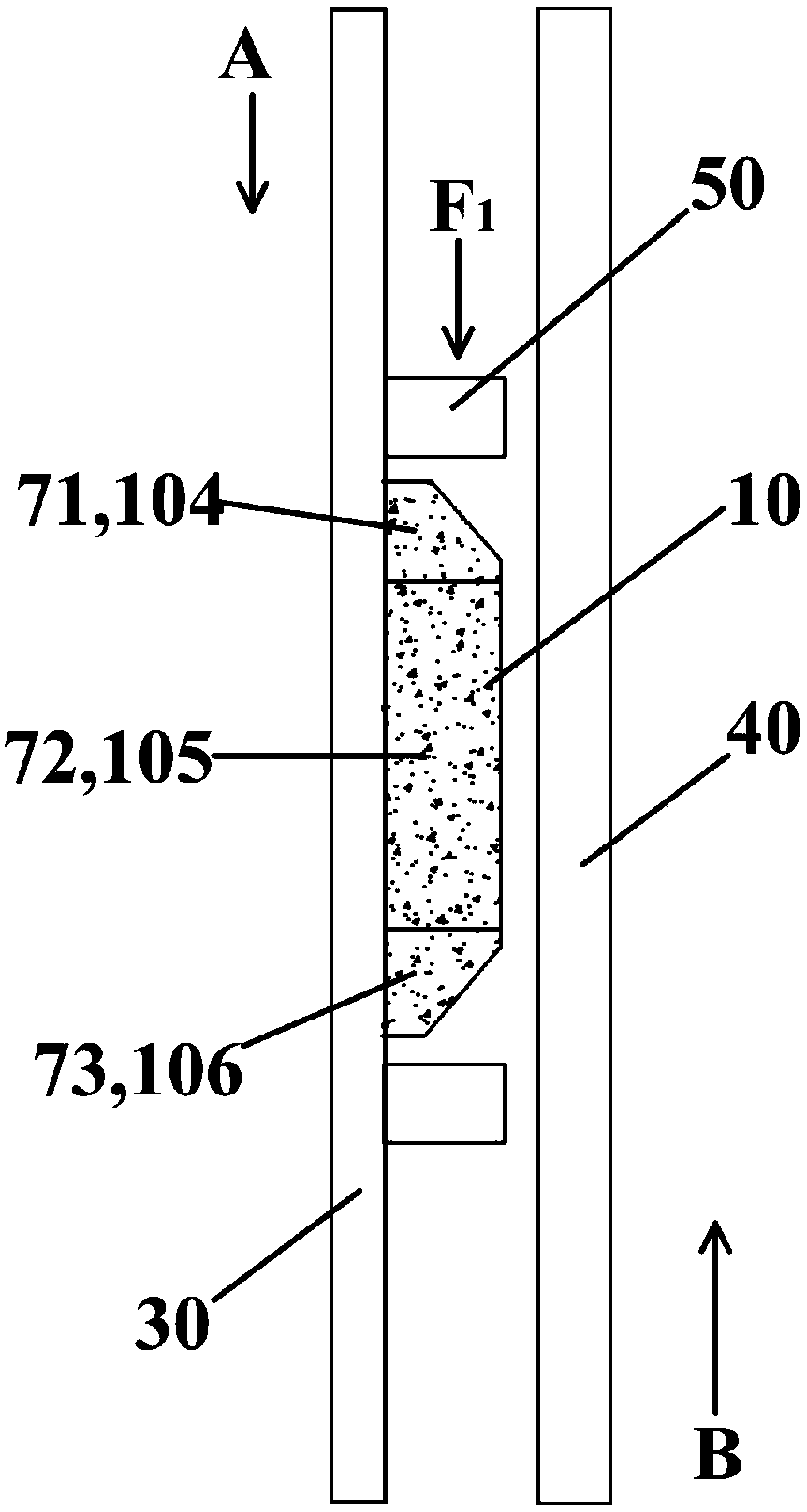

Rubber sleeve with lower end seal ring covered with opened copper sheet, packer and bridge plug

The invention relates to the field of sealing, in particular to a rubber sleeve with a lower end seal ring covered with an opened copper sheet, a packer and a bridge plug, wherein the rubber sleeve is used in the oil exploitation industry and can bearing high temperature and high pressure. The lower end seal ring of the rubber sleeve is covered with the first copper sheet, the first copper sheet covers the upper surface, the lower surface, the inner side face and the outer side face of the lower end seal ring, and the thickness of the first copper sheet is set in the mode that when the upper end bears first axial pressure, the lower end seal ring deforms in the radial direction so that the part, distributed on the inner surface of the lower end seal ring, of the first copper sheet can butt against a center tube and the part, distributed on the outer surface of the lower end seal ring, of the first copper sheet can butt against the sleeve; an annular opening is formed in the edge, located on the upper surface of the lower end seal ring, of the first copper sheet. The lower end seal ring is covered with the first copper sheet, the degradation function on the rubber sleeve by high-temperature and high-pressure steam micromolecules is reduced or prevented, and the sealing long-term effect of the rubber sleeve is improved.

Owner:TIANDING SEALING TECH BEIJING CO LTD

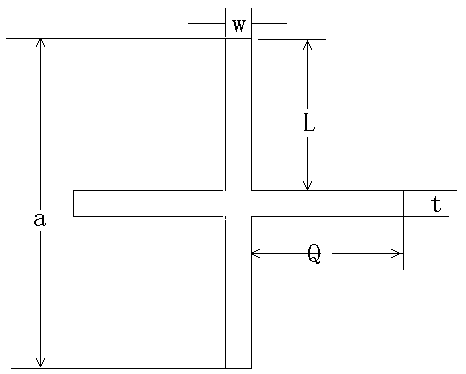

Conformal load-bearing antenna structure for realization of array surface heat radiation by employing FSS and micro heat pipe

ActiveCN107834152AIncrease structural rigidityImproved structural and thermal functional propertiesRadiating element housingsAntennas earthing switches associationAirflowSurface heat

Owner:XIDIAN UNIV

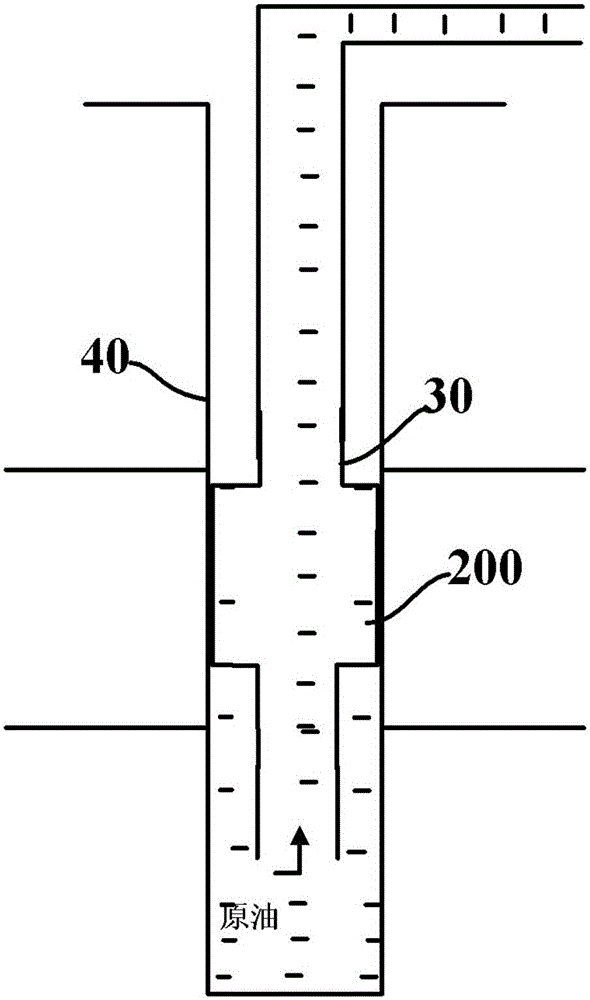

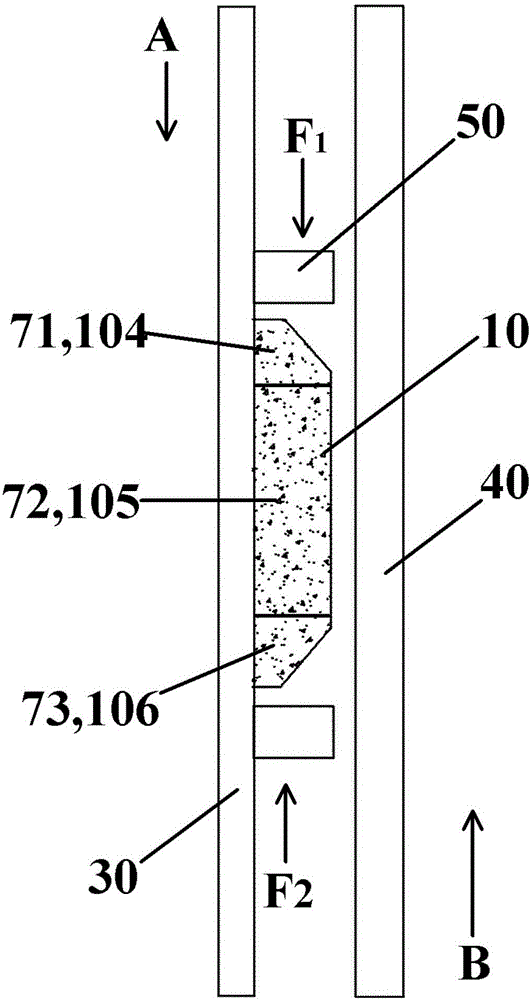

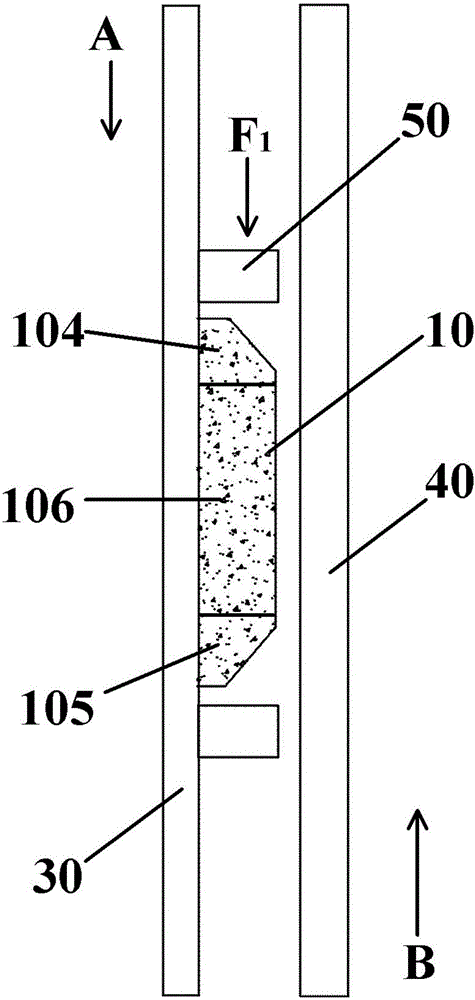

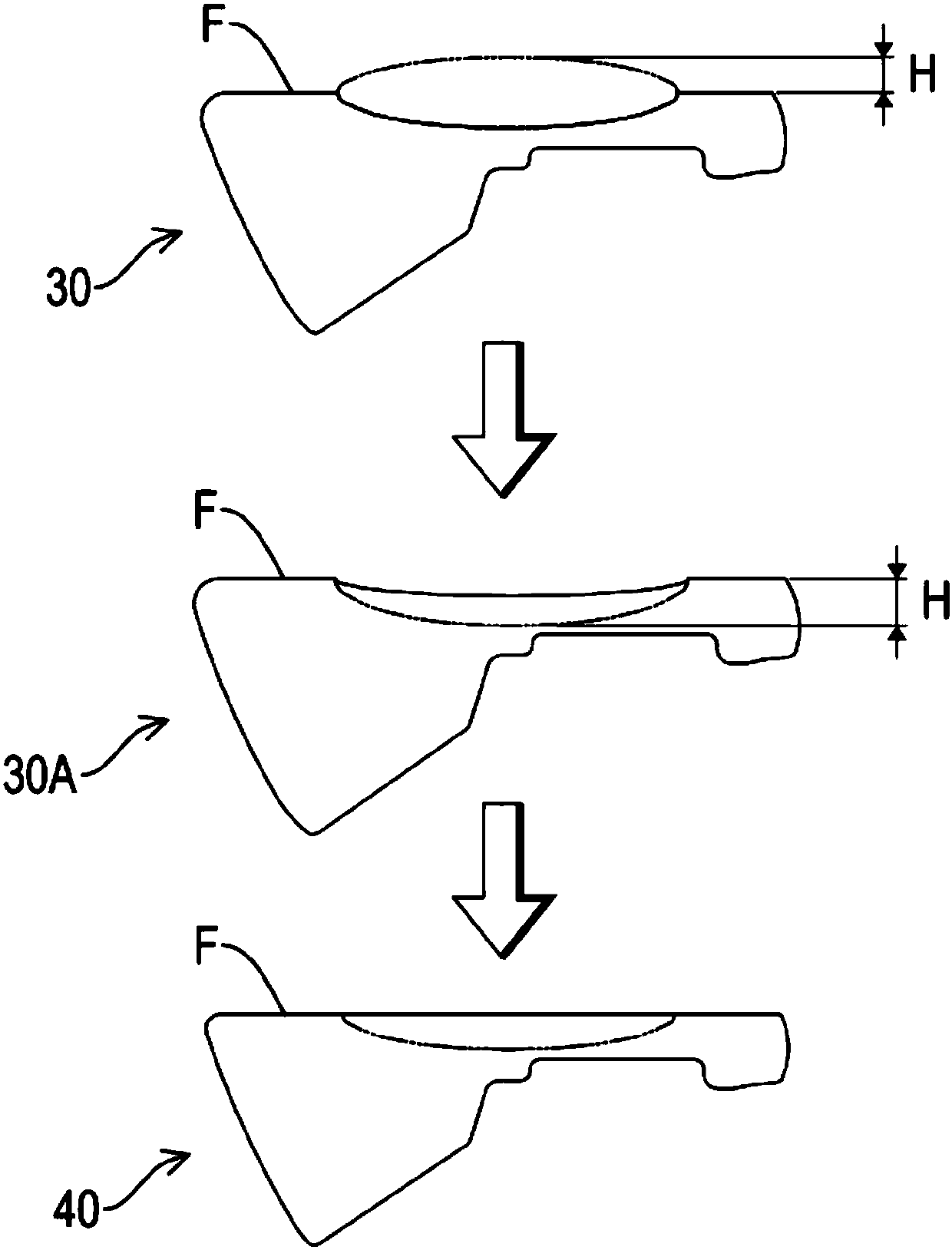

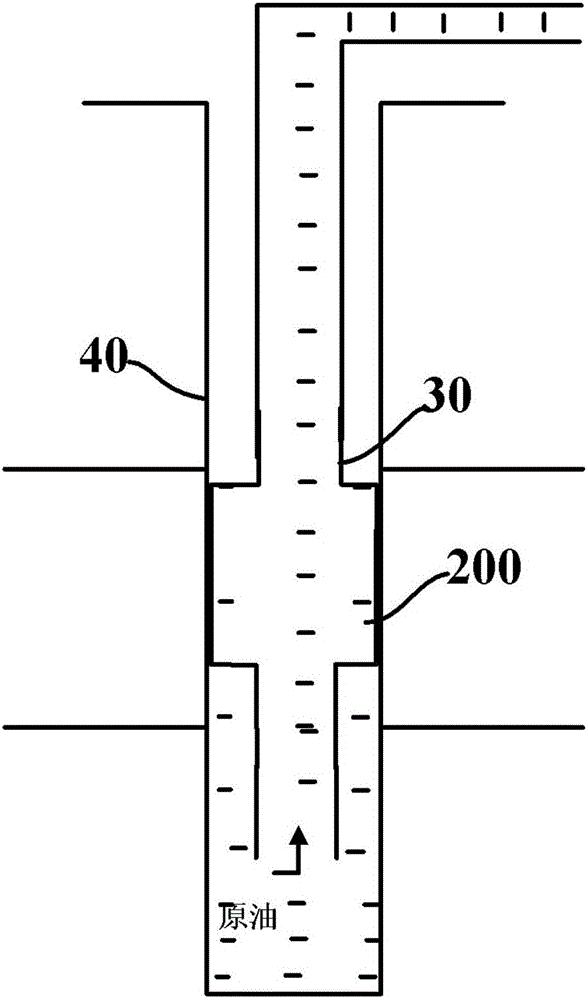

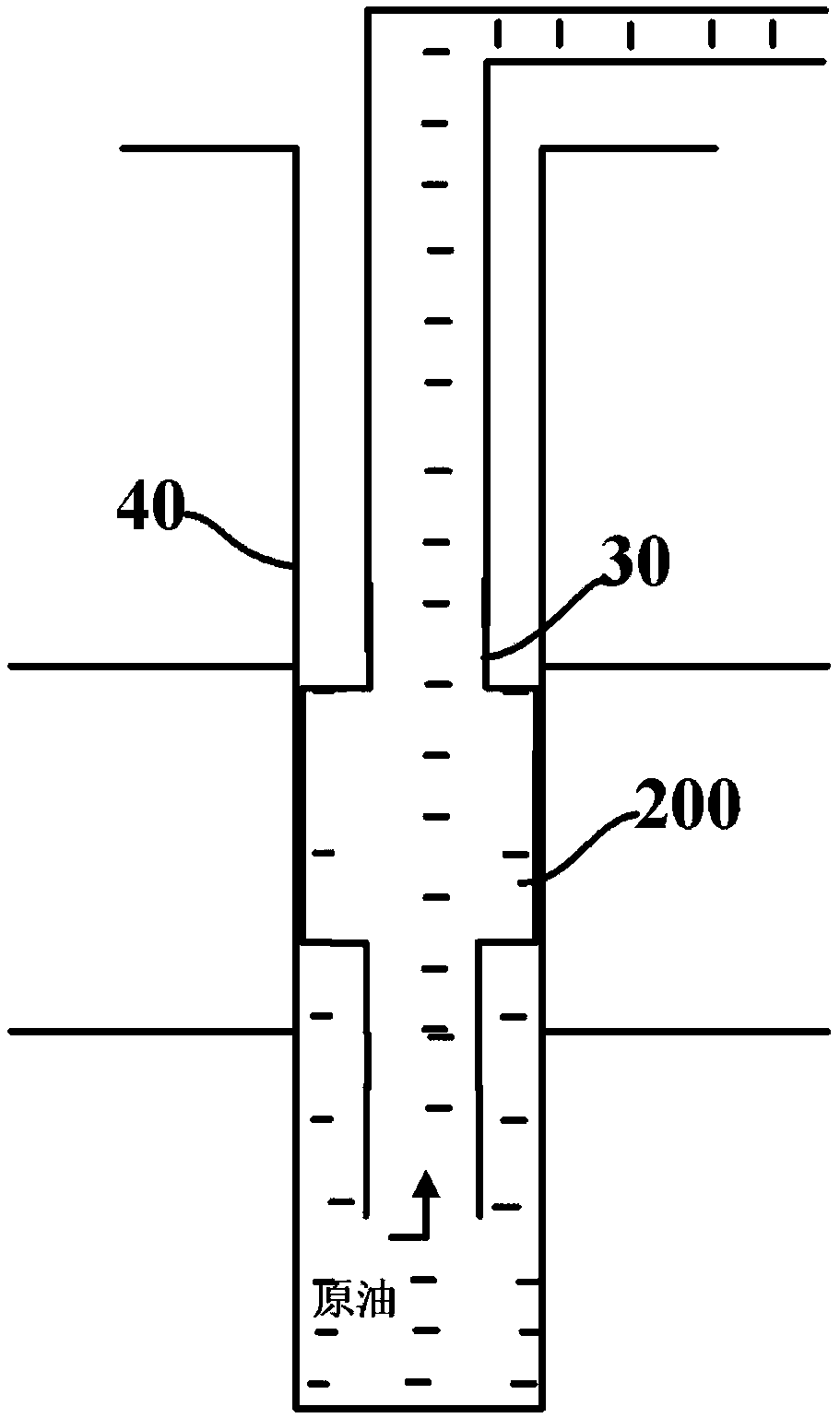

Rubber barrel with relatively hard upper and lower end parts, packer and bridge plug

The invention relates to the field of sealing and particularly relates to a rubber barrel with relatively hard upper and lower end parts, which is used in an oil exploitation process and can bear high temperature and high pressure, a packer and a bridge plug. According to one aspect of the invention, the rubber barrel is provided; and the hardness of the upper end part of the rubber barrel is greater than that of the middle part of the rubber barrel, so that the deformation of the middle part in the radial direction is greater than that of the upper end part in the radial direction when the upper end part bears first axial pressure. The hardness of the upper end part of the rubber barrel is greater than that of the middle part of the rubber barrel, so that the upper end part is almost used for transmitting the first axial pressure to the middle part and the lower end part, but not utilizes the first axial pressure to self radial deformation when the upper end part bears the first axial pressure. Therefore, the middle part and the lower end part have the radial deformation when the relatively small first axial pressure is used, and the sealing of the whole rubber barrel is realized.

Owner:TIANDING SEALING TECH BEIJING CO LTD

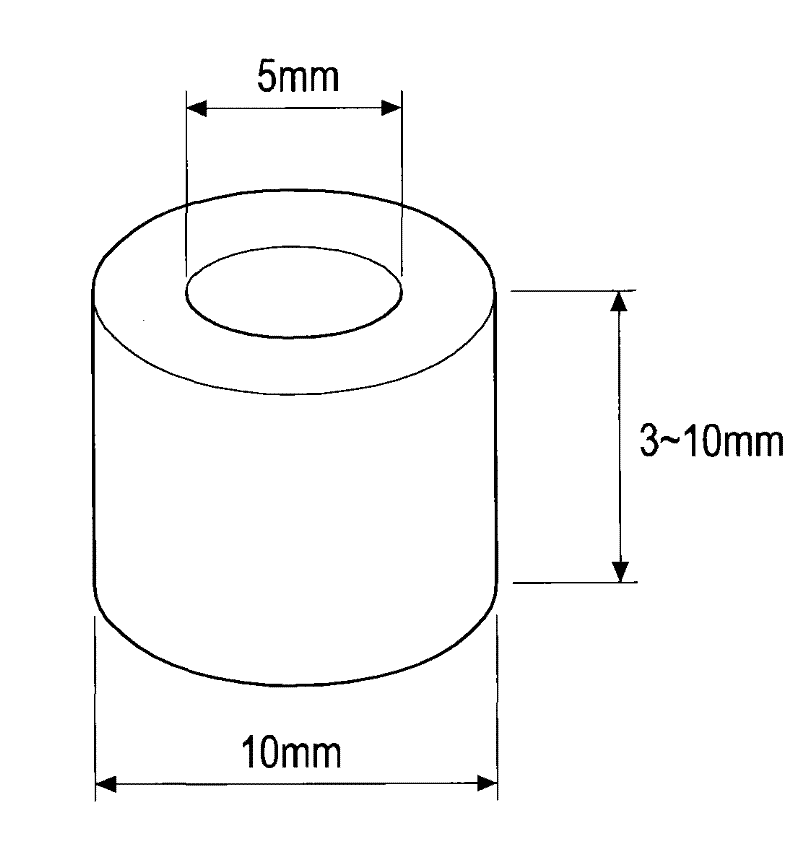

Preparation method of structure-enhanced silver/copper antibacterial zeolite and product prepared from structure-enhanced silver/copper antibacterial zeolite

InactiveCN102452664AImprove structural performanceHigh mechanical strengthBiocideDisinfectantsIndoor air qualityPotassium hydroxide

The invention relates to a preparation method of structure-enhanced silver / copper antibacterial zeolite and a product prepared from the structure-enhanced silver / copper antibacterial zeolite. According to the invention, the silicon-to-aluminum ratio of the zeolite is changed and a proper amount of modifiers (such as refractory mortar, zirconium phosphate or fly ash) are added so as to enhance the mechanical strength and stability of the zeolite and improve the defect that the traditional zeolite product is nondurable; and a gelatinizing agent of a sodium hydroxide or potassium hydroxide alkaline aqueous solution is added, and a hydrothermal gelatinizing process, molding (such as carrying out oil pressing to form a hollow cylinder shape), drying and calcining are carried out so as to prepare the durable and high-practicability zeolite product. In the antibacterial zeolite provided by the invention, silver ions with the best antibacterial property and copper ions with good antibacterial property and low cost are used as antibacterial metal ions; and compared with the conventional method in which single antibacterial metal is used, the preparation method disclosed by the invention can maintain the excellent antibacterial capacity of the silver ions, and by mixing the copper ions, the preparation cost is reduced, the acceptability of the antibacterial zeolite product is increased, so that the antibacterial zeolite product can be more widely applied to purification of indoor air.

Owner:NATIONAL YUNLIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

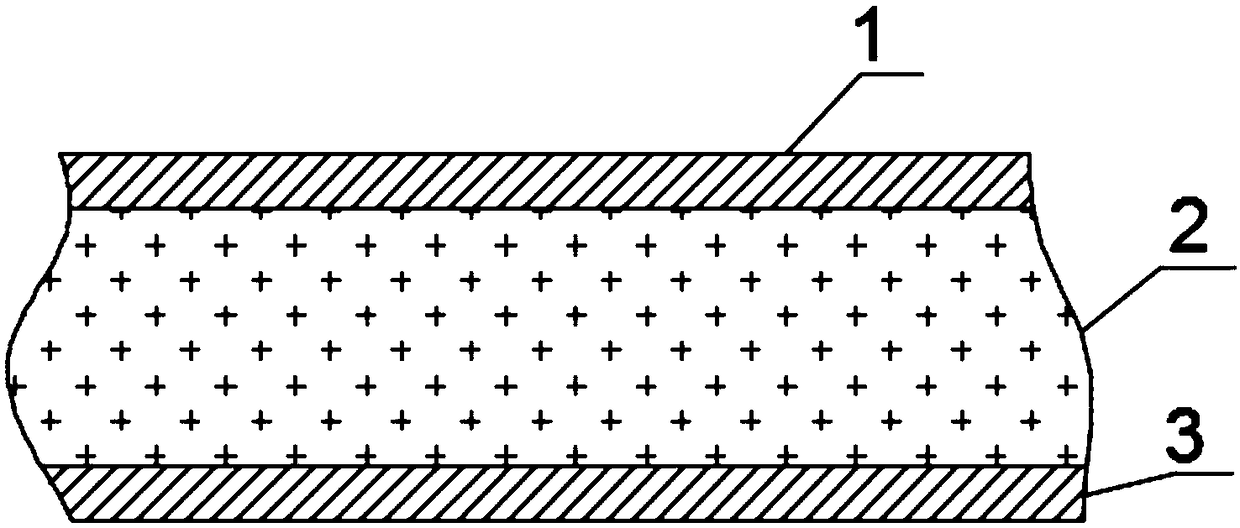

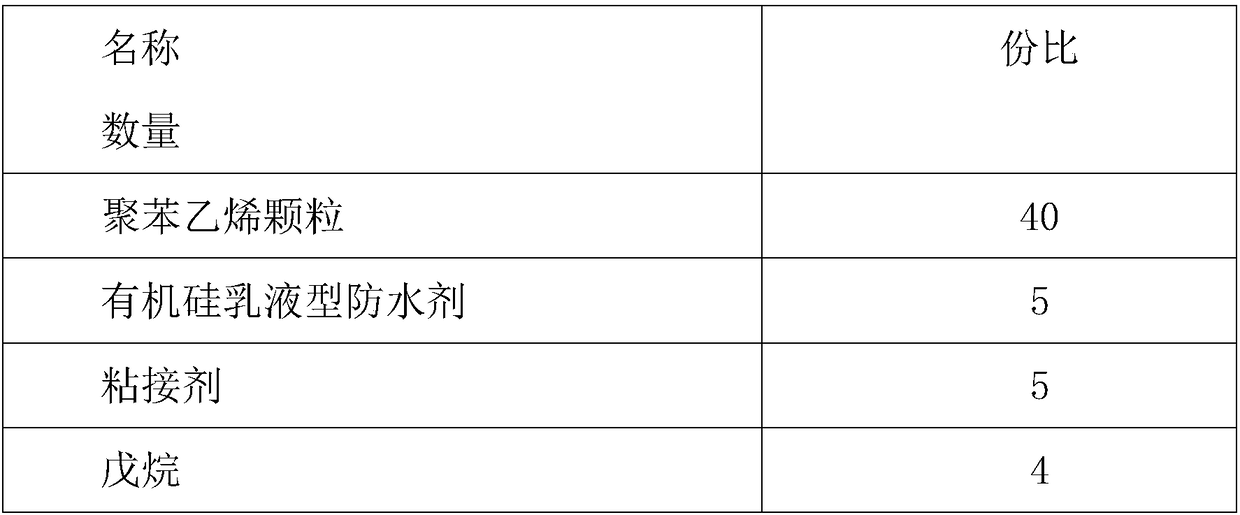

Production process of composite cored EPS foam plastic panel

InactiveCN108724885AHealth without riskImprove heat resistanceSynthetic resin layered productsLaminationEpoxyAdhesive

The invention discloses a production process of a composite cored EPS foam plastic panel. The composite cored EPS foam plastic panel comprises an upper epoxy resin board, wherein an EPS foam plastic board is arranged at the bottom of the upper epoxy resin board, and a lower epoxy resin board is arranged at the bottom of the EPS foam plastic board; and the EPS foam plastic board contains the following raw maters in parts by weight: 40-50 parts of polystyrene particles, 5-10 parts of an organic silicon emulsion waterproof agent, 5-10 parts of an adhesive, 4-8 parts of pentane, 4-8 parts of a flame retardant, 3-5 parts of methyl hexahydrophthalic anhydride, 3-5 parts of hydrogen-containing silicone oil and 3-5 parts of benzotriazole. By utilizing decabromodiphenyl ether as the flame retardant, the composite cored EPS foam plastic panel has good heat resistance, is healthy to a human body, has no risk and is environmentally friendly; hydrogen-containing silicone oil is added to be matchedwith the double-layer epoxy resin board and methyl hexahydrophthalic anhydride during the curing and stirring, so that the structural strength of the machined and formed EPS foam plastic panel is improved, and the EPS foam plastic panel dost not attract dust in a working environment with a high dust content, and the aesthetic degree of the EPS foam plastic panel is increased.

Owner:NANAN CHUANGPEI ELECTRONICS TECH CO LTD

Rubber barrel with inner side of lower seal ring not coated with copper sheet, packer, and bridge plug

The application relates to the field of sealing, in particular to a rubber barrel with inner side of a lower seal ring not coated with copper sheet, a packer and a bridge plug, with the rubber barrel capable of bearing high temperature and high pressure in the oil production industry. The outside of the lower seal ring of the rubber barrel is covered with first copper sheet, and the first copper sheet covers the upper surface, lower surface and outer side of the lower seal ring instead of the inner side of the lower seal ring; the thickness of the first copper sheet is configured such that when an upper portion bears first axial pressure, the lower seal ring deforms radially to enable the first copper sheet distributed on the inner side of the lower seal ring to contact a center tube, and the first copper sheet distributed on the outer surface of the lower seal ring to contact a sleeve. The lower seal ring of the application is covered with the first copper sheet, the degrading effect of high-temperature high-pressure steam small molecules on the rubber barrel is decreased or avoided, and long-term sealing effectiveness of the rubber barrel is improved.

Owner:TIANDING SEALING TECH BEIJING CO LTD

Rubber sleeve comprising metal wire sealing ring, packer and bridge plug

The invention relates to the field of sealing, in particularly to a rubber sleeve which can bear high temperature and high pressure and comprises a metal wire sealing ring, a packer and a bridge plug used in the oil exploitation industry. The rubber sleeve comprises the metal wire sealing ring and a fiber wire sealing ring, wherein the metal wire sealing ring and the fiber wire sealing ring abut against each other and are arranged on the lower portion. The metal wire sealing ring comprises a plurality of mutually intersecting metal wires and glue bonding the metal wires together. The fiber wire sealing ring comprises a plurality of fiber wires which mutually intersect and resist high temperature and high pressure and glue bonding the fiber wires together. When the metal wire sealing ring is arranged below the fiber wire sealing ring, axial pressure transmitted to the fiber wire sealing ring can be reduced due to the friction between the metal wire sealing ring and a central pipe and / or a sleeve pipe, and at the time axial pressure on the fiber wire sealing ring can be effectively reduced. The reason for generation of shoulder protrusion is too large axial pressure, so that generation of shoulder protrusion can be reduced or prevented through the design.

Owner:TIANDING SEALING TECH BEIJING CO LTD

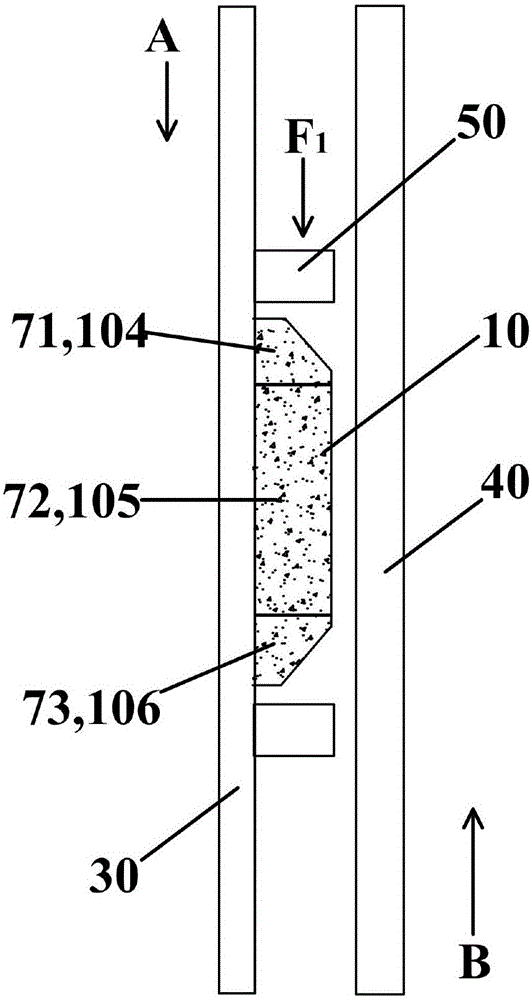

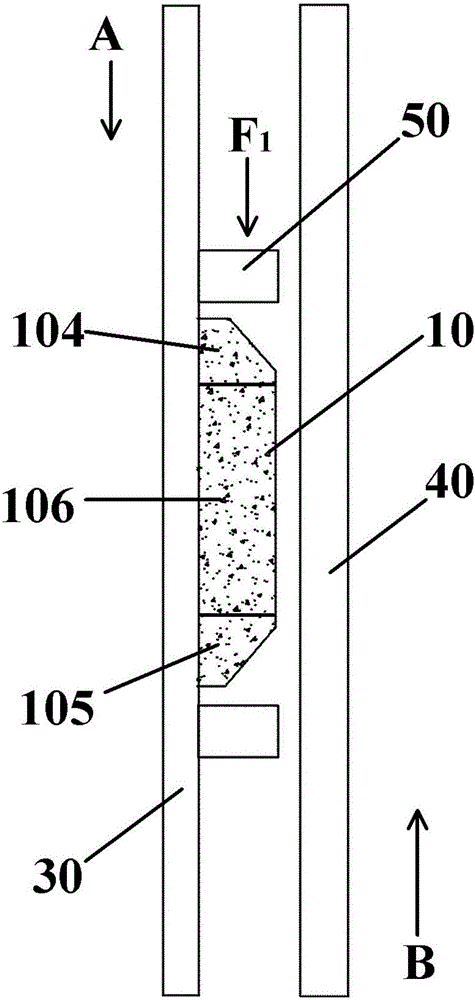

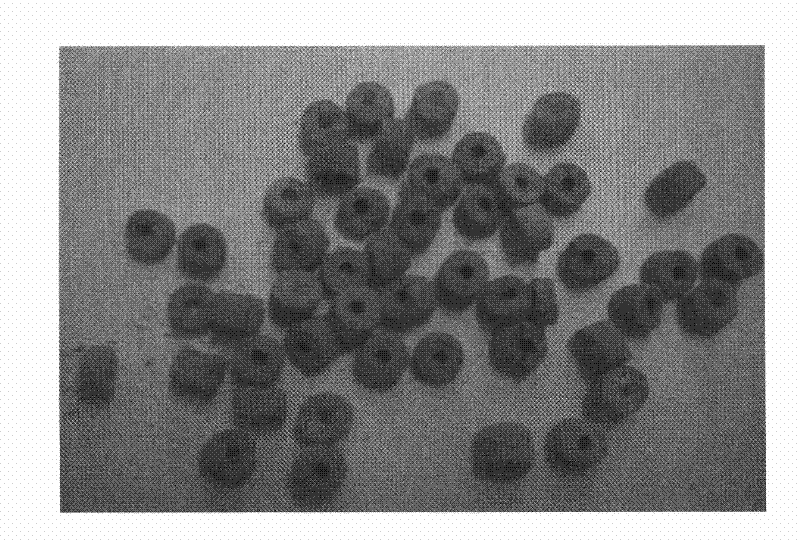

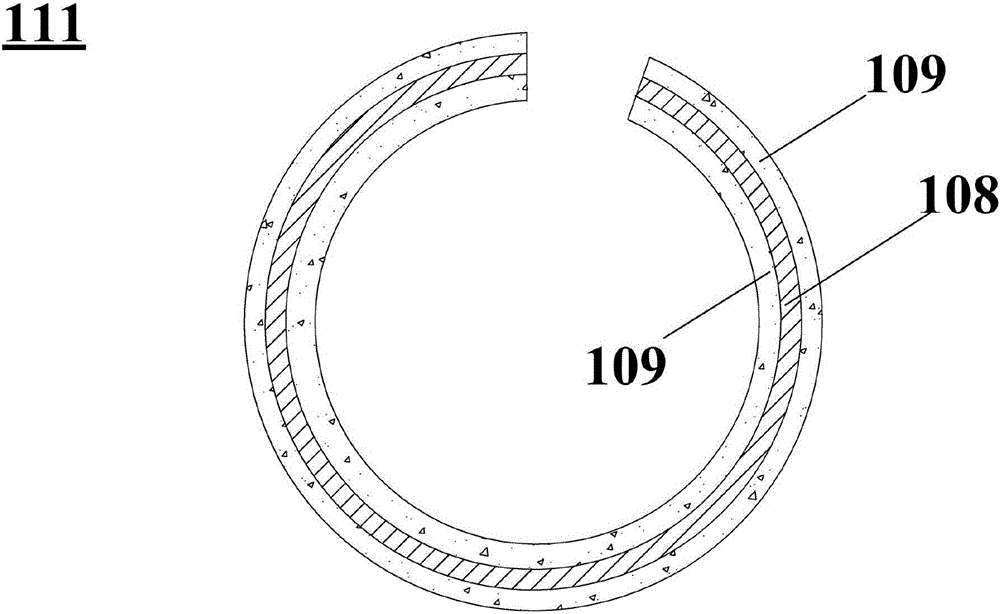

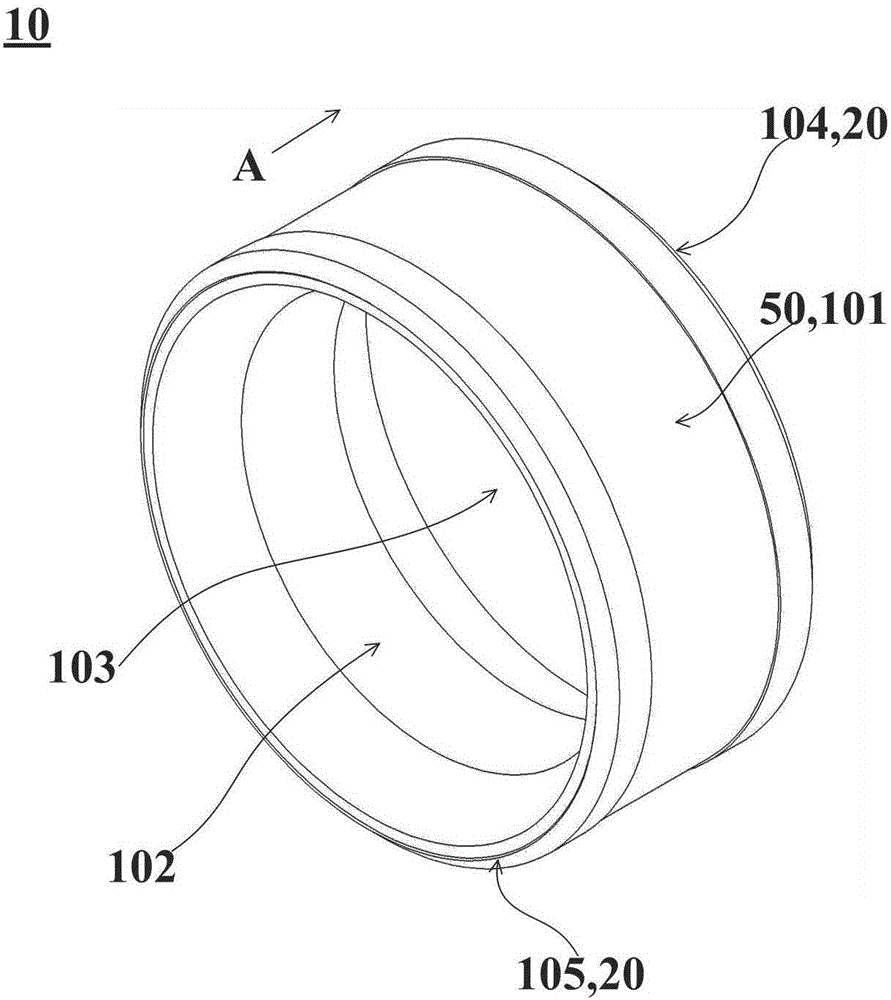

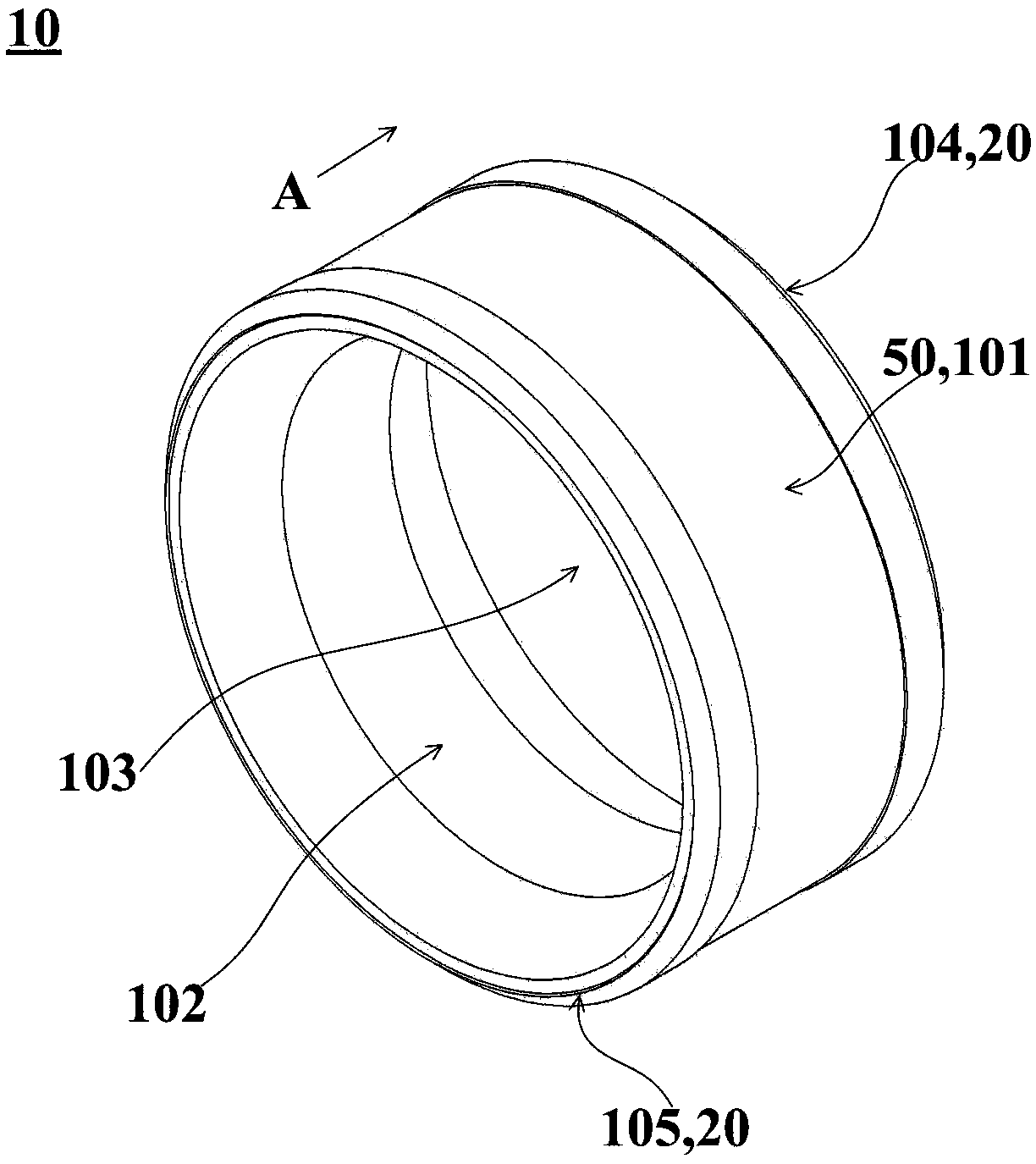

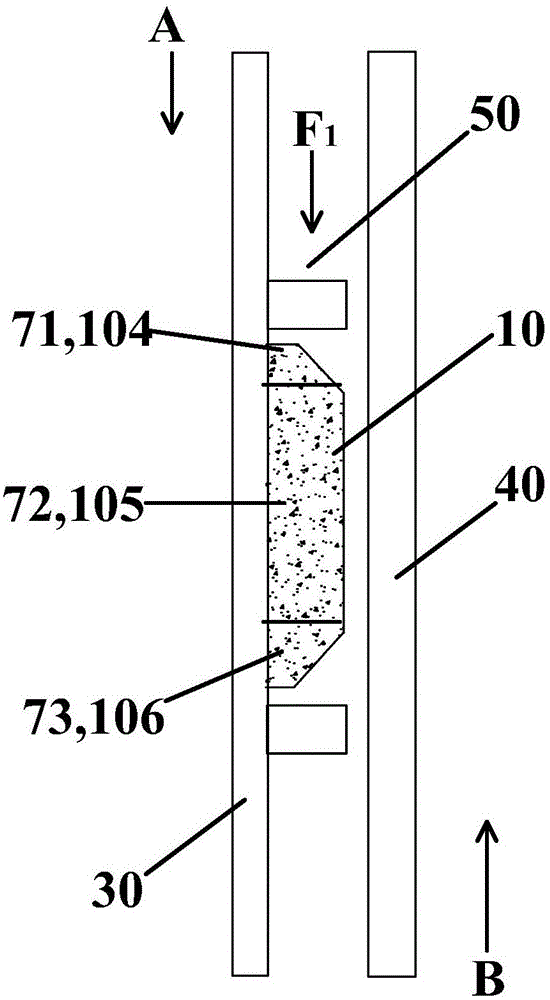

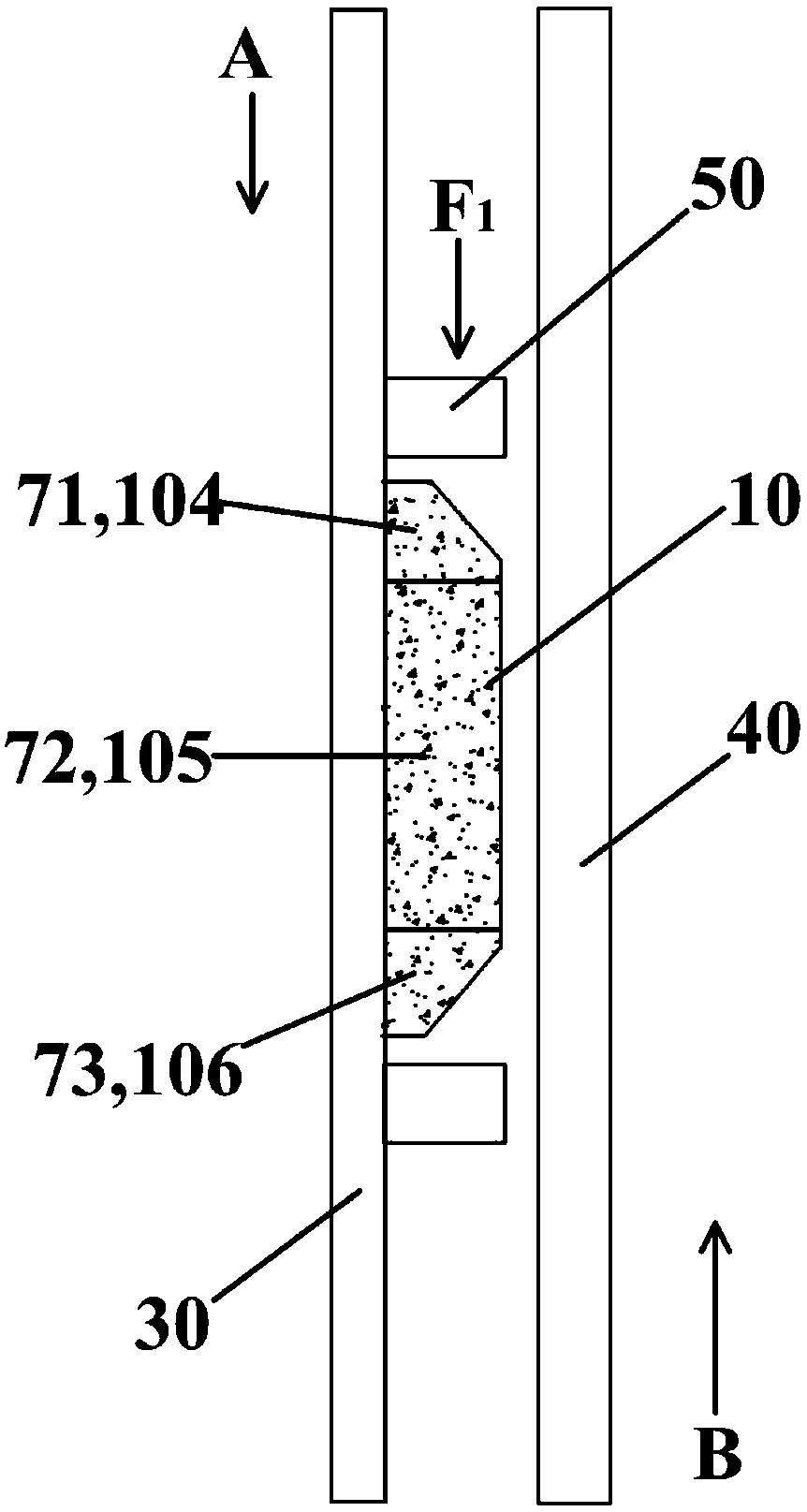

Rubber cylinder with inner cores provided with spiral packing, packer and bridge plug

InactiveCN105781480AChange hardnessIncreased compressive strength rangeSealing/packingFiberAxial pressure

The invention relates to the technical field of sealing in oil exploitation industry, in particular to a rubber cylinder capable of withstanding high temperature and high pressure and with inner cores provided with spiral packing, and a packer and a bridge plug with the rubber cylinder. The inner cores of the rubber cylinder are provided with colloids and spiral matrices, the plurality of inner cores are arranged entirely along the axial direction of the rubber cylinder, the matrices are formed by a plurality of intercrossing high temperature and high pressure resistant fibers, the colloids are adhered to the fibers, and distributed on the surface of each of the matrices so that the inner sides and the outer sides of the axially arranged inner cores form inside surfaces and outside surfaces. The colloids coat the inner cores, the inner cores are provided with intercrossing fibers, and the colloids are distributed on the surface and the inner side of each of the inner cores and adhered to the fibers. When the rubber cylinder expands under action of axial pressure, the fibers can limit the expansion so that structural hardness of the cylinder rubber is completely increased, and compressive strength of the rubber cylinder is raised.

Owner:TIANDING SEALING TECH BEIJING CO LTD

Rubber cylinder coated with upper and lower copper skins on lower end sealing ring as well as packer and bridge plug

The invention relates to the field of sealing, in particular to a rubber cylinder coated with upper and lower copper skins on a lower end sealing ring as well as a packer and a bridge plug, which are used in the petroleum production industry. A first copper skin coats the lower end sealing ring of the rubber cylinder; the first copper skin comprises an upper side copper skin and a lower side copper skin; the upper side copper skin coats the upper surface, the external side surface and the internal side surface of the lower end sealing ring; the lower side copper skin coats the lower surface, the internal side surface and the external side surface of the lower end sealing ring; and the upper side copper skin and the lower side copper skin are overlapped on the internal side surface and the external side surface of the lower end sealing ring. According to the invention, as the first copper skin coats the lower end sealing ring, a degradation effect, on the rubber cylinder, of small molecules of high temperature high pressure vapor is lightened or prevented and the long-term effect of the sealing of the rubber cylinder is enhanced.

Owner:TIANDING SEALING TECH BEIJING CO LTD

Rubber barrel with harder upper end part as well as packer and bridge plug

The invention relates to the field of sealing, and particularly relates to a rubber barrel with harder upper end part which is used in an oil exploitation industry and can bear a high temperature and a high pressure a packer and a bridge plug. According to one aspect of the invention, the rubber barrel is provided, wherein the hardness of the upper end part of the rubber barrel is more than the hardness of the middle part of the rubber barrel, so that the shape change of the middle part in the radial direction is more than the shape change of the upper end part in the radial direction when the upper end part bears first axial pressure. The hardness of the upper end part is more than the hardness of the middle part, in this way, when the upper end part bears the first axial pressure, the upper end part tends to transfer the first axial pressure to the middle part and a lower end part rather than uses the first axial pressure for self radial deformation. Thus, the middle part and the lower end part can be enabled to generate radial deformation when a smaller first axial pressure is used, so as to achieve the integral sealing of the rubber barrel.

Owner:TIANDING SEALING TECH BEIJING CO LTD

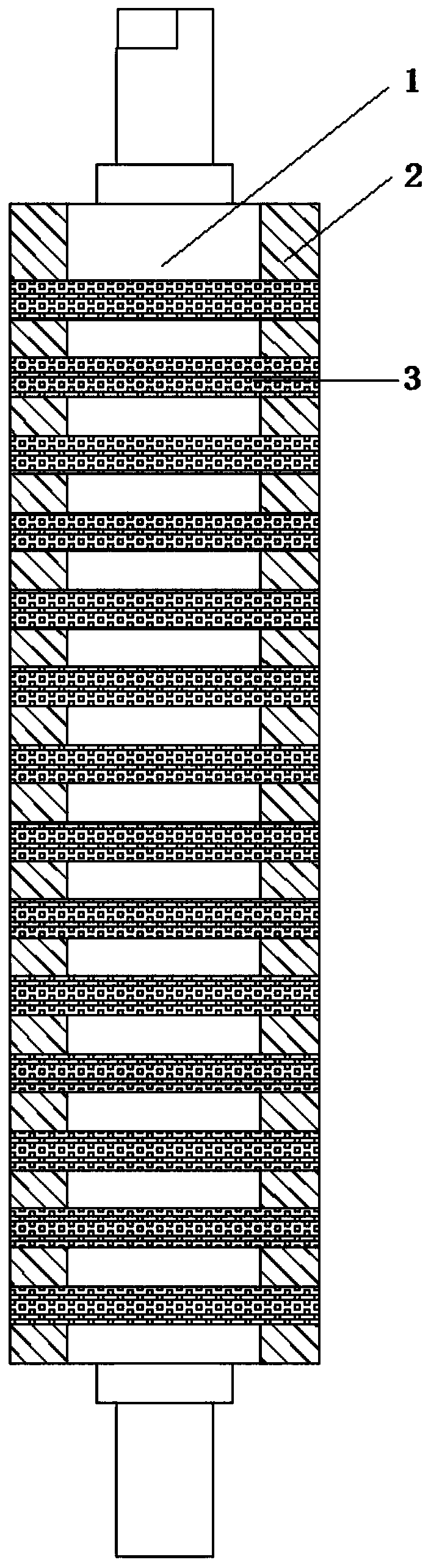

Rubber cylinder with spiral inner cores

The invention relates to the technical field of sealing in oil exploitation industry, in particular to a rubber cylinder with spiral inner cores. The rubber cylinder comprises a plurality of cylindrical inner cores, wherein each inner core extends in an axial direction of the rubber cylinder as a whole and is provided with an opening in the axial direction; each inner core spirally surrounds a through hole as a whole and extends towards the outer surface; each inner core has mutually crossed high-temperature-resistant and high-pressure-resistant fiber silks; and a rubber matrix is distributed on the surface and in the interior of each inner core and bonds the fiber silks. The interior of the rubber matrix is covered with the inner cores and each inner core has the mutually crossed fiber silks, so that the rubber matrix is distributed on the surface and in the interior of each inner core and bonds the fiber silks. When the rubber cylinder is expanded due to an axial pressure, the fiber silks limit the expansion, so that the structure hardness of the rubber cylinder is improved as a whole and the compressive strength of the rubber cylinder is enhanced.

Owner:TIANDING SEALING TECH BEIJING CO LTD

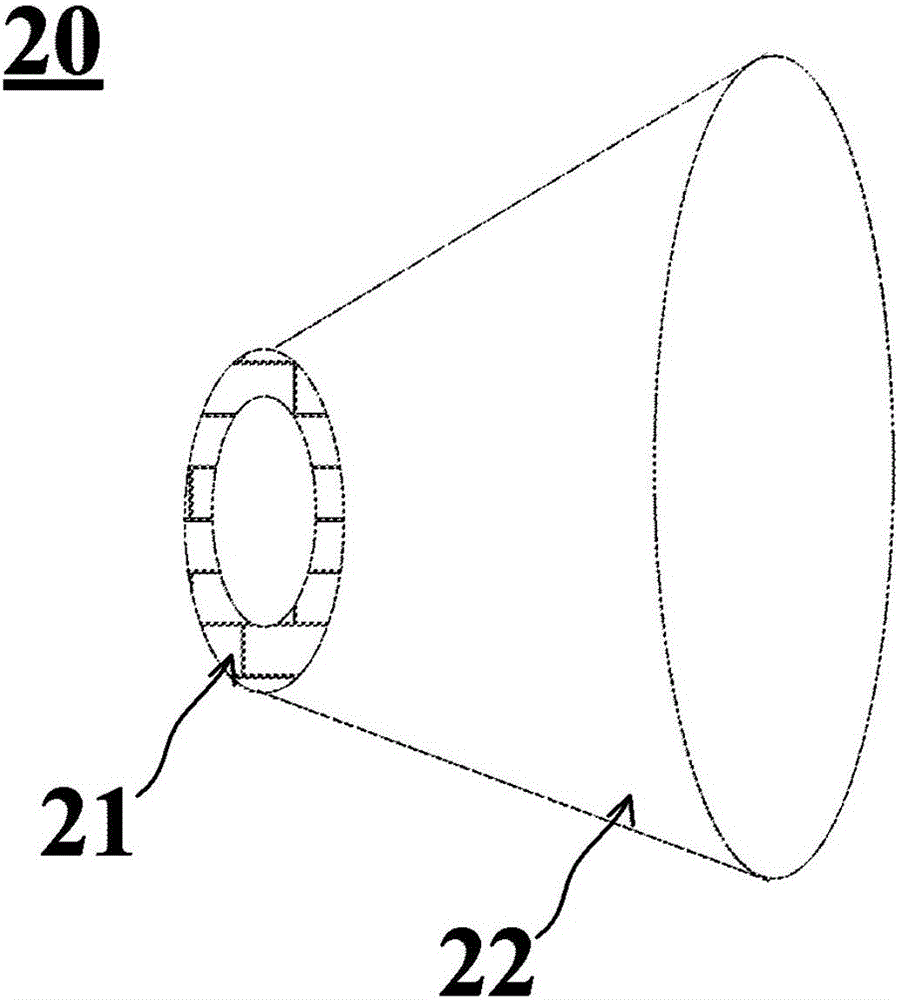

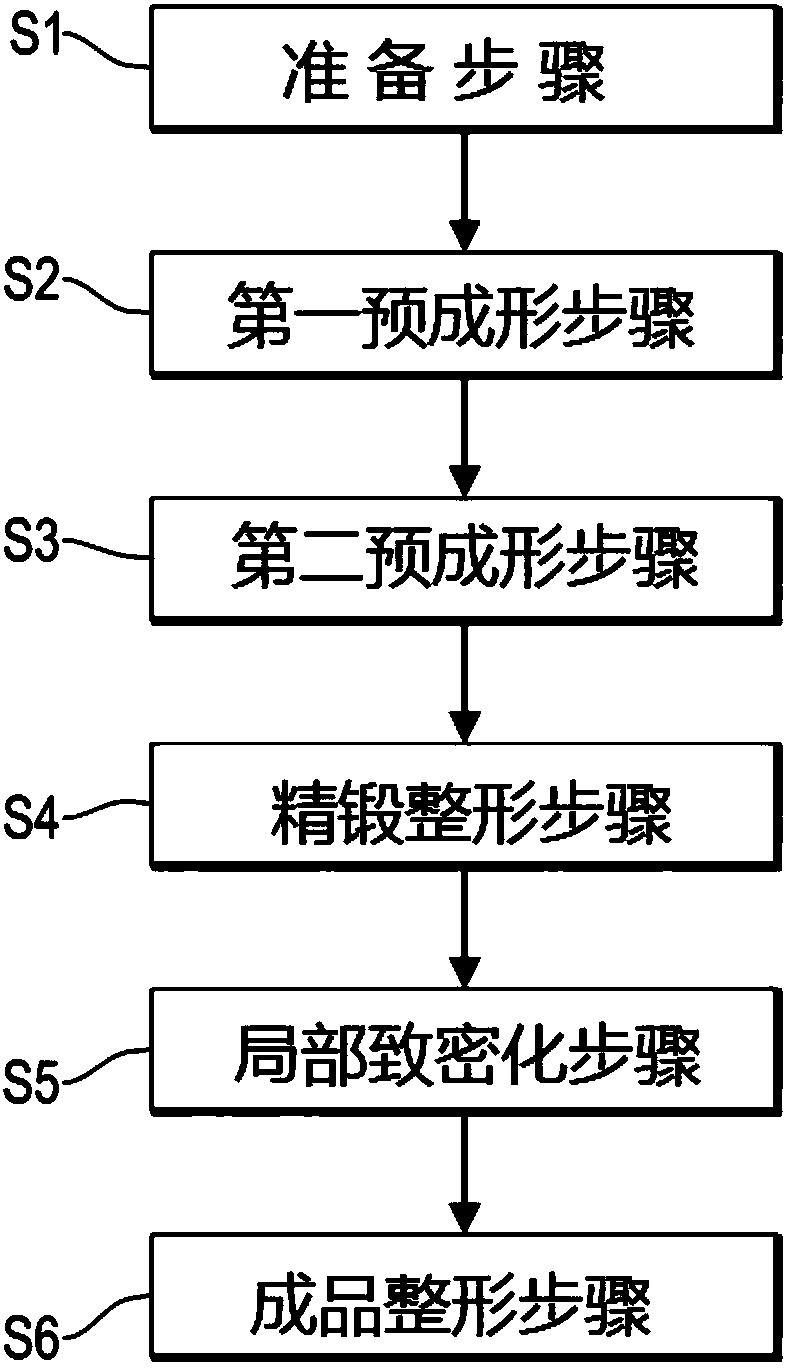

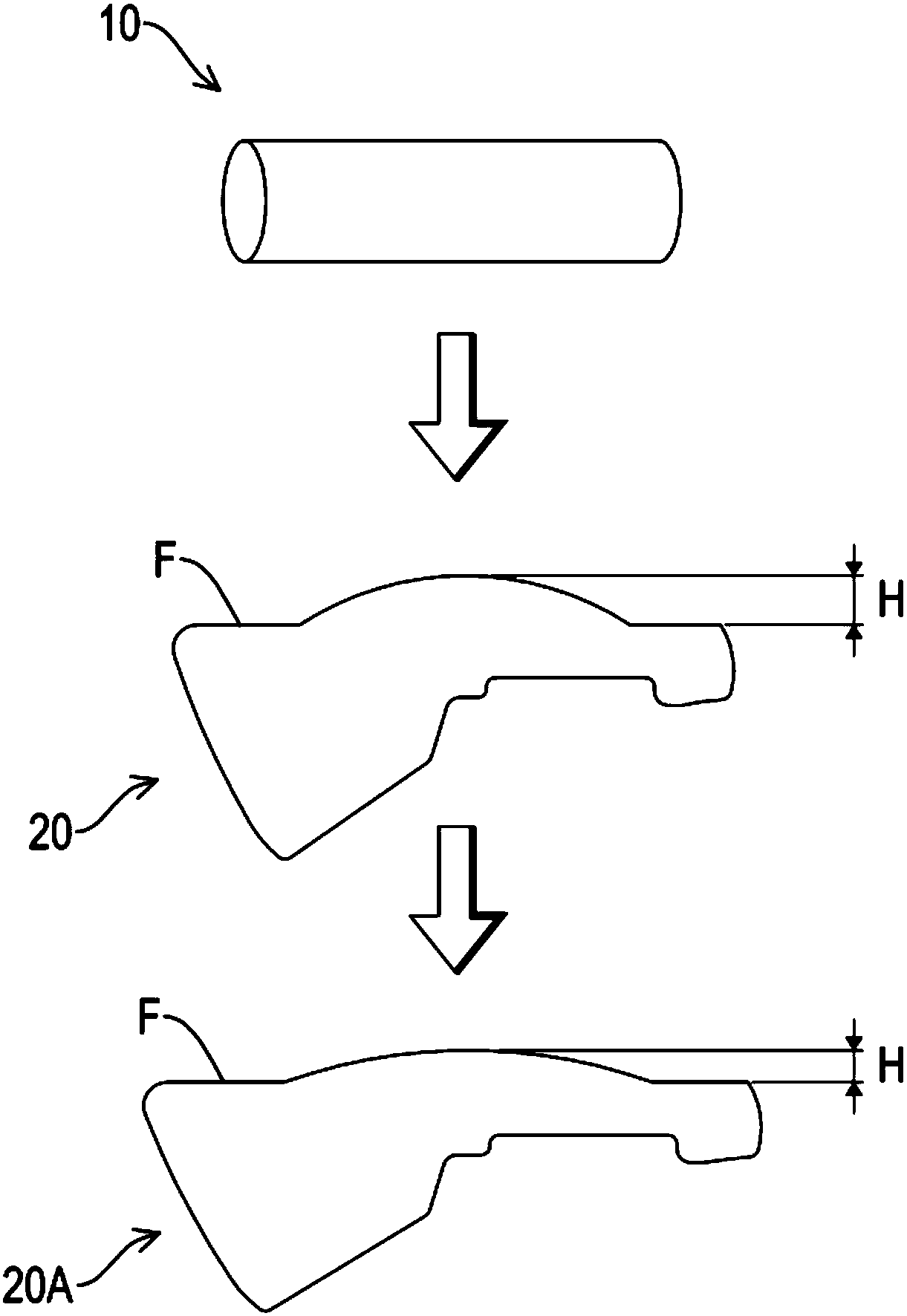

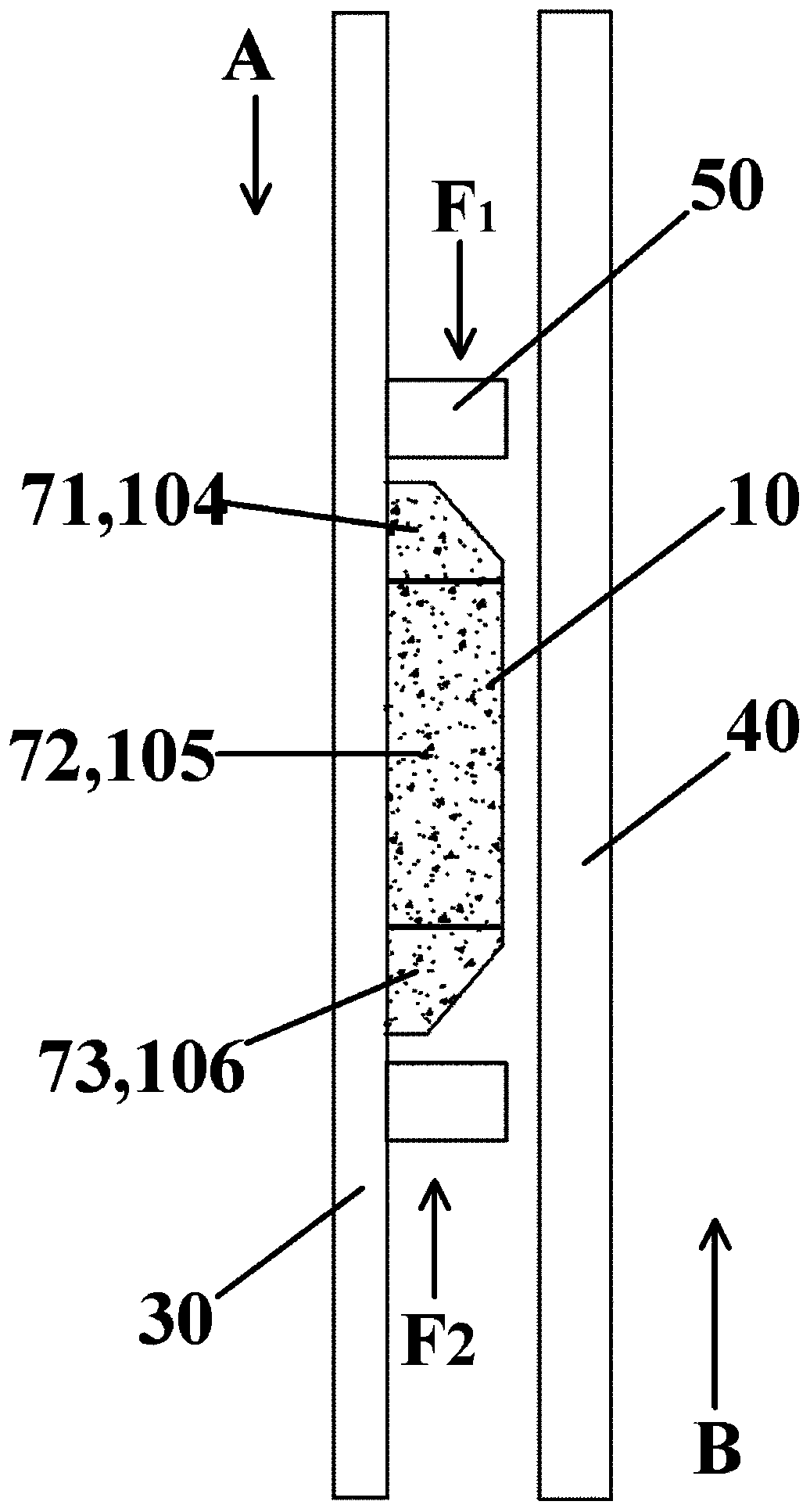

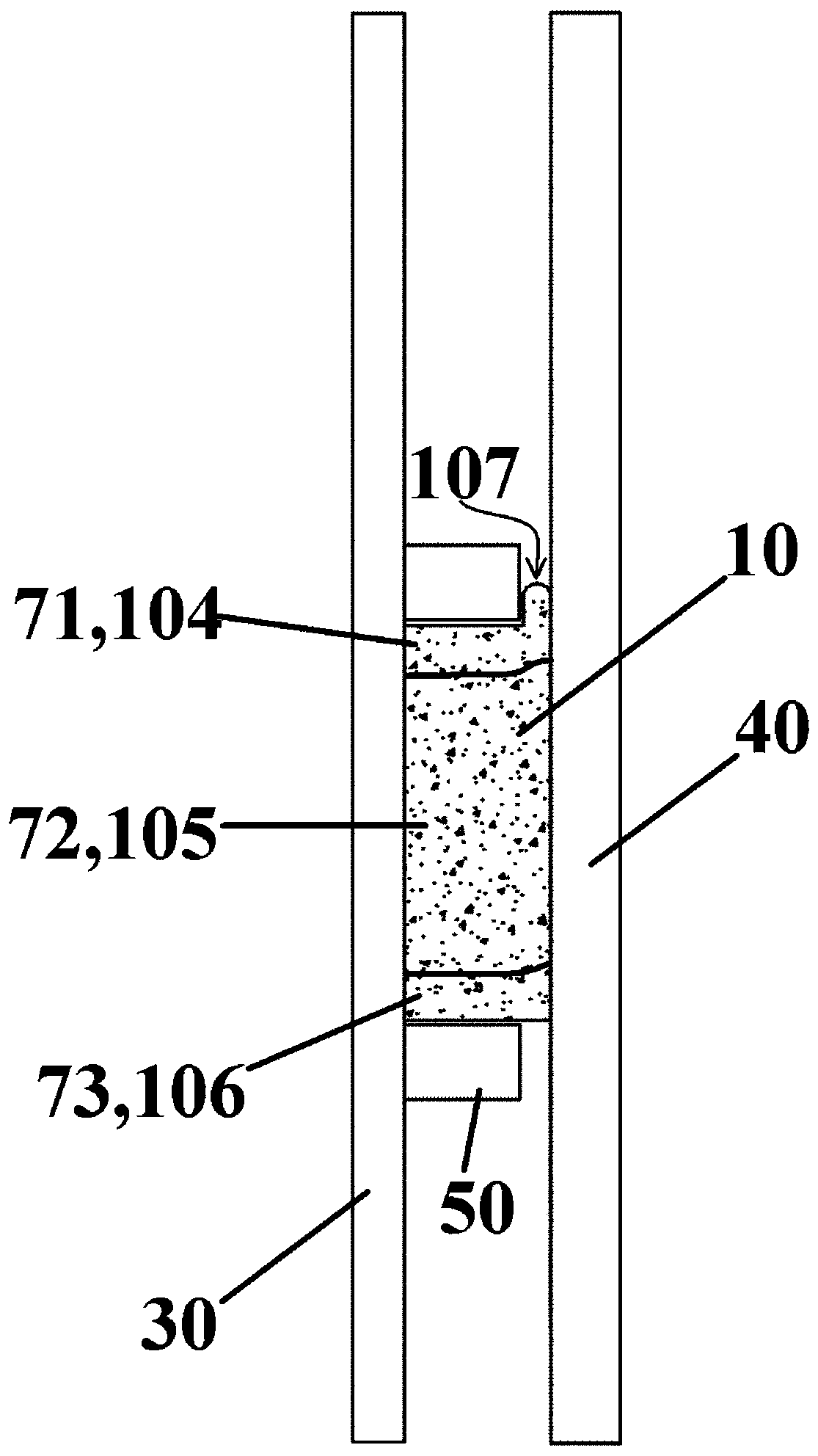

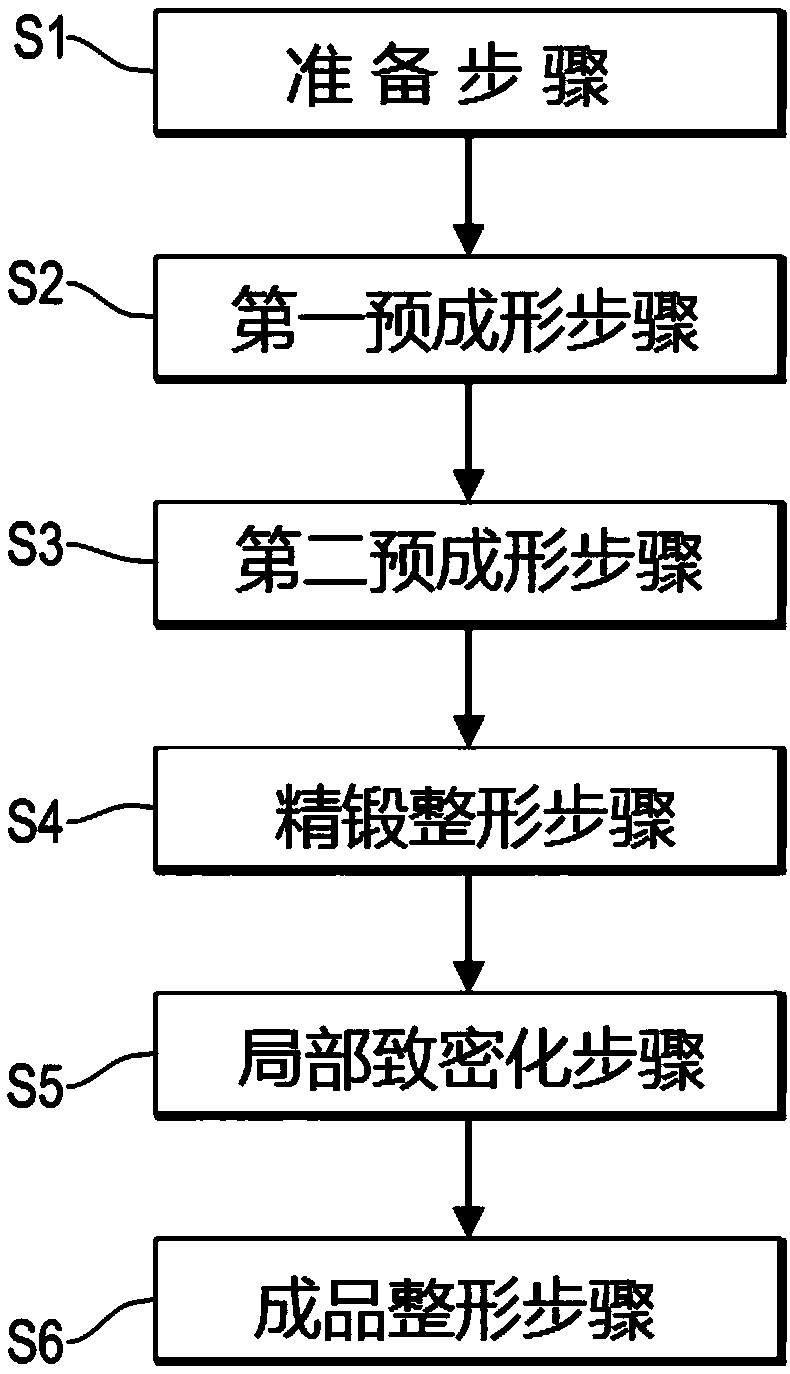

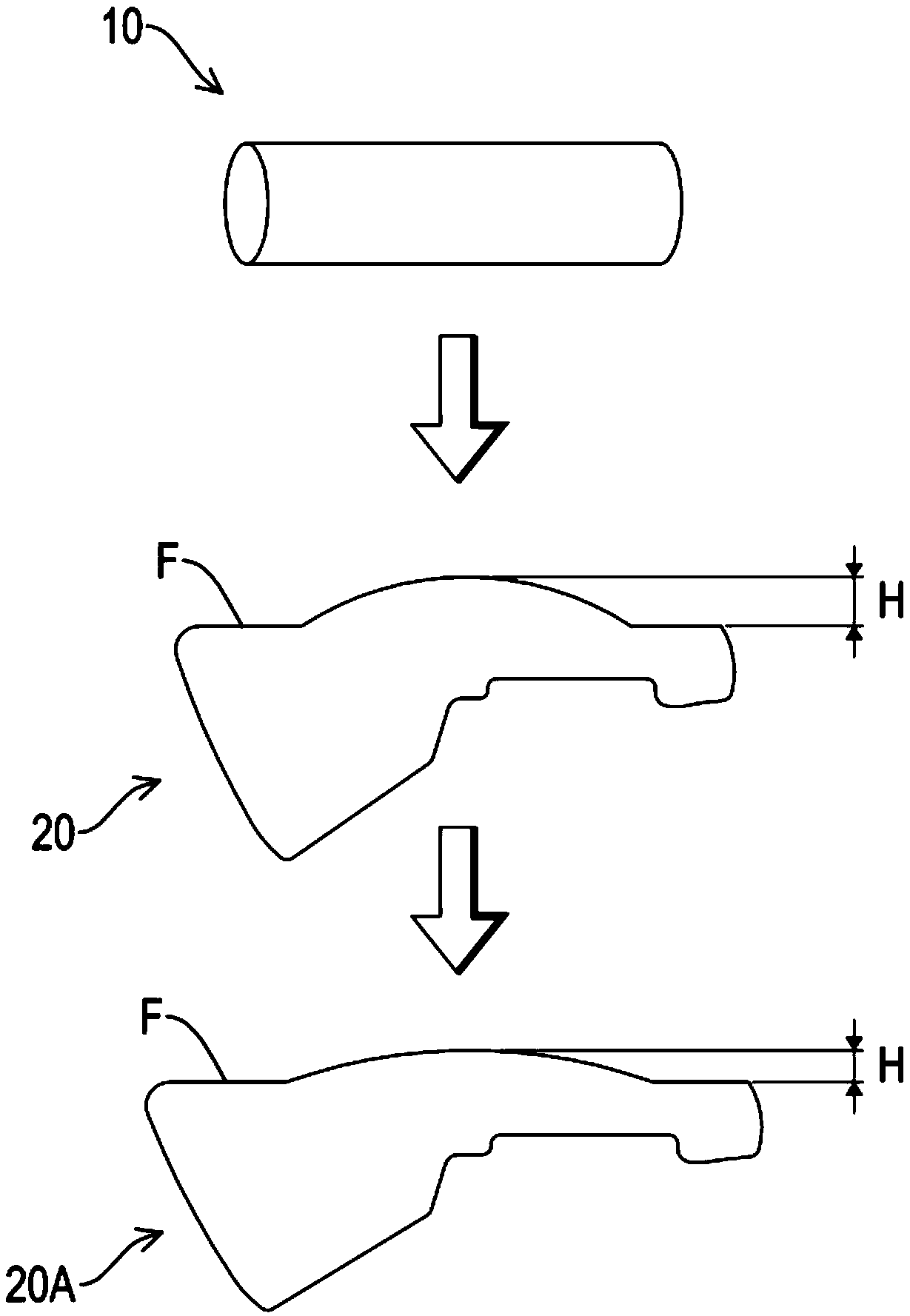

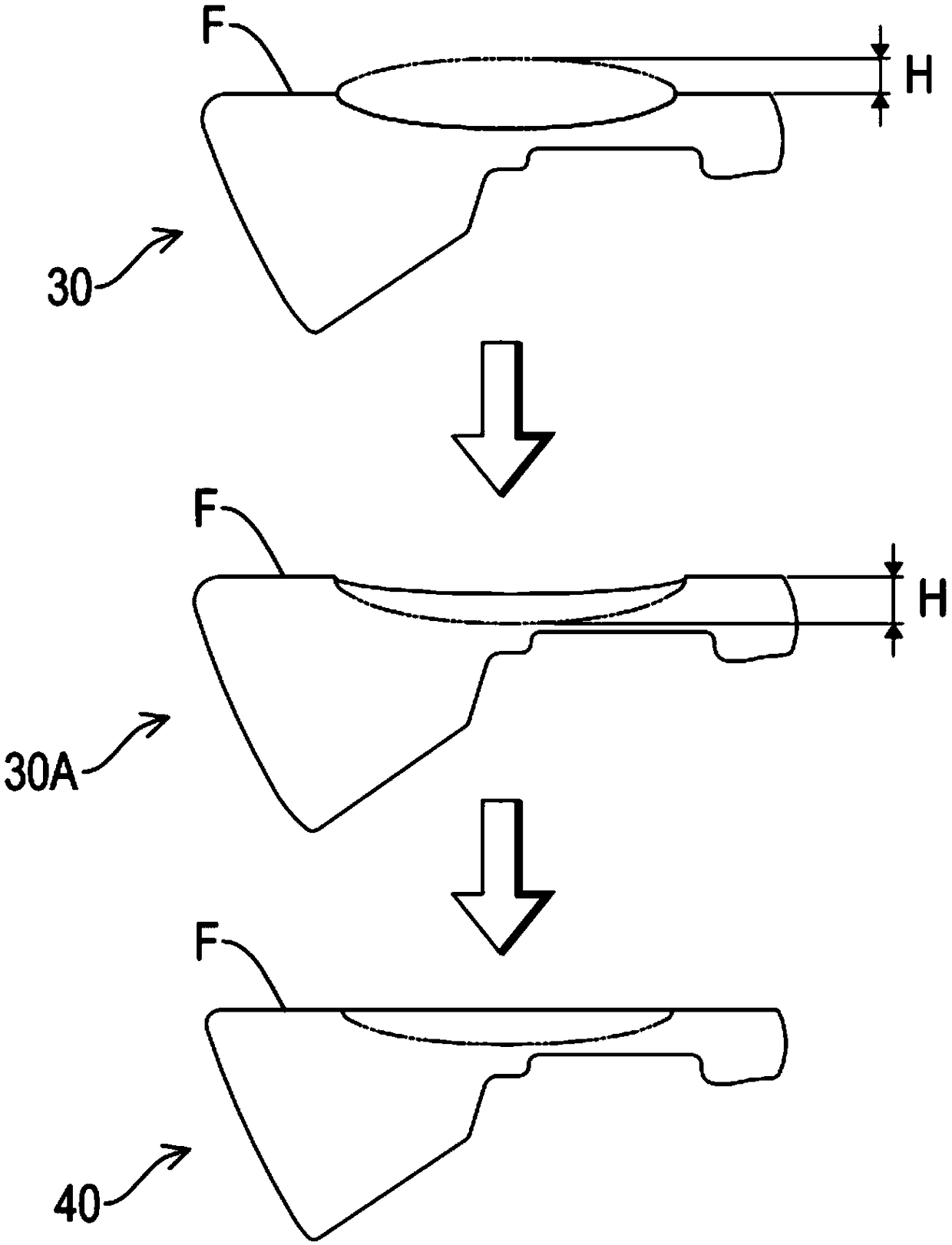

Manufacturing method for forging ball head to achieve local structure compaction and ball head produced through method

ActiveCN107649640AIncrease structural rigidityLoud and melodiousGolf clubsHeating/cooling devicesEngineeringGolf Ball

The invention relates to the field of golf clubs, in particular to a manufacturing method for forging a ball head to achieve local structure compaction and the ball head produced through the method, the manufacturing method comprises the following steps of preparation; first performing; second performing; finish forging reshaping; local compaction; and finished product reshaping. According to themanufacturing method and the ball head, through the steps, the forged ball head achieves the effect of metallographic crystallization compaction in a sweet zone of a hitting face, the ball hitting structural strength of the sweet zone of the forged ball head is further improved, the hitting sound is improved, and the better ball hitting experience is achieved for users.

Owner:四川宇钛体育用品有限公司

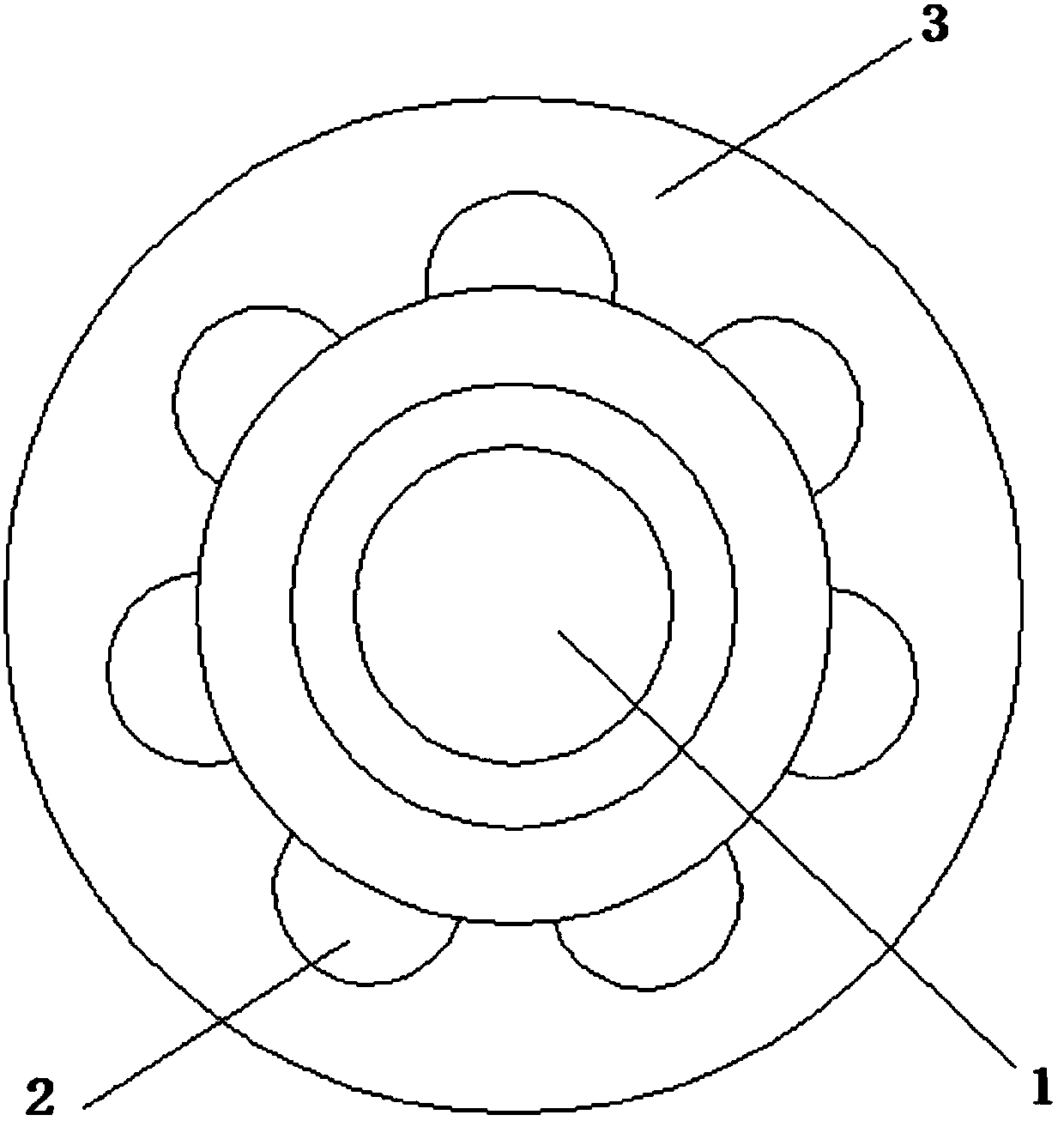

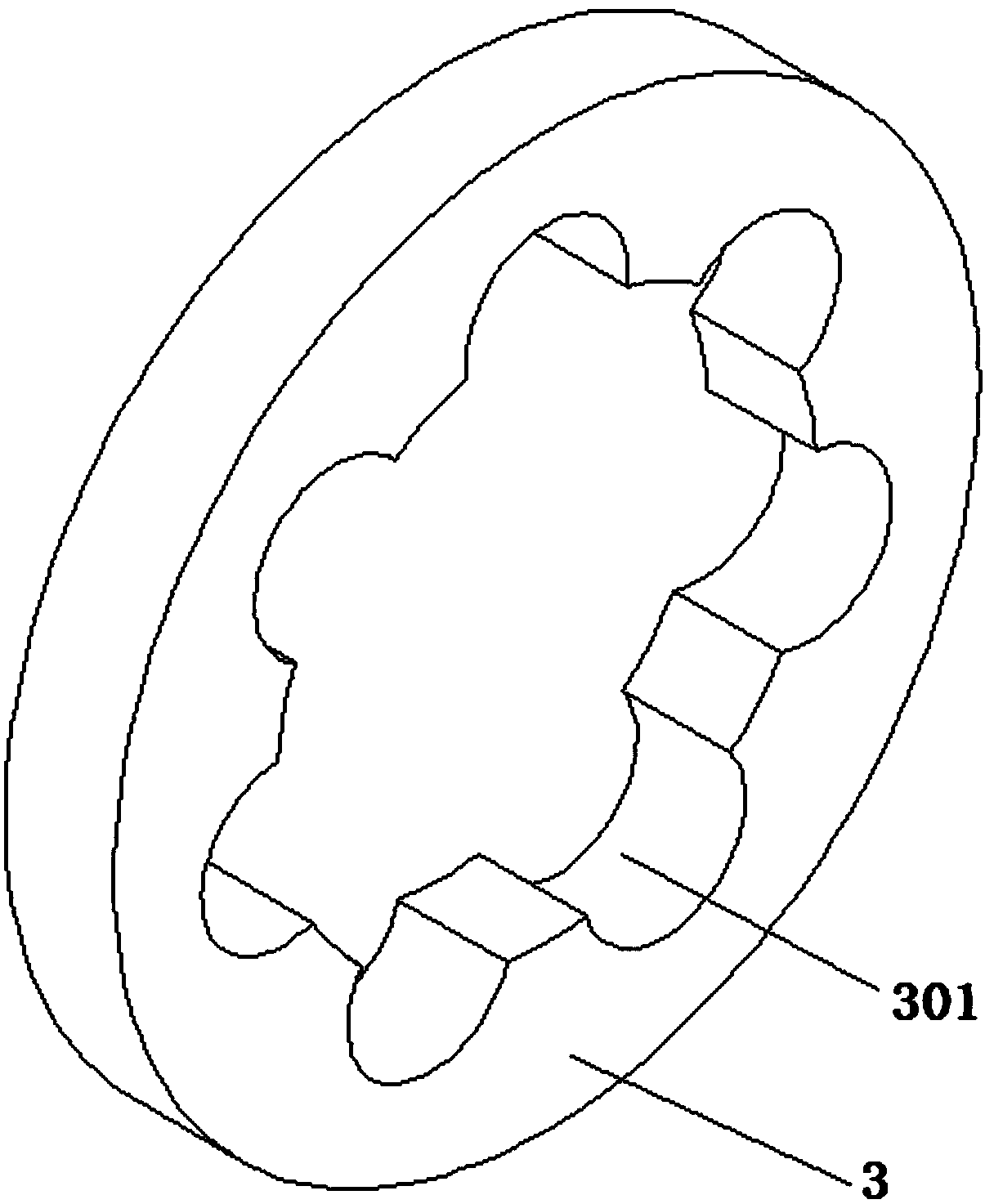

Rubber barrel with annular packing in inner cores, packer and bridge plug

The invention relates to the technical field of sealing of a petroleum exploitation industry and particularly relates to a rubber barrel with annular packing in inner cores, which can bear high temperature and high pressure, and a packer and a bridge plug which are provided with the rubber barrel. A sealing body of the rubber barrel comprises the plurality of inner cores, wherein each inner core is provided with a rubber body and an annular base body; the whole bodies of the plurality of inner cores are arrayed along the axial direction of the rubber barrel; each base body is composed of a plurality of high-temperature-resisting and high-pressure-resisting fiber yarns which are mutually crossed; and the rubber bodies are stuck with the fiber yarns and the rubber bodies are distributed on the surfaces of the base bodies so that inner surfaces and outer surfaces are formed on the inner parts and the outer parts of the plurality of inner cores which are arrayed along the axial direction respectively. The base bodies have the fiber yarns which are mutually crossed, and the rubber bodies are distributed on the surfaces and the inner parts of the base bodies and are used for sticking all the fiber yarns. When the rubber barrel is subjected to axial pressure and is expanded, the fiber yarns limit the expansion, so that the structure rigidity of the rubber barrel is wholly increased and the compressive strength of the rubber barrel is improved.

Owner:TIANDING SEALING TECH BEIJING CO LTD

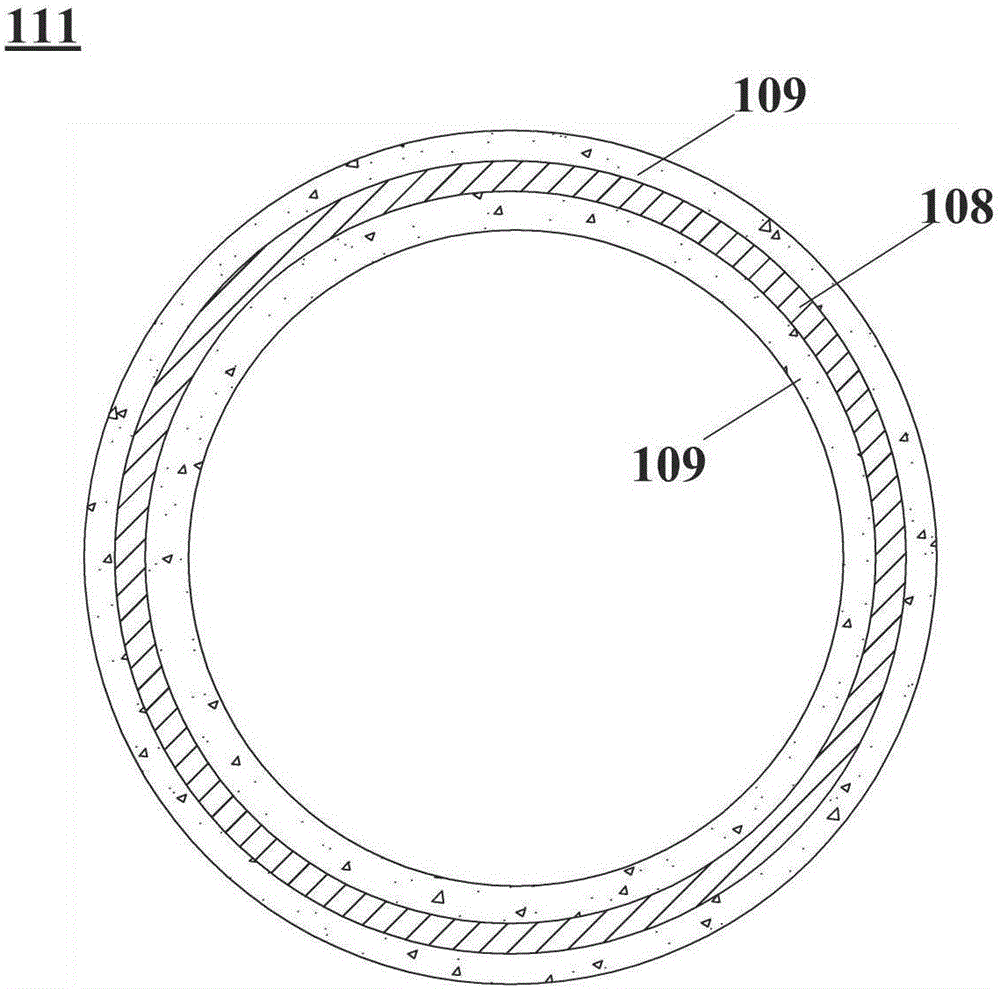

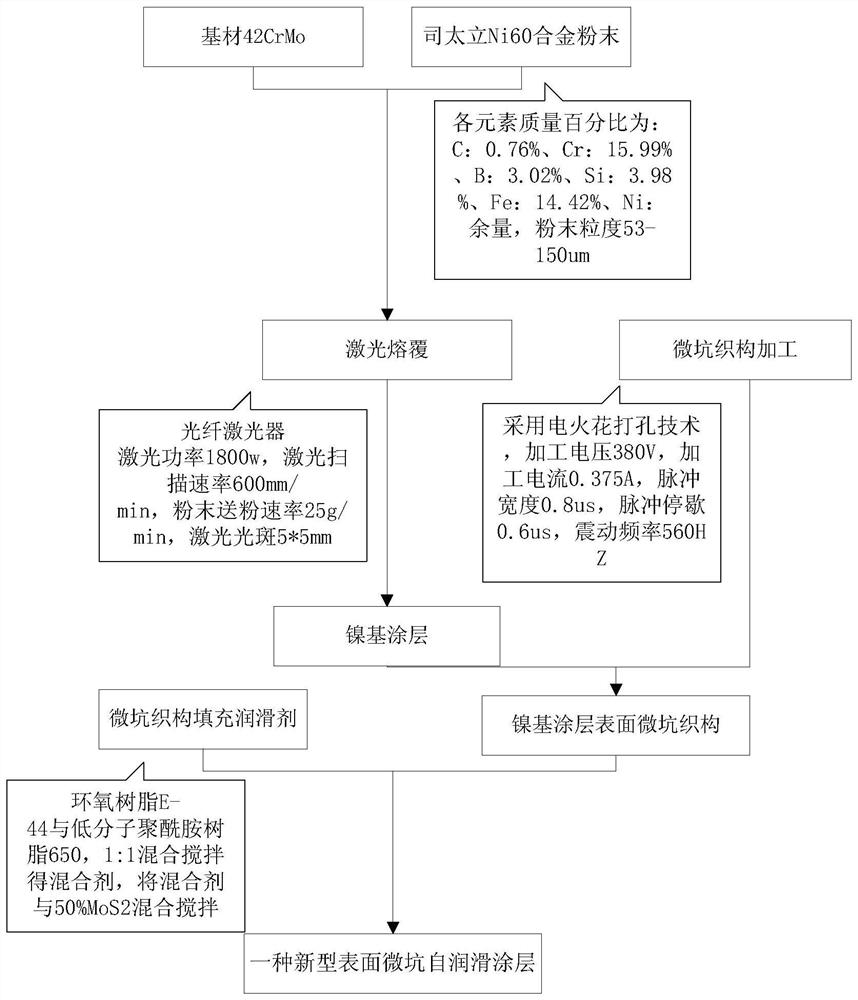

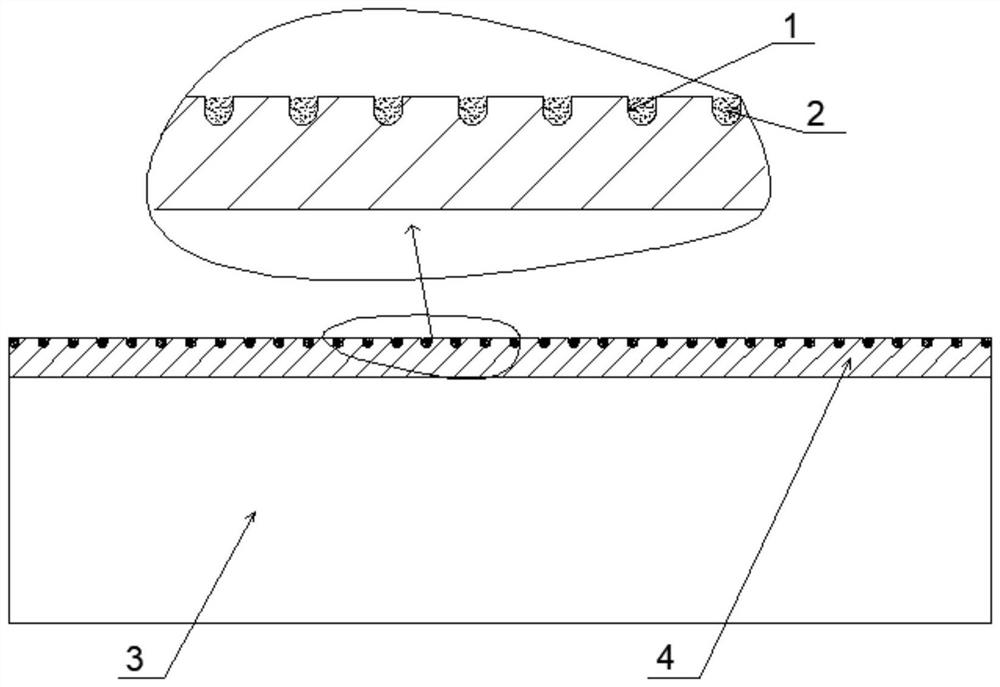

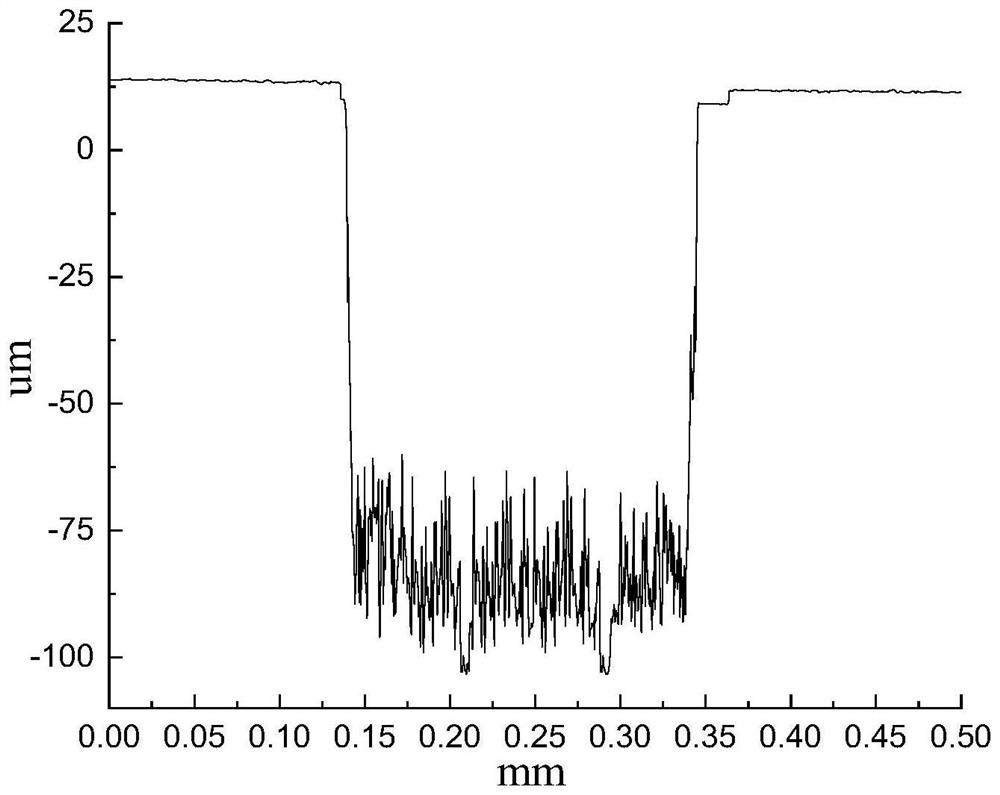

Surface micro-pit self-lubricating coating and preparation method thereof

PendingCN113445043AHigh bonding strengthIncrease structural rigidityMetallic material coating processesLubricationSurface friction

The invention discloses a surface micro-pit self-lubricating coating and a preparation method thereof. The self-lubricating coating comprises that a nickel-based coating is arranged on a base material surface in a laser cladding mode; a micro-pit texture is machined on the surface of the nickel-based coating through electric spark machining; and a solid lubricant and resin are mixed and then are filled into the micro-pit texture. According to the surface micro-pit self-lubricating coating and the preparation method thereof, three antifriction wear-resistant methods, namely the high hardness performance of the nickel-based coating, the antifriction performance of the surface micro-pit texture and the lubricating performance of the lubricant, are combined, so that the obtained coating has better acting time efficiency, the service life is also prolonged, and the coating has excellent lubricating performance, wear resistance, self-repairability and stability; and according to the structure, the surface friction resisting and antifriction performance is improved, meanwhile, surface self-lubrication is achieved, and the use requirements of parts under harsh working conditions are met.

Owner:XIAN TECHNOLOGICAL UNIV

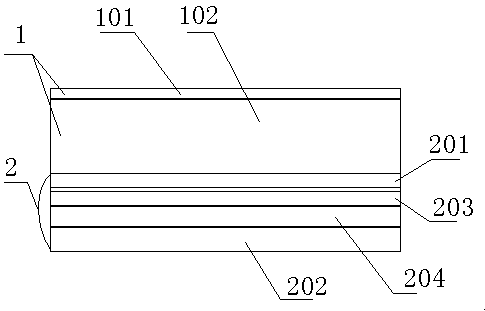

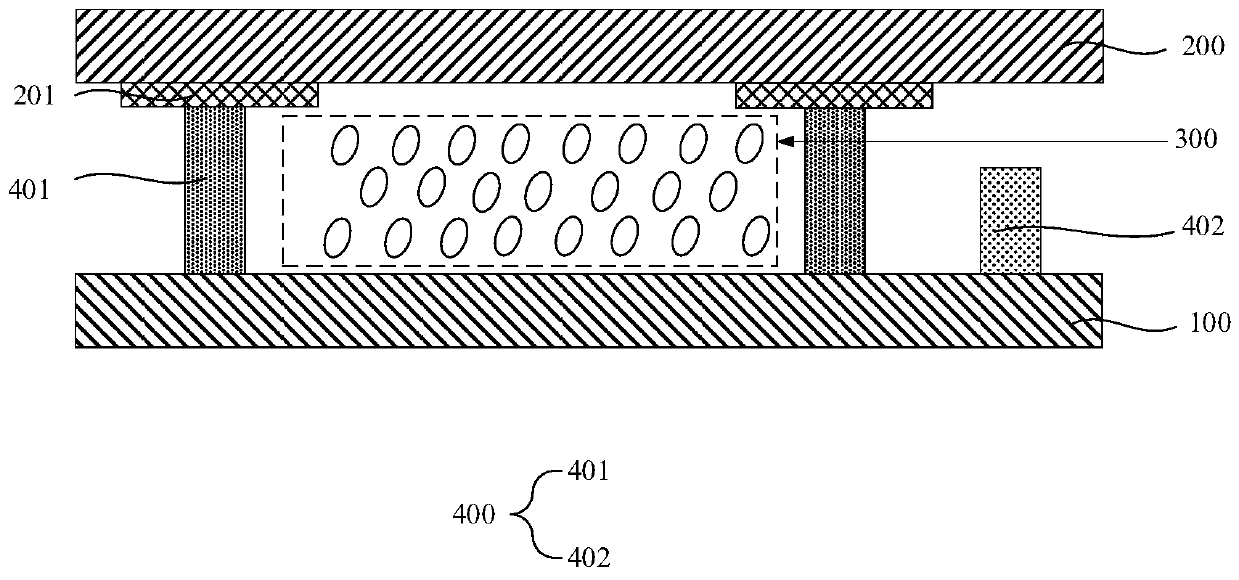

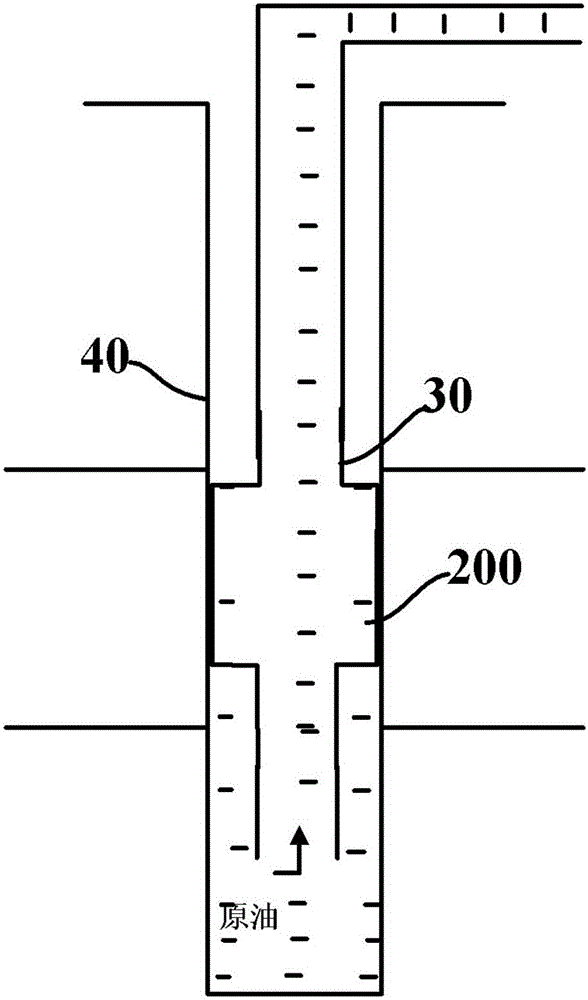

Display panel

InactiveCN111190311AGuaranteed compressionIncrease structural rigidityNon-linear opticsEngineeringMechanical engineering

The invention provides a display panel. The display panel comprises a first substrate, a second substrate and a liquid crystal layer; a black matrix is arranged on one side, facing the first substrate, of the second substrate; a spacer layer is arranged on one side, facing the second substrate, of the first substrate; the spacer layer comprises a plurality of first spacers and second spacers; wherein the first spacers and the second spacers are oppositely located below the black matrix, at least the first spacers and the black matrix are arranged in a staggered mode, and the first spacers andthe black matrix are in butt joint to support the first substrate and the second substrate. According to the display panel, the first substrate and the second substrate in the display panel are supported in the mode that the spacers and the black matrix are in butt joint, pressed displacement of the spacers can be effectively reduced, meanwhile, an alignment film is prevented from being scratched,and a dark-state spot light leakage phenomenon is prevented.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Rubber sleeve without copper sheet coating inner side face of sealing ring at lower end, packer and bridge plug

InactiveCN106014329APrevent the rubber tube from splittingAvoid failureSealing/packingChemistryAxial pressure

The invention relates to the field of sealing, in particular to a rubber sleeve which is used in the oil exploitation industry, can bear high temperature and high pressure and does not coat the inner side face of a sealing ring at the lower end with a copper sheet, a packer and a bridge plug. The outside of the sealing ring at the lower end of the rubber sleeve is coated with a first copper sheet; the upper surface, the lower surface and the outer side face of the sealing ring at the lower end are coated with the first copper sheets but the inner side face of the sealing ring at the lower end is not coated with the first copper sheet; the thicknesses of the first copper sheets are set as follows: when an upper end part bears a first axial pressure, the sealing ring at the lower end deforms in the radial direction, further the first copper sheet distributed on the inner side face of the sealing ring at the lower end is enabled to prop against a central pipe, and the first copper sheet distributed on the outer surface of the sealing ring at the lower end is enabled to prop against a casing pipe. The sealing ring at the lower end, disclosed by the invention, is coated with the first copper sheets, so that a degradation effect of micromolecules of high-temperature and high-pressure steam on the rubber sleeve is reduced or prevented, and the long-term efficacy of rubber sleeve sealing is improved.

Owner:TIANDING SEALING TECH BEIJING CO LTD

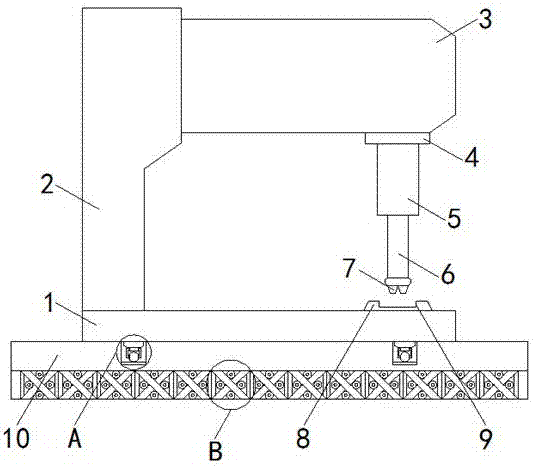

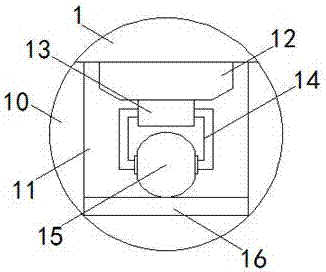

Movable type fixed seat with high structure stability for button sewing machine

InactiveCN107130369AImprove structural stabilityEasy to adjustSewing-machine elementsMovable typeEngineering

The invention relates to the technical field of button sewing machines, and discloses a movable type fixed seat with high structure stability for a button sewing machine. The movable type fixed seat comprises a base; a support arm is fixedly installed on the top of the base; a feeding box is fixedly installed at the right side of the support arm; a connecting block positioned at the right side of the support arm is fixedly installed at the bottom of the feeding box; a pneumatic outer arm is fixedly installed at the bottom of the connecting block; a pneumatic inner arm is fixedly installed at the bottom of the pneumatic outer arm; a button sewing gun is fixedly installed at the bottom of the pneumatic inner arm; a working platform positioned on the top of the base is fixedly installed under the button sewing gun. The movable type fixed seat with the high structure stability for the button sewing machine can effectively enhance the overall firmness and stability of the button sewing machine; a first inclined support rod and a second inclined support rod can effectively improve the overall structural hardness; furthermore, a whole fixed base is enabled to have a certain elasticity, so that the function of improving the structural stability is reached.

Owner:阜宁九龙输送装备有限公司

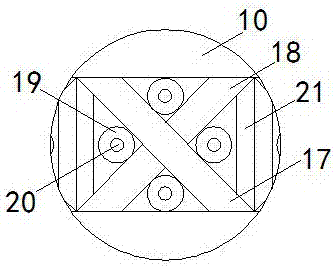

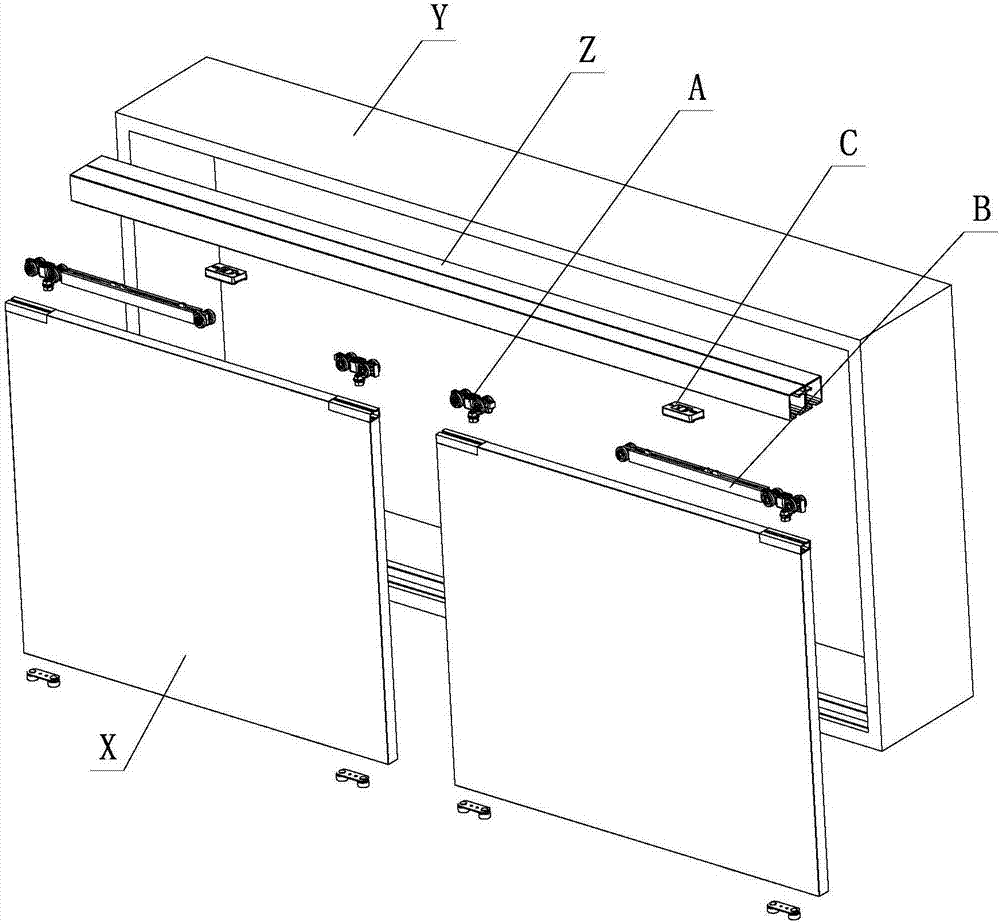

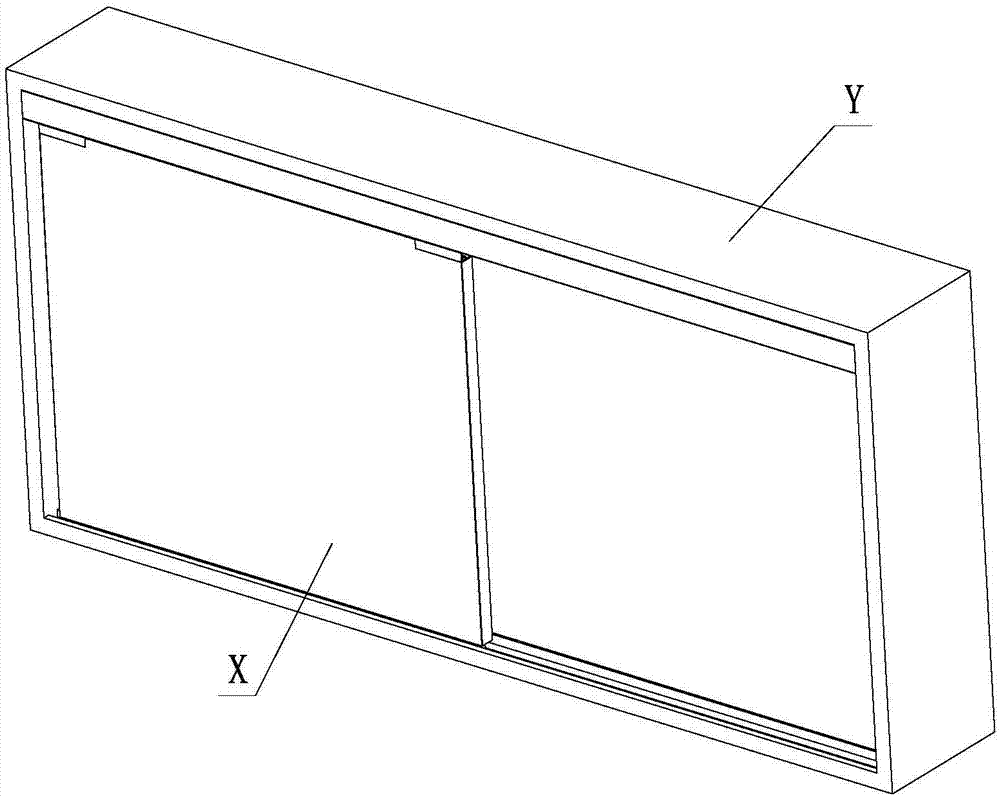

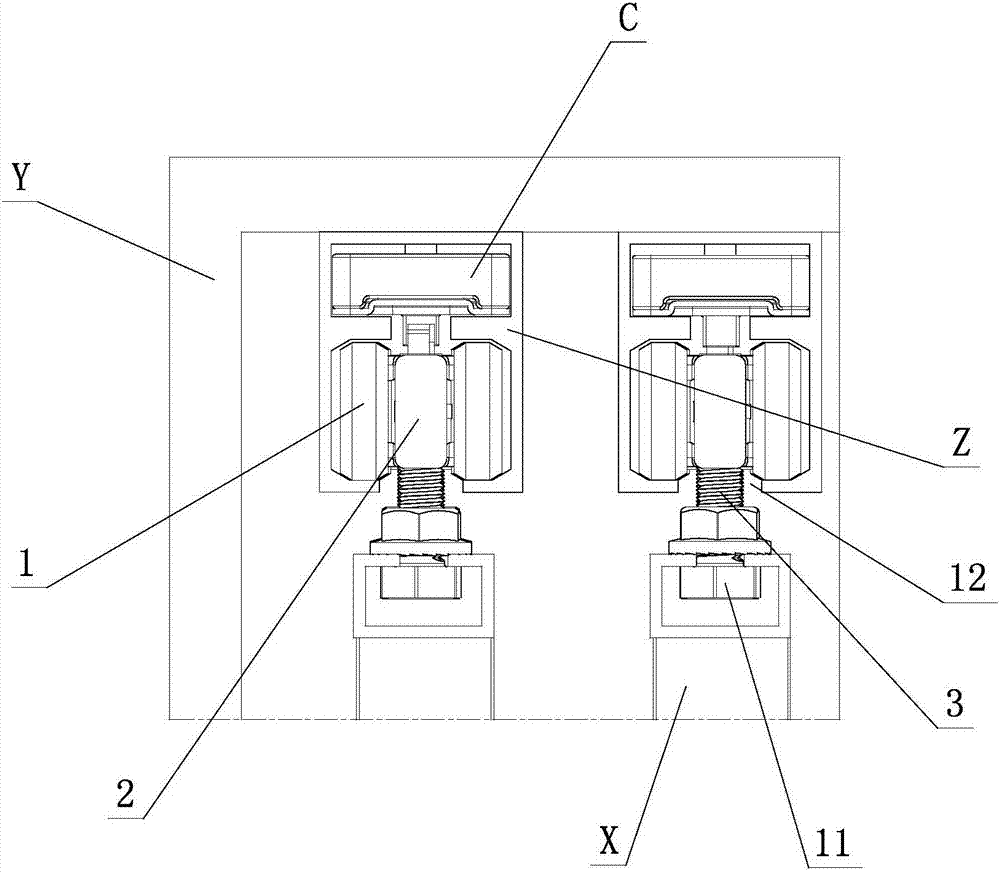

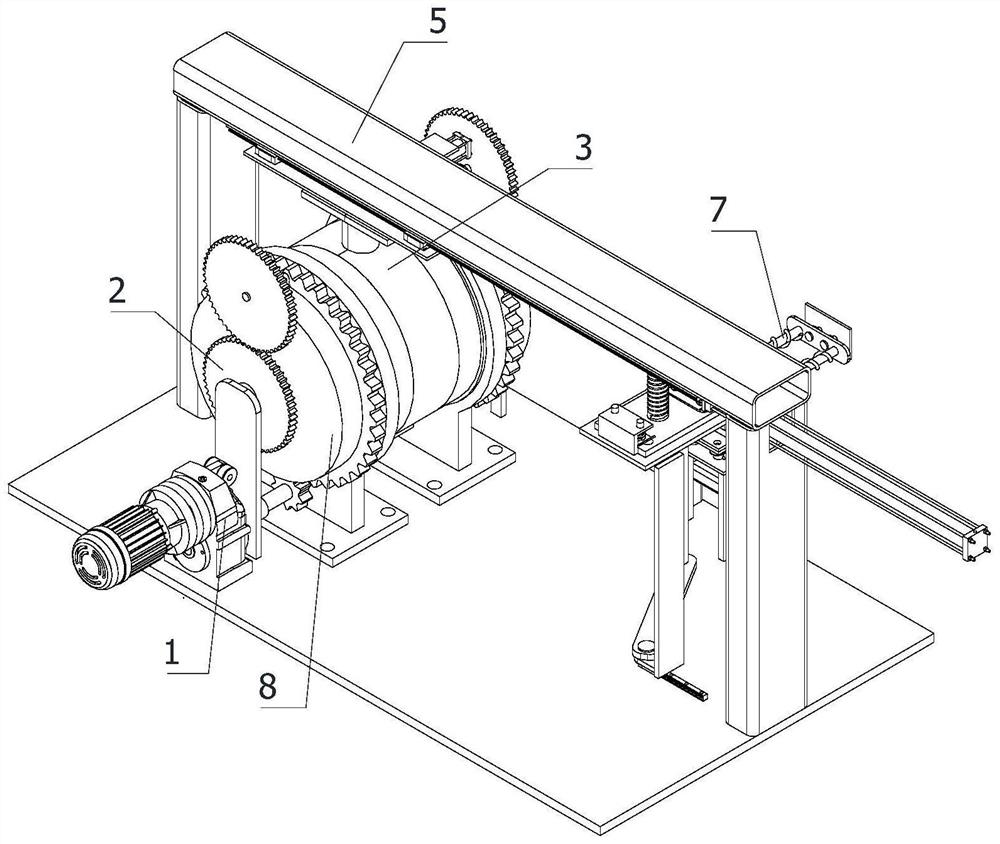

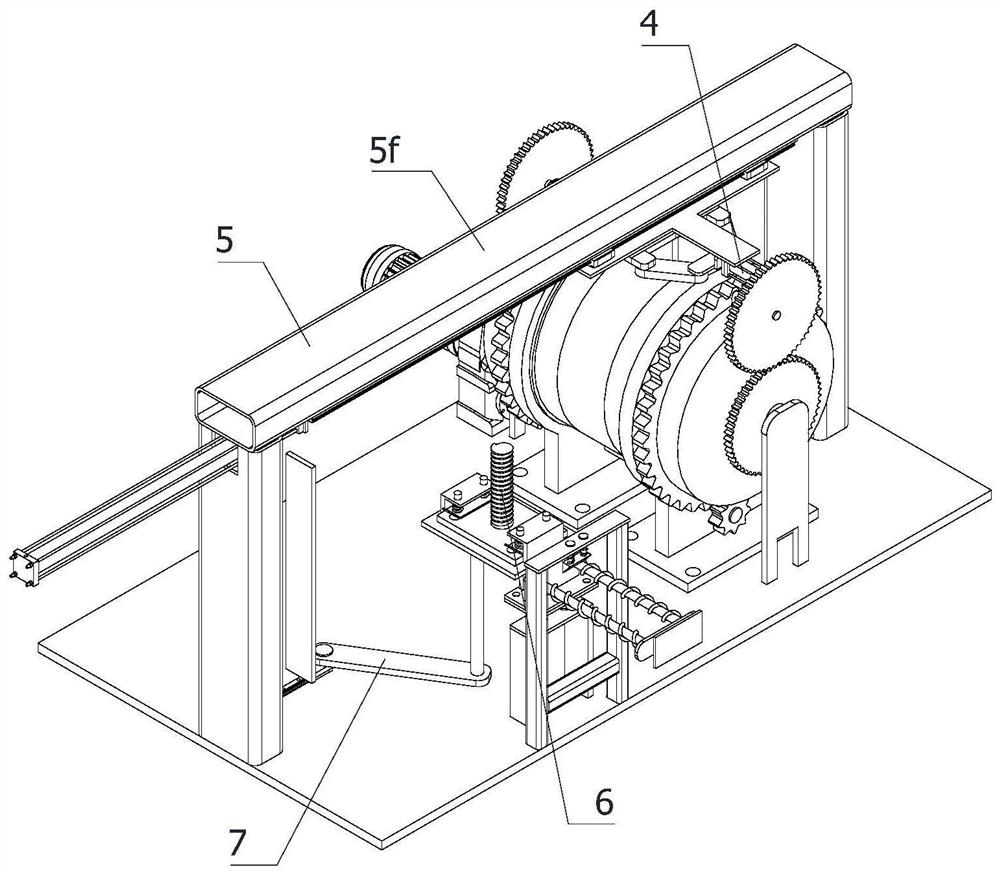

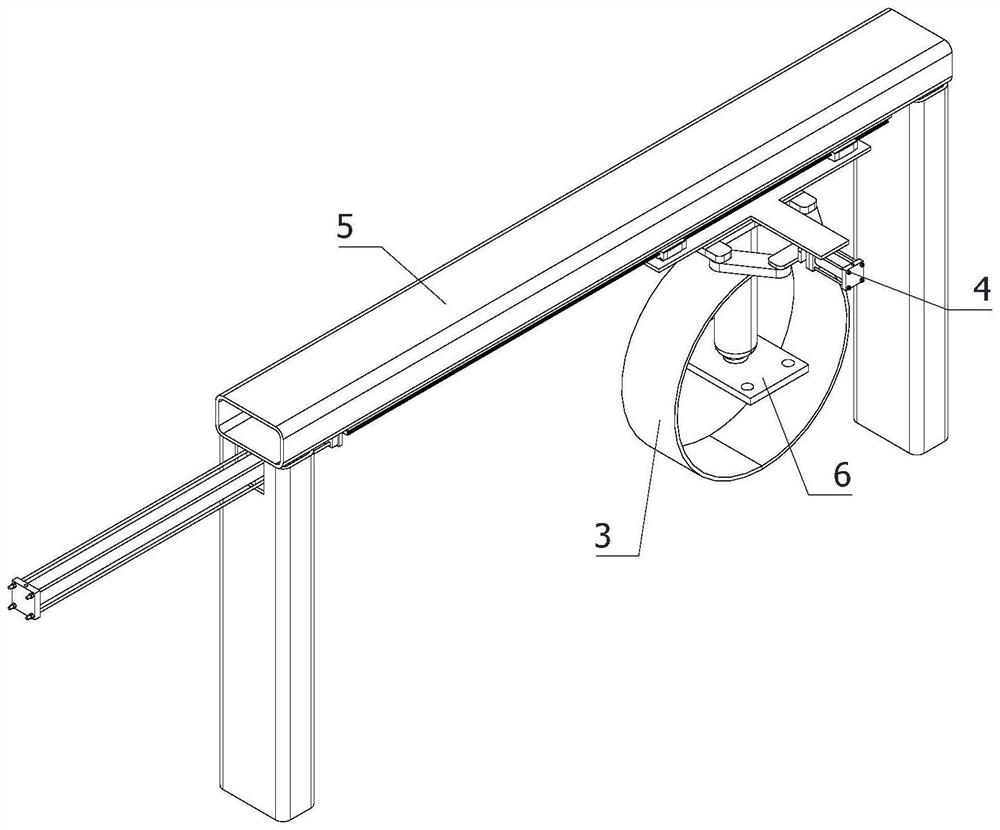

Suspension type furniture sliding door

PendingCN107975314AAvoid bouncing up and downAvoid shaking from side to sideWing suspension devicesMechanical engineeringEngineering

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

Hub and machining process capable of improving adhesive force of film of hub

InactiveCN109881050ATightly boundWheel hub performance optimizationPretreated surfacesCoatingsMicrowaveEngineering

The invention belongs to the technical field of hub machining, and particularly relates to a hub and a machining process capable of improving adhesive force of a film of the hub. The machining processcomprises the following steps that firstly, hub forming and preliminary machining are achieved; secondly, the surface of the hub is treated, the surface of the hub is subjected to chemical film forming, and the hub is subjected to standing curing; thirdly, a protection film is sprayed to the surface of the hub, then color spraying is carried out to form the film, and the film on the surface of the hub is subjected to standing curing; fourthly, the surface of the hub is subjected to finish turning, surface brightening and extrusion forming, and then high-temperature microwave washing and tankliquor cleaning are carried out; and fifthly, finally the surface of the hub is subjected to lacquer varnish spraying, then standing curing is carried out, and the finished hub is obtained.

Owner:BINZHOU DAISEN WHEEL TECH CO LTD

Rubber sleeve with lower end sealing ring wrapped with copper sheet, packer and bridge plug

ActiveCN106050184APrevent the rubber tube from splittingAvoid failureSealing/packingAxial pressureEngineering

The invention relates to the field of sealing, in particular to a rubber sleeve with a lower end sealing ring wrapped with a copper sheet, a packer and a bridge plug, wherein the rubber sleeve can bear high temperature and high pressure in the oil exploitation industry. The lower end sealing ring of the rubber sleeve is wrapped with the first copper sheet. The upper surface, the lower surface, the inner side face and the outer side face of the lower end sealing ring are wrapped with the first copper sheet. The thickness of the first copper sheet is set according to the standards that when the upper end bears the first axial pressure, the lower end sealing ring deforms in the radial direction so that the portion, distributed on the inner surface of the lower end sealing ring, of the first copper sheet can abut against a central pipe, and the portion, distributed on the outer surface of the lower end sealing ring, of the first copper sheet can abut against a casing. According to the rubber sleeve, the packer and the bridge plug, the lower end sealing ring is wrapped with the first copper sheet, the degradation function of small molecules of high-temperature and high-pressure steam to the rubber sleeve is reduced or prevented, and the long-term effect of sealing of the rubber sleeve is improved.

Owner:TIANDING SEALING TECH BEIJING CO LTD

Rubber cartridges, packers and bridge plugs with annular packings in the inner core

The invention relates to the technical field of sealing of a petroleum exploitation industry and particularly relates to a rubber barrel with annular packing in inner cores, which can bear high temperature and high pressure, and a packer and a bridge plug which are provided with the rubber barrel. A sealing body of the rubber barrel comprises the plurality of inner cores, wherein each inner core is provided with a rubber body and an annular base body; the whole bodies of the plurality of inner cores are arrayed along the axial direction of the rubber barrel; each base body is composed of a plurality of high-temperature-resisting and high-pressure-resisting fiber yarns which are mutually crossed; and the rubber bodies are stuck with the fiber yarns and the rubber bodies are distributed on the surfaces of the base bodies so that inner surfaces and outer surfaces are formed on the inner parts and the outer parts of the plurality of inner cores which are arrayed along the axial direction respectively. The base bodies have the fiber yarns which are mutually crossed, and the rubber bodies are distributed on the surfaces and the inner parts of the base bodies and are used for sticking all the fiber yarns. When the rubber barrel is subjected to axial pressure and is expanded, the fiber yarns limit the expansion, so that the structure rigidity of the rubber barrel is wholly increased and the compressive strength of the rubber barrel is improved.

Owner:TIANDING SEALING TECH BEIJING CO LTD

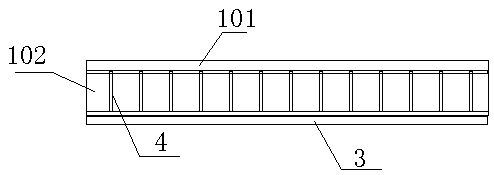

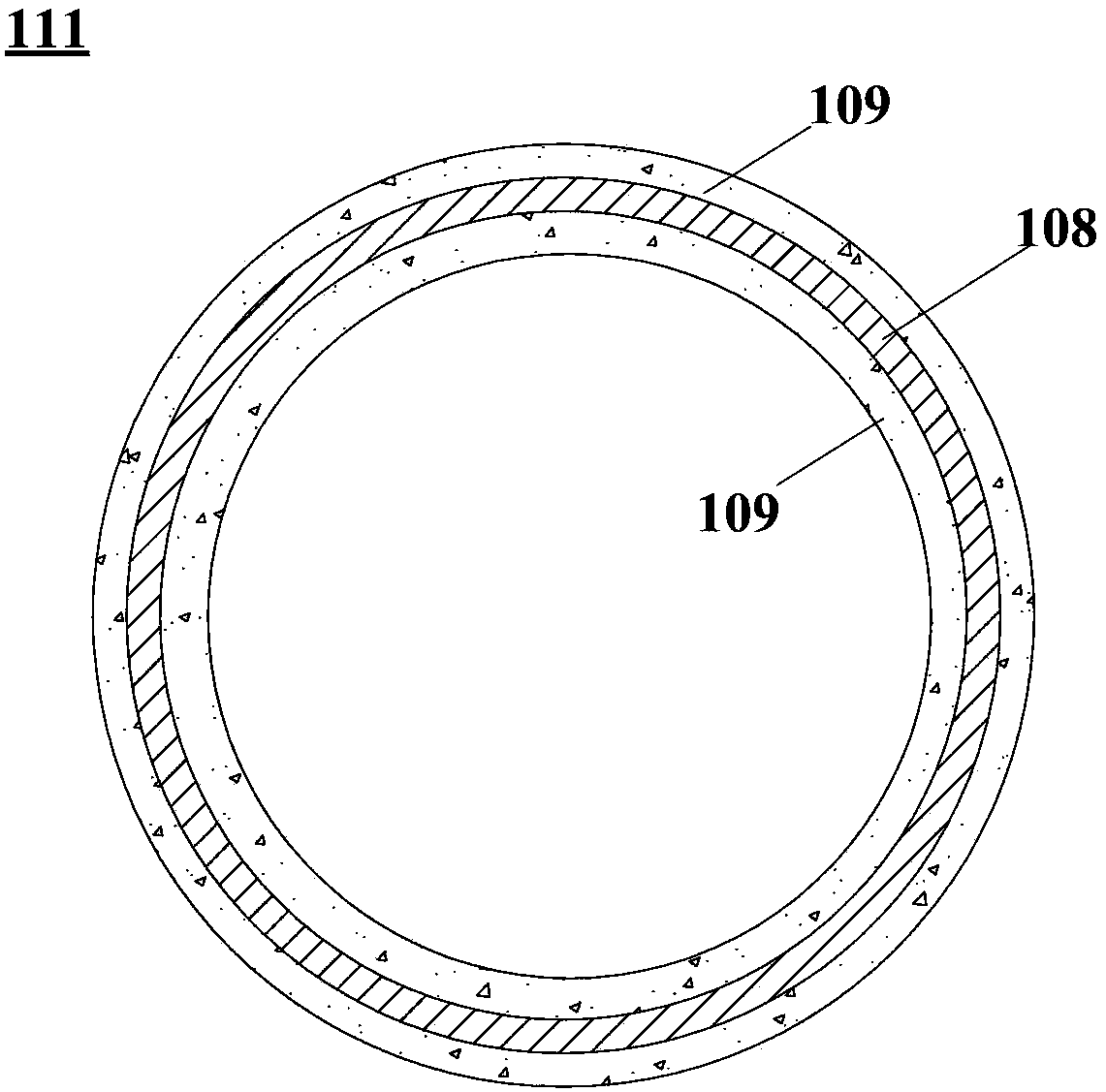

A high wear-resistant ceramic composite guide roller and its preparation method

ActiveCN106077583BExtended service lifeIncrease structural rigidityRollsMetal rolling arrangementsCeramic compositeWear resistant

The invention discloses a high wear-resistant ceramic composite guide roller and a preparation method thereof. It includes a roller core and a ceramic ring, and the ceramic rings are arranged side by side on the roller core at equal intervals, and the spacing is in the range of 1cm-5cm; the ceramic ring is fixed on the roller core through a fusion base; the inner surface of the ceramic ring is evenly distributed There is a gap. In the present invention, the guide roller adopts ceramic rings arranged side by side at equal intervals on a roller core, and the ceramic ring is fixed on the roller core through a fusion base; the peripheral side of the ceramic ring is used as a working surface, and the fusion base is used as a composite base material. The ceramic ring is made of titanium carbide ceramics or titanium silicon carbide or alumina ceramics or zirconium carbide ceramics, which has high structural hardness and strong wear resistance, which improves the service life of the guide roller.

Owner:安徽东方新材料有限公司

Cartridges, Packers and Bridge Plugs Including Wire Seal Rings

The invention relates to the field of sealing, in particularly to a rubber sleeve which can bear high temperature and high pressure and comprises a metal wire sealing ring, a packer and a bridge plug used in the oil exploitation industry. The rubber sleeve comprises the metal wire sealing ring and a fiber wire sealing ring, wherein the metal wire sealing ring and the fiber wire sealing ring abut against each other and are arranged on the lower portion. The metal wire sealing ring comprises a plurality of mutually intersecting metal wires and glue bonding the metal wires together. The fiber wire sealing ring comprises a plurality of fiber wires which mutually intersect and resist high temperature and high pressure and glue bonding the fiber wires together. When the metal wire sealing ring is arranged below the fiber wire sealing ring, axial pressure transmitted to the fiber wire sealing ring can be reduced due to the friction between the metal wire sealing ring and a central pipe and / or a sleeve pipe, and at the time axial pressure on the fiber wire sealing ring can be effectively reduced. The reason for generation of shoulder protrusion is too large axial pressure, so that generation of shoulder protrusion can be reduced or prevented through the design.

Owner:TIANDING SEALING TECH BEIJING CO LTD

High-wear-resistance aluminum alloy material treatment process

The invention discloses a high-wear-resistance aluminum alloy material treatment process which comprises the following operation steps that a pure aluminum block is added into a boiler for melting, and subjected to impurity removing and deoxidizing; an aluminum alloy material is put into a refining furnace for refining; alloy is added for modulation treatment, and an aluminum alloy melt X is obtained; the aluminum alloy melt X is subjected to argon shield die casting at the temperature of 600 DEG C, and finally subjected to air cooling to the room temperature; and the aluminum alloy melt X iscast through a semi-continuous casting method, water cooling is conducted after casting, and an aluminum alloy casting body Y is obtained. Through the heat treatment process, the cracking risk of thecasting can be greatly reduced on the premise that the mechanical property of the aluminum alloy casting is improved, and the quenching quality of parts is improved, so that the structural hardness ofthe aluminum alloy material can be greatly improved, and the wear resistance of the material is further improved. According to the high-wear-resistance aluminum alloy material treatment process, an aluminum alloy cylinder body is subjected to surface treatment through electrochemistry, and the surface hardness of the aluminum alloy after surface treatment is high.

Owner:江苏信轮美合金发展有限公司

Manufacturing method for densifying local structure of forged ball head and ball head produced by the method

ActiveCN107649640BIncrease structural rigidityLoud and melodiousGolf clubsHeating/cooling devicesEngineeringGolf Ball

The invention relates to the field of golf clubs, in particular to a manufacturing method for forging a ball head to achieve local structure compaction and the ball head produced through the method, the manufacturing method comprises the following steps of preparation; first performing; second performing; finish forging reshaping; local compaction; and finished product reshaping. According to themanufacturing method and the ball head, through the steps, the forged ball head achieves the effect of metallographic crystallization compaction in a sweet zone of a hitting face, the ball hitting structural strength of the sweet zone of the forged ball head is further improved, the hitting sound is improved, and the better ball hitting experience is achieved for users.

Owner:四川宇钛体育用品有限公司

Rubber cylinder with lower sealing ring coated with upper and lower copper skins, packer and bridge plug

The invention relates to the field of sealing, in particular to a rubber cylinder with a lower sealing ring coated with upper and lower copper skins, a packer and a bridge plug at high temperature and high pressure in petroleum production industry. A first copper skin is coated at the exterior of the lower sealing ring of the rubber cylinder, and consists of an upper copper skin and a lower copper skin; the upper copper skin is coated on the upper surface, outside surface and inside surface of the lower sealing ring; the lower copper skin is coated on the lower surface, inside surface and outside surface of the lower sealing ring; the upper copper skin and the lower copper skin are overlapped on the inside surface and outside surface of the lower sealing ring. The rubber cylinder has the advantage that the lower sealing ring is coated by the first copper skin, so that the degrading function of high-temperature and high-pressure steam small molecules on the rubber cylinder is reduced or prevented, and the sealing validity of the rubber cylinder is improved.

Owner:TIANDING SEALING TECH BEIJING CO LTD

Rubber cartridge, packer and bridge plug covered with two pieces of copper skin on the lower sealing ring

The invention relates to the field of sealing, in particular to a packer element with a lower end sealing ring wrapped by two copper sheets, a packer and a bridge plug which are used in the oil production industry and can bearing high temperature and high pressure. The packer element adopts the structure that a first copper sheet wraps the upper surface, the lower surface, the inner side surface and the outer side surface of the lower end sealing ring, and consists of an inner copper sheet and an outer copper sheet; the inner copper sheet wraps the upper surface, the lower surface and the inner side surface of the lower end sealing ring; the outer copper sheet wraps the upper surface, the lower surface and the outer side surface of the lower end sealing ring; the inner copper sheet and the outer copper sheet overlap on the upper surface and the lower surface of the lower end sealing ring. As the lower end sealing ring is wrapped by the first copper sheets, the degradation effect of micromolecules in high-temperature high-pressure steam on the packer element can be reduced or avoided, and the long-acting sealing effect of the packer element is improved.

Owner:TIANDING SEALING TECH BEIJING CO LTD

An automatic painting device for foundation support

The invention relates to the field of painting, in particular to an automatic painting device for foundation supports, which includes a rotary drive mechanism, a stud clamping mechanism, an opening and closing control mechanism, a linear movement mechanism, support material conveying equipment, and two spray angle adjustment mechanisms 1. The rotating mounting base and the painting mechanism. The automatic painting device of the foot support drives the spray head to move through the spray angle adjustment mechanism, which will make the spray head drive the rotating plate to swing on the second fixed plate, and spray paint in this swinging way. , which in turn can reduce the space in the sealed circular plate, so that the flow range of the spray paint is reduced, the time for the paint surface to adhere to the inner wall of the rotating ring is faster, the diffusion range of the paint smell is reduced, and the health hazards to the workers are reduced. Through the angle swing, Carry out rotary painting on the bottom plate, so that the thickness of the paint on the edge of the bottom plate is obviously greater than the thickness of the paint on the inner edge of the nozzle. Due to the thicker edge, the structural hardness of the paint surface will be increased, the paint will be reduced, and the paint in the middle will be reduced. quantity.

Owner:芜湖艾蔓设备工程有限公司

Rubber cartridges, packers and bridge plugs covered with open copper skin on the lower sealing ring

Owner:TIANDING SEALING TECH BEIJING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com