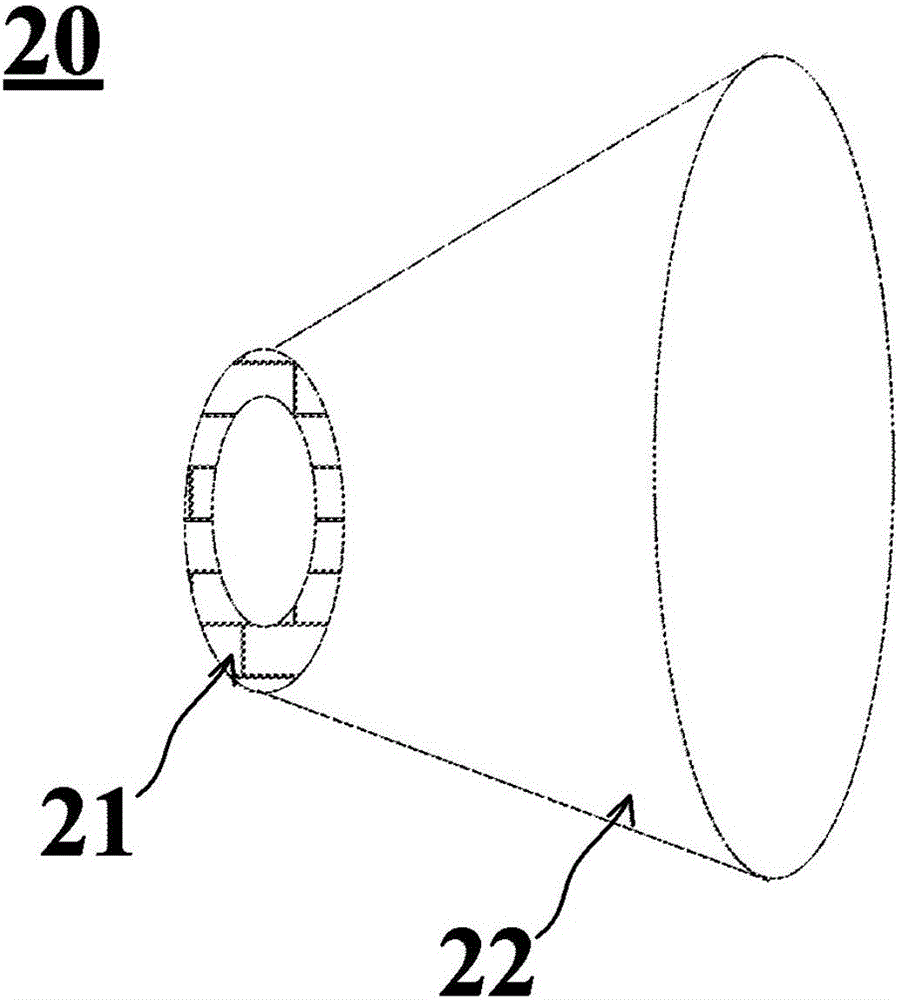

Rubber cylinder with spiral inner cores

A technology of helical and rubber cylinders, applied in the field of rubber cylinders with a helical inner core, can solve problems such as crushing, rubber cylinder failure, rubber cylinder crushing, etc., and achieve the effect of reducing production costs and improving use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

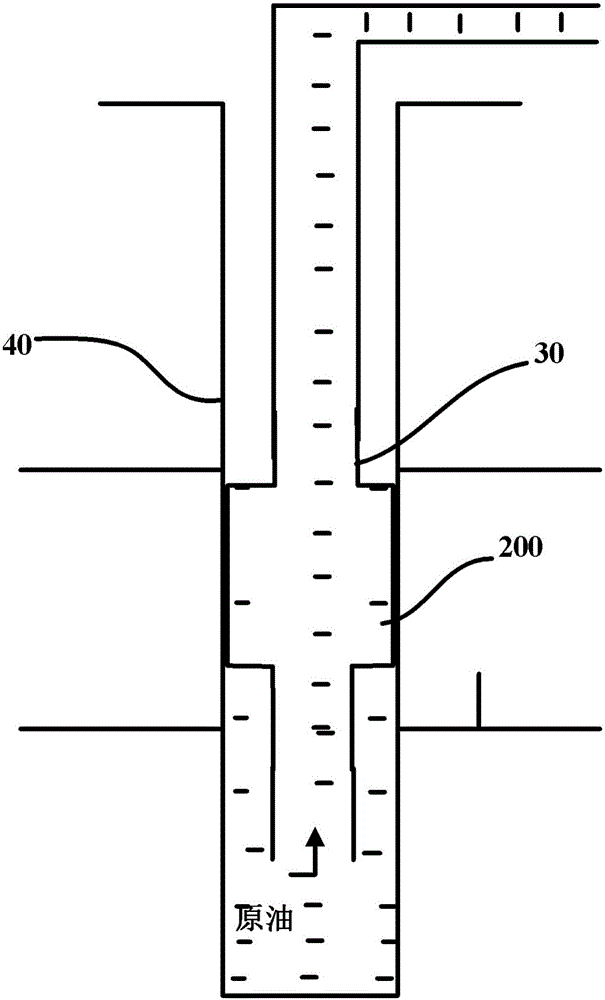

[0039] Packer is a key tool for downhole oil production in oilfields. It is widely used in various operations such as oilfield injection, layered reconstruction, layered oil production, mechanical pipeline water plugging, etc. The packer needs to be used for annular isolation. The core component to realize annular space isolation is the rubber cartridge. As the core component of the packer, the quality of the rubber cartridge directly affects the use effect and service life of the packer, and plays a decisive role in the packer. The inventors found that due to the difference in softness and hardness of the colloids constituting the rubber cartridge, for example, when polyether ether ketone is used as the colloid, since the polyether ether ketone is relatively hard, the pressure to achieve the setting is relatively high. When using softer colloids to make rubber cartridges, the rubber cartridges will be crushed because they cannot withstand the rated axial pressure.

[0040] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com