Rubber cartridges, packers and bridge plugs covered with open copper skin on the lower sealing ring

A sealing ring and rubber barrel technology, which is applied in the directions of sealing/isolation, wellbore/well components, and earth-moving drilling, etc. The effect of increasing the compressive strength range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

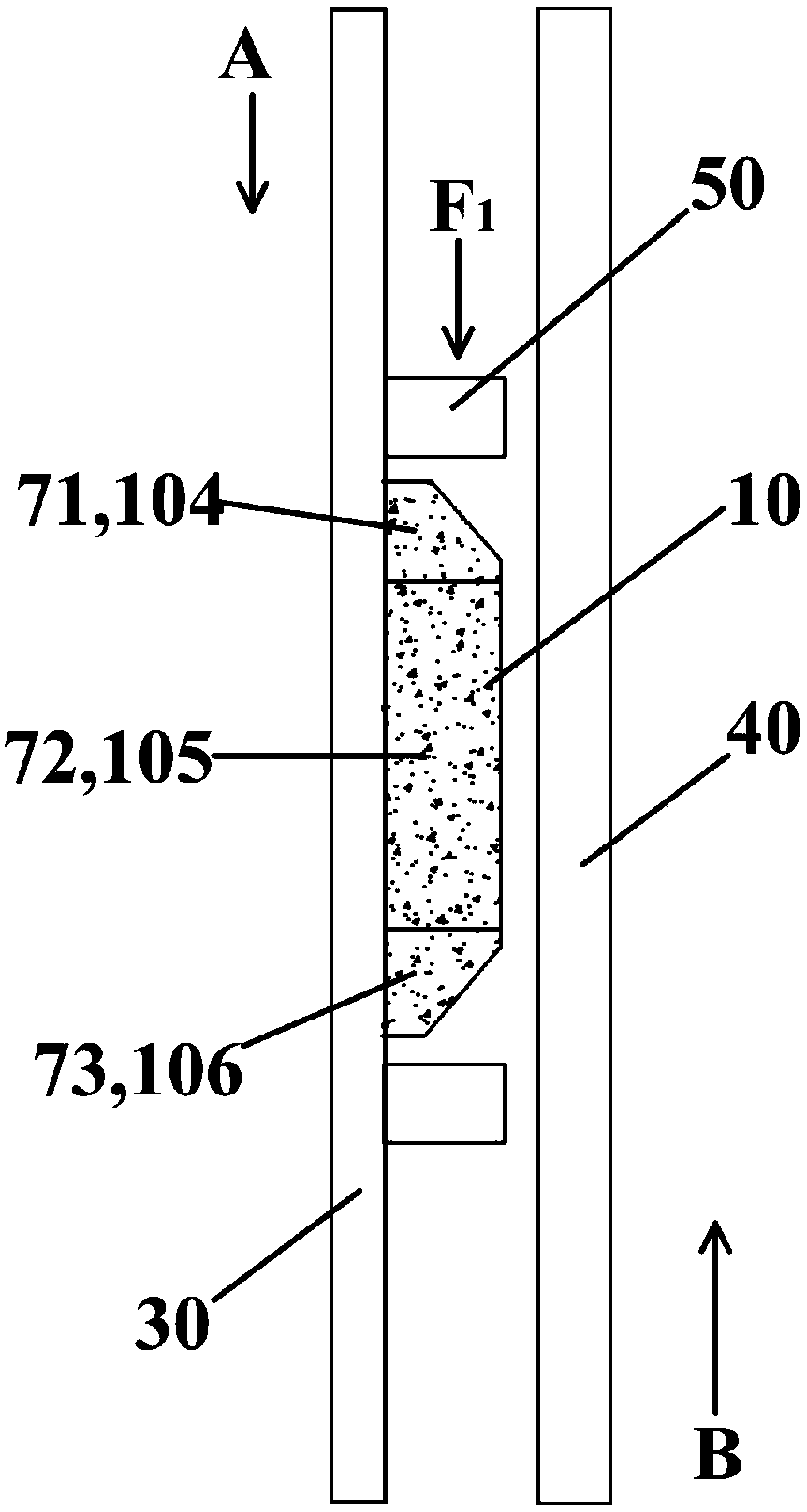

[0063] The directions "up" and "down" mentioned below are figure 2 Narrated as a reference.

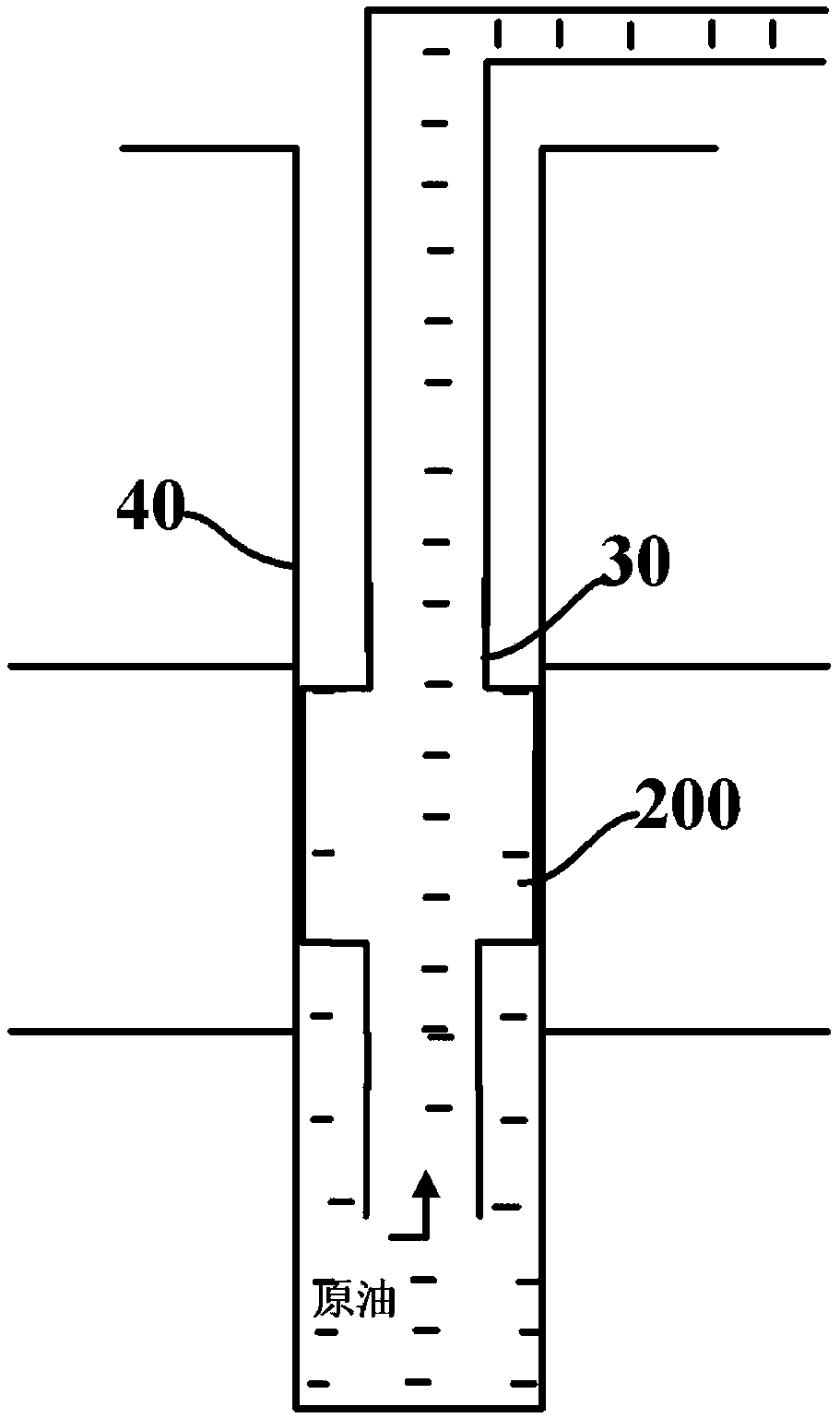

[0064] Such as figure 1 The illustrated compression packer 200 has the glue cartridge 10 of the present application. The compression packer 200 is connected to the central pipe 30 and placed in the casing 40. The compression packer 200 needs to separate different oil and water layers in the wellbore and withstand a certain pressure difference. It is required to be able to go down to a predetermined position in the wellbore, be tightly sealed, and be durable downhole. Get out smoothly.

[0065] Such as figure 2 As shown, the rubber cylinder 10 is located in the annular gap formed by the sleeve 40 and the central tube 30, and the rigid spacer ring 50 provides a first axial pressure F in the axial direction from top to bottom (ie, the first axial direction A) 1 In other embodiments, the rigid spacer 50 can be removed and the first axial pressure F can be applied to the rubber cylinder 10 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com