Device and method for eliminating displacement gap of rotating drum vacuum valve element

A vacuum valve and clearance technology, applied in valve devices, engine components, mechanical equipment, etc., can solve the problems of increased valve core weight, valve channel leakage, screw loosening, etc., to avoid leakage problems and eliminate the effect of playing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

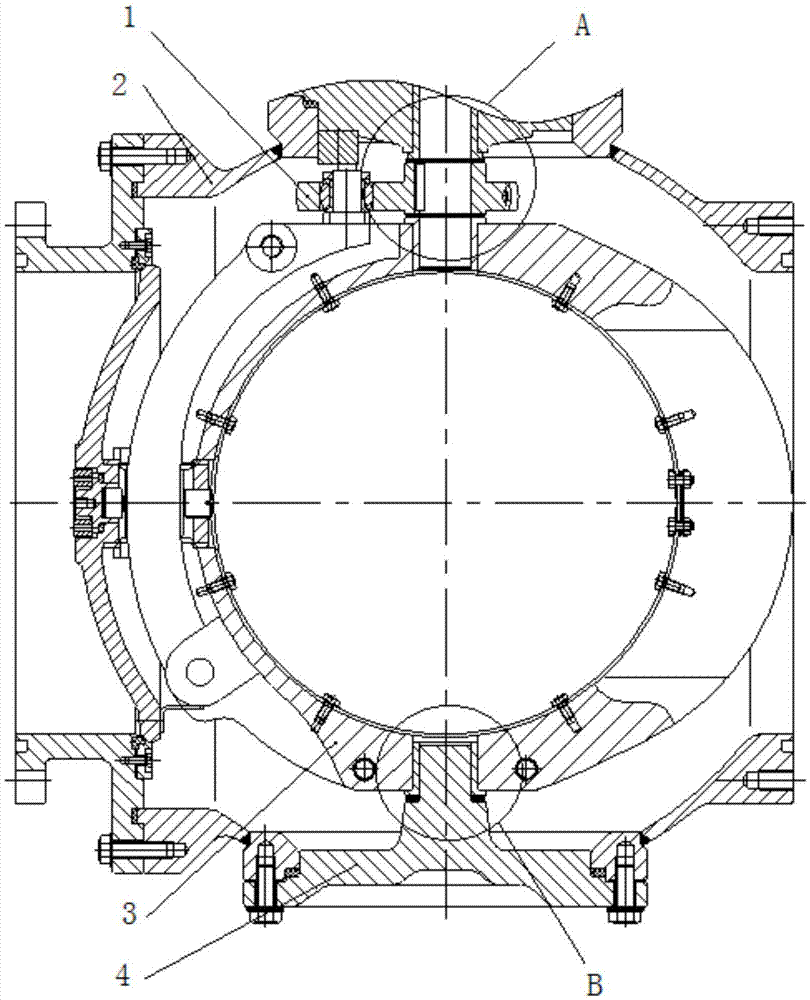

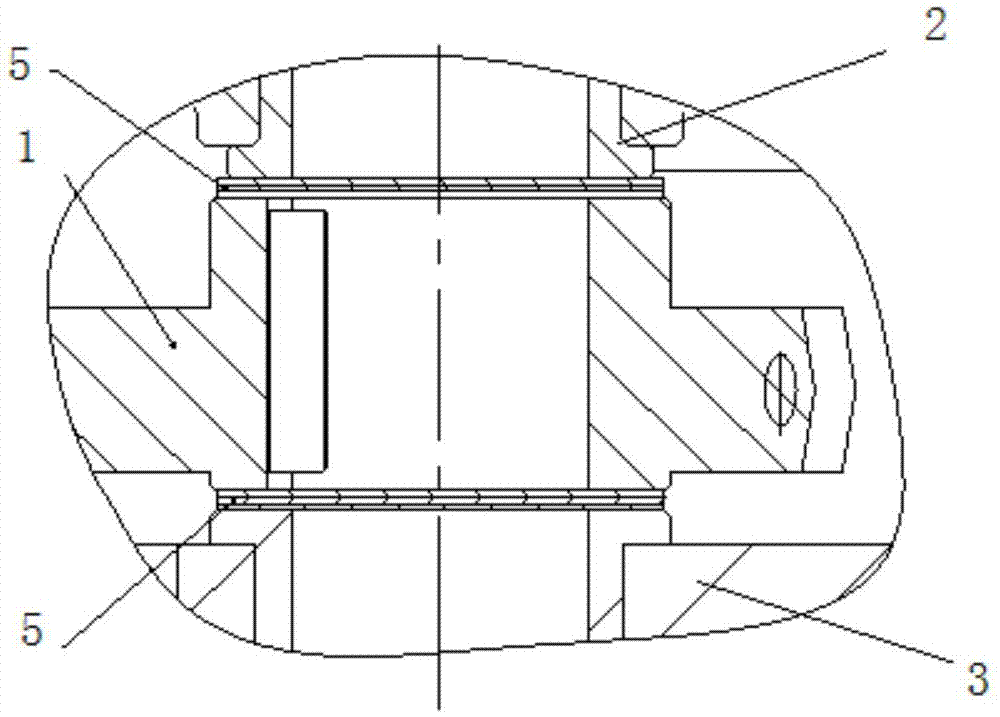

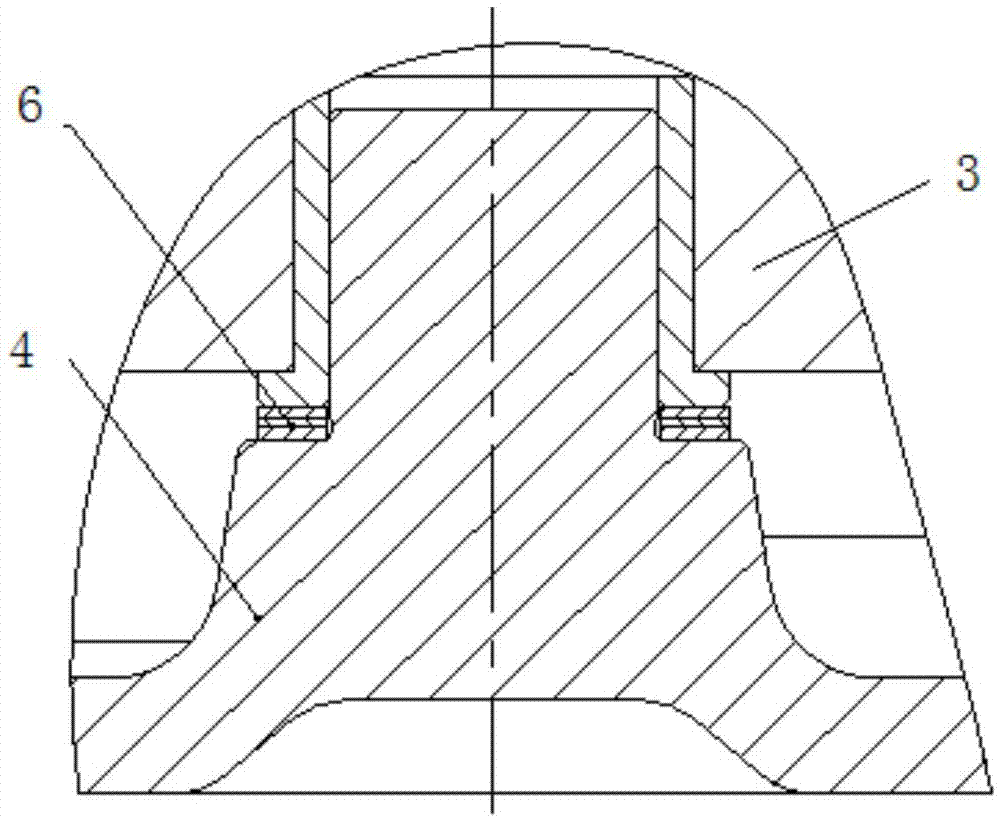

[0017] Such as Figure 1~3 As shown, a device for eliminating the movement clearance of the drum vacuum valve spool includes a gasket A5 installed on the upper and lower surfaces of the cam 1 and a gasket B6 installed between the valve seat 4 and the valve core assembly 3, wherein the cam 1 Installed between the upper end of the valve core assembly 3 and the valve body 2, between the upper surface of the cam 1 and the contact surface of the valve body 2, and between the lower surface of the cam 1 and the upper end contact surface of the valve core assembly with the same diameter and different thickness Stainless steel gasket A5, so that there is an appropriate gap between the cam 1 and the valve body 4 and the valve core assembly 3, so as to meet the rotation requirements; between the contact surface of the valve seat 4 and the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com