Conformal load-bearing antenna structure for realization of array surface heat radiation by employing FSS and micro heat pipe

A micro-heat pipe and array technology, which is applied to antennas, antenna components, antenna grounding switch structural connections, etc., can solve the problems that the temperature changes of the wave-transparent cover and the filled core layer are greatly affected, and it is difficult to meet the antenna design requirements. Achieve the effect of improving structural and thermal functional properties and increasing structural rigidity

Active Publication Date: 2018-03-23

XIDIAN UNIV

View PDF6 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Phased array antenna front The dielectric skin and filling core layer of the traditional cover are integrated structure. In the phased array antenna front project, the antenna has strict temperature difference requirements (for example, the Ka frequency band requir

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

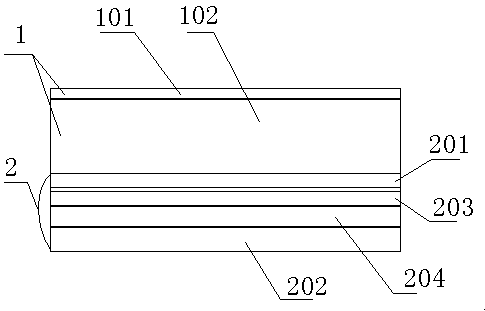

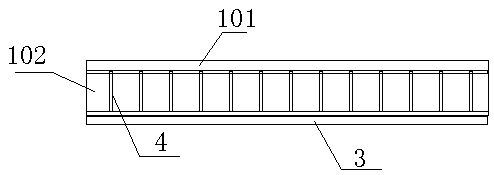

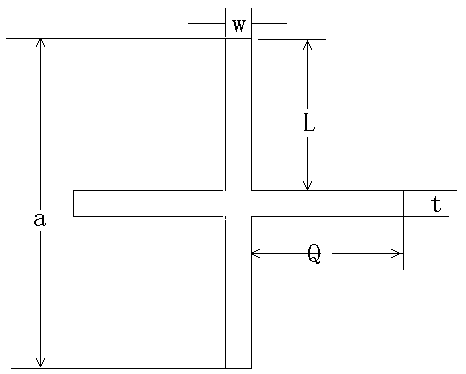

The present invention relates to a conformal load-bearing antenna structure for realization of array surface heat radiation by employing an FSS and a micro heat pipe. The conformal load-bearing antenna structure at least comprises: a wave-transparent cover body unit configured to bear an external load to protect an internal antenna; and an antenna unit. The wave-transparent cover body unit and theantenna unit are subjected to hot-pressing bonding by employing heat conduction materials to form a conformal load-bearing antenna structure. A heat radiation structure formed by the micro heat pipeand the frequency selective surface (FSS) is employed to form a cover body portion, the micro heat pipe is configured to transfer heat of the antenna array surface to the skinned FSS, so that the conformal load-bearing antenna structure can effectively increase the structure rigidity and intensity while employing external high-speed air flow to achieve heat radiation, facilitates improving of theCLAS structure and the heat function characteristic, and has a frequency selection wave-transparent characteristic.

Description

technical field [0001] The invention relates to a conformal load-carrying antenna, in particular to a conformal load-carrying antenna which utilizes FSS and miniature heat pipes to realize front heat dissipation. Background technique [0002] Conformal Load-bearing Antenna Structure (CLAS) is an antenna structure that has both the electromagnetic function of the antenna and the structural load-bearing function. It can be highly integrated with the shape of the carrier and has great application prospects. [0003] Phased array antenna front The dielectric skin and filling core layer of the traditional cover are integrated structure. In the phased array antenna front project, the antenna has strict temperature difference requirements (for example, the Ka frequency band requires the front temperature difference to be ≤3°C, X The front temperature difference in the frequency band is ≤7℃), the wave-transparent cover and the filling core layer are greatly affected by temperature c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01Q1/02H01Q1/42H01Q1/50

CPCH01Q1/02H01Q1/422H01Q1/50

Inventor 李鹏许万业宋立伟龚俊源陈磊黄进王从思李娜

Owner XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com