Production process of composite cored EPS foam plastic panel

A production process and foam plastic board technology, applied in the direction of synthetic resin layered products, layered products, lamination, etc., can solve the problems of low structural strength, easy dust collection, etc., to improve the appearance, prolong the service life, resist the good thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

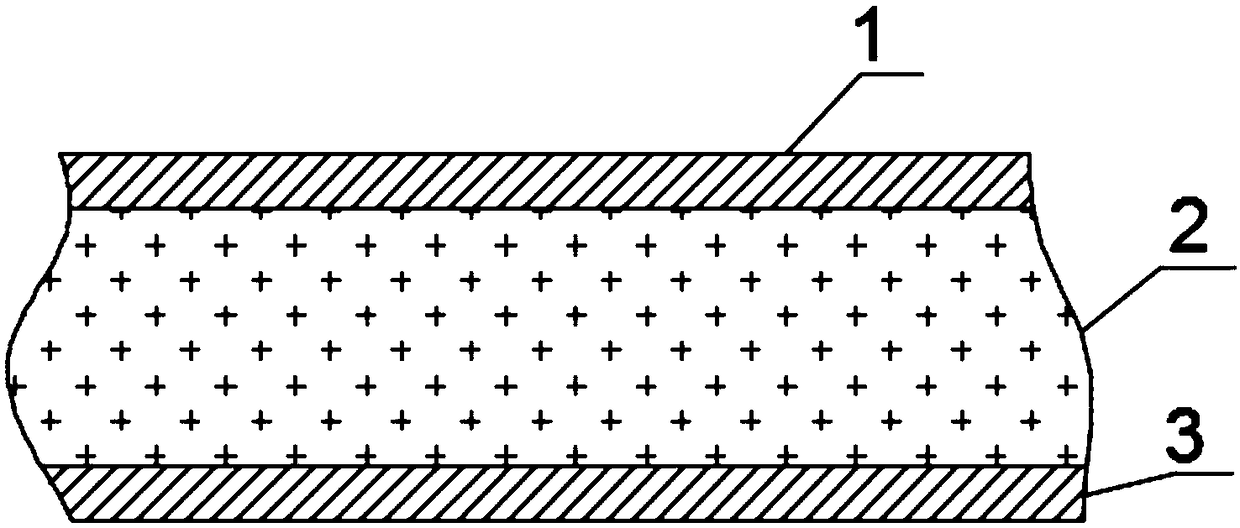

[0029] A production process for a composite cored EPS foamed plastic plate, the composite cored EPS foamed plastic plate comprises an upper epoxy resin plate 1, the bottom of the upper epoxy resin plate 1 is provided with an EPS foamed plastic plate 2, and the EPS foamed plastic plate The bottom of the plastic plate 2 is provided with a lower epoxy resin plate 3;

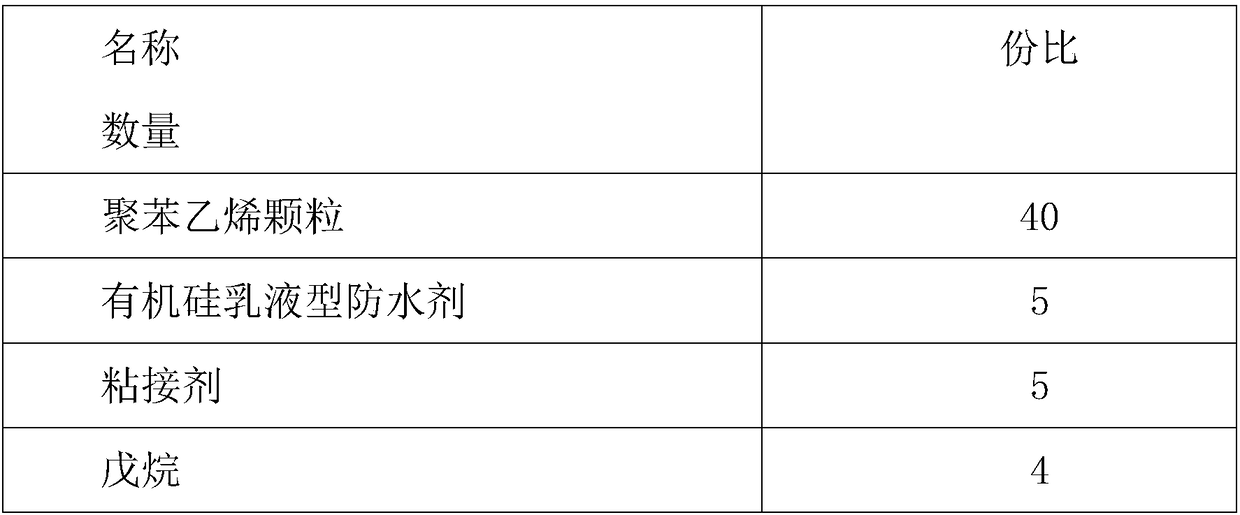

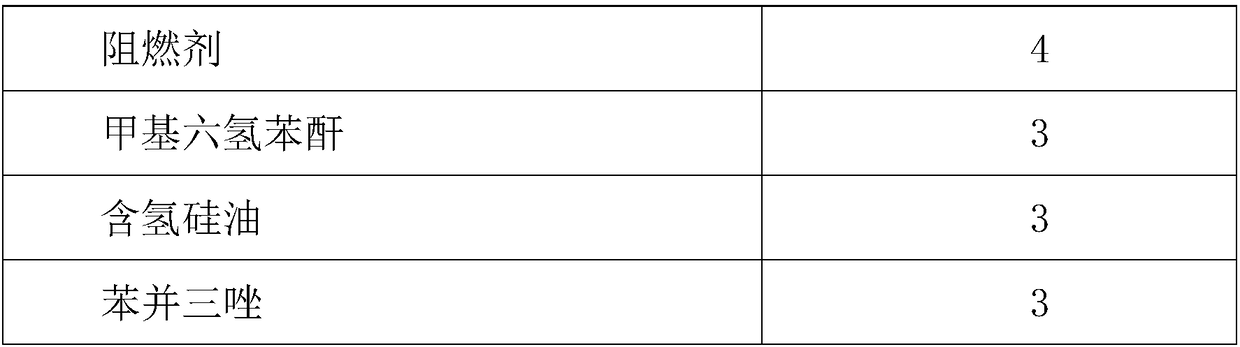

[0030] The raw materials used in the EPS foam plastic plate 2 and the mass percentages are: 40 parts of polystyrene particles, 5 parts of silicone emulsion type waterproofing agent, 5 parts of adhesive, 4 parts of pentane, 4 parts of flame retardant 3 parts, 3 parts of methyl hexahydrophthalic anhydride, 3 parts of hydrogen-containing silicone oil and 3 parts of benzotriazole. The specific production process is as follows:

[0031] Step 1: Mix 40 parts of polystyrene particles, 5 parts of silicone emulsion waterproofing agent, 5 parts of adhesive, 4 parts of pentane and 4 parts of flame retardant with water and pour...

Embodiment 2

[0040] A production process for a composite cored EPS foamed plastic plate, the composite cored EPS foamed plastic plate comprises an upper epoxy resin plate 1, the bottom of the upper epoxy resin plate 1 is provided with an EPS foamed plastic plate 2, and the EPS foamed plastic plate The bottom of the plastic plate 2 is provided with a lower epoxy resin plate 3;

[0041] The raw materials used in the EPS foam plastic plate 2 and their mass percentages are: 50 parts of polystyrene particles, 10 parts of silicone emulsion type waterproofing agent, 10 parts of adhesive, 8 parts of pentane, and 8 parts of flame retardant 5 parts, 5 parts of methyl hexahydrophthalic anhydride, 5 parts of hydrogen-containing silicone oil and 5 parts of benzotriazole, the specific production process is as follows:

[0042] Step 1: Mix 50 parts of polystyrene particles, 10 parts of silicone emulsion waterproofing agent, 10 parts of adhesive, 8 parts of pentane and 8 parts of flame retardant with wate...

Embodiment 3

[0050] The composite cored EPS foam plastic plate includes an upper epoxy resin plate 1, the bottom of the upper epoxy resin plate 1 is provided with an EPS foam plastic plate 2, and the bottom of the EPS foam plastic plate 2 is provided with a lower epoxy resin plate 3;

[0051] The raw materials used for the second material of the EPS foam plastic board and the mass percentage are: 45 parts of polystyrene particles, 8 parts of silicone emulsion type waterproofing agent, 8 parts of adhesive, 6 parts of pentane, and 6 parts of flame retardant 4 parts, 4 parts of methyl hexahydrophthalic anhydride, 4 parts of hydrogen-containing silicone oil and 4 parts of benzotriazole. The specific production process is as follows:

[0052] Step 1: Mix 45 parts of polystyrene particles, 8 parts of silicone emulsion waterproofing agent, 8 parts of adhesive, 6 parts of pentane and 6 parts of flame retardant with water and pour them into a mixer for stirring at a stirring speed of 55 rpm, the stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com