Manufacturing method for forging ball head to achieve local structure compaction and ball head produced through method

A technology of local structure and manufacturing method, which is applied in the manufacture of tools, rackets, golf balls, etc., can solve the problems of monotonous hitting sound and mediocre ball head strength, and achieve the effects of pleasant and loud sound, improved hardness, and increased structural hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to be able to understand the technical features and practical effects of the present invention in detail, and to implement them according to the contents of the specification, the preferred embodiment shown in the drawings will be described in detail as follows:

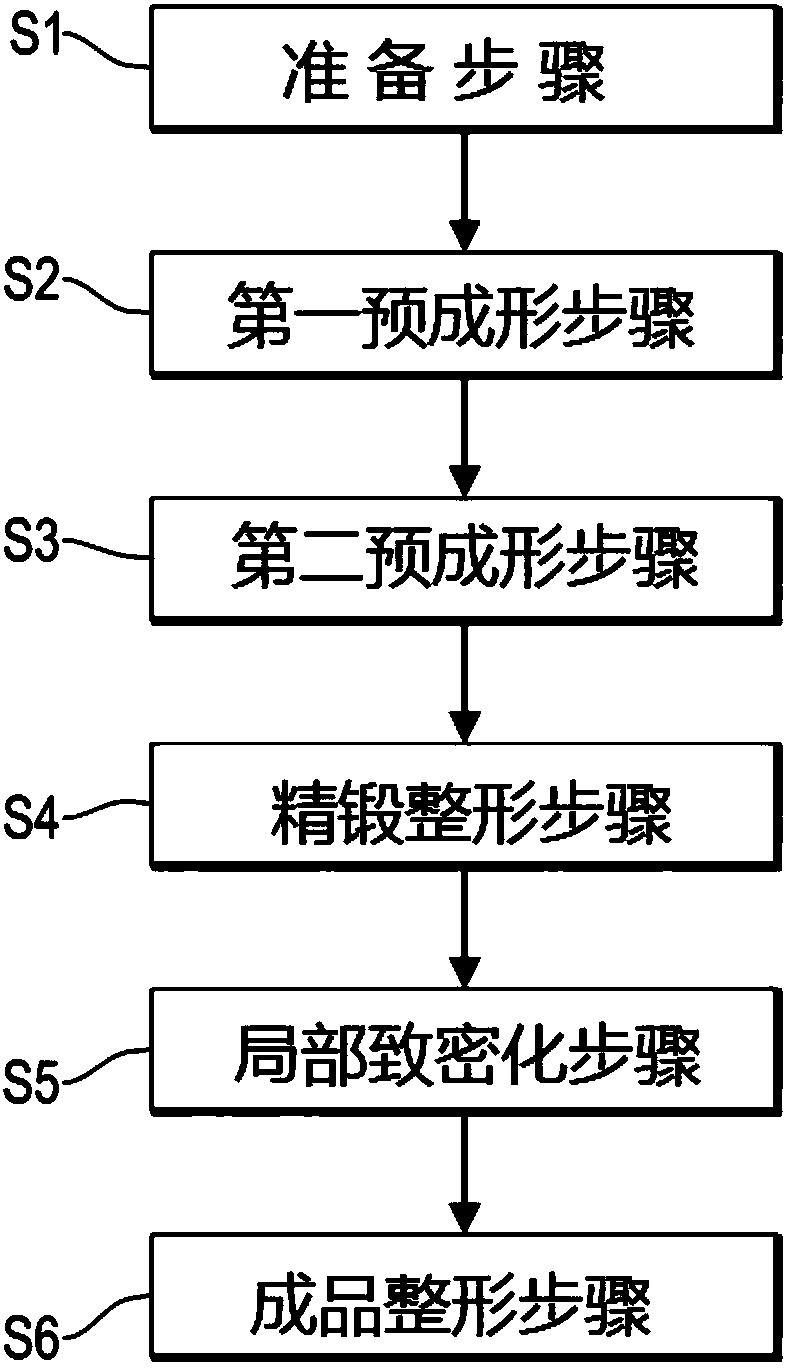

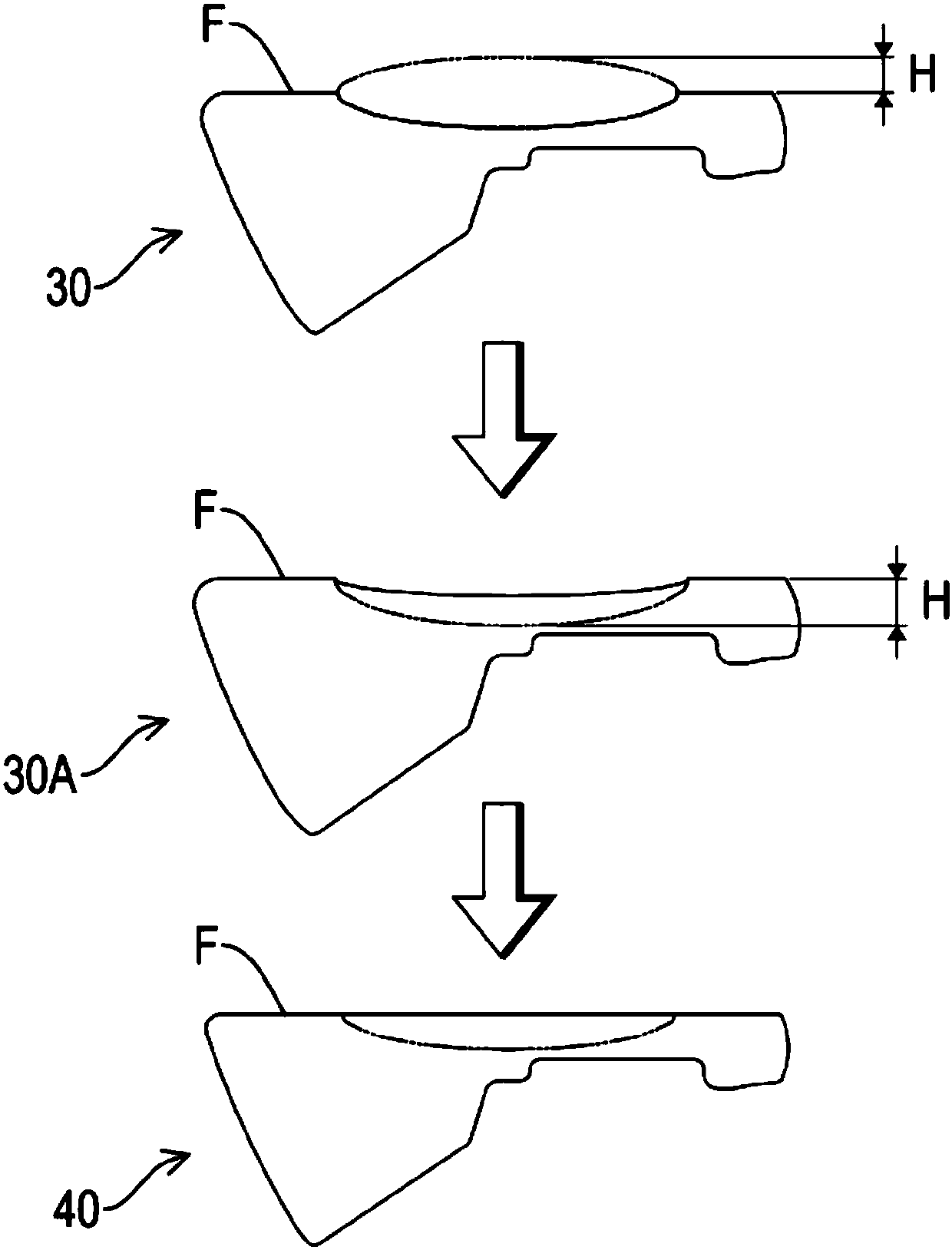

[0032] The present invention is a manufacturing method for densifying the local structure of a forged ball head, please refer to Figure 1 to Figure 4 The preferred embodiment includes a preparation step S1, a first preforming step S2, a second preforming step S3, a precision forging shaping step S4, a local densification step S5, and a finished product shaping step S6.

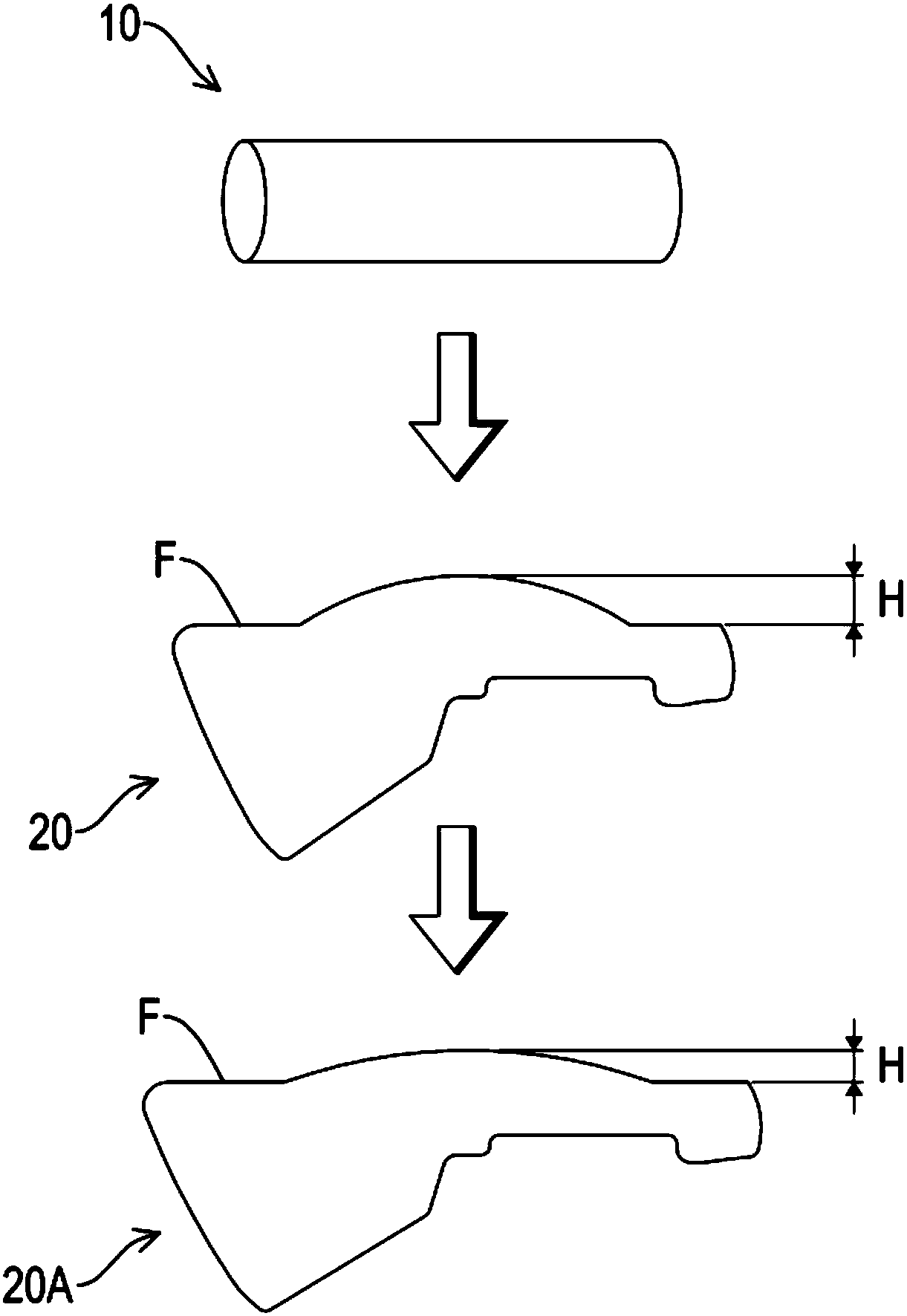

[0033] Such as figure 1 and figure 2 As shown, in the preparation step S1, a rod 10 of appropriate length is prepared, and the rod 10

[0034] It is a medium and low carbon steel material commonly used for forging.

[0035] Such as figure 1 and figure 2 As shown, in the first preforming step S2, after heating the rod 10 to 900...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com