Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Increase floatability difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for sorting waste plastics

Owner:四川长虹格润环保科技股份有限公司

Beneficiation method for tungsten polymetallic ore

InactiveCN103934113AIncrease floatability differenceRealize flotation separationFlotationFoaming agentCalcite

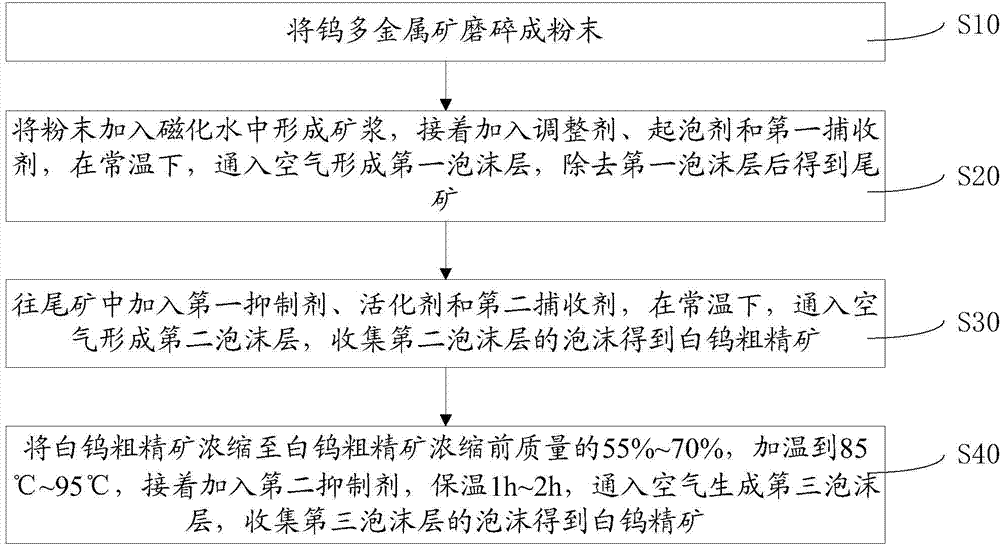

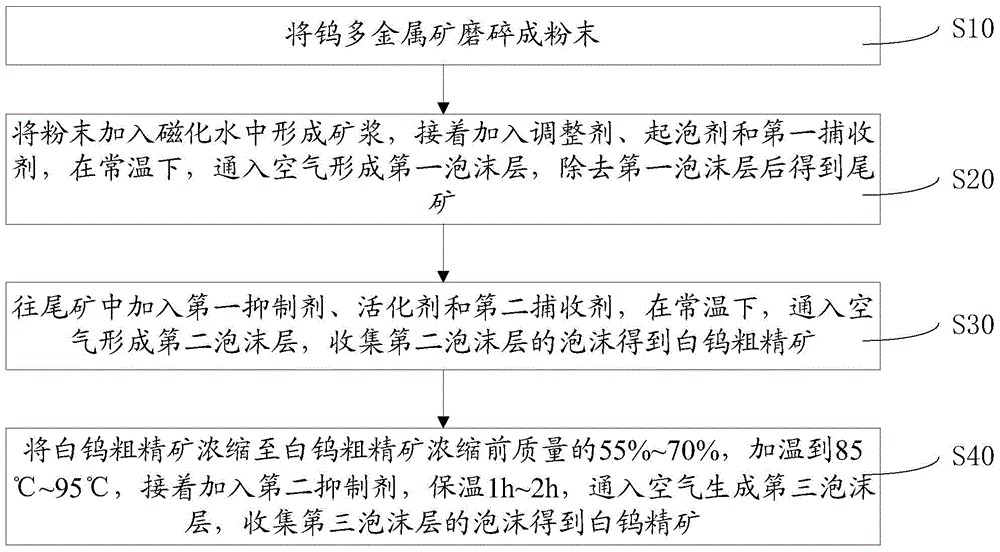

The invention discloses a beneficiation method for tungsten polymetallic ore. The beneficiation method comprises the following steps of (1) grinding the tungsten polymetallic ore to form powder, (2) adding the powder to magnetized water to form ore pulp, then, adding regulators, foaming agents and first collecting agents, feeding in air to form a first foam layer, obtaining tailings after removing the first foam layer, (3) adding first inhibitors, activators and second collecting agents to the tailings, feeding in air to form a second foam layer, collecting the second foam layer to obtain white tungsten rough concentrate, and (4) concentrating the white tungsten rough concentrate till the mass of the white tungsten rough concentrate ranges from 55% to 70% of the mass of the white tungsten rough concentrate before concentration, heating the white tungsten rough concentrate to the temperature which ranges from 85 DEG C to 95 DEG C, adding second inhibitors, feeding in air to generate a third foam layer, and collecting the third foam layer to obtain white tungsten concentrate. According to the beneficiation method for the tungsten polymetallic ore, the magnetized water is used in the technological process, difference between floatability of the white tungsten ore and floatability of calcium minerals can be increased, flotation separation of the white tungsten ore and the calcium minerals such as fluorite and calcite is achieved, and the recovery rate of the white tungsten ore is increased.

Owner:HUNAN YOUSE TECH DEV

A separating method of mixed plastics

ActiveCN105399983AEasy to separateEfficient separationPlastic recyclingAqueous solutionNuclear chemistry

The invention relates to a separating method of mixed plastics and belongs to the technical field of waste plastic recovery. The method includes subjecting mixed plastic particles to surface modification by dipping the mixed plastic particles into an aqueous solution containing a wetting agent until an adsorption amount of the wetting agent on surfaces of the mixed plastic particles is not less than 5 g / t, performing solid liquid separation, adding the obtained solid into an eluant, eluting for not more than 20 min, performing solid liquid separation to obtain solid that is eluted mixed plastic particles, and subjecting the eluted mixed plastic particles to floatation to obtain a single plastic with high purity. The method is high in separation efficiency, simple in operation, easily controllable and low in cost and facilitates large-scale industrial application.

Owner:CENT SOUTH UNIV

Separation method of low-grade fluorite barite paragenic ore rich in calcite

ActiveCN111298956AImprove hydrophilicityIncrease floatability differenceFlotationWet separationOre concentrateCalcite

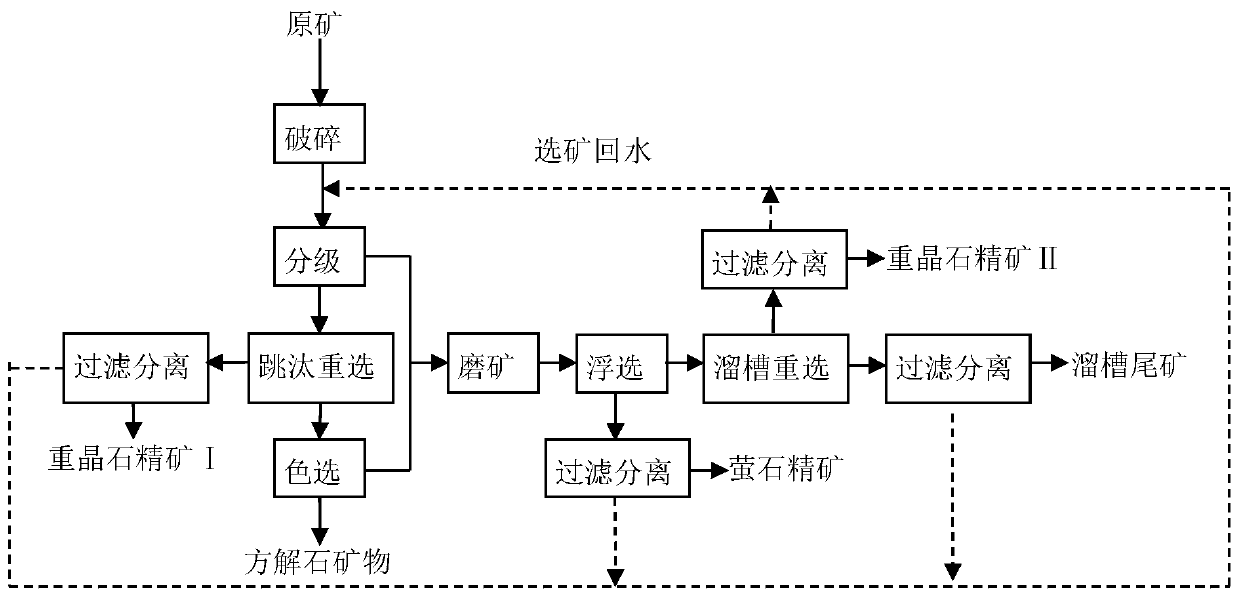

The invention discloses a separation method of low-grade fluorite barite paragenic ore rich in calcite. The method comprises the following steps that firstly, crushing is carried out; secondly, grading is carried out to obtain fine fraction ore, medium fraction ore and coarse fraction ore; thirdly, jigging reselection is carried out on the medium fraction ore, so that medium fraction concentrate and gangue I are obtained; fourthly, jigging reselection is carried out on the coarse fraction ore, so that coarse fraction concentrate and gangue II are obtained; fifthly, the medium fraction concentrate and the coarse fraction concentrate are combined to obtain barite concentrate I, the gangue I and the gangue II are combined, and jigging gangue is obtained; sixthly, the jigging gangue is subjected to color sorting, so that calcite ore and color-sorting gangue are obtained; seventhly, fine fraction ore and the color sorting gangue are combined and milled, so that a floating-in material is obtained; eighthly, separating flotation is carried out, so that fluorite concentrate and flotation gangue are obtained; and ninthly, the flotation gangue is subjected to chute reselection, so that barite concentrate II and chute gangue are obtained. The method achieves the effects that excellent-quality acid fraction fluorite concentrate with CaF2 larger than or equal to 98% and barite concentrate are obtained, and flotation return water can be recycled.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

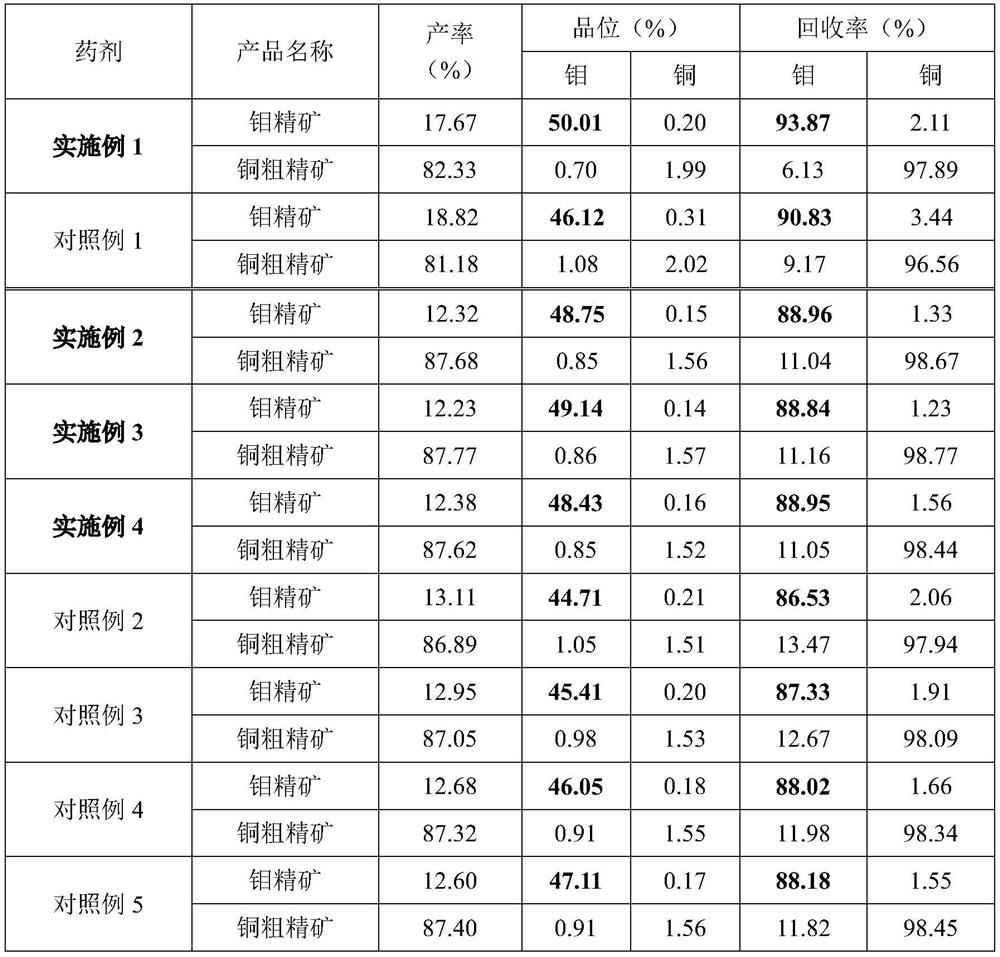

Flotation separation agent system for copper-molybdenum mixed concentrates and application of flotation separation agent system

The invention discloses a flotation separation agent system for copper-molybdenum mixed concentrates and application of the flotation separation agent system. The flotation separation agent system forthe copper-molybdenum mixed concentrates comprises a copper mineral inhibitor, a molybdenum mineral collector and a foaming agent in a copper-molybdenum flotation separation process. The copper mineral inhibitor comprises the following components in parts by weight: 3-7 parts of sodium hydroxide, 3-6 parts of hydrogen peroxide, 15-25 parts of sodium thioglycolate, 2-5 parts of pentasodium diethylenetriaminepentaacetate and a proper amount of water; the molybdenum mineral collector comprises the following components in parts by weight: 20-30 parts of kerosene and 5-10 parts of tert-dodecyl mercaptan; and the foaming agent is 2-hexanol. The inhibitor and the collector are high in selective adsorption capacity, the synergy performance is excellent, the activity of groups of the foaming agentis high, formed foams are crisp and compact, and the mineralization effect is good. According to the flotation separation agent system for copper and molybdenum, the floatability difference between molybdenum minerals and copper minerals in the complex copper and molybdenum mixed concentrates difficult to separate can be greatly improved, the mutual content of the copper and the molybdenum is effectively reduced, the separation index is excellent, adopted agents are nontoxic and harmless, and the influence on the environment is small.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

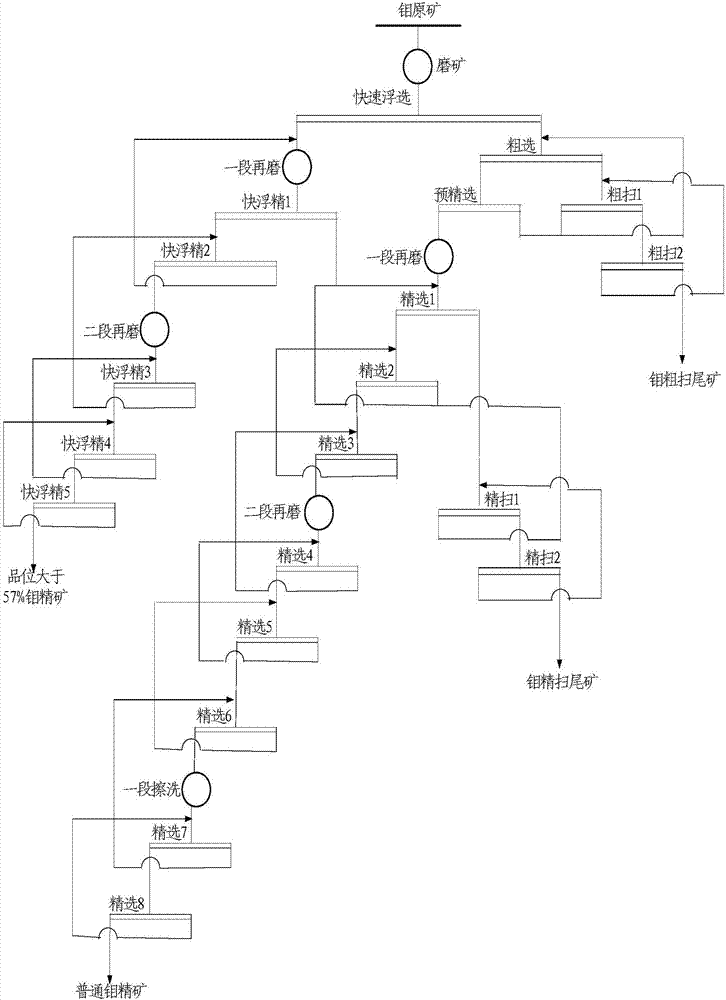

Process for step-by-step production of high-grade molybdenum concentrates and ordinary molybdenum concentrates

ActiveCN107309074AIncrease floatability differenceFewer picksFlotationWet separationTotal recoveryPre selection

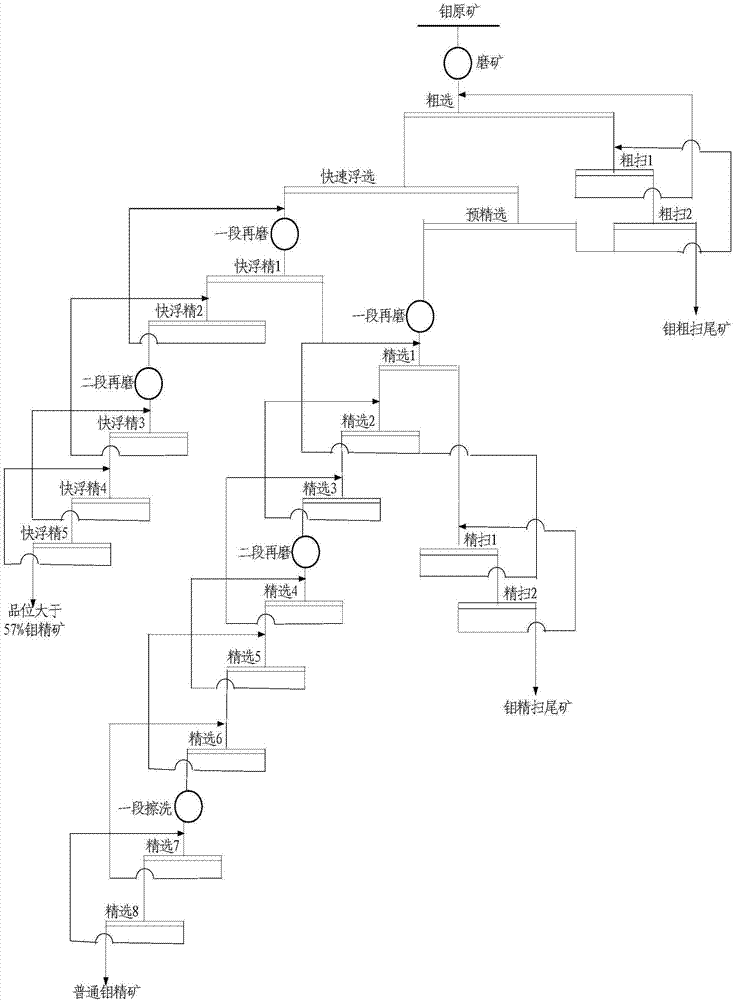

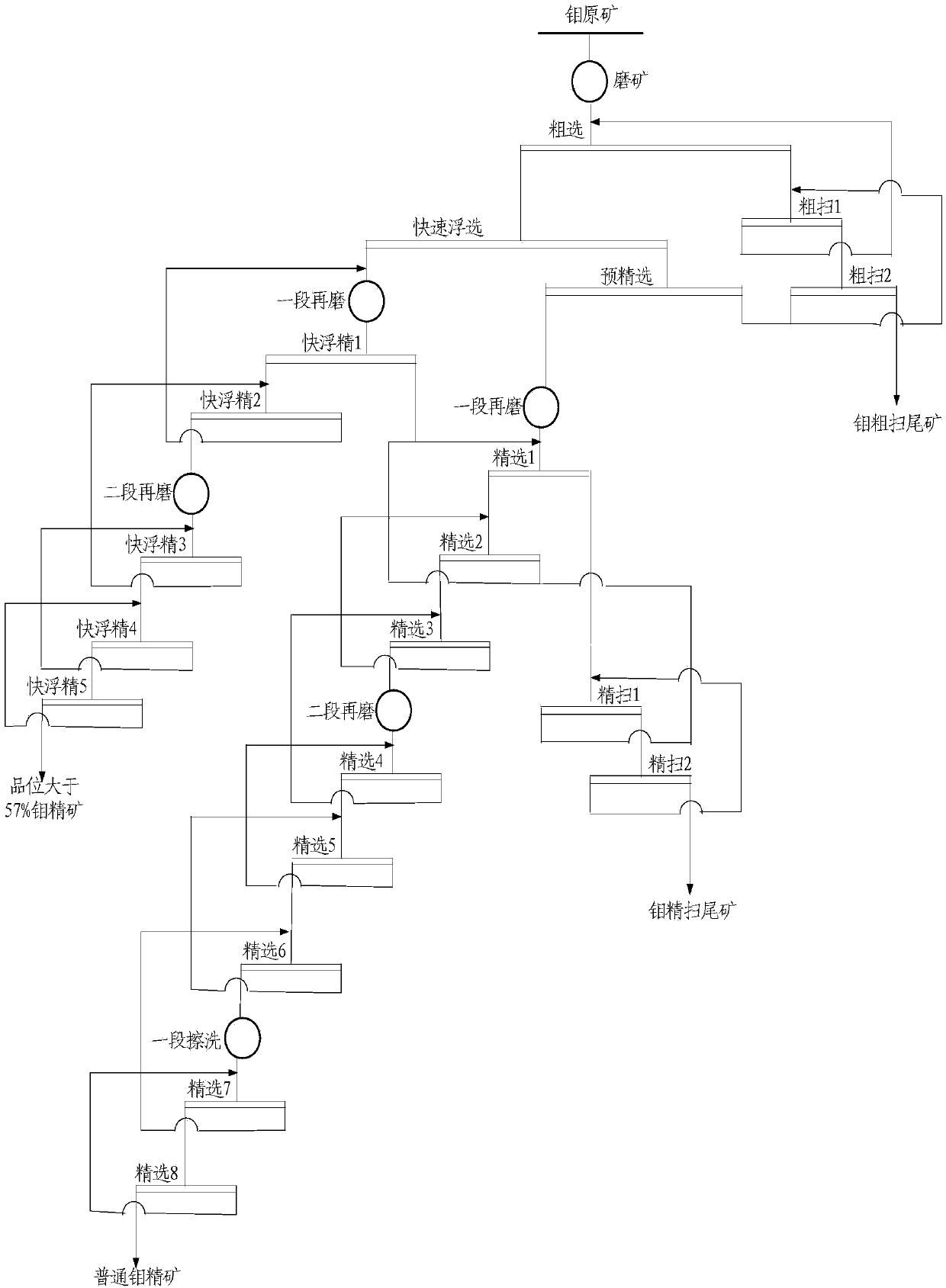

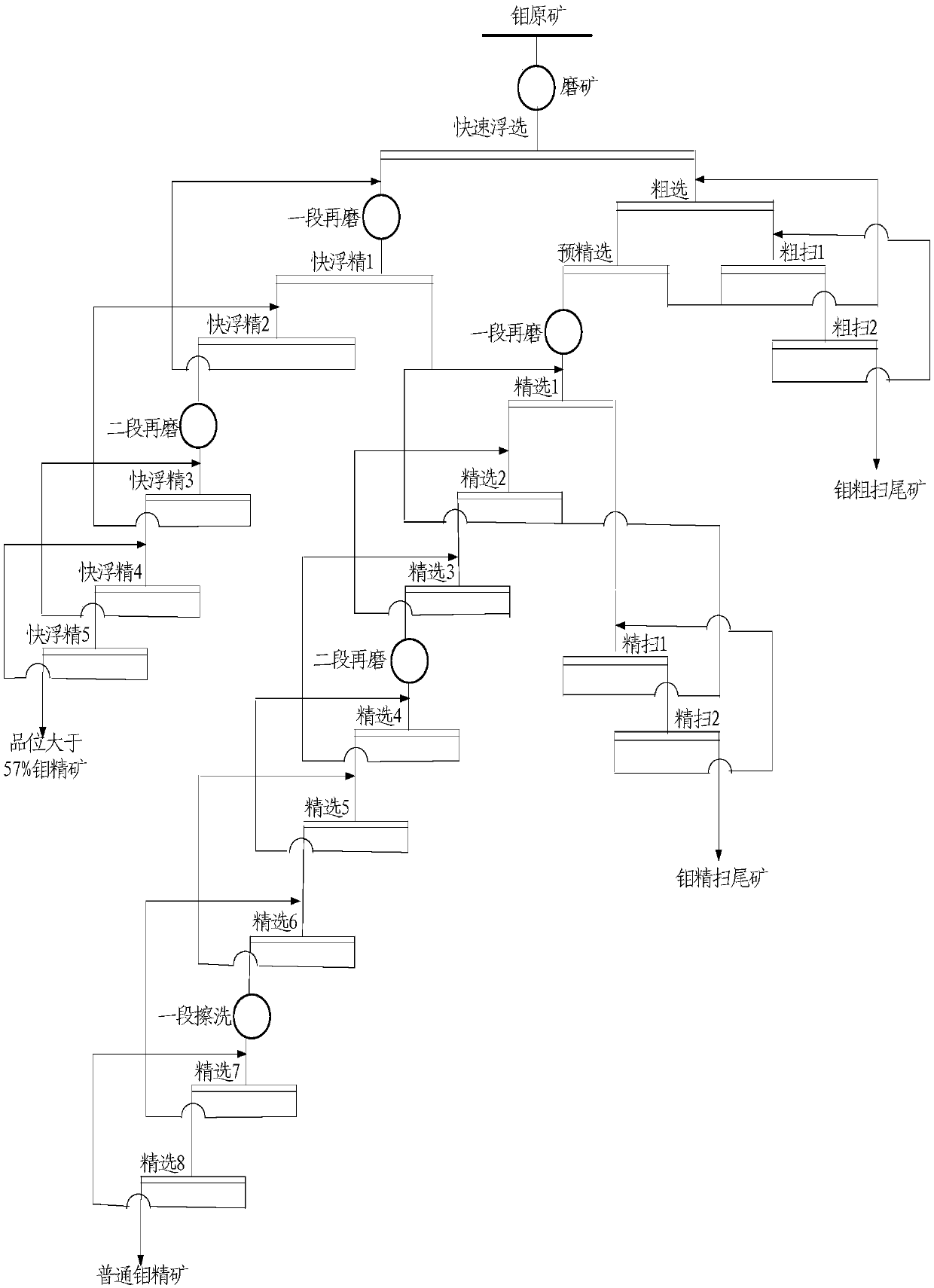

The invention discloses a process for step-by-step production of high-grade molybdenum concentrates and ordinary molybdenum concentrates. The process comprises the following steps that 1, molybdenum crude ore is added with water and ground, and molybdenum ore pulp is obtained; 2, the molybdenum ore pulp is subjected to roughing, molybdenum rough concentrates and molybdenum rough tailings are obtained, the molybdenum rough concentrates or the molybdenum ore pulp is subjected to fast flotation, and fast flotation molybdenum rough concentrates and fast flotation molybdenum tailings are obtained; 3, the fast flotation molybdenum rough concentrates are subjected to two-stage regrinding and selection for five times, and the high-grade molybdenum concentrates where the grade of molybdenum is larger than 57% are obtained; 4, the fast flotation molybdenum tailings obtained through the molybdenum ore pulp are subjected to roughing, and molybdenum rough concentrates and molybdenum rough tailings are obtained; and 5, the fast flotation molybdenum tailings obtained through the molybdenum rough concentrates or the molybdenum rough concentrates in the step 4 are subjected to pre-selection at first and then subjected to two-stage regrinding, selection for eight times and scrubbing for one time, and molybdenum fine tailings and the ordinary molybdenum concentrates where the grade of molybdenum is 52%-55% are obtained. According to the process for step-by-step production of the high-grade molybdenum concentrates and the ordinary molybdenum concentrates, a differential flotation technology is utilized, the molybdenum concentrates of different grades are obtained, the number of selection is shortened, and the total recovery rate of the molybdenum concentrates is increased.

Owner:JINDUICHENG MOLYBDENUM CO LTD

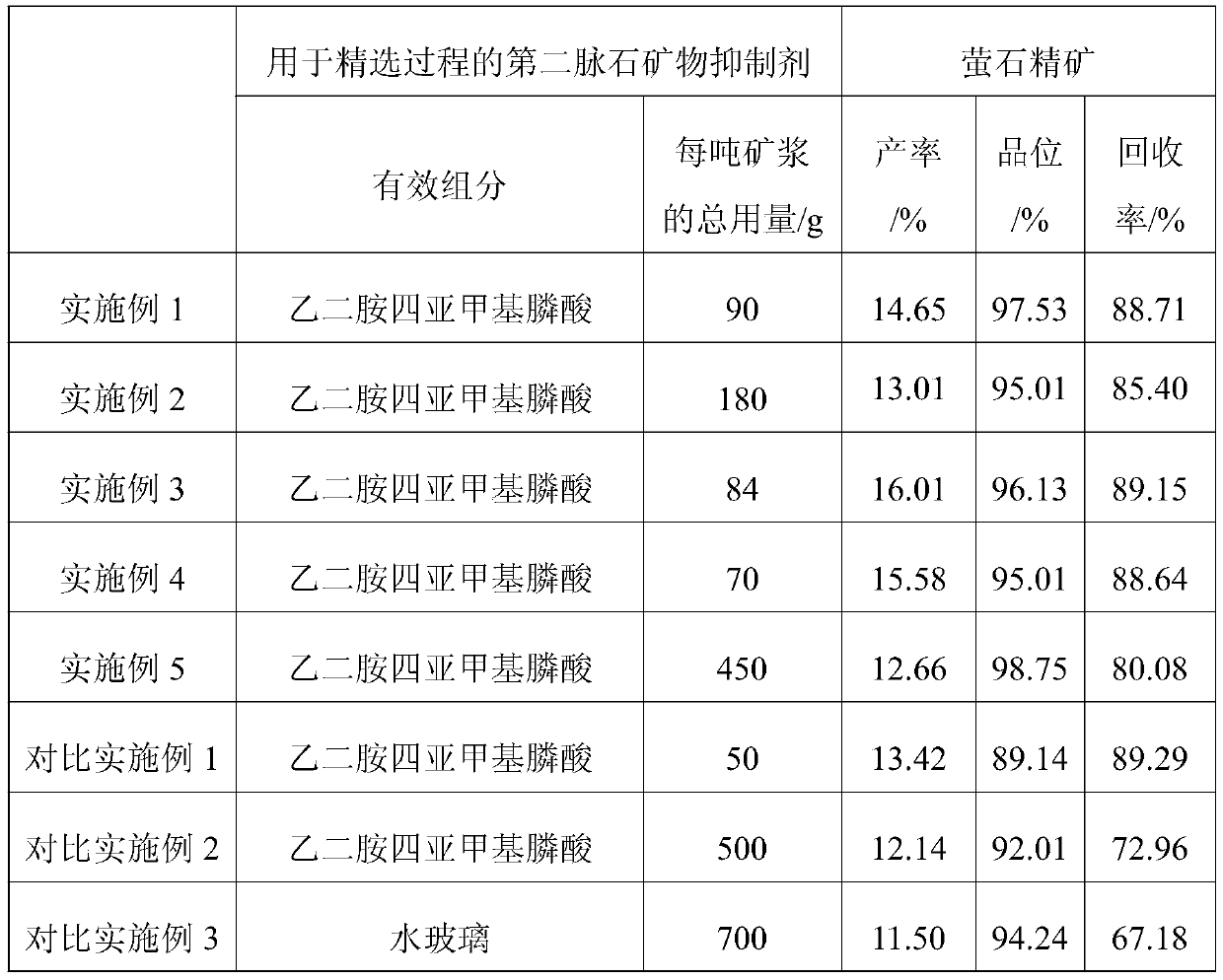

Inhibitor for direct flotation of high-calcium fluorite and flotation method

ActiveCN111215247AIncrease floatability differenceGood flotation effectFlotationOre concentrateEthylenediaminetetra(methylenephosphonic)acid

The invention provides an inhibitor for direct flotation of high-calcium fluorite. The inhibitor is an aqueous solution of ethylenediamine tetramethylene phosphonic acid. The invention further provides a high-calcium fluorite direct flotation method, which comprises the steps: firstly, crushing fluorite raw ores into powder and preparing the fluorite powder into ore pulp; then, adding a pH regulator into the ore pulp to control the pH value of the ore pulp to be 6-8 all the time; meanwhile, adding water glass and sodium oleate into the ore pulp, and carrying out roughing and scavenging on thefluorite raw ores to obtain fluorite rough concentrate; and finally, adding the inhibitor containing ethylenediamine tetramethylene phosphonic acid into the ore pulp containing the fluorite rough concentrate, and carrying out concentration on the fluorite rough concentrate to obtain fluorite concentrate, the total dosage of ethylenediamine tetramethylene phosphonic acid in each ton of fluorite rawores being 70-450 g. The inhibitor has the advantages of being low in cost, remarkable in selectivity, mild in using environment and free of secondary pollution, fluorite and calcite in the high-calcium fluorite can be efficiently separated, and the grade and the recovery rate of the fluorite are high.

Owner:CENT SOUTH UNIV

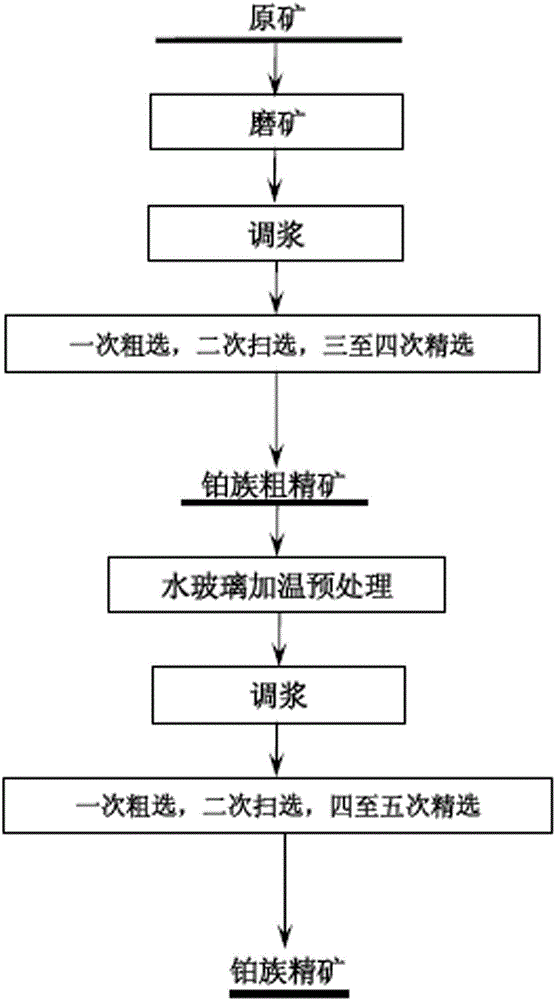

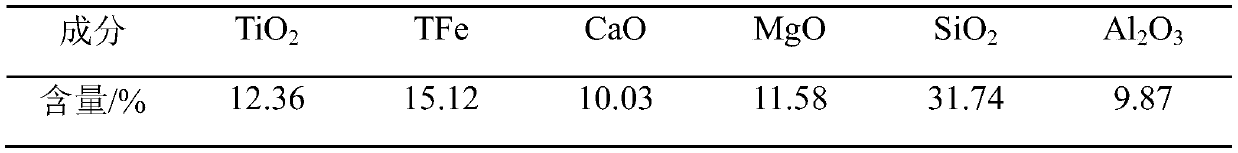

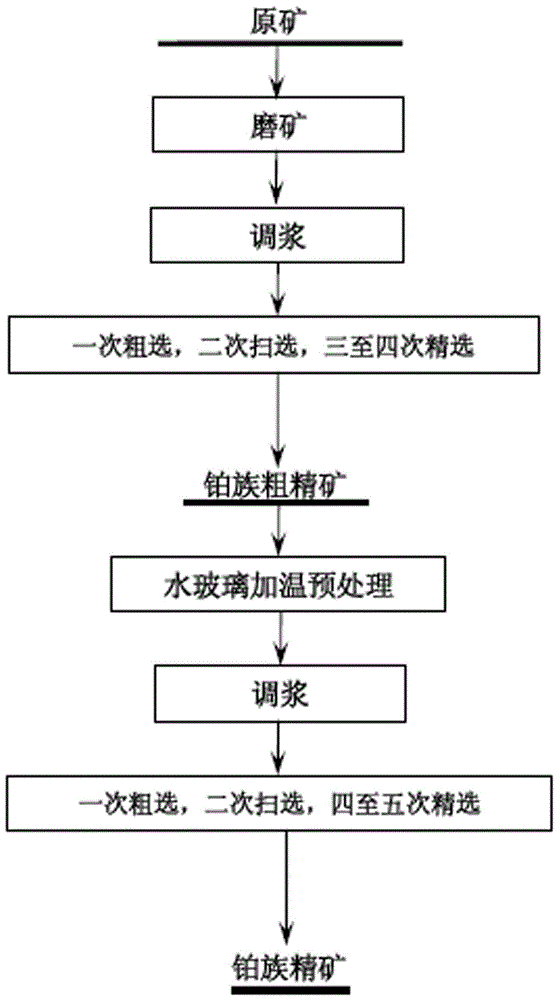

Primary platinum ore beneficiation method

ActiveCN105032621AImprove hydrophilic abilityIncrease floatability differenceFlotationPlatinumSulfur

A primary platinum ore beneficiation method is characterized in that rough platinum family concentrate is obtained after ore grinding and floatation are conducted on primary ore; the rough platinum family concentrate is heated and preprocessed through water glass; size mixing and floatation are conducted on the preprocessed rough concentrate to obtain platinum family concentrate high in platinum family metal grade. Compared with an existing primary platinum ore beneficiation method, the method has the advantages that valuable mineral and gangue mineral are thoroughly separated, and the concentrate grade is high. The method is suitable for primary platinum ore and particularly suitable for low-sulfur, low-platinum and low-palladium primary platinum ore.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

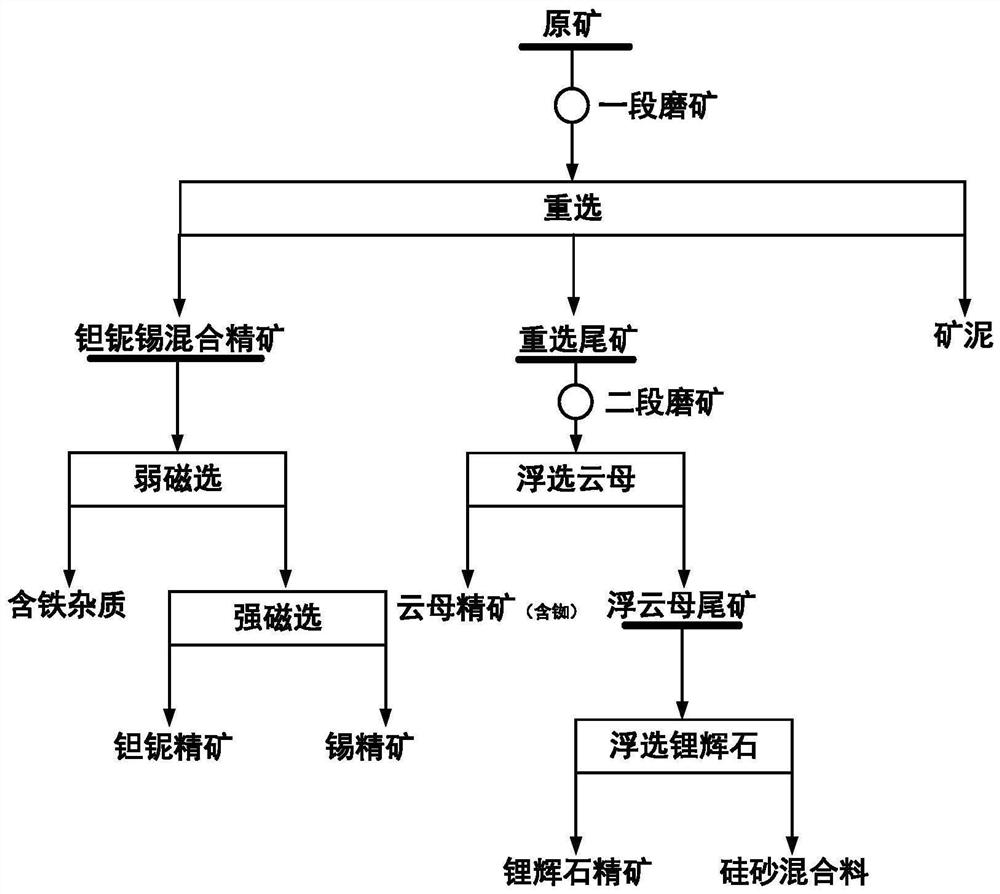

Beneficiation method for recovering molybdenum from tungsten tin associated sulfide ore bulk concentrate

InactiveCN105537005AIncrease floatability differenceGood hydrophobicityFlotationOre concentrateTungsten

The invention discloses a beneficiation method for recovering molybdenum from a tungsten tin associated sulfide ore bulk concentrate. The beneficiation method is characterized by comprising the following steps: after the heating reagent removal is performed for a sulfide ore bulk concentrate obtained from a tungsten tin associated sulfide ore; water is added for mixing pulp; quicklime is added for stirring to adjust the pulp; an inhibitor and a collecting agent are added for primary roughing to obtain a primary roughing concentrate and a primary roughing tailing; the collecting agent is added in the primary roughing tailing for secondary selection to obtain a secondary selection concentrate and a secondary selection tailing; and three times of blank selection are performed for the secondary selection concentrate to obtain a molybdenum concentrate. The method obtains the molybdenum concentrate with a molybdenum grade of 48-52% and a molybdenum recovery rate of 87-93%, reduces the molybdenum selection cost, generates no waste water and other substances harmful to the environment, and is an environment-friendly beneficiation method. The method is suitable for recovering molybdenum from the tungsten tin associated sulfide ore bulk concentrate.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS +1

Flotation method and pretreatment method for calcite-containing phosphorus ore

ActiveCN111330744AReduce separation efficiencyEnhanced inhibitory effectFlotationPretreatment methodMining engineering

The invention discloses a flotation pretreatment method for calcite-containing phosphorus ore. According to the method, a surface treating agent and an inhibitor are added into phosphorus ore slurry containing calcite before flotation. Precipitates generated by reaction of the surface treating agent and the calcite are attached to the surface to change the surface property, and the inhibitor can be better adsorbed to the surface of the calcite. The invention also discloses a flotation method of the calcite-containing phosphorus ore, which comprises the following steps: adding a pH regulator and a collecting agent after the pretreatment of the flotation pretreatment method of the calcite-containing phosphorus ore is completed, stirring and mixing slurry, carrying out froth flotation after slurry mixing to obtain rough concentrate, and concentrating the rough concentrate to obtain high-grade phosphate concentrate. The methods are used for treating phosphorus ore with high calcite content, and are simple in process, low in cost and high in recovery rate.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

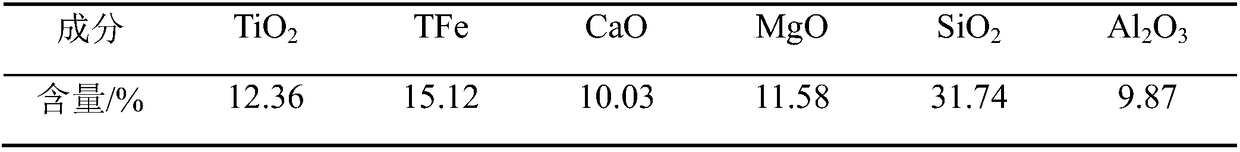

Method for improving flotation efficiency of ilmenite through microwave treatment

ActiveCN108311290AIncrease floatability differenceThe flotation process is simpleFlotationMaceralTitanium

The invention relates to the field of mineral processing, and discloses a method for improving the flotation efficiency of ilmenite through microwave treatment. The method comprises the following steps that flotation raw ore is firstly levigated, and then the ore is subjected to subsection microwave pretreatment; and the ore is conveyed into flotation equipment for flotation after being cooled toroom temperature. Due to microwave pretreatment, ferrous ions on the surface of ilmenite can be oxidized into ferric ions, the adsorption function of a collecting agent on the ferric ions is promoted,and the floatability of floatability is improved. Therefore, the recycling rate of ilmenite is increased, the consumption of sulfuric acid and beneficiation reagents in the flotation process is reduced, and the method is beneficial to environmental friendliness.

Owner:NORTHEASTERN UNIV

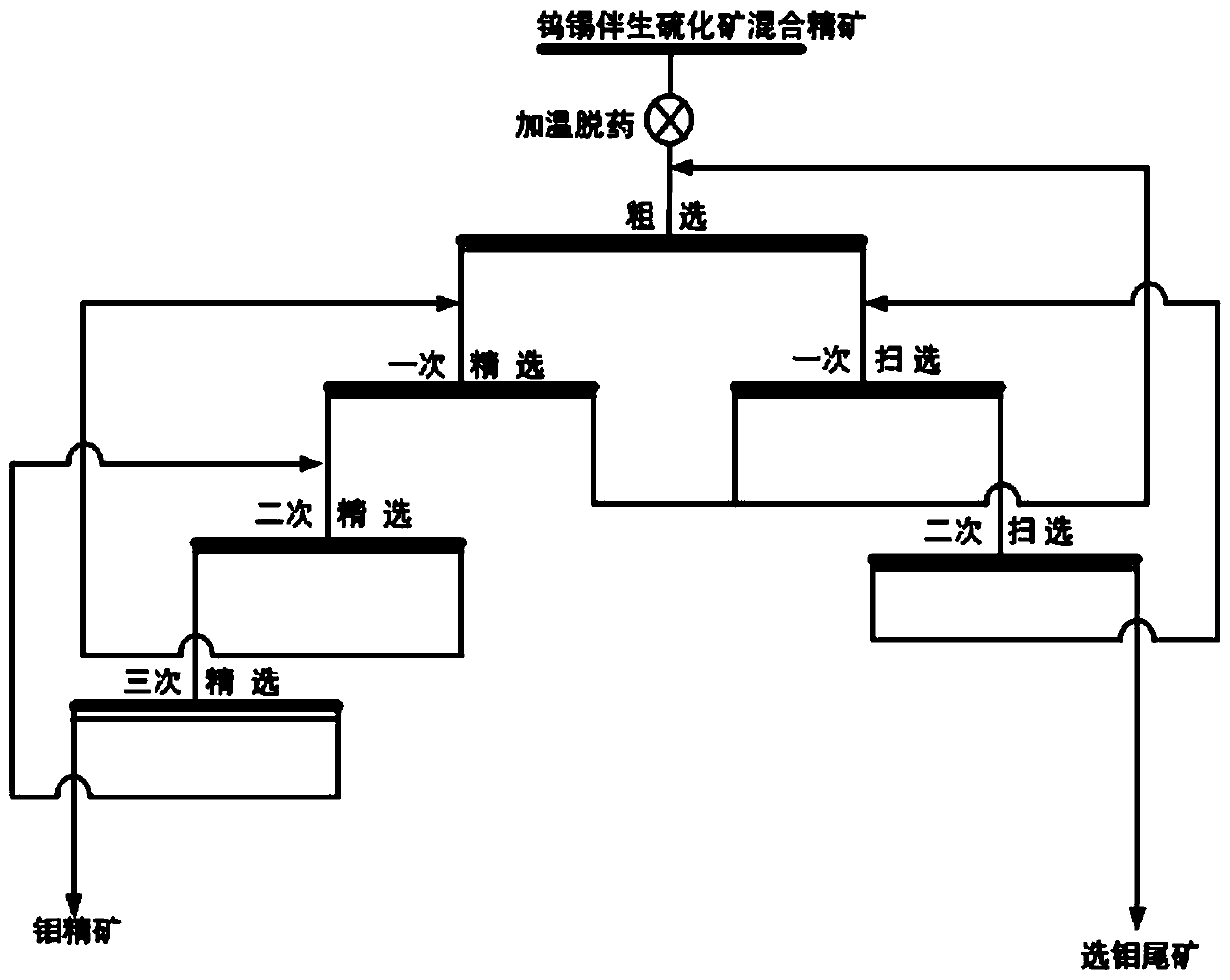

Production online flotation arsine-reduction method for high arsenic-containing copper concentrate

InactiveCN106733142ASimplify the arsenic reduction processSimple and efficient operationSolid separationArsineArsenic

The invention discloses a production online flotation arsine-reduction method for high arsenic-containing copper concentrate. Firstly, bulk flotation high arsenic-containing copper concentrate is produced through a copper-sulfur-arsenic bulk flotation technique, and tailings are treated through a tin re-flotation technique; before copper-sulfur-arsenic separation flotation for arsine reduction, a long-conical hydrocyclone is adopted for slight steel forging and classified fine grinding, inhibitors are added to achieve effective monomer separation, analytic reagent removal and reinhibition; and finally, production online arsine reduction is conducted through the copper-sulfur-arsenic separation flotation arsine-reduction technique, low arsenic-containing copper concentrate and high arsenic-containing copper-sulfur-arsenic separation sulfur concentrate are produced, the propose of production online direct flotation arsine reduction in the production process of tin-copper-sulfur-arsenic symbiotic complex refractory multi-metal sulfide ores is achieved. According to the production online flotation arsine reduction method for the high arsenic-containing copper concentrate, the steps of the copper concentrate arsine reduction technique are simplified, operation is easy, the production online flotation arsine reduction method is practical, operation cost is low, the arsenic content of the copper concentrate is low, copper metal loss in the arsine reduction technological process is greatly reduced, and the recycling rate of copper and tin metal is increased.

Owner:YUNNAN TIN

Beneficiation method for pegmatite type lithium polymetallic ore

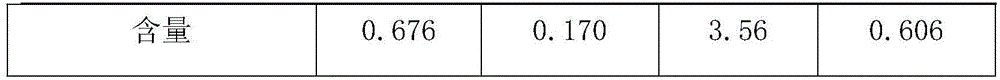

ActiveCN112958273AAchieve high enrichmentAchieve recyclingSolid separationMechanical material recoveryNiobiumSeparation technology

The invention relates to a beneficiation method for pegmatite type lithium polymetallic ore. The beneficiation method comprises the steps of first-stage ore grinding, screening, reselection, magnetic separation, second-stage ore grinding, size mixing, flotation of rubidium-containing mica, flotation of spodumene and the like. The tantalum-niobium concentrate, the tin concentrate, the mica concentrate, the spodumene concentrate and the silica sand mixture are obtained through the gravity-magnetism-flotation combined technology, comprehensive recovery of tantalum, niobium, tin, rubidium, lithium, silicon, aluminum and other elements is sequentially achieved, and the method has the advantages of being simple and convenient in separation technology, good in separation effect, high in resource utilization rate and the like.

Owner:INST OF RESOURCES COMPREHENSIVE UTILIZATION GUANGDONG ACAD OF SCI

Heating floatation method for middling pulp in zinc oxide ore

InactiveCN105013618AImprove stabilityIncrease vulcanization rateFlotationFoaming agentOpen-circuit test

The invention relates to a heating floatation method for middling pulp in zinc oxide ore and belongs to the technical field of ore processing. After raw ore of the zinc oxide ore is broken and ground, a conventional floatation method is used for conducting an open-circuit test, and therefore concentrates, middlings and tailings are obtained; the obtained middlings are merged; the mass percentage concentration of the pulp is adjusted to be 20%-40%; the pulp is heated to 40-60 DEG C; then, Na2S activating agents are added in sequence so that the pH of the pulp can reach 11-11.5; collecting agents and foaming agents in a conventional floatation process are used for conventional floatation, and therefore concentrates and tailings are obtained; and the obtained concentrates and the concentrates obtained through the open-circuit test are merged, and final zinc concentrates meeting the index requirement are obtained through preparation. According to the heating floatation method, the problems that the middlings in the zinc oxide ore separation process are hard to process, the pH of the middling pulp is low, the use amount of sodium sulfide is too large, closed-circuit work deteriorates due to sludge, and the sludge is hard to scatter are solved.

Owner:KUNMING UNIV OF SCI & TECH

A kind of beneficiation method for recovering molybdenum from tungsten-tin associated sulfide ore mixed concentrate

InactiveCN105537005BMineral processing method to solve recoveryIncrease floatability differenceFlotationWastewaterTungsten

The invention discloses a beneficiation method for recovering molybdenum from a tungsten tin associated sulfide ore bulk concentrate. The beneficiation method is characterized by comprising the following steps: after the heating reagent removal is performed for a sulfide ore bulk concentrate obtained from a tungsten tin associated sulfide ore; water is added for mixing pulp; quicklime is added for stirring to adjust the pulp; an inhibitor and a collecting agent are added for primary roughing to obtain a primary roughing concentrate and a primary roughing tailing; the collecting agent is added in the primary roughing tailing for secondary selection to obtain a secondary selection concentrate and a secondary selection tailing; and three times of blank selection are performed for the secondary selection concentrate to obtain a molybdenum concentrate. The method obtains the molybdenum concentrate with a molybdenum grade of 48-52% and a molybdenum recovery rate of 87-93%, reduces the molybdenum selection cost, generates no waste water and other substances harmful to the environment, and is an environment-friendly beneficiation method. The method is suitable for recovering molybdenum from the tungsten tin associated sulfide ore bulk concentrate.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS +1

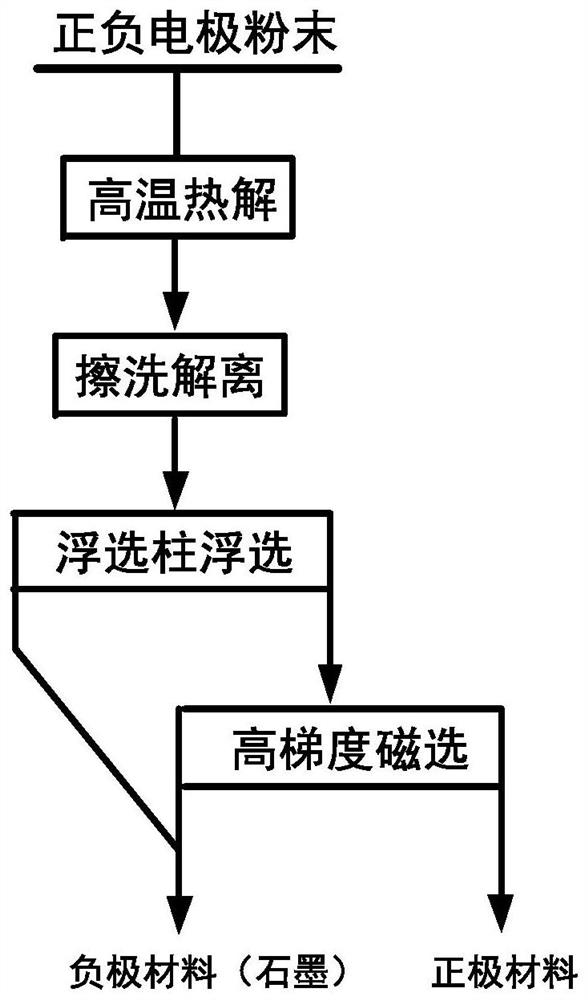

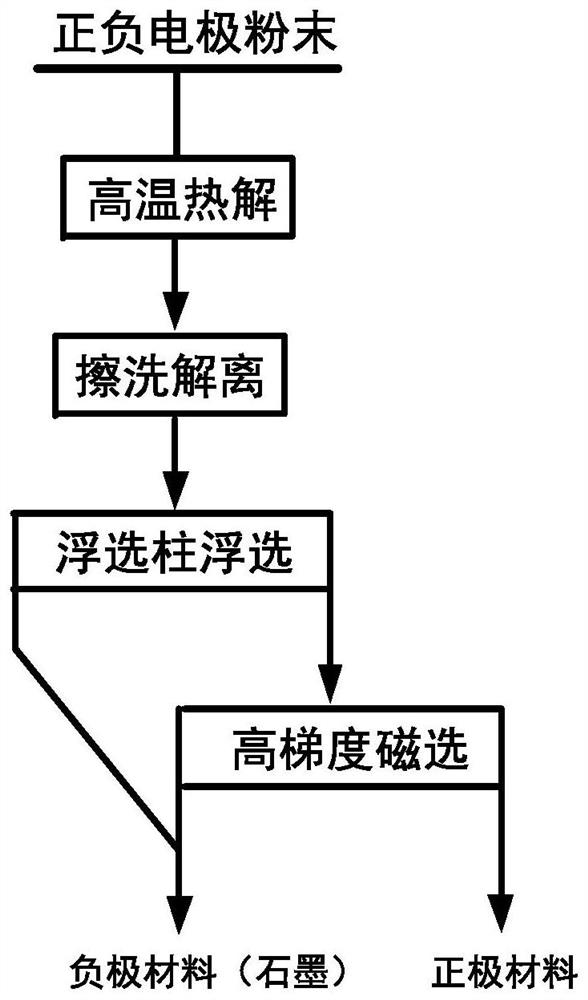

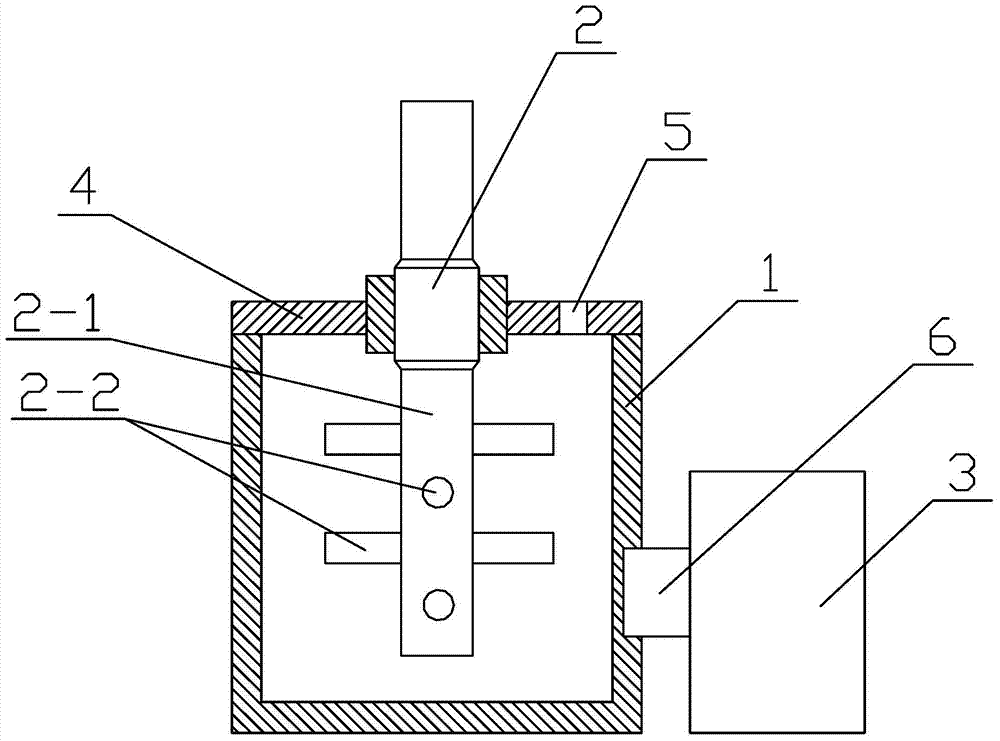

A physical separation and recovery method for positive and negative electrode materials of waste ternary lithium batteries

ActiveCN112736314BEliminate adhesionEliminate flotation environmentWaste accumulators reclaimingBattery recyclingProcess engineeringGraphite

The invention relates to the technical field of recycling waste power lithium-ion batteries, and specifically discloses a method for physically sorting and recovering positive and negative electrode materials of waste ternary lithium batteries. The invention lays the foundation for clean and environmentally friendly physical separation by pyrolyzing the positive and negative electrode materials while removing organic matter, and eliminates the adhesion between the positive electrode material and the graphite by stirring and scrubbing, providing a solid foundation for subsequent flotation and The step-by-step recovery of graphite by magnetic separation creates favorable conditions. The method has the advantages of economy and environmental protection, simple operation and high product purity, realizes efficient separation of positive and negative electrode materials, and improves resource utilization.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Physical sorting and recycling method for positive and negative electrode materials of waste ternary lithium battery

ActiveCN112736314AEliminate adhesionEliminate flotation environmentWaste accumulators reclaimingBattery recyclingElectrical batteryGraphite

The invention relates to the technical field of recycling of waste power lithium ion batteries, and particularly discloses a physical sorting and recycling method of positive and negative electrode materials of a waste ternary lithium battery. Herein, the positive electrode material and the negative electrode material are pyrolyzed, wherein a foundation is laid for clean and environment-friendly physical separation while organic matter is removed; the adhesion effect between the positive electrode material and graphite is eliminated through stirring and scrubbing, and beneficial conditions are created for step-by-step recovery of the graphite through subsequent flotation and magnetic separation. The method has the advantages of economy, environmental protection, simple operation, high product purity and the like, realizes efficient separation of positive and negative electrode materials, and improves the utilization rate of resources.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Flotation method of high-magnesium sulphide ore

The invention discloses a flotation method of high-magnesium sulphide ore. The method comprises the following steps: a, crushing ore, adding an electrostatic buffer regulator, and grinding and pulpingto obtain ore pulp; b, adding a magnesium-containing gangue mineral inhibitor into the ore pulp obtained in the step a, and uniformly stirring; c, adding an activation regulator into the mixed material obtained in the step b, and uniformly stirring, wherein the activation regulator comprises 1-10 parts by weight of soluble copper salt, 0-200 parts by weight of ammonium / amine salt and 1-100 partsby weight of a reducing active agent; d, adding a flotation reagent into the mixed material obtained in the step c, and uniformly stirring; and e, carrying out flotation on the mixed material obtainedin the step d, and separating to obtain target mineral concentrate and flotation tailings. According to the method, the separation process of sulfide minerals and magnesium-containing gangue mineralscan be strengthened, and magnesium mineral components in the product are effectively reduced.

Owner:CHINA ENFI ENGINEERING CORPORATION

Flotation recovery method for high-calcium-magnesium high-argillaceous zinc carbonate

The invention relates to a high-calcium-magnesium high-argillaceous zinc carbonate flotation recovery method which comprises the following steps: (1) desliming flotation: taking lead-zinc sulfide flotation tailings as raw ores, adding a slime collecting agent, stirring and reacting for 3-6 minutes, and then desliming before zinc oxide flotation to respectively obtain slime-containing ore pulp and deslimed tailing ore pulp; (2) roughing zinc oxide: adding regulators of sodium carbonate, sodium sulfide, gangue inhibitor, lauryl amine acetate and butyl xanthate into the deslimed tailing pulp for roughing zinc to respectively obtain zinc rough concentrate pulp and roughed tailing pulp; (3) zinc oxide concentration: performing concentration operation on the zinc rough concentrate pulp twice to obtain zinc oxide concentrate; and (4) zinc oxide scavenging: performing one-time zinc oxide scavenging operation on the roughing tailing pulp to obtain zinc oxide scavenged tailings. According to the method, the floatability of the zinc oxide mineral can be remarkably enhanced, and better mineral separation technical indexes are obtained.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

A Flotation Separation Agent System of Copper-Molybdenum Mixed Concentrate and Its Application

ActiveCN110548600BReduce mutual inclusionExcellent separation indexFlotationPharmacySodium thioglycollate

The invention discloses a copper-molybdenum mixed concentrate flotation separation agent system and its application; the copper-molybdenum mixed concentrate flotation separation agent system includes a copper mineral inhibitor and a molybdenum mineral collector in the copper-molybdenum flotation separation process and foaming agents. Wherein, the copper mineral inhibitor includes by weight: 3-7 parts of sodium hydroxide, 3-6 parts of hydrogen peroxide, 15-25 parts of sodium thioglycolate, 2 parts of pentasodium diethylenetriaminepentaacetate -5 parts, an appropriate amount of water; the molybdenum mineral collector includes by weight parts: 20-30 parts of kerosene, 5-10 parts of tert-dodecylmercaptan; the foaming agent is 2-hexanol. The inhibitor and collector of the invention have strong selective adsorption capacity, excellent synergistic performance, strong foaming agent group activity, brittle and dense foam formed, and good mineralization effect. The copper-molybdenum flotation separation agent system of the present invention can greatly improve the difference in floatability between molybdenum minerals and copper minerals in complex and difficult-to-separate copper-molybdenum mixed concentrates, effectively reduce the mutual inclusion of copper and molybdenum, and the separation index is excellent. It is harmless and has little impact on the environment.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Sequential priority flotation separation method of low-sulfur copper-lead-zinc polymetallic ore

ActiveCN110280395BInhibition of mutual inclusionReduce mutual inclusionFlotationMineral SourcesMining engineering

The invention discloses a method for separating low-sulfur type copper-lead-zinc polymetallic ores by sequential preferential flotation. The technical scheme is carried out in the order of first flotation of copper and then flotation of lead. In the copper priority flotation operation, the combined inhibitor T‑9 is used to realize the combination of valuable elements copper, lead, and Effective separation of zinc; in the lead priority flotation operation, the inhibitor F‑8 is used to effectively inhibit the flotation of zinc minerals. T-9 reduces the planktonic activity of lead and zinc minerals, effectively increases the difference in floatability between copper and lead and zinc minerals, and its components are non-toxic, harmless, green and non-polluting; inhibitor F-8 has a strong effect on sphalerite Good inhibitory effect, while galena and silver minerals have high activity, and galena has a certain collection effect, which is beneficial to reduce the mutual content of lead and zinc in the product. After the method is adopted, the target minerals copper, lead and zinc are effectively separated, and the purpose of comprehensive recovery and utilization of mineral resources is achieved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

A Modified Pretreatment Method for Separation of Coal and Rock Components

ActiveCN104437879BIncrease floatability differenceImprove flotation separation effectFlotationPretreatment methodRoom temperature

Owner:XIAN UNIV OF SCI & TECH

A method of flotation after high calcium fluorite acid leaching pretreatment

The invention discloses a method for flotation after acid etching pretreatment of high-calcium fluorite. Acid is added into high-calcium fluorite pulp before flotation, inhibitors are added while the acid is added, and acid etching pretreatment is carried out; pH regulators and collecting agents are sequentially added after pretreatment is completed, and then air agitation pulp mixing is carried out; foam flotation is carried out after pulp mixing is completed, and rough concentrate is obtained; and the rough concentrate is further subjected to concentration to obtain high-quality fluorite concentrate. The method is clean, environmentally friendly, efficient and low in cost, and the obtained fluorite concentrate is high in grade and recovery rate.

Owner:CENT SOUTH UNIV

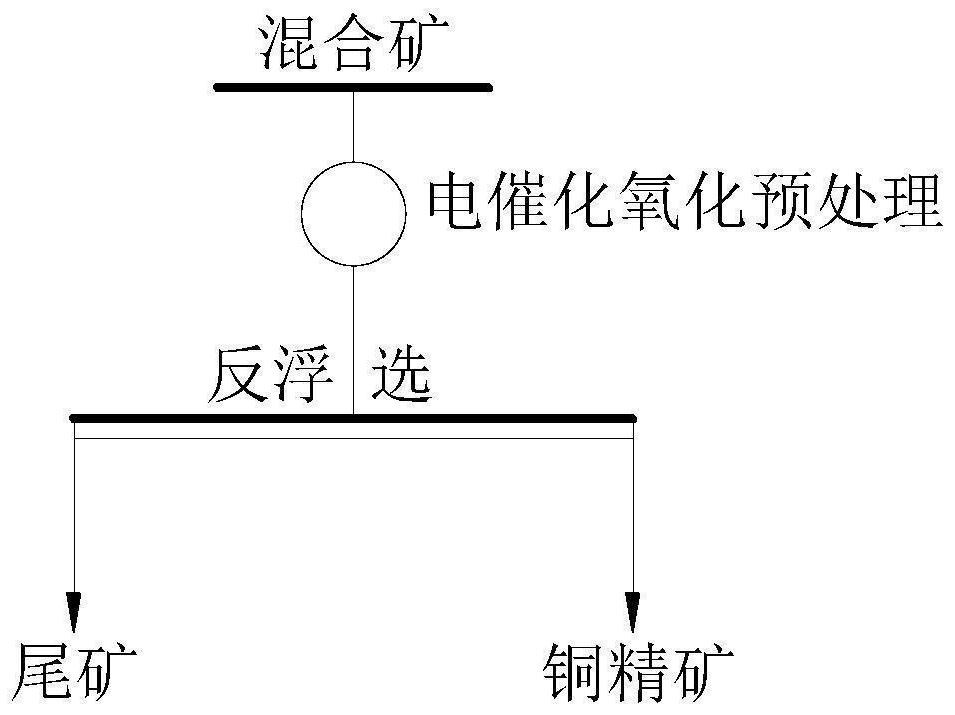

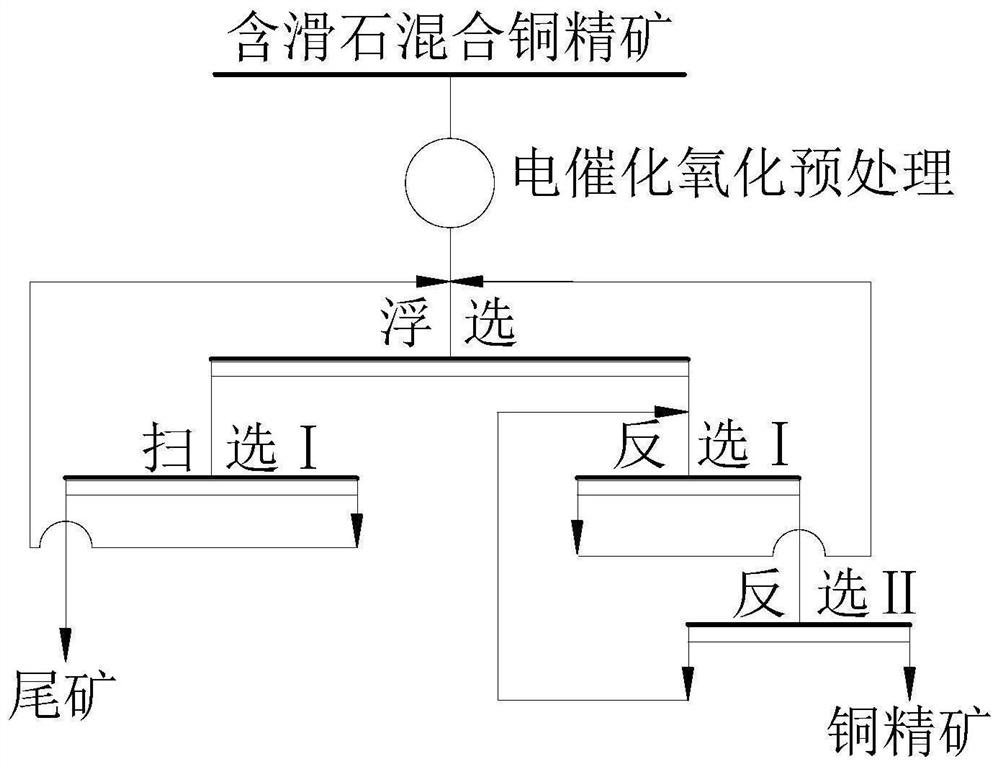

Flotation separation method for talc and copper sulphide

ActiveCN114247569AIncrease floatability differenceEfficient separationFlotationCatalytic oxidationCopper sulfide

The invention relates to a flotation separation method for talc and copper sulfide, which comprises the following steps: step 1, respectively inserting a cathode and an anode into an electrolytic bath, adding a salt solution into the electrolytic bath, and adding talc-containing copper sulfide bulk concentrate into the electrolytic bath while stirring; 2, after uniform stirring, stirring continues to be kept, a constant current source is turned on, current is applied to the electrolytic bath, constant current pretreatment is conducted for 15-35 min, and electrocatalytic oxidation pretreatment mixed ore pulp is obtained; and thirdly, the electrocatalytic oxidation pretreatment mixed ore pulp is transferred to a flotation system to be subjected to flotation operation, and copper sulfide and tailings are obtained. According to the invention, the surface hydrophobicity of the copper sulfide is reduced, so that the floatability difference between the talc and the copper sulfide is increased; effective separation of the two in flotation is achieved, and a large number of talc inhibitors do not need to be used.

Owner:ZHENGZHOU UNIV

A method of microwave pretreatment to improve ilmenite flotation efficiency

Owner:NORTHEASTERN UNIV LIAONING

A kind of primary platinum ore beneficiation method

ActiveCN105032621BImprove hydrophilic abilityIncrease floatability differenceFlotationPlatinumSulfur

A primary platinum ore beneficiation method is characterized in that rough platinum family concentrate is obtained after ore grinding and floatation are conducted on primary ore; the rough platinum family concentrate is heated and preprocessed through water glass; size mixing and floatation are conducted on the preprocessed rough concentrate to obtain platinum family concentrate high in platinum family metal grade. Compared with an existing primary platinum ore beneficiation method, the method has the advantages that valuable mineral and gangue mineral are thoroughly separated, and the concentrate grade is high. The method is suitable for primary platinum ore and particularly suitable for low-sulfur, low-platinum and low-palladium primary platinum ore.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

The beneficiation method of tungsten polymetallic ore

InactiveCN103934113BIncrease floatability differenceRealize flotation separationFlotationFoaming agentCalcite

The invention discloses a beneficiation method for tungsten polymetallic ore. The beneficiation method comprises the following steps of (1) grinding the tungsten polymetallic ore to form powder, (2) adding the powder to magnetized water to form ore pulp, then, adding regulators, foaming agents and first collecting agents, feeding in air to form a first foam layer, obtaining tailings after removing the first foam layer, (3) adding first inhibitors, activators and second collecting agents to the tailings, feeding in air to form a second foam layer, collecting the second foam layer to obtain white tungsten rough concentrate, and (4) concentrating the white tungsten rough concentrate till the mass of the white tungsten rough concentrate ranges from 55% to 70% of the mass of the white tungsten rough concentrate before concentration, heating the white tungsten rough concentrate to the temperature which ranges from 85 DEG C to 95 DEG C, adding second inhibitors, feeding in air to generate a third foam layer, and collecting the third foam layer to obtain white tungsten concentrate. According to the beneficiation method for the tungsten polymetallic ore, the magnetized water is used in the technological process, difference between floatability of the white tungsten ore and floatability of calcium minerals can be increased, flotation separation of the white tungsten ore and the calcium minerals such as fluorite and calcite is achieved, and the recovery rate of the white tungsten ore is increased.

Owner:HUNAN YOUSE TECH DEV

Method for flotation separation of chalcopyrite and arsenopyrite in copper rough concentrate

The invention relates to a method for flotation separation of copper pyrites and arsenopyrite in copper rough concentrate, and belongs to the technical field of mineral processing. The mass percent concentration and pH of pulp of the copper rough concentrate are regulated, Na2S2O3, NH4Cl and CuSO4 are sequentially added to conduct conventional flotation to obtain a rough concentrate product, and the rough concentrate product is subjected to multiple times of concentration to obtain a final rough concentrate product. The method effectively eliminates the activation effect of copper ions to arsenopyrite, an AsO4NH4Cu-6H2O hydrophilic film generated after reaction prevent xanthic acid from being adsorbed on the surface of arsenopyrite. Meanwhile, a copper sulfide film is generated on the surface of copper pyrites, adsorption of xanthic acid on the surface of the copper pyrites is promoted, the hydrophobicity of the copper pyrites is improved, and thus the floatability difference between the copper pyrites and the arsenopyrite is improved.

Owner:KUNMING UNIV OF SCI & TECH

A kind of flotation method and pretreatment method of calcite-containing phosphate rock

ActiveCN111330744BReduce separation efficiencyEnhanced inhibitory effectFlotationPretreatment methodPhysical chemistry

The invention discloses a flotation pretreatment method for calcite-containing phosphate rock. In the method, a surface treatment agent and an inhibitor are added to calcite-containing phosphate rock pulp before flotation. The precipitate generated by the reaction between the surface treatment agent and calcite adheres to the surface to change its surface properties, and the inhibitor can be better adsorbed on the surface of calcite. The invention also discloses a flotation method for phosphate rock containing calcite. The method is to add a pH adjuster and a collector to the flotation pretreatment method of the phosphate rock containing calcite and then add a pH adjuster and a collector to stir and adjust the slurry. Carry out froth flotation to obtain rough concentrate, and after the rough concentrate is selected, high-grade phosphorus concentrate is obtained. The method of the invention is used to process phosphate rock with high calcite content, and has simple process, low cost and high recovery rate.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

A process for step-by-step production of high-grade molybdenum concentrate and ordinary molybdenum concentrate

ActiveCN107309074BIncrease floatability differenceFewer picksFlotationWet separationTotal recoveryMaterials science

The invention discloses a process for step-by-step production of high-grade molybdenum concentrates and ordinary molybdenum concentrates. The process comprises the following steps that 1, molybdenum crude ore is added with water and ground, and molybdenum ore pulp is obtained; 2, the molybdenum ore pulp is subjected to roughing, molybdenum rough concentrates and molybdenum rough tailings are obtained, the molybdenum rough concentrates or the molybdenum ore pulp is subjected to fast flotation, and fast flotation molybdenum rough concentrates and fast flotation molybdenum tailings are obtained; 3, the fast flotation molybdenum rough concentrates are subjected to two-stage regrinding and selection for five times, and the high-grade molybdenum concentrates where the grade of molybdenum is larger than 57% are obtained; 4, the fast flotation molybdenum tailings obtained through the molybdenum ore pulp are subjected to roughing, and molybdenum rough concentrates and molybdenum rough tailings are obtained; and 5, the fast flotation molybdenum tailings obtained through the molybdenum rough concentrates or the molybdenum rough concentrates in the step 4 are subjected to pre-selection at first and then subjected to two-stage regrinding, selection for eight times and scrubbing for one time, and molybdenum fine tailings and the ordinary molybdenum concentrates where the grade of molybdenum is 52%-55% are obtained. According to the process for step-by-step production of the high-grade molybdenum concentrates and the ordinary molybdenum concentrates, a differential flotation technology is utilized, the molybdenum concentrates of different grades are obtained, the number of selection is shortened, and the total recovery rate of the molybdenum concentrates is increased.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com