Production online flotation arsine-reduction method for high arsenic-containing copper concentrate

A technology of copper concentrate and flotation, which is applied in the direction of solid separation, etc., can solve the problems of large metal loss, increased sorting cost, and high labor intensity of copper concentrate, and achieves the reduction of arsenic content, treatment cost, and operating cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

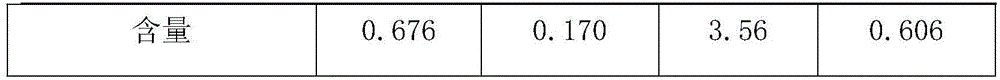

[0030] Yunnan Gejiu Yunxi Kafang Branch Co., Ltd. 600 tons / day tin, copper, sulfur and arsenic symbiotic polymetallic sulfide ore, and the copper concentrate production line of the symbiotic sulfide ore process reduces arsenic. The raw ore composition of the symbiotic sulfide ore is shown in Table 1:

[0031] Table 1. Multi-element analysis (%)

[0032] name Cu S As grade(%) 2.083 18.81 1.090

[0033] The production line flotation arsenic reduction method of this copper concentrate is as follows:

[0034] (1) Copper-sulfur-arsenic mixed flotation process is used to produce mixed flotation high-arsenic copper rough concentrate, and the tailings enter the gravity separation process; copper-sulfur-arsenic mixed flotation process includes roughing, secondary sweeping Separation and detinning flotation, the reagent system is as follows:

[0035] Rough selection: mixed base xanthate 120g / t, 2# oil 45g / t;

[0036] One sweep: mixed base xanthate 80g / t, 2#...

Embodiment 2

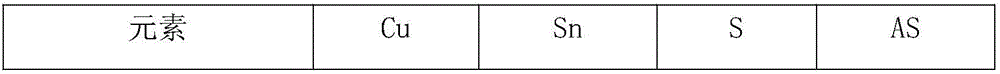

[0049] Yunnan Wenshan Hualian Zinc and Indium Co., Ltd. Tongjie Ore Concentrator Copper Street Concentrator Copper Concentrate Production Line Reduces Arsenic in Single Copper Sulfide Ore Process. The composition of single copper sulfide ore is shown in Table 3:

[0050] Table 3. Multi-element analysis (%)

[0051]

[0052]

[0053] The copper oxidation rate of the mine is as high as 24.95%.

[0054] The on-line flotation method for reducing arsenic in the production of this single copper sulfide ore is as follows:

[0055] (1) Copper-sulfur-arsenic mixed flotation process is used to produce mixed flotation high-arsenic copper rough concentrate, and the tailings enter the gravity separation process; copper-sulfur-arsenic mixed flotation process includes roughing, secondary sweeping Separation and detinning flotation, the reagent system is as follows:

[0056] Rough selection: mixed base xanthate 150g / t, 2# oil 60g / t;

[0057] One sweep: mixed base xanthate 60g / t, 2# o...

Embodiment 3

[0070] The production line flotation arsenic reduction method of high-arsenic copper concentrate has the following steps:

[0071] (1) Copper-sulfur-arsenic mixed flotation process is used to produce mixed flotation high-arsenic copper rough concentrate, and the tailings enter the gravity separation process; copper-sulfur-arsenic mixed flotation process includes roughing, secondary sweeping Separation and detinning flotation, the reagent system is as follows:

[0072] Rough selection: mixed base xanthate 60g / t, 2# oil 25g / t;

[0073] One sweep: mixed base xanthate 40g / t, 2# oil 20g / t;

[0074] Secondary sweeping: mixed base xanthate 25g / t, 2# oil 5g / t;

[0075] Detin flotation: blank;

[0076] (2) The high-arsenic copper coarse concentrate of mixed flotation is classified by long cone cyclone, and the small steel forging is finely ground, and the grinding fineness is r -200 Mesh>90%, grinding concentration is 45%; add lime 2000g / t, sodium humate 180g / t to the mill, keep th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com