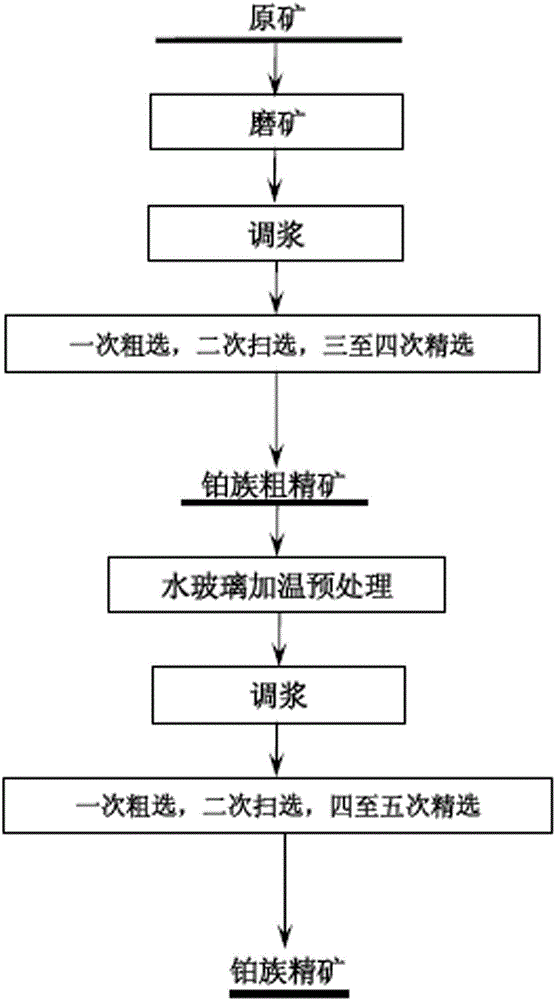

Primary platinum ore beneficiation method

A beneficiation method and original technology, applied in flotation, solid separation, etc., can solve the problems of good buoyancy, restricted utilization value, low grade of platinum group concentrate, etc., to expand the difference in floatability, easy to mix with water glass Function, the effect of strong hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The raw ore is a primary platinum mine in Inner Mongolia, China.

[0025] (1) Grind the raw ore to -0.074mm to account for 80%, add water to adjust the slurry to a pulp concentration of 27%, add 2000g / t of sodium carbonate based on the weight of the ore, stir for 3 minutes, carboxymethyl cellulose 500g / t, Stir for 3 minutes, 240g / t butyl xanthate, stir for 2 minutes, 30g / t terpineol oil, stir for 1 minute, do rough selection; add 60g / t butyl xanthate, stir for 2 minutes, 10g / t terpineol oil, stir 1 minute, do a sweep; add 40g / t of butyl xanthate, stir for 2 minutes, pine oil 10g / t, stir for 1 minute, do a second sweep; add carboxymethyl cellulose 100g / t, stir for 3 minutes , carry out a beneficiation, add carboxymethyl cellulose 60g / t, stir for 3 minutes, carry out a second beneficiation, and obtain platinum group crude concentrate;

[0026] (2) Concentrate the platinum group rough concentrate to a slurry concentration of 45%, add water glass 100Kg / t based on the weigh...

Embodiment 2

[0029] The original ore is a primary platinum mine in a certain place in Heilongjiang, China.

[0030] (1) Grind the raw ore to -0.074mm to account for 75%, add water to adjust the pulp to a pulp concentration of 30%, add sodium carbonate 1000g / t, stir for 3 minutes, and water glass 2000g / t, stir for 3 minutes , 300g / t of butyl xanthate, stirred for 2 minutes, 30g / t of terpineol oil, stirred for 1 minute, and made rough selection; added 80g / t of butyl xanthate, stirred for 2 minutes, 10g / t of terpineol oil, stirred for 1 minute, Do a sweep; add 60g / t of butyl xanthate, stir for 2 minutes, 10g / t terpineol oil, stir for 1 minute, and do a second sweep; add 800g / t of water glass, stir for 3 minutes, and perform a sweep; Add 600g / t of water glass, stir for 3 minutes, and carry out second beneficiation; add 400g / t of water glass, stir for 3 minutes, and carry out three beneficiation to obtain rough concentrate;

[0031] (2) Concentrate the rough concentrate to a pulp concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com