A kind of beneficiation method for recovering molybdenum from tungsten-tin associated sulfide ore mixed concentrate

A technology of mixed concentrate and ore dressing method, which is applied in flotation, solid separation, etc., can solve the problems of high input cost, large environmental impact, and complicated molybdenum recovery process, and achieve complete drug removal, small dosage, and expanded floatability difference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The ore feed is the mixed concentrate of tin-associated sulfide ore obtained from a tin ore-associated polymetallic sulfide ore after several flotation operations, in which the molybdenum grade is 1.28%.

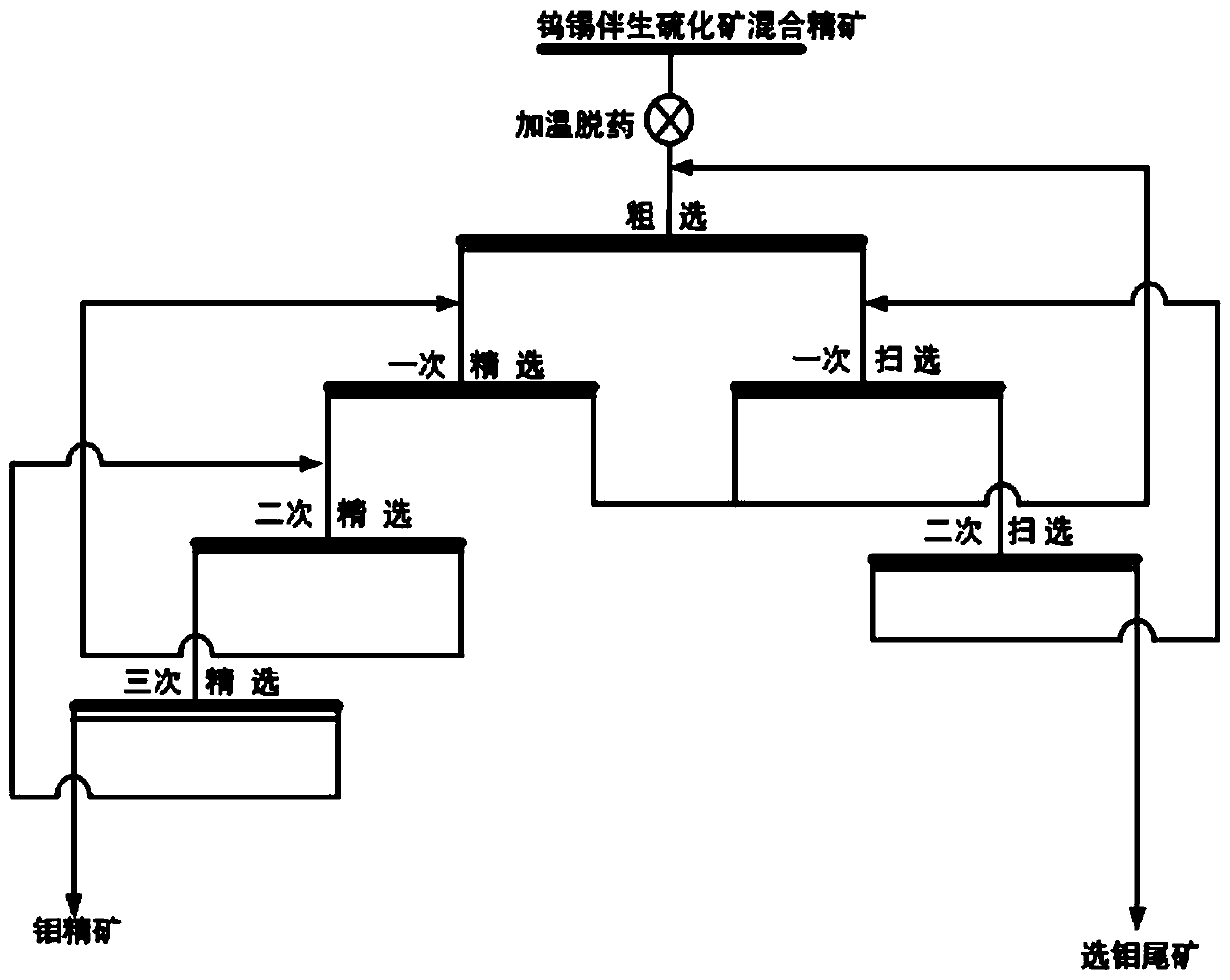

[0032]Stir and heat the mixed concentrate with a concentration of 50% at 90°C for 90 minutes, add water to the mixed concentrate of sulfide ore after heating and demedication to adjust the pulp concentration to 34%, add quicklime to adjust the pH of the pulp to 12, and stir for 3 minutes Add sodium humate 200g / t and starch 200g / t, stir for 3 minutes, add kerosene 110g / t, stir for 2 minutes, carry out a roughing operation, obtain a roughing concentrate and a roughing tailings; Add kerosene 40 / t to the dressing tailings, stir for 2 minutes, and do a sweep to obtain a sweep concentrate and a sweep tailing; a sweep concentrate enters a rougher; in a sweep tailings Add 20g / t of kerosene, stir for 2 minutes, and do the second scavenging to obtain the second scavenging conce...

Embodiment 2

[0034] The ore feed is a mixed concentrate of tungsten-associated sulfide ore obtained from a tungsten ore-associated polymetallic sulfide ore after several flotation operations, in which the molybdenum grade is 0.95%.

[0035] Stir and heat the mixed concentrate with a concentration of 60% at 80°C for 100 minutes, add water to the mixed concentrate of sulfide ore after heating and demedication to adjust the pulp concentration to 35%, add quicklime to adjust the pH of the pulp to 12.5, and stir for 3 minutes Add dextrin 450g / t and stir for 3 minutes; add diesel oil 150g / t and stir for 2 minutes to perform a roughing operation to obtain a roughing concentrate and a roughing tailings; add diesel oil to the roughing tailings 50 / t, stirring for 2 minutes; do a sweep to get a sweep concentrate and a sweep tailings; a sweep concentrate enters a rough separation; add diesel oil 30g / t to a sweep tailings, Stir for 2 minutes; do secondary sweeping to obtain secondary sweeping concentra...

Embodiment 3

[0037] The ore feed is a tungsten-associated sulfide ore mixed concentrate obtained from a tungsten ore-associated polymetallic sulfide ore through mixed flotation operations, in which the molybdenum grade is 0.82%.

[0038] Stir and heat the mixed concentrate with a concentration of 55% at 90°C for 60 minutes, add water to the mixed concentrate of sulfide ore after heating and demedication to adjust the slurry to 33%, add quicklime to adjust the pH of the slurry to 12, stir for 3 minutes, add 200g / t of carboxymethyl cellulose and 250g / t of sodium humate, stirred for 3 minutes, added 120g / t of kerosene, stirred for 2 minutes, and carried out a roughing operation to obtain a roughing concentrate and a roughing tailing; Add 45 / t of kerosene to the tailings of the first roughing, stir for 2 minutes, and do a sweep to obtain the concentrate of the first sweep and the tailings of the first sweep; the concentrate of the first sweep enters the first rougher; Add 30g / t of kerosene to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com