Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Increase age intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

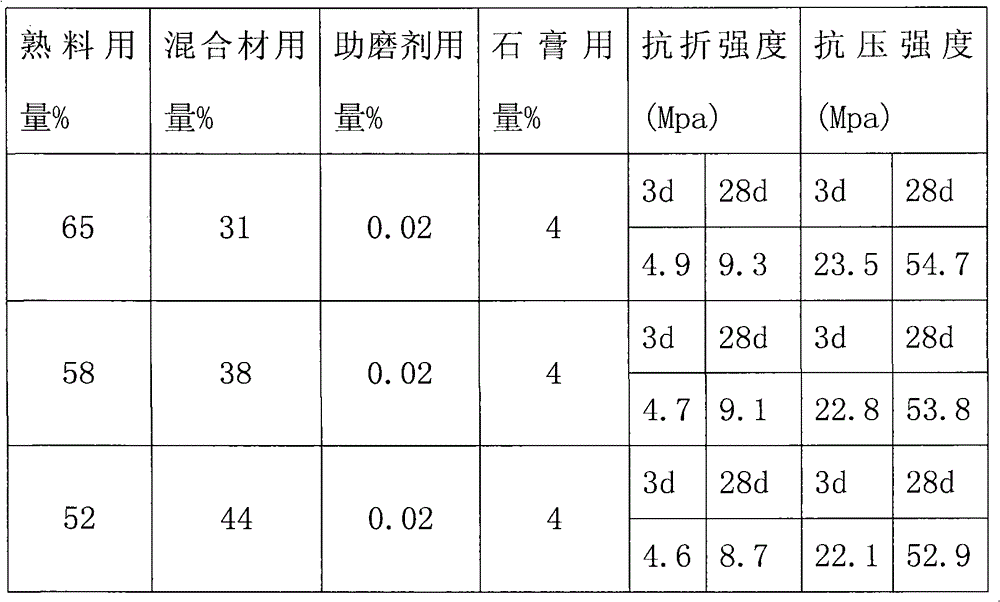

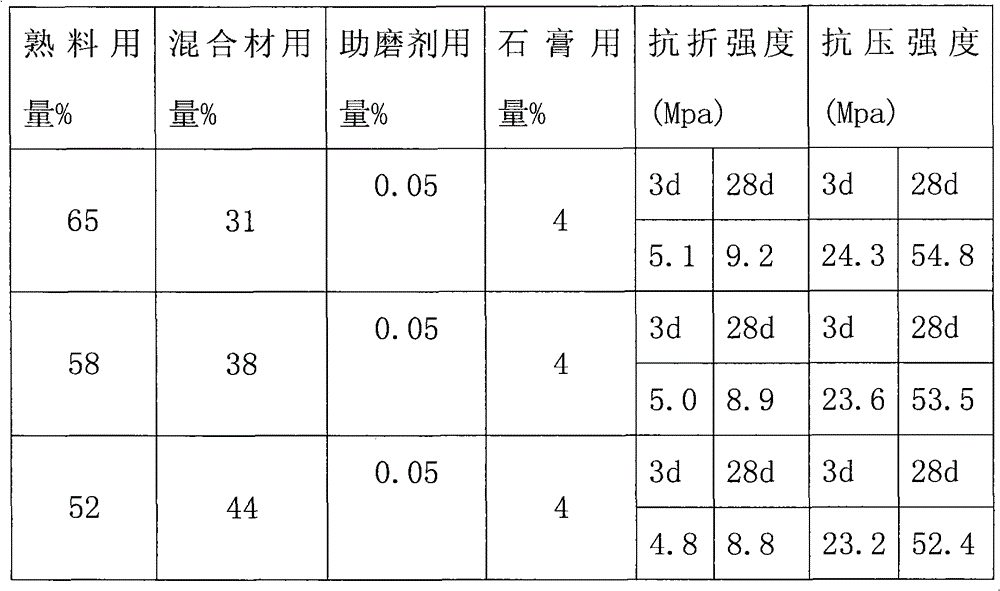

Silicate cement grinding aid and preparation method thereof

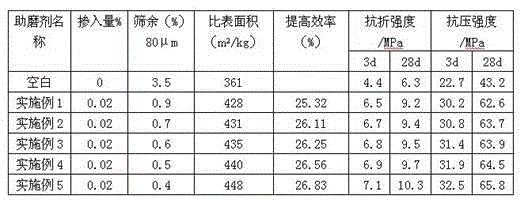

The invention discloses a silicate cement grinding aid and a preparation method thereof. The silicate cement grinding aid is prepared from the following main raw materials by weight: 3-6 parts of sodium hexametaphosphate, 2-5 parts of aluminum sulfate, 5-8 parts of tetra sodium salt of amino trimethylene phosphonic acid (ATMP.Na4), 4-6 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 38-45 parts of polymeric alkylol amine, 34-42 parts of triisopropanolamine, 8-12 parts of waste engine oil, 2-5 parts of sodium alpha-olefin sulfonate, 10-16 parts of sorbitol, 15-20 parts of diethylene glycol, 8-13 parts of polypropylene wax, 6-10 parts of oxidized polyethlene wax, 4-8 parts of lignite wax, 20-30 parts of odium thiosulfate, 12-18 parts of sodium thiosulfate and 15-20 parts of quicklime powder. The prepared silicate cement grinding aid has the advantages that the quality is stable, the effect is remarkable, the adding amount is small, the use is simple, and the adding is more convenient and reliable to control.

Owner:王金奎

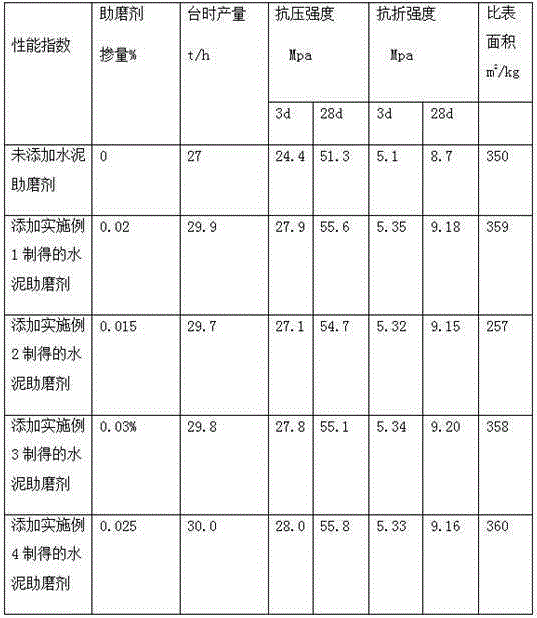

Cement grinding aid and preparation method thereof

The invention relates to a cement grinding aid, in particular to a cement grinding aid and a preparation method thereof. The cement grinding aid is prepared from, by weight, 13-18 parts of polymeric polylol, 8-12 parts of tri-isopropanolamine, 12-15 parts of polyol ether, 15-20 parts of ethanediol, 25-30 parts of triethanolamine, 15-18 parts of molasses, 13-15 parts of lignin, 0.03-0.06 part of sodium chloride, 0.5-1 part of silane coupling agents and 40-45 parts of water. By means of the obtained cement grinding aid, in the cement production process, the phenomena of clinker fine particle aggregation and ball pasting can be effectively improved, mobility of clinker particles is enhanced, thereby the pulverization effect of grinding media in a grinding machine for materials is enhanced, grinding efficiency can be improved by 15-20%, the cement machine-hour yield is increased, electricity consumption is greatly lowered, production cost is lowered, in addition, strength of cement at different ages can be remarkably improved, and flowability of the cement is improved.

Owner:内蒙古同佳技术发展有限公司

Ecotypic cementing material

ActiveCN102515588AIncreases hydration activityImprove grinding efficiencyCement productionSodium metasilicateBrick

The invention relates to an ecotypic cementing material, which comprises the components of: 40-60 parts of building waste brick powder, 15-30 parts of slag, 10-20 parts of steel plant semi-dry sintering flue gas desulfurization ash, and 10-15 parts of a composite grinding aid activator, which is prepared by raw materials in the following weight ratio: 70-85 parts of calcination modified desulfurization gypsum, 5-10 parts of sodium metasilicate pentahydrate, 5-10 parts of sodium aluminate, 1-5 parts of a naphthalene-based water reducer, 0.1-0.5 part of triethanolamine, 0.05-0.1 part of potassium humate, and 0.05-0.1 part of glycerol. The cementing material of the invention utilizes the synergetic and complementary effects of component materials, realizes resource utilization of building waste brick powder and semi-dry desulphurization ash as well as other solid wastes, thus making waste profitable.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

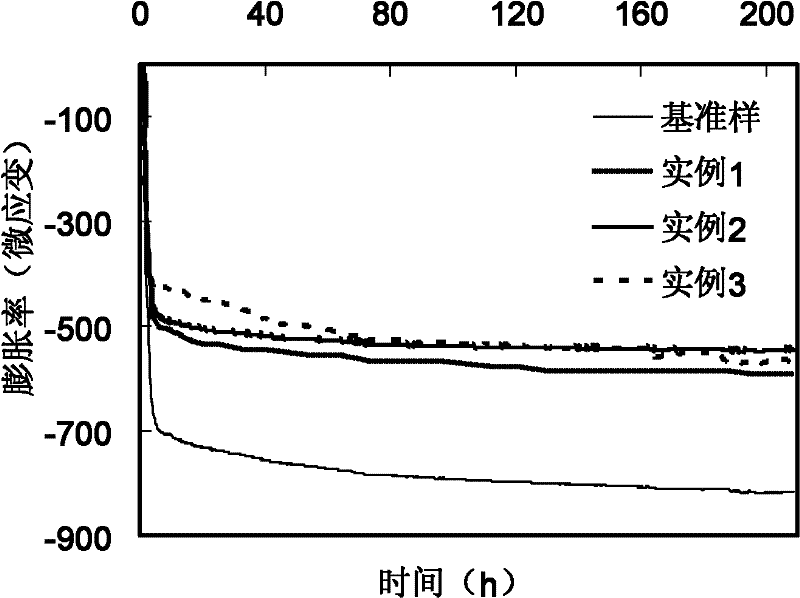

Modified metakaolin-based permeation-resistant and crack-resistant agent for concrete

The invention discloses a modified metakaolin-based permeation-resistant and crack-resistant agent for concrete. The modified metakaolin-based permeation-resistant and crack-resistant agent for concrete comprises: by mass, 10 to 75% of modified metakaolin, 5 to 40% of fine limestone powder, 4 to 40% of superfine coal ash, 1 to 20% of calcined hydrotalcite, 2 to 40% of fine quartz sand and 0.2 to 20% of solid silane powder. A preparation method of the modified metakaolin comprises the following steps of putting dry and washed kaolin into a bowl mill, carrying out grinding to obtain kaolin powder, carrying out calcination of the kaolin powder at a temperature of 500 to 1000 DEG C for 0.5 to 6.0 hours to obtain metakaolin, putting the metakaolin into a dispersion machine, adding an organic modifier of sulfamate or triethanolamine into the metakaolin, wherein a mass ratio of the metakaolin and the organic modifier is in a range of (5000: 1) to (100: 1), and carrying out dispersion to obtain the modified metakaolin having a contact angle of 50 to 100 degrees and a specific surface area of 8000 to 15000m<2> / kg. The modified metakaolin-based permeation-resistant and crack-resistant agentfor concrete can be utilized as a concrete additive, improves strength of concrete at different ages, does not produce obvious influences on concrete work performances, obviously improves anti-chloride ion penetration capability of concrete, reduces total shrinkage of concrete and improves crack resistance of concrete.

Owner:WUHAN UNIV OF TECH +1

New ultrafine sand concrete

ActiveCN102093001AReduce internal defectsImprove structural featuresSolid waste managementWater reducerFiber

The invention discloses new ultrafine sand concrete. The new ultrafine sand concrete comprises the following components in parts by weight: 1.3 parts of cementing material, 1.5 parts of fine aggregate, 4 parts of coarse aggregate, 0.01 part of high efficiency water reducing agent and 0.32 part of water. The ultrafine sand concrete also contains expanding agent, water reducing agent, grinding aid, surfactant and reinforced fiber. By adopting the coordination of various components, particularly adding the reinforced fiber in the ultrafine sand concrete disclosed by the invention, the technical defect of the prior art that concrete is easy to crack can be overcome, the anti-seepage function of concrete can be enhanced and the cracking of concrete can be inhibited.

Owner:CHONGQING CONSTR ENG MUNICIPAL TRAFFIC ENG

Multifunction anti-crack water-proof agent for concrete and preparation method

A multifunctional anti-cracking water-proofing agent for improving the flowability and slump of concrete, increasing the strength, impervious performance and compactness of solidified concrete, and decreasing the consumption of water is prepared proportionally from high-concentration naphthelene-series efficient water reducing agent, sodium laurylsulfate, sodium gluconate, hydroxypropyl methylcellulose, vinyl acetate-ethene copolymer emulsion and water through sequential mixing and stirring.

Owner:李建红

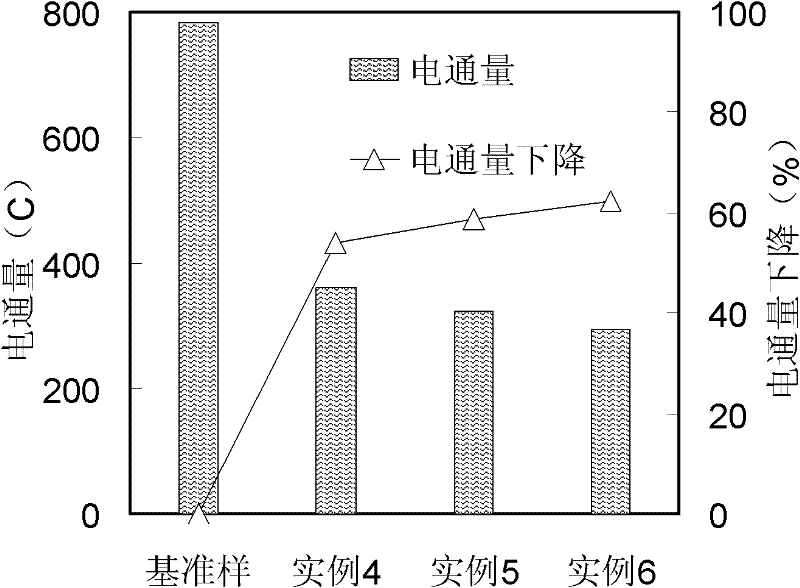

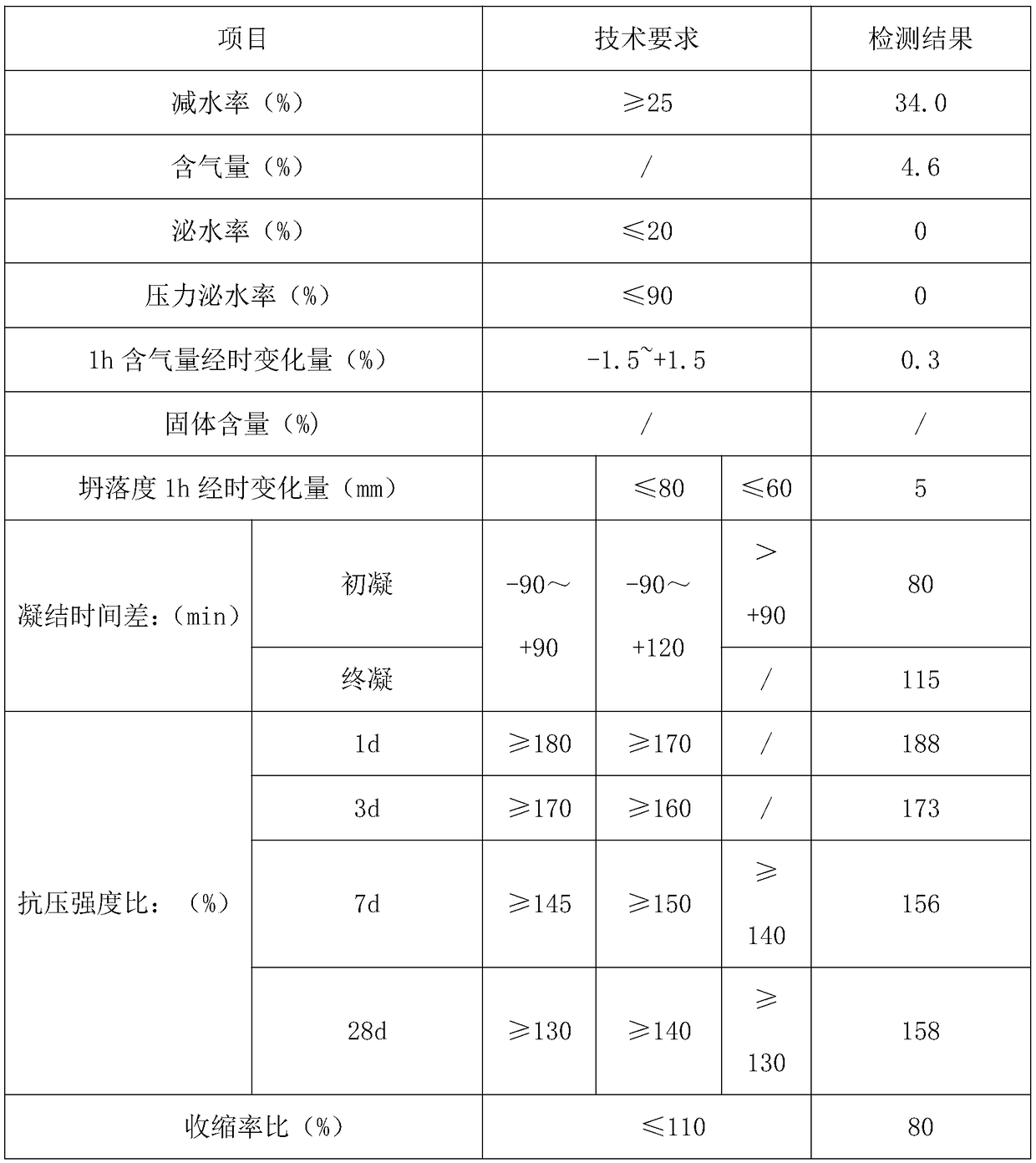

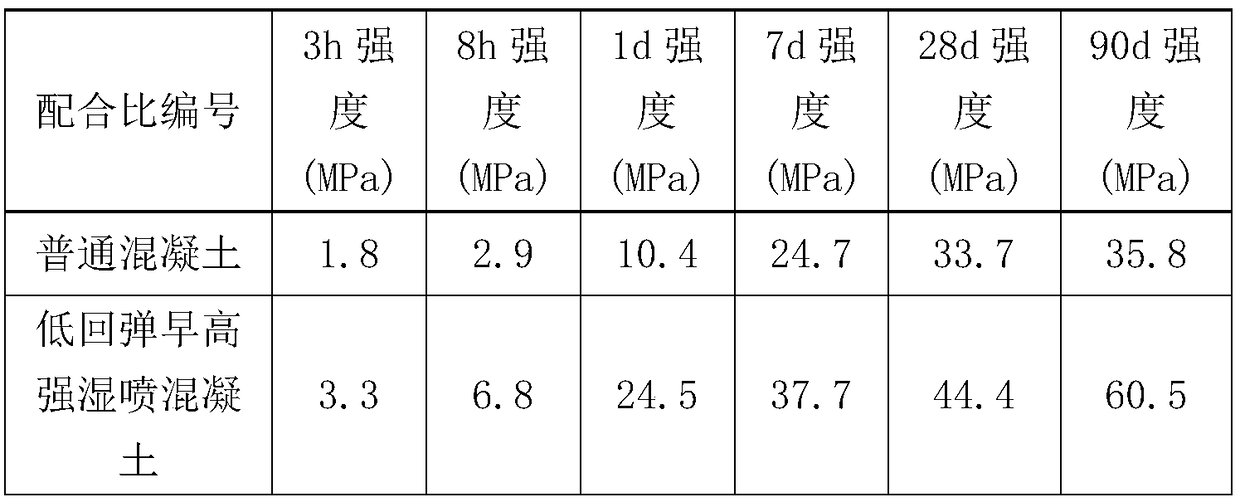

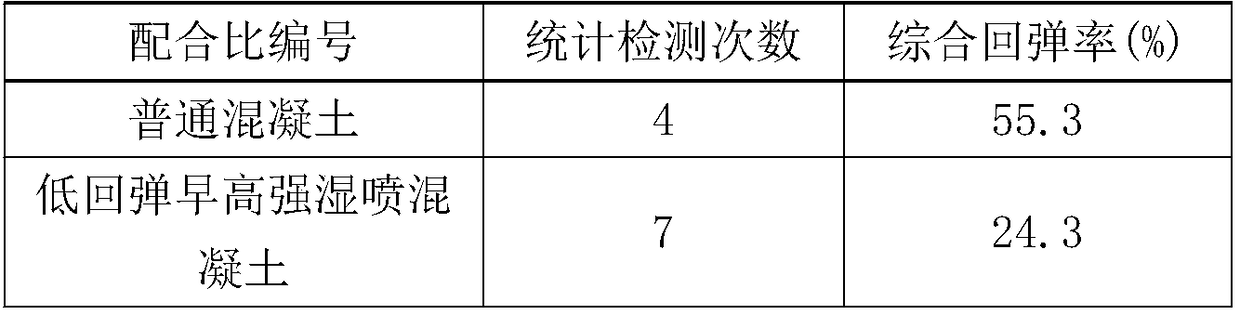

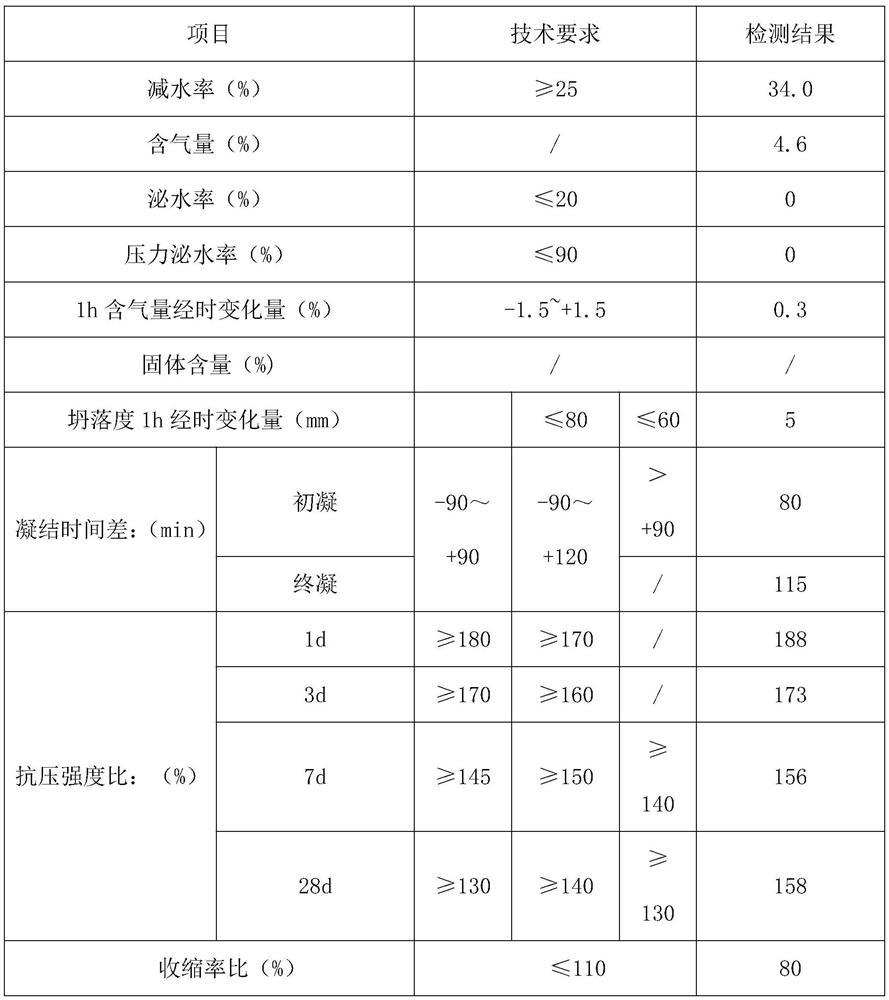

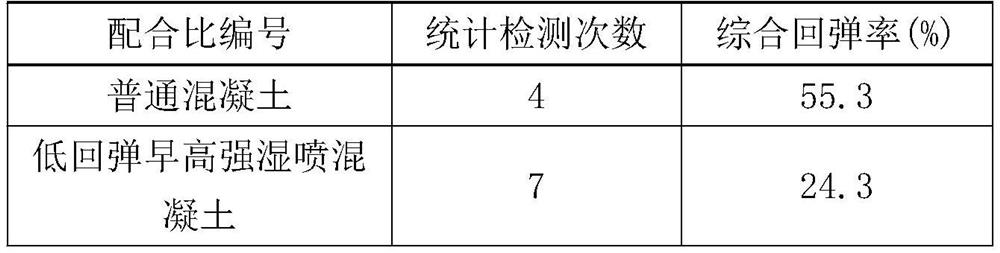

Low-resilience, early-strength and high-strength wet-spraying concrete and application thereof

The invention relates to the field of building materials and in particular provides low-resilience, early-strength and high-strength wet-spraying concrete and application thereof. The low-resilience,early-strength and high-strength wet-spraying concrete is prepared from the following raw materials in parts by weight: 380 to 500 parts of cement, 800 to 1000 parts of sand, 650 to 800 parts of crushed stone, 10 to 30 parts of a setting accelerator, 160 to 200 parts of water, 20 to 30 parts of a high-strength ultra-micro additive and 40 to 50 parts of fly ash. According to the low-resilience, early-strength and high-strength wet-spraying concrete prepared by the invention, the binding force is greatly improved and the resilience rate of the concrete is reduced; the concrete can be normally sprayed in a water-rich region and a result reaches the advanced level in China; the low-resilience, early-strength and high-strength wet-spraying concrete can be directly applied to primary supportingconstruction of tunnels and a novel technical way is explored for the primary supporting construction of the tunnels.

Owner:TRANSTECH ENG CORP

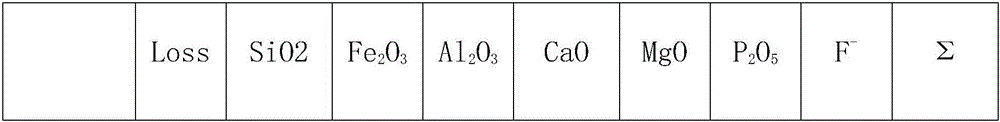

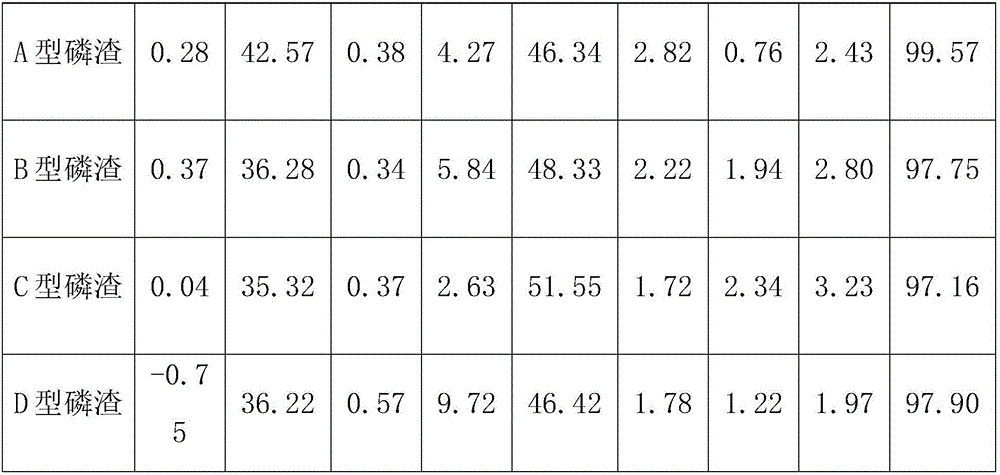

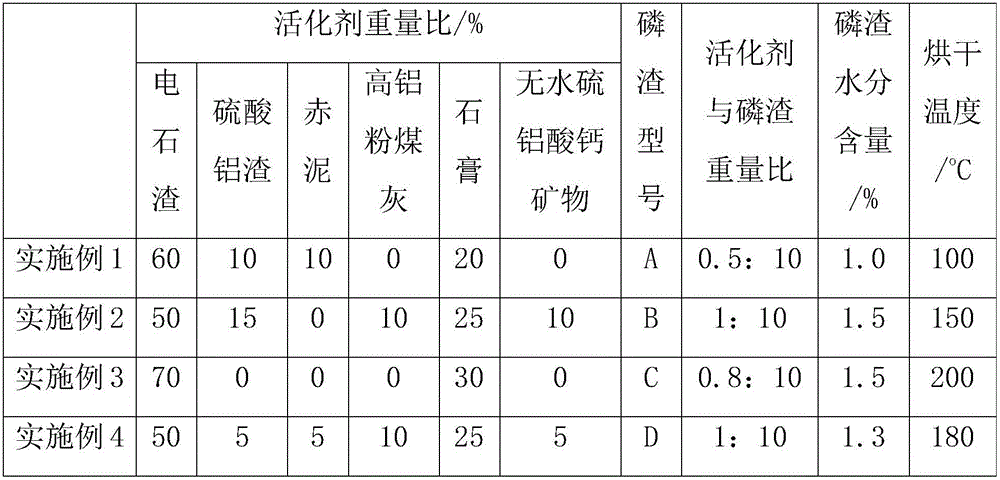

Modified and activated phosphorus slag, preparation method and modified and activated phosphorus slag cement and concrete

ActiveCN106477931AShorten the setting timeHigh strengthCement productionAluminium saltsAdverse effect

The invention relates to modified and activated phosphorus slag, a preparation method and modified and activated phosphorus slag cement and concrete. The modified and activated phosphorus slag consists of an activating agent and phosphorus slag in mass ratio of (0.5-1):10; the moisture in the phosphorus slag is less than 2% of the weight of the phosphorus slag; and the activating agent consist of the following components in parts by weight: 50-70 parts of carbide slag, 0-40 parts of aluminum sulfate slag, 0-40 parts of red mud, 0-30 parts of high-aluminum fly ash, 20-30 parts of gypsum and 0-30 parts of anhydrous calcium sulphoaluminate mineral. The modified and activated phosphorus slag eliminates the influence of harmful ingredients in the phosphorus slag on the properties of cement and concrete, shortens the cement setting time and improves the cement intensity, and simultaneously improves the intensity of concrete at each age, and the drying shrinkage rate at each age is less than the drying shrinkage rate of slag powder. The activating agents used for modifying and activating the phosphorus slag are various industrial residues and do not contain chemi-excitation reagents, have no adverse effects on the service performance, endurance quality and the like of cement and concrete, enable application of high phosphorus slag content in cement and concrete, and achieve the purpose of changing waste into valuable.

Owner:CHINA BUILDING MATERIALS ACAD

Grouting material for rock mass cracks of rock caves and preparation method therefor

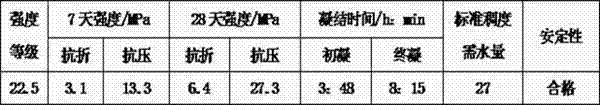

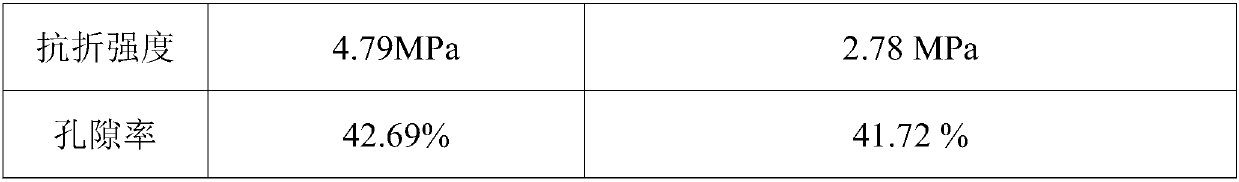

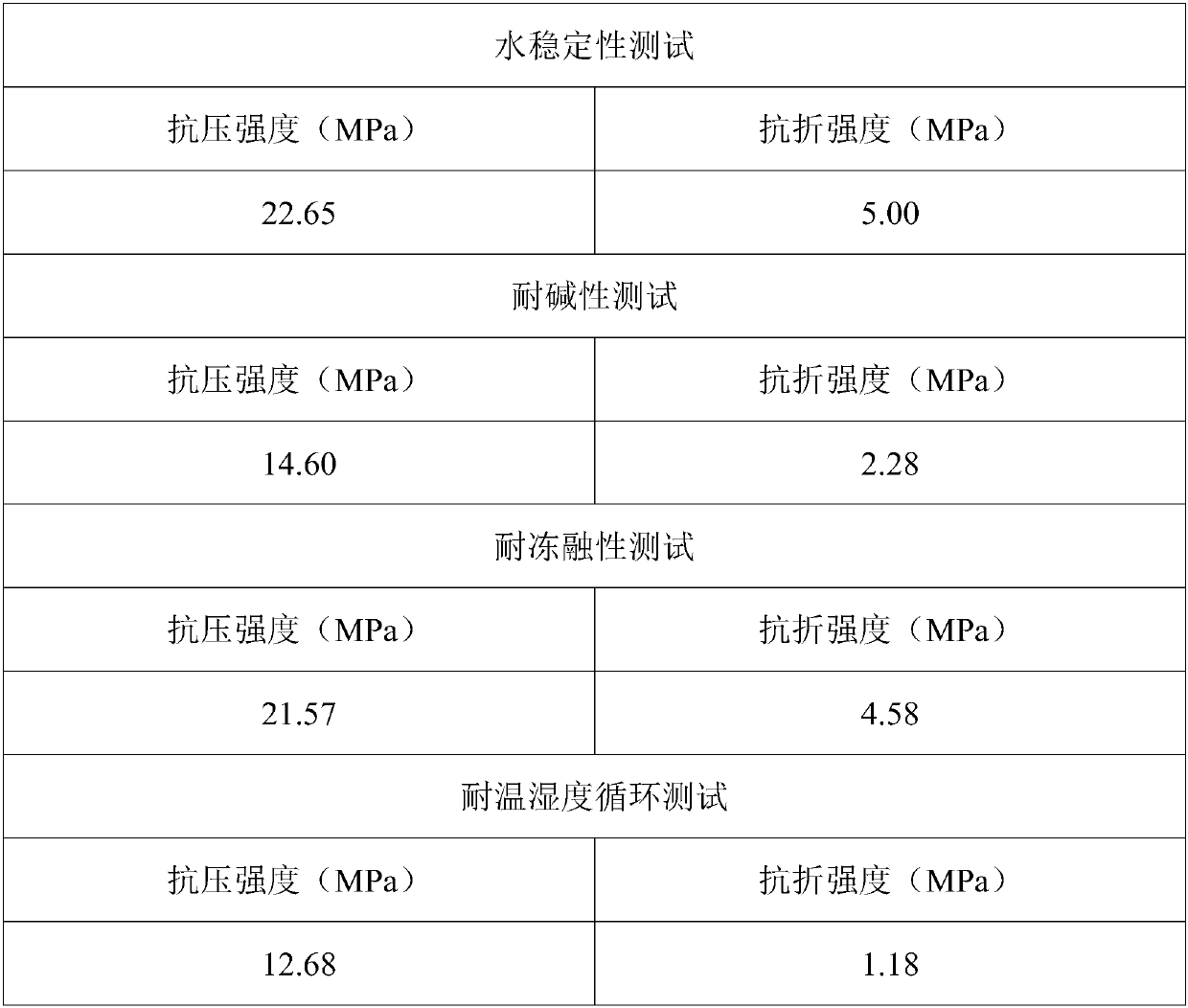

The invention relates to a grouting material for rock mass cracks of rock caves and a preparation method therefor. The method comprises the steps: a. mixing hydraulic-activity oyster dust, silica sandand metakaolin which are in the mass ratio of 4: 5: 1; b. adding an expanding agent AEA, of which the weight accounts for 5% of total mass, into the mixture, and carrying out uniform stirring in a stirrer; and c. stirring the mixed powder for 20 minutes for later use by a water-cement ratio of 0.37. According to the grouting material, slurry of a reinforcement material has an initial setting timeof about 275min and a final setting time of about 9 hours, the set shrinking percentage of the slurry is lower than 0.08%, the average porosity is 43.95%, the compressive strength in 50 days is not lower than 24MPa, the folding strength is not lower than 5.5MPa, and the compressive strength of 18 freeze-thaw cycles is 25.94MPa. More choices are provided for solving the problem of crack grouting of cave temples.

Owner:中国文化遗产研究院 +1

Liquid cement grinding aid with low alcohol amine content and preparation method of liquid cement grinding aid

The invention discloses a liquid cement grinding aid with low alcohol amine content and a preparation method of the liquid cement grinding aid. The liquid cement grinding aid is formed by waste molasses, sodium lignosulphonate, sodium formate, triethanolamine, sodium alkyl benzene sulfonate, silicone defoamer, polycarboxylic acid water reducer and water through mixing. The liquid cement grinding aid comprises the following components by weight: 18-25% of the waste molasses, 8-12% of the sodium lignosulphonate, 5-6% of the sodium formate, 6-10% of the triethanolamine, 1-4% of surface active agent, 8-10% of polycarboxylic acid water reducer, and the balance of water. In the product, the alcohol amine content is reduced, industrial waste liquid or regenerant waste molasses and the sodium lignosulphonate are used, resources are reasonably used, a proper amount of the sodium alkyl benzene sulfonate is added at the same time so as to be beneficial for the dispersion of the grinding aid, andtherefore, the grinding aid effect of the product is good, the output of one machine can be obviously improved, and the later strength of cement can be improved.

Owner:云浮市裕隆水泥助磨剂科技发展有限公司

Composite concrete grinding-assistant reinforcing agent

InactiveCN101948268AGood stabilityOptimizing cement fineness gradationCement productionChlorine.freeCalcium formate

The invention discloses a composite concrete grinding-assistant reinforcing agent which is prepared by using the following methods: adding 500kg of polycarboxylic acid copolymer, 90kg of triisopropanolamine, 100kg of triethanolamine, 40kg of propanediol and 70kg of glycol into a reaction container; heating to 50-60 DEG C; stirring for 0.5-1.5 hours to uniformly mix to prepare a mixture No.1; adding 50kg of esterifying agent, 250kg of carbamide, 180kg of calcium formate and 20kg of adjusting solidification agent into 700kg of water; fully stirring for 0.5-1.0 hour at 50 DEG C-60 DEG C to prepare a mixture No.2; and keeping the temperature of the mixture No.1 at 50 DEG C-60 DEG C, slowly pouring the mixture No.2 into the No.1 mixture while stirring; fully stirring for 0.5-1.5 hours to obtain the composite concrete grinding-assistant reinforcing agent which is brown liquid and hardly precipitates. The invention has the advantages of favorable stability performance, no influence on cement condensation time, electricity saving, chlorine free, enhancement, simple use, low doping content, small investment and the like, improves output table yield of the cement by 15 percent to 30 percent and improves the age strength of the cement.

Owner:衡阳市银利实业有限公司

Titanium slag-based solid waste cementing material and preparation method thereof

The invention discloses a titanium slag-based solid waste cementing material and a preparation method thereof. The titanium slag-based solid waste cementing material comprises the following raw materials by weight: 70-80% of a titanium slag-based material, 15-25% of gypsum, and 2.5-7.5% of cement clinker. The preparation method is simple, and the used materials are subjected to separate or mixed grinding according to different types of grindability differences, and then are mixed and stirred. In the raw materials, the titanium-containing slag-based material is used as a main component and is matched with the cement clinker and the gypsum to form the gel material, so that effective comprehensive utilization of a large amount of high-titanium-containing slag and industrial byproduct gypsum resources produced by iron and steel enterprises in Panzhihua, Leshan sand bay and the like in the southwest region can be realized, most of conventional engineering applications can be met, and the material can also be used in a construction environment with rich tunnel terrestrial heat.

Owner:JIAHUA SPECIAL CEMENT

Ultrafine inorganic grouting material for tunnel inverted arches, and preparation method thereof

ActiveCN109020419AGuaranteed mechanical propertiesImprove early strengthWater reducerMaterials science

The invention discloses an ultrafine inorganic grouting material for tunnel inverted arches. The grouting material comprises, by mass, 75-90% of an ultrafine cementing material, 5-20% of a mineral filler, 2.5-7.5% of a composite expansion agent, 0.04-0.08% of a fluid volume stabilizer, 0.5-1.5% of a film forming modifier, 0.4-0.8% of a water reducer, 0.02-0.05% of a defoamer, 0.1-0.4% of a dispersant, 0.05-0.1% of an anti-seepage water repellent and 1-5% of a nano-reinforcing component. Above components are uniformly mixed, water is added according to a water-cement ratio of 0.25-0.30, and stirring is performed to obtain the grouting material which can be used for grouting reinforcement portions and defect parts of the tunnel inverted arches. The inorganic grouting material obtained in theinvention is suitable for repairing and stabilizing defects and dangerous rock bodies of tunnel inverted arches at 5-35 DEG C, has the advantages of high fluidity, high bonding strength, no shrinkage, good impermeability and good durability, and is suitable for being promoted and applied.

Owner:HUBEI UNIV

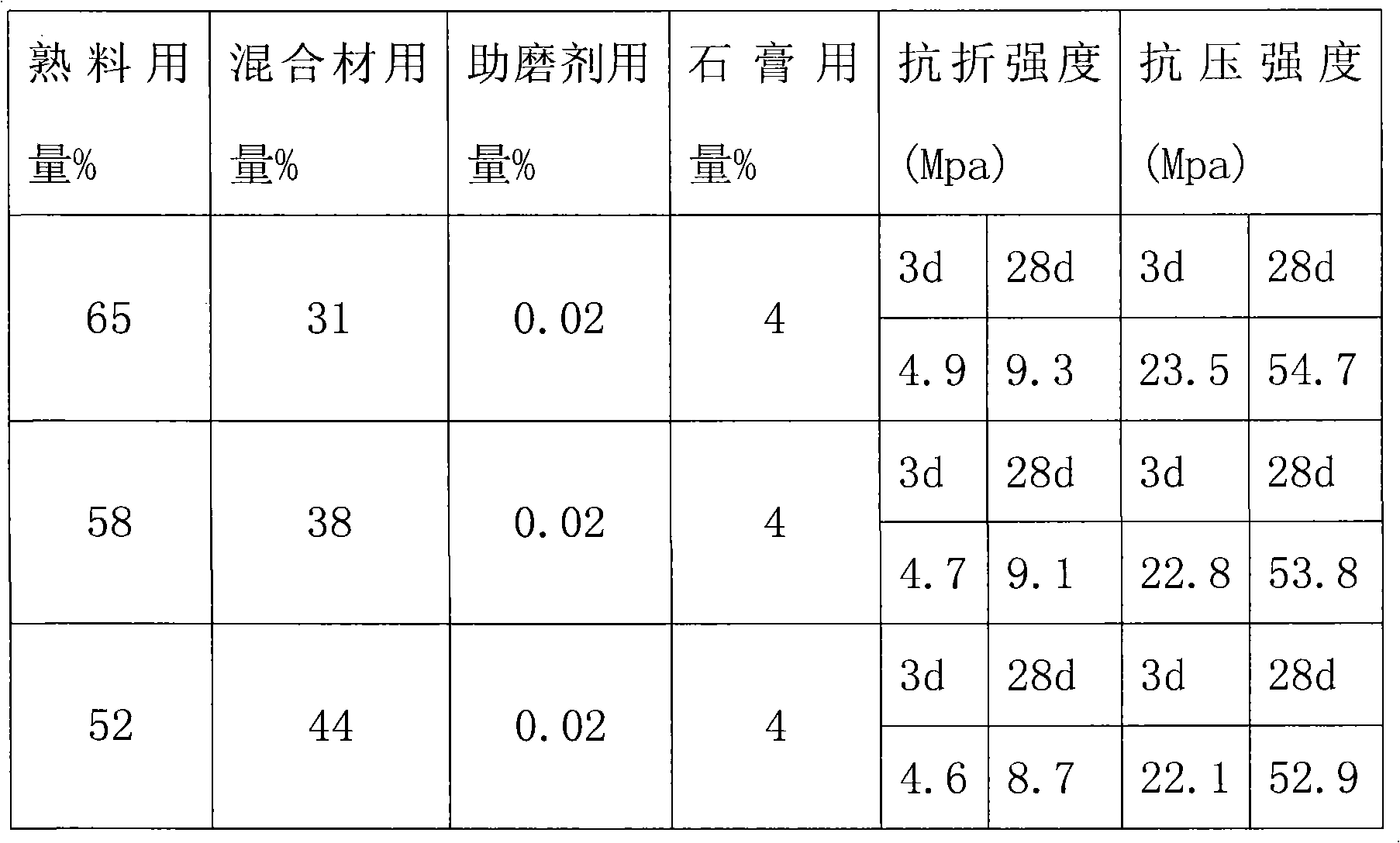

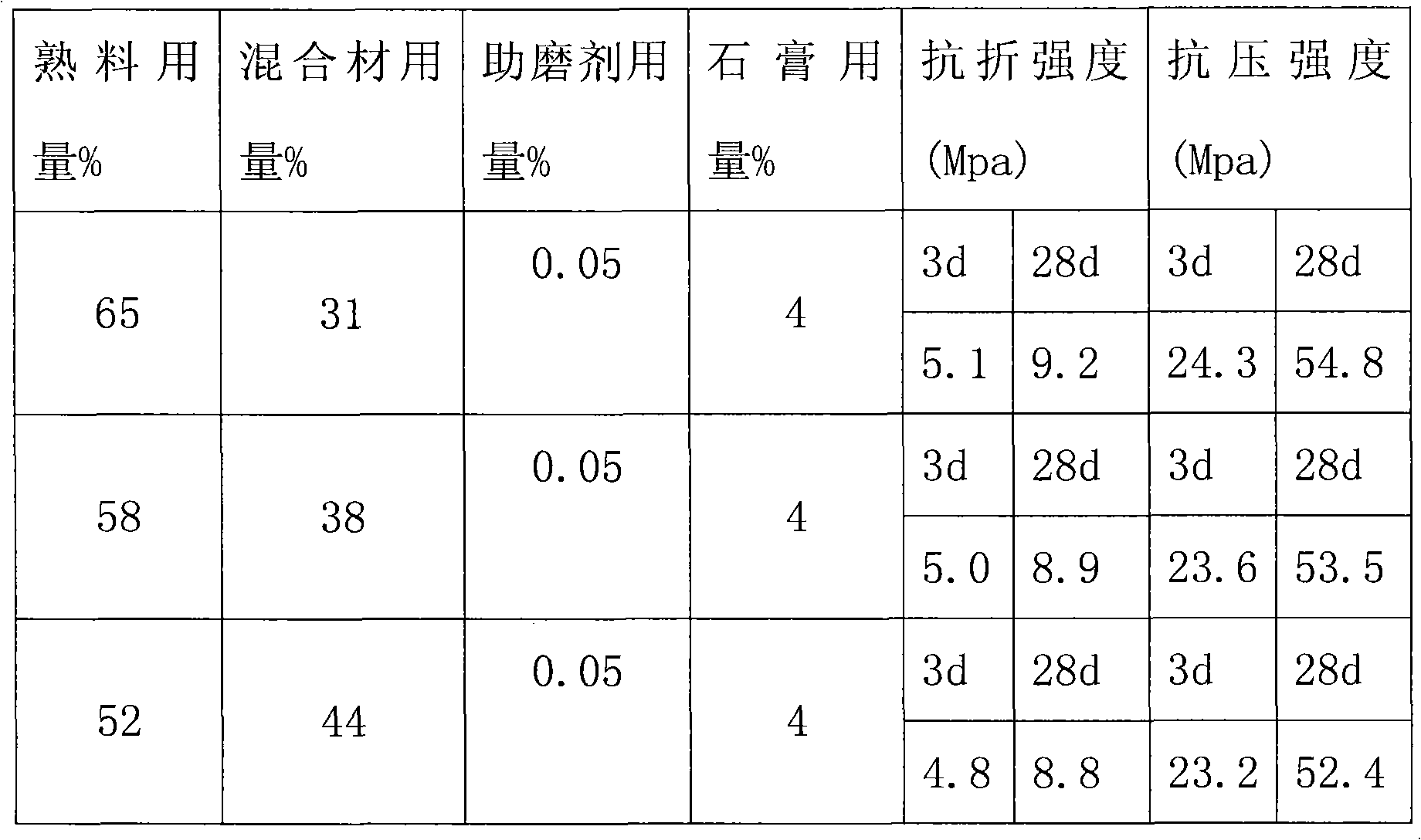

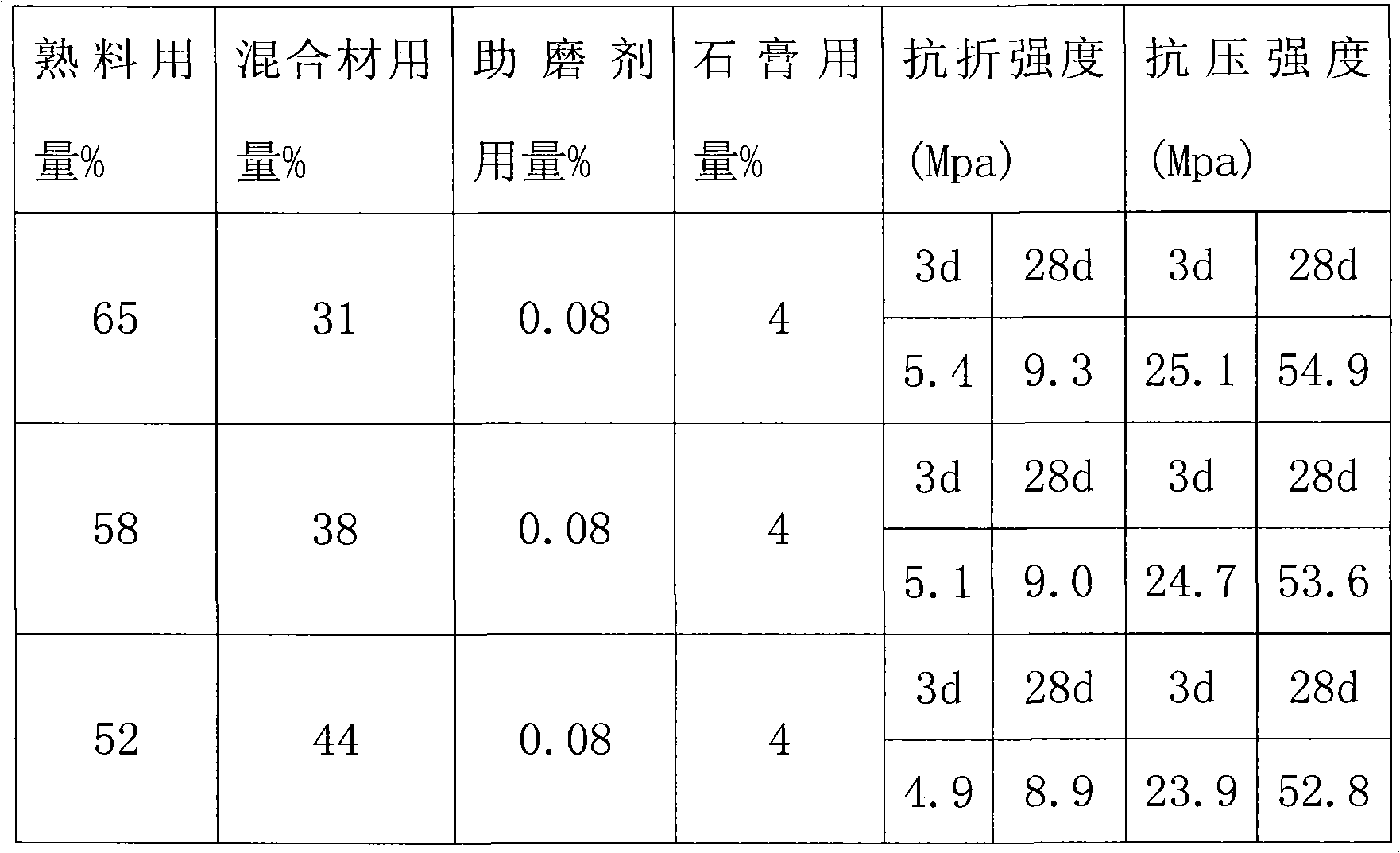

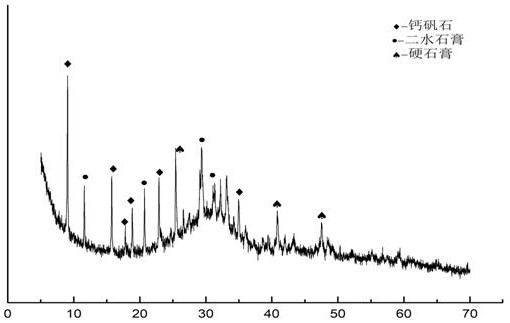

General portland cement modifying agent containing high cementing property mineral* and application method thereof

The invention relates to a general portland cement modifying agent containing high cementing property mineral and an application method thereof. The modifying agent is formed by reasonably designing ingredient minerals by using waste residues with high aluminum content and natural or industrial by-product plaster as well as natural limestone as raw materials, the modifying agent is calcined for 15-60 min at 1250-1350 DEG C to prepare a modifying agent clinker; and the modifying agent clinker is added into the plaster to prepare the general portland cement modifying agent with higher mineral content. The application method comprises the steps of: doping the modifying agent clinker or the modifying agent into the general portland cement in the proper proportion to replace a part of clinkers to play a role in quick hydration of early strength minerals and excitation function to mixed materials, such as slag, flyash and the like, so as to form more hydration products, such as ettringite, alumina gel and the like and regulate the category and the proportion of the portland cement hydration product. The invention solves the problems of narrow coexistence temperature of C3S and minerals and non-matching of the temperature, and guarantees the effective utilization of the high cementing property mineral with early strength property to achieve the aims of improving the general portland cement performance and reducing the production cost.

Owner:UNIV OF JINAN

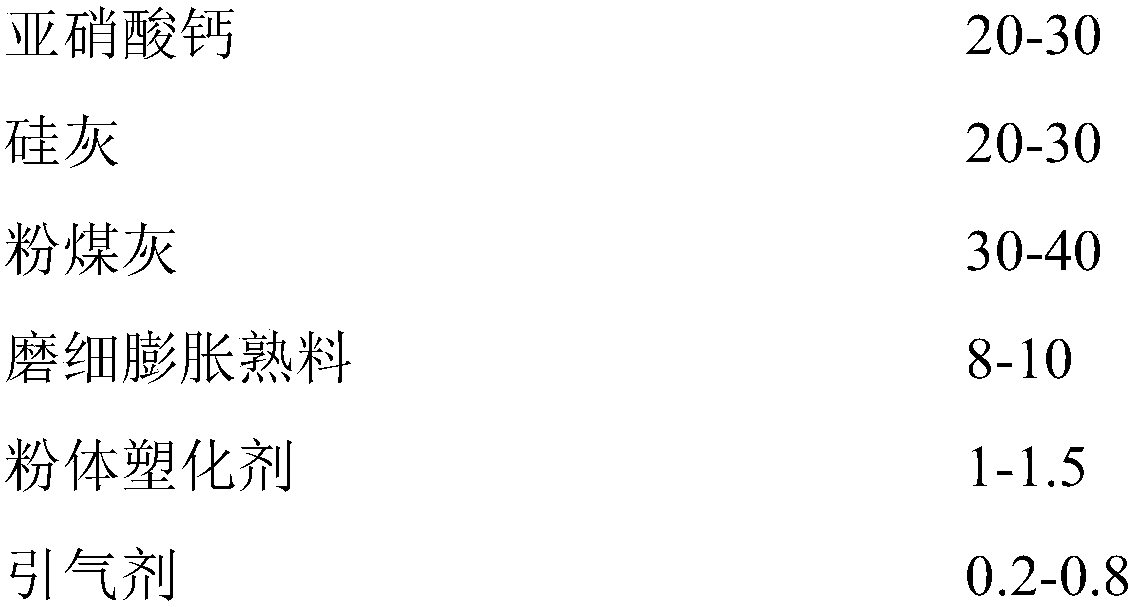

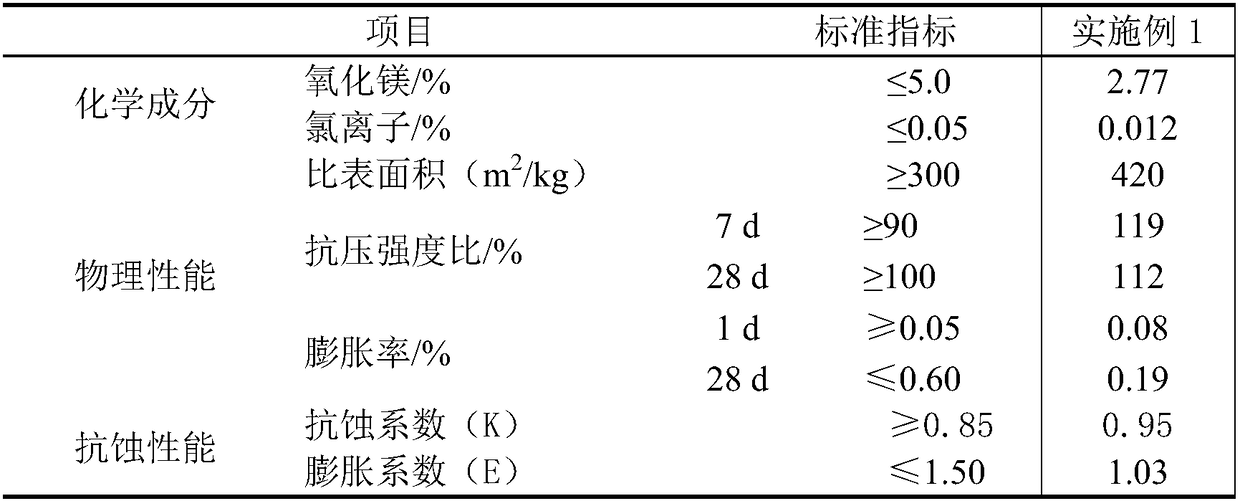

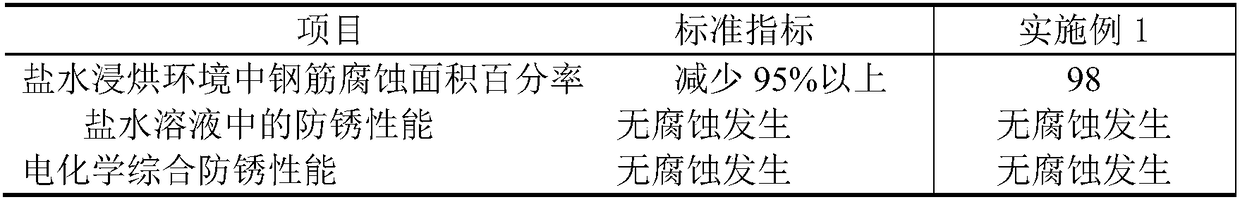

Concrete anticorrosive rust inhibitor for cast-in-place piles

The invention discloses a concrete anticorrosive rust inhibitor for cast-in-place piles. The concrete anticorrosive rust inhibitor is formed by mixing and stirring the following components by mass: 20-30% of calcium nitrite, 20-30% of silica fume, 30-40% of fly ash, 8-10% of finely ground expansive clinker, 1-1.5% of a powder plasticizer and 0.2-0.8% of an air entraining agent. The concrete anticorrosive rust inhibitor has no significant effect on working performance of concrete under appropriate dosage, improves age strength of the concrete, increases compactness of the concrete by certain self-expansion, forms a dense protective layer on a surface of a reinforcing bar, and effectively improves sulfate corrosion resistance of the concrete and erosion resistance of the reinforcing bar.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

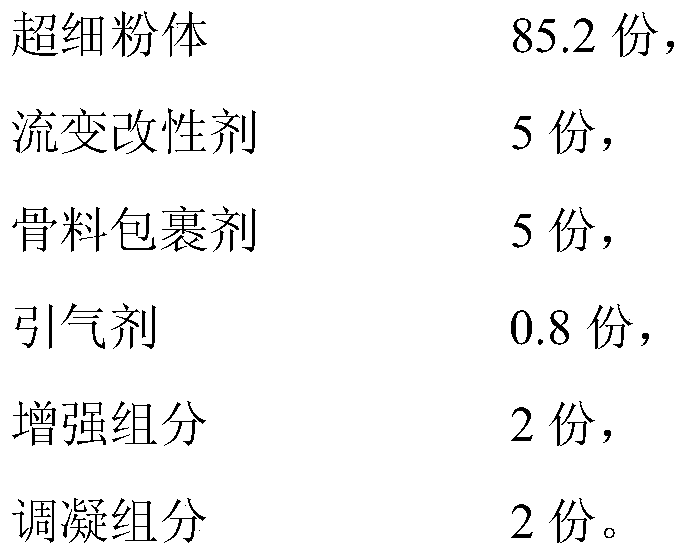

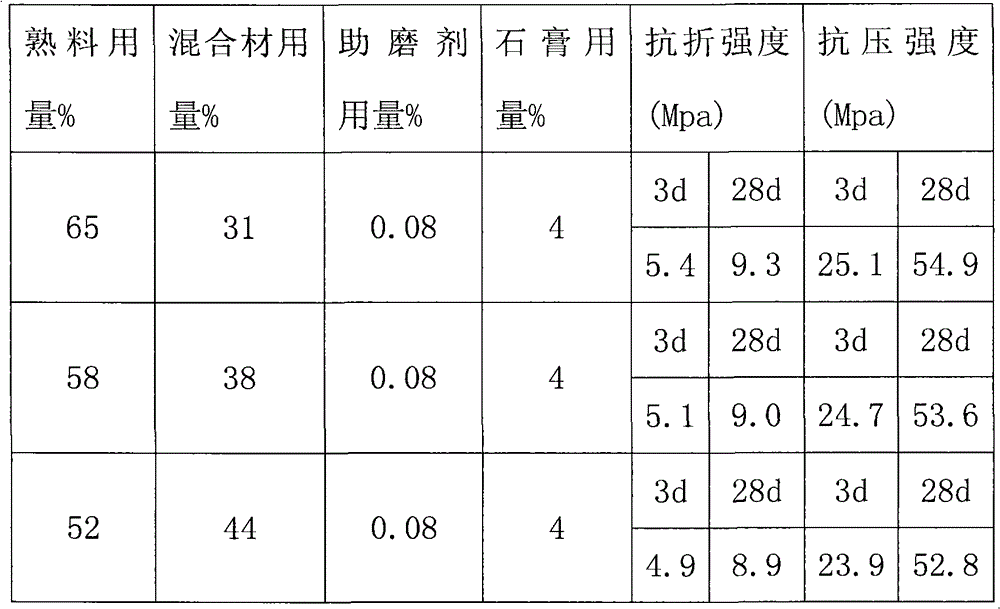

Viscosity adjusting admixture for spray construction and preparation method thereof

The invention discloses a viscosity adjusting admixture for spray construction and a preparation method thereof. The viscosity adjusting admixture is composed of following components in parts by weight: 60 to 90 parts of ultrafine powder, 5 to 10 parts of a rheology modifier, 5 to 10 parts of an aggregate wrapping agent; 0.5 to 1 part of an air entraining agent; 1 to 10 parts of a reinforcing component; and 1 to 10 parts of a setting control component; wherein the ultrafine powder is ultrafine limestone flour with a size of 600 to 1000 meshes, and the aggregate wrapping agent is a nano aggregate wrapping agent. The provided viscosity adjusting admixture can reduce the rebound rate, improves the construction efficiency, enhances the strength of all stages, and obviously improves the qualityof construction engineering that uses motor spraying and concrete spraying. The admixture can be used to adjust the viscosity of a spraying material. The pipe obstruction is inhibited. The construction efficiency is improved. The rebound rate of spraying construction, the strength of materials of all stages, and the bonding strength are all improved.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

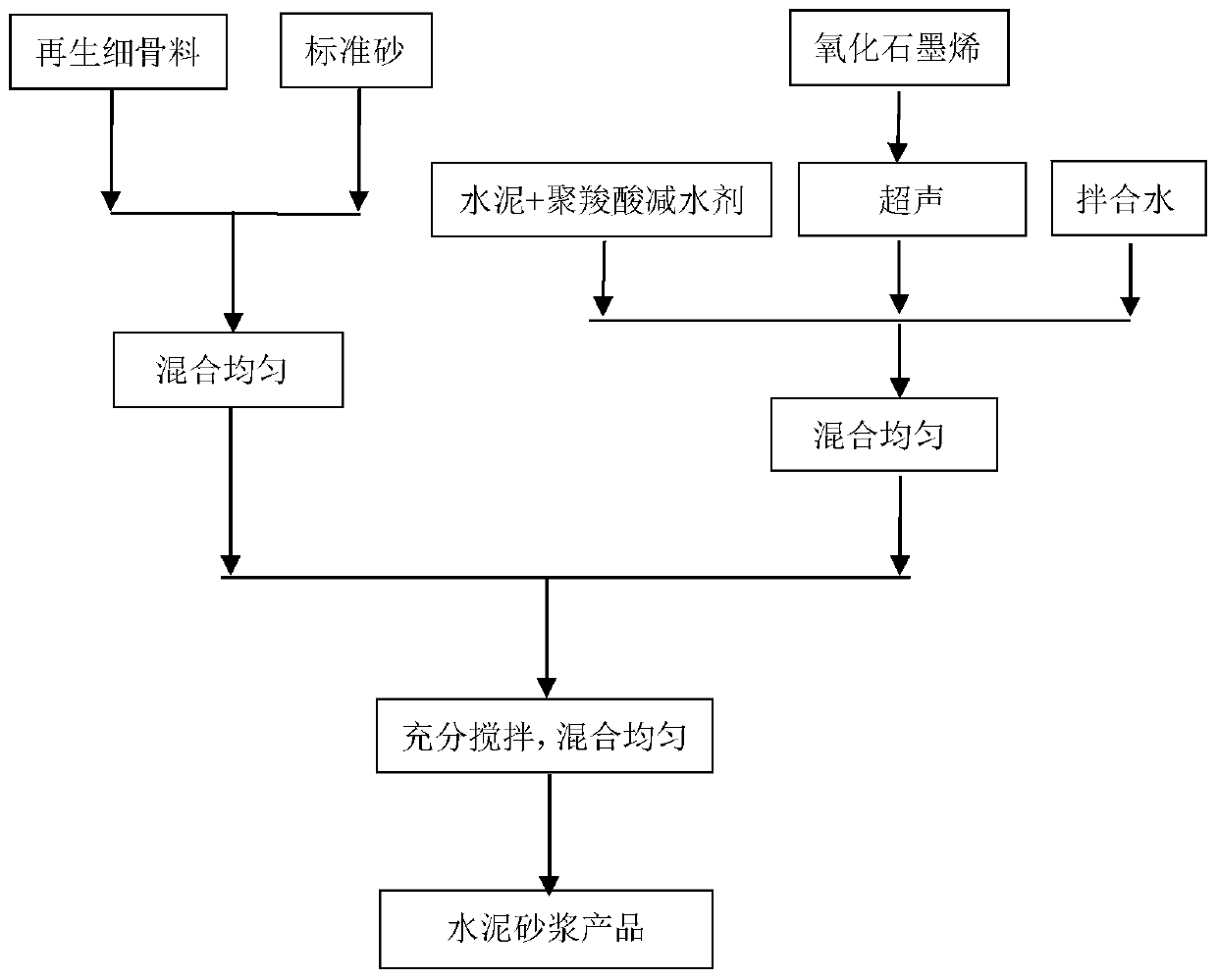

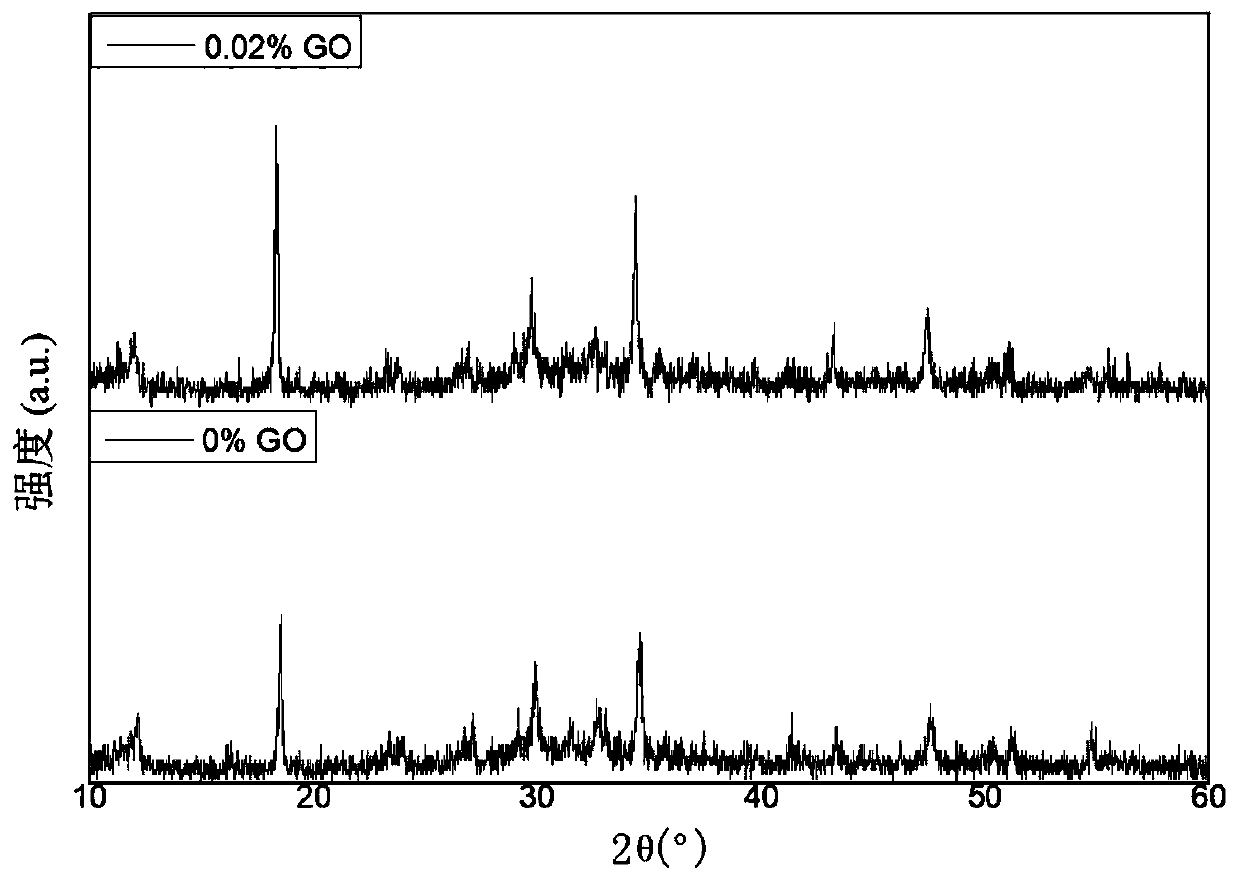

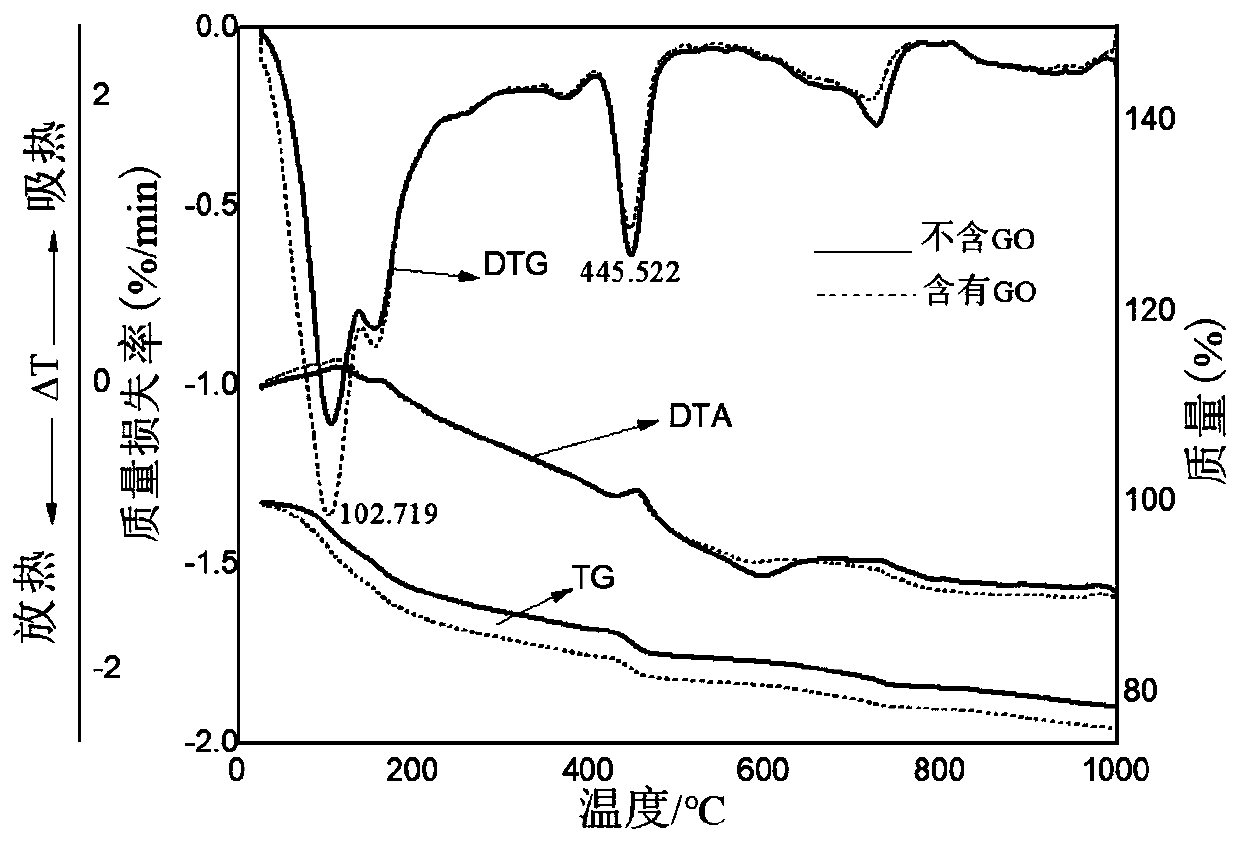

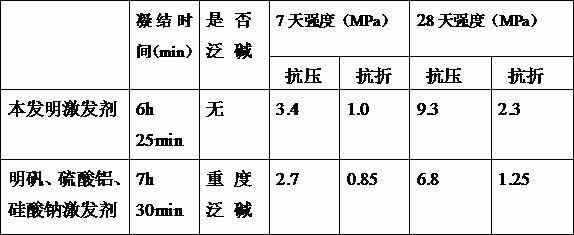

Composite graphene high-strength construction waste cement mortar and preparation method thereof

ActiveCN111410478AGood dispersionReduce frictional resistanceSolid waste managementAggregate (composite)Compressive resistance

The invention discloses composite graphene high-strength construction waste cement mortar and a preparation method thereof, the composite graphene high-strength construction waste cement mortar is prepared by mixing construction waste and standard sand as aggregate, using graphene oxide as a modifier, and then adding a polycarboxylate superplasticizer, cement and water. The performance indexes ofthe cement mortar disclosed by the invention meet the requirements that the 28-day standard compressive strength is 57.6 MPa, and the breaking strength is 9.03 MPa (tested according to GB / T17617-1999and JGJ / T70-2009); the mass loss and the strength loss of 150 times of anti-freezing cycles are both less than 5% (according to GB / T50476-2008 test); and the Cl<-> content in the product is 0.0067%, and the IRa is 0.08, and the Ir is 0.15 (tested according to GB6566-2010).

Owner:ANHUI UNIV OF SCI & TECH

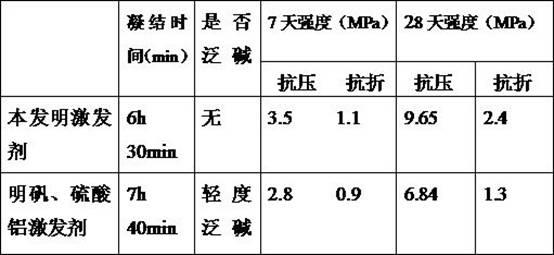

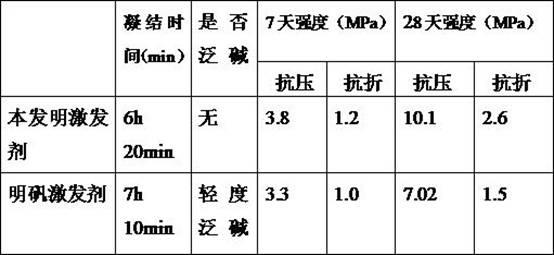

Calcination-free industrial gypsum byproduct dry-mixed mortar activator

The invention discloses a calcination-free industrial gypsum byproduct dry-mixed mortar activator, which belongs to the field of dry-mixed mortar additives. The dry-mixed mortar activator is prepared with the following mixed materials in part by weight: 10 to 25 parts of calcium chloride, 3 to 8 parts of calcium nitrite, 5 to 15 parts of triethanolamine, 5 to 15 parts of triisopropanolamine, 30 to 50 parts of industrial sugar residue, 10 to 30 parts of water and a plurality of parts of mountain flour. Compared with the prior art, the dry-mixed mortar activator is characterized in that: the application range is wide, efflorescence cannot take place, and the strength of mortar at each age can be enhanced.

Owner:SHANDONG CHENGHUA BUILDING MATERIAL TECH

Enhanced composite cement grinding aid

The invention belongs to the technical field of cement additives, in particular to an enhanced composite cement grinding aid. The enhanced composite cement grinding aid is prepared from the following raw materials in parts by weight: 20-30 parts of triethanolamine, 10-20 parts of triisopropanolamine, 8-16 parts of sodium tripolyphosphate, 2-6 parts of alkyl glycoside, 1-6 parts of zinc stearate, 0.6-2.2 parts of sodium sulfosuccinate and 35-55 parts of water. With the adoption of the enhanced composite cement grinding aid, the strength of cement at ages of 1 day, 7 days and 28 days can be significantly improved, and defects in the prior art are overcome.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Cement grinding aid for improving grinding effect and preparation method of cement grinding aid

The invention provides a cement grinding aid for improving a grinding effect and a preparation method of the cement grinding aid. The cement grinding aid is characterized by being prepared from the following components in parts by weight: 53-57 parts of water, 11-12 parts of industrial salt, 1-3 parts of anhydrous sodium sulfate, 1-2 parts of sodium thiosulfate, 1-2 parts of sodium nitrite, 1-2 parts of urea, 1-3 parts of sodium lignin sulfonate, 6-8 parts of triethanolamine, 11-13 parts of composite alkylol amine, 4-5 parts of glycerinum and 1-2 parts of sugar. By adopting the cement grindingaid, the cement dispersibility can be remarkably improved, and the cement grinding effect can be improved.

Owner:浙江长盈建材科技有限公司

Concrete synergist and preparation method thereof

InactiveCN107935431AIncrease age intensityImprove compactnessDiethylenetriamineUltimate tensile strength

The invention discloses a concrete synergist and a preparation method thereof. The concrete synergist consists of the following raw materials in percentage by weight: 8-22 percent of sodium thiosulfate, 12-20 percent of triethanolamine, 12-20 percent of sodium hexametaphosphate, 8-15 percent of diethylenetriamine pentarboxylic acid sodium, 4-11 percent of acrylamide and the balance of water. Moreover, the invention also discloses the preparation method of the concrete synergist. The invention discloses the high-performance concrete synergist which has the benefits that through improving the dispersing property of cement, the effect of the cement is furthest stimulated, and the hydration degrees of cement minerals are improved, so that the strength of concrete at each age is improved; through promoting the hydration of minerals more difficult to hydrate, the amount of gel is increased, the compaction degree of the concrete is improved, and the slump of the concrete is reduced. Meanwhile, the synergist disclosed by the invention has a certain dispersing property and can improve the dispersing properties of cement particles and mineral admixtures, thereby improving the homogeneity andthe peaceability of a concrete mixture.

Owner:GUYAN TECH DEV CO LTD

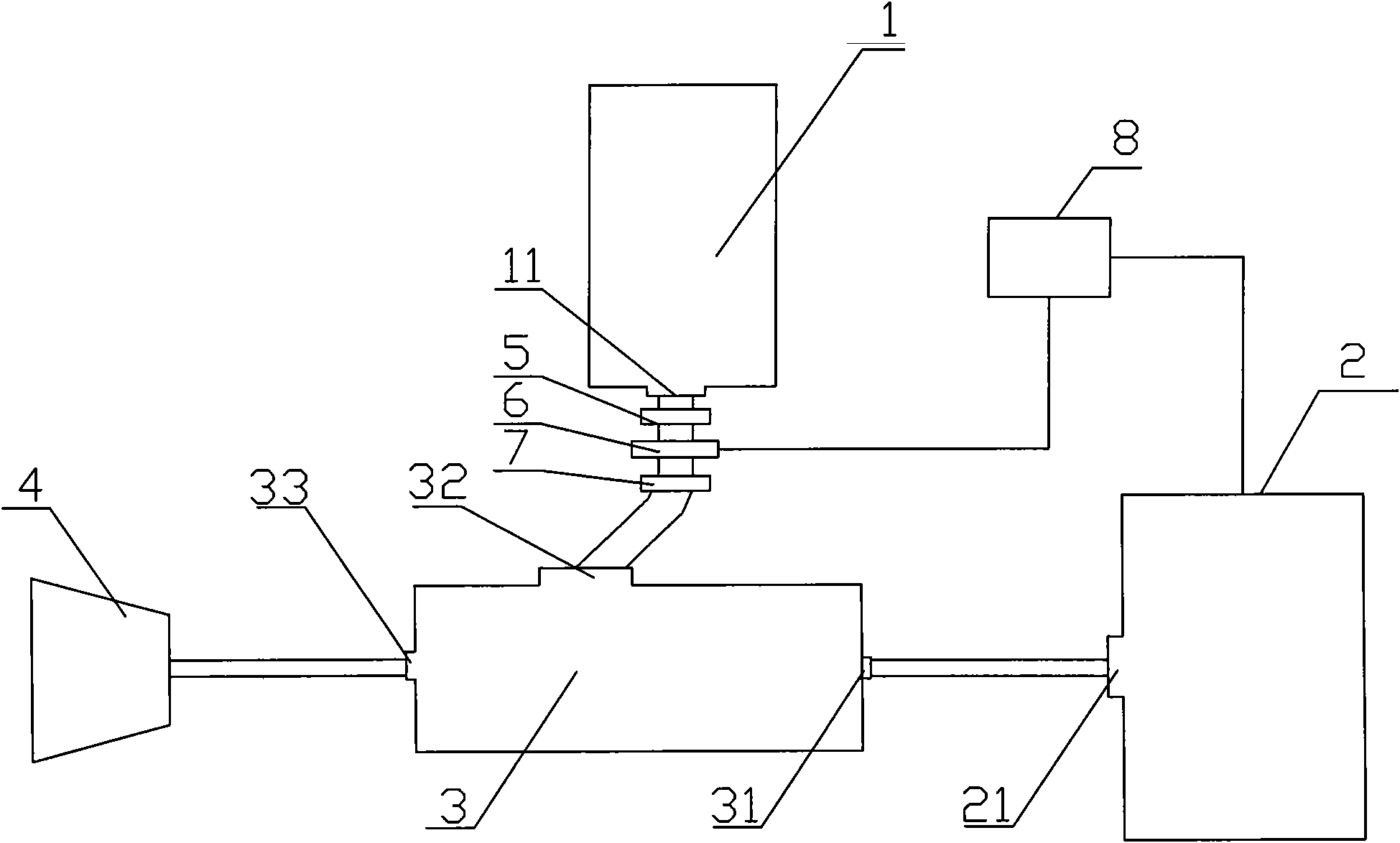

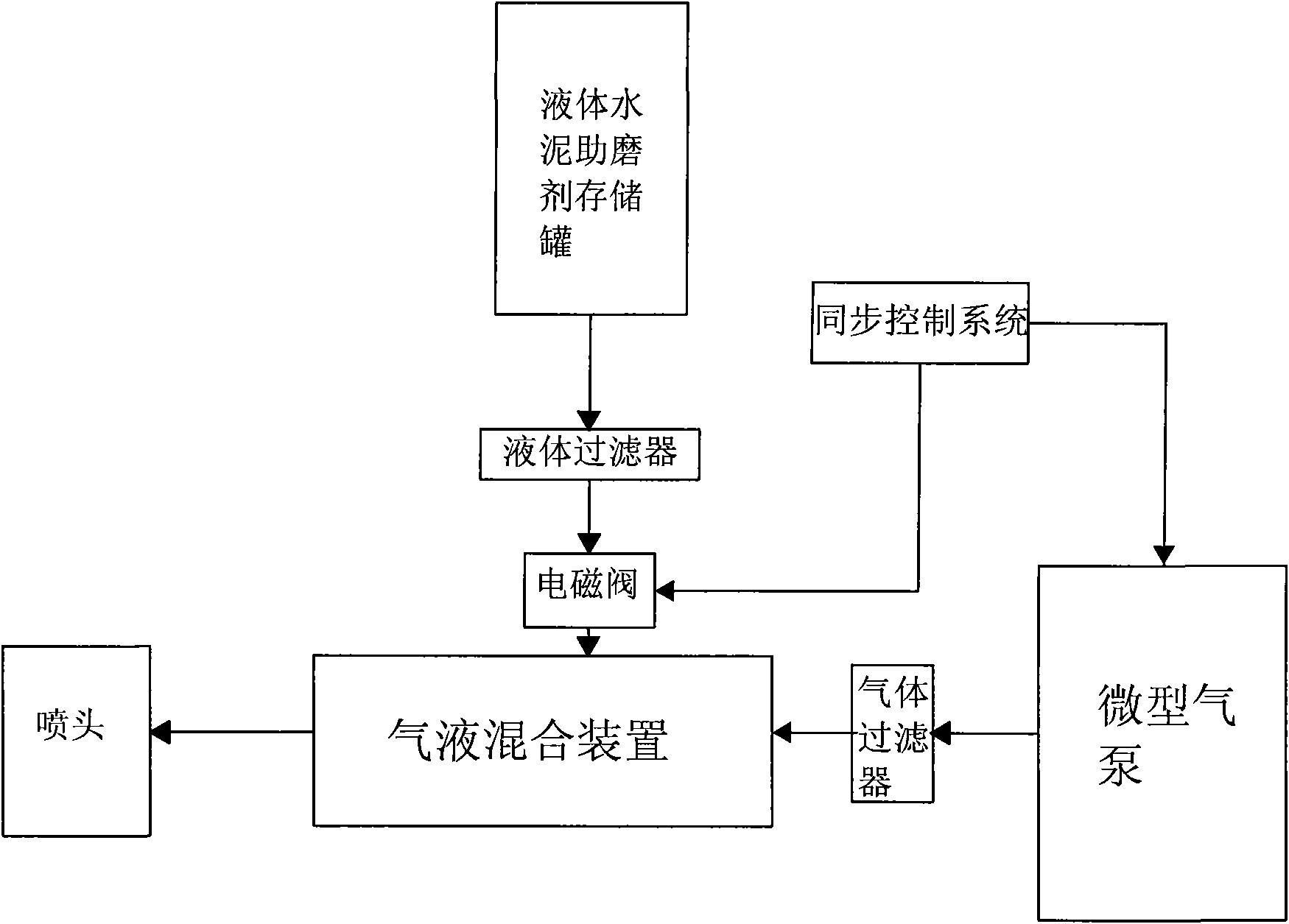

Atomization device for cement grinding aid and using method thereof

InactiveCN102049360AImproved particle size distributionRaise the gradeCement productionLiquid spraying apparatusSynchronous controlAir pump

The invention relates to an atomization device for a cement grinding aid. The atomization device comprises a liquid tank, an air pump, a gas-liquid mixing device and a spray head, wherein the air pump and the liquid tank are connected with the gas-liquid mixing device respectively, and the spray head is arranged on the discharge hole of the gas-liquid mixing device. The invention also relates to a using method for the liquid atomization device. The using method comprises the following steps of: filling the liquid cement grinding aid into the liquid tank, and then arranging the liquid tank on an electromagnetic valve; butting the air outlet of the micro air pump and the air inlet of the gas-liquid mixing device; arranging and connecting a synchronous controller, the electromagnetic valve and the micro air pump, and switching on a power supply; and regulating the electromagnetic valve and the micro air pump, and controlling the atomization granule diameter of the liquid cement grinding aid to be 3.2 to 10 microns. Under the condition that a cement grinder equipment system is not changed, by adopting the cement grinding aid atomization device, the dispersibility and flowability of a material in the grinder can be changed, electrostatic adsorption and ball paste grinding of cement micro granules are effectively eliminated and the cement granule graduation is optimized.

Owner:魏文龙

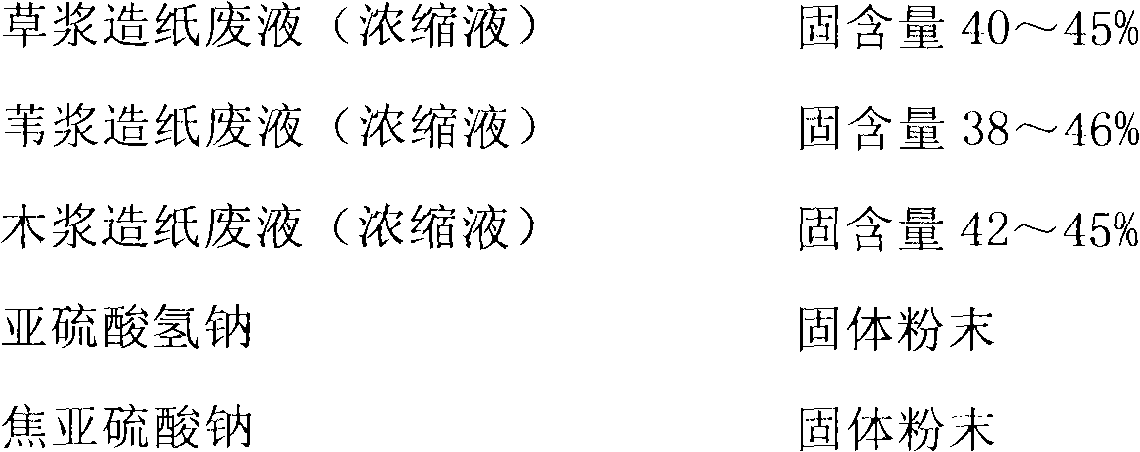

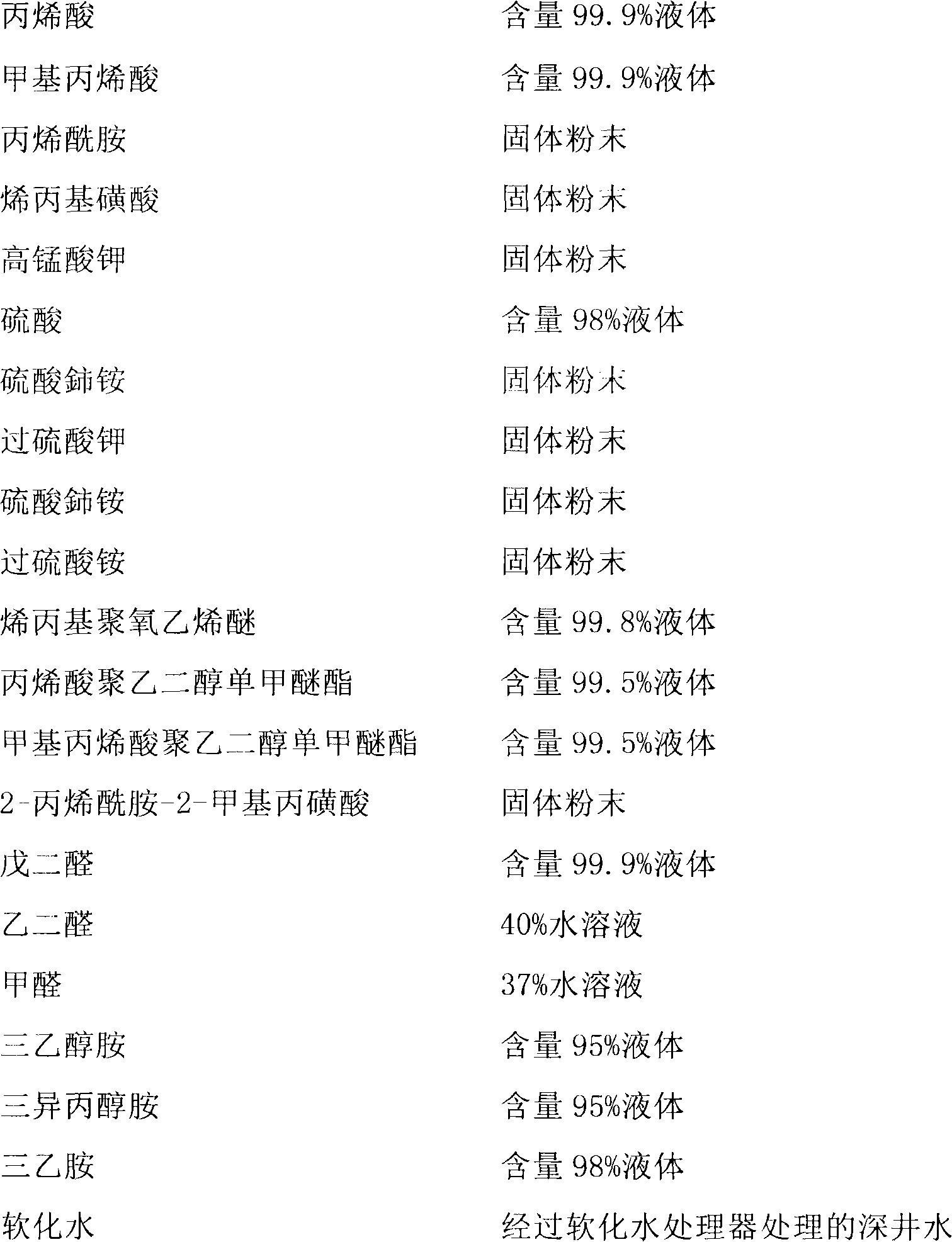

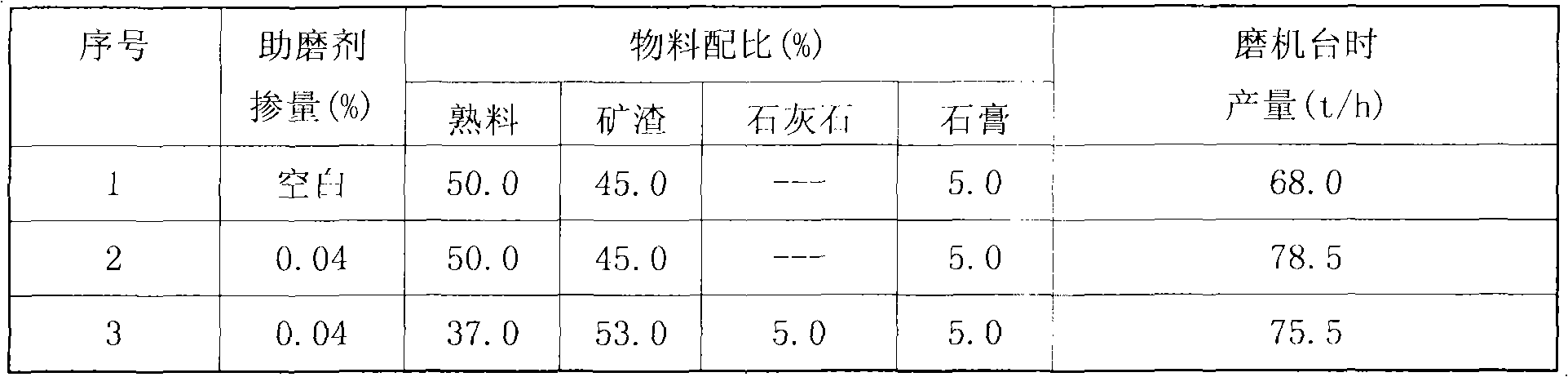

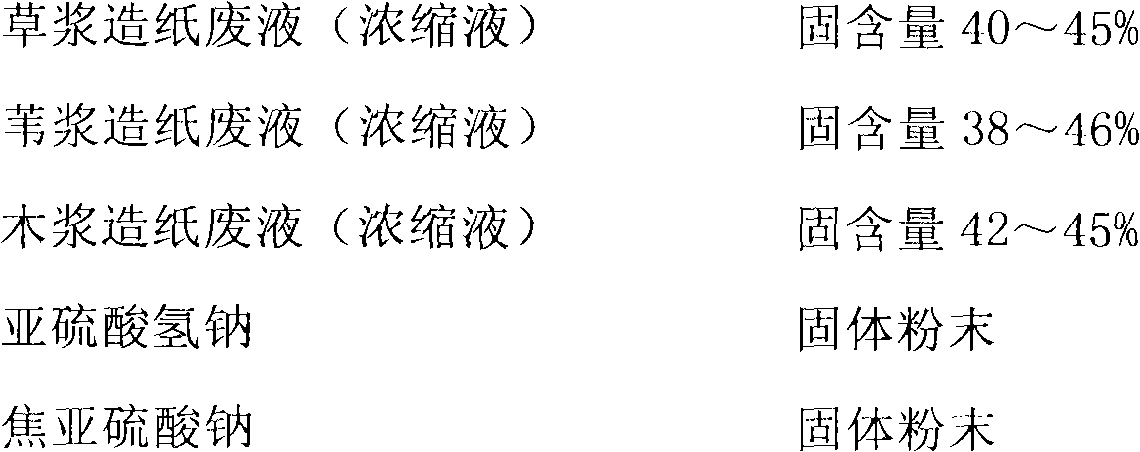

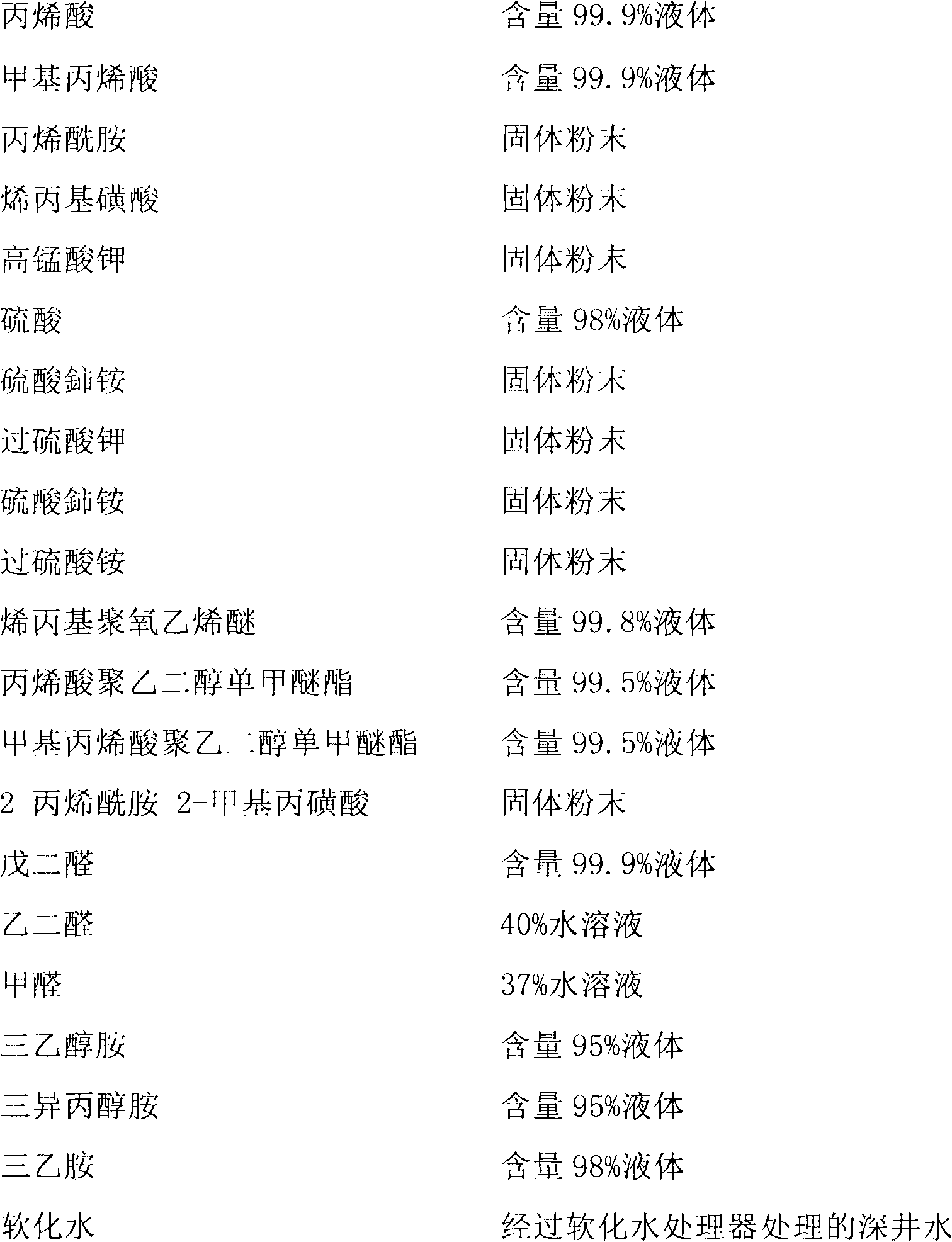

A water-soluble polymer grinding aid produced from papermaking waste liquid and its manufacturing method

The invention discloses a water-soluble polymer grinding aid prepared from papermaking waste liquor and a preparation method thereof. The water-soluble polymer grinding aid comprises the following raw materials: a basic reaction material, a sulfonating agent, a graft modification agent, a graft initiating agent, a water-soluble polymerization reaction material, a copolymerization initiator, a cross-linking agent, a neutralizing agent and softened water. The manufacture method comprises the following steps: putting the basic reaction material into a reaction kettle; then, adding the sulfonating agent for sulfonating; then adding the graft modification agent and the graft initiating agent for graft modification to obtain a graft modification substance; then, adding the water-soluble polymerization reaction material and the copolymerization initiator to obtain a water-soluble copolymer; adding the cross-linking agent for crosslinking reaction to obtain an interpenetrating network water-soluble polymer; and finally, adding the neutralizing agent for neutralizing to obtain the grinding aid. According to the invention, the papermaking waste liquor serves as the main raw material, pollution caused by the papermaking waste liquor is reduced, which is favorable for environment protection, energy saving and cost reduction; and substantial economic benefit and social benefit can be brought for enterprises and society.

Owner:刘长福

Multifunction anti-crack water-proof agent for concrete and preparation method

A multifunctional anti-cracking water-proofing agent for improving the flowability and slump of concrete, increasing the strength, impervious performance and compactness of solidified concrete, and decreasing the consumption of water is prepared proportionally from high-concentration naphthelene-series efficient water reducing agent, sodium laurylsulfate, sodium gluconate, hydroxypropyl methylcellulose, vinyl acetate-ethene copolymer emulsion and water through sequential mixing and stirring.

Owner:李建红

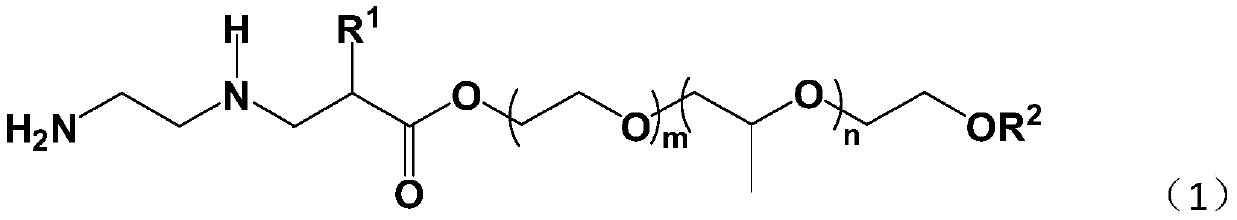

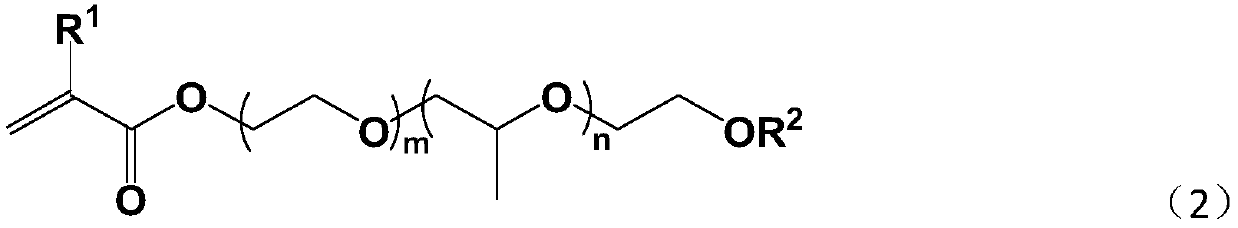

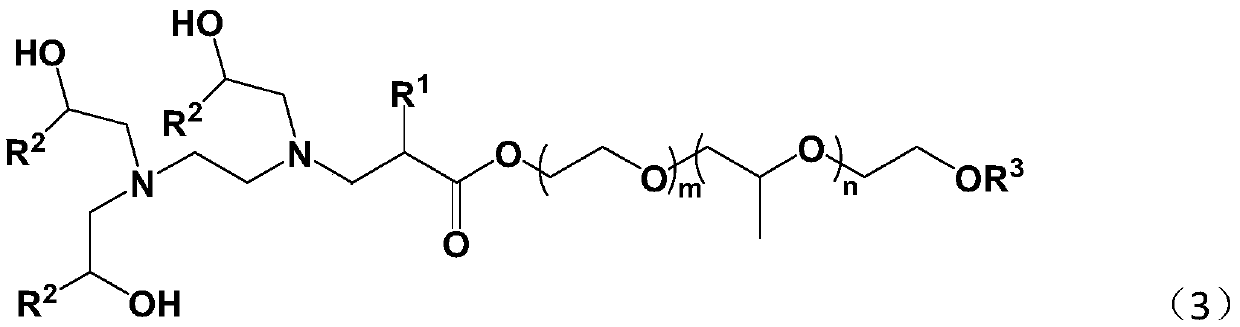

Preparation method of cement grinding aid

The invention discloses a preparation method of a cement grinding aid, and the method comprises the following steps of: polymerizing polyamine monomers, unsaturated carboxylic acid esters, diluents, amine polyether and alkylene oxide according to a certain molar ratio under appropriate conditions. The invention provides a grinding aid with simple preparation method, strong structural adjustability, good grinding aid effect and high storage stability.

Owner:江苏金木土科技有限公司

Water-soluble polymer grinding aid prepared from papermaking waste liquor and preparation method thereof

The invention discloses a water-soluble polymer grinding aid prepared from papermaking waste liquor and a preparation method thereof. The water-soluble polymer grinding aid comprises the following raw materials: a basic reaction material, a sulfonating agent, a graft modification agent, a graft initiating agent, a water-soluble polymerization reaction material, a copolymerization initiator, a cross-linking agent, a neutralizing agent and softened water. The manufacture method comprises the following steps: putting the basic reaction material into a reaction kettle; then, adding the sulfonating agent for sulfonating; then adding the graft modification agent and the graft initiating agent for graft modification to obtain a graft modification substance; then, adding the water-soluble polymerization reaction material and the copolymerization initiator to obtain a water-soluble copolymer; adding the cross-linking agent for crosslinking reaction to obtain an interpenetrating network water-soluble polymer; and finally, adding the neutralizing agent for neutralizing to obtain the grinding aid. According to the invention, the papermaking waste liquor serves as the main raw material, pollution caused by the papermaking waste liquor is reduced, which is favorable for environment protection, energy saving and cost reduction; and substantial economic benefit and social benefit can be brought for enterprises and society.

Owner:刘长福

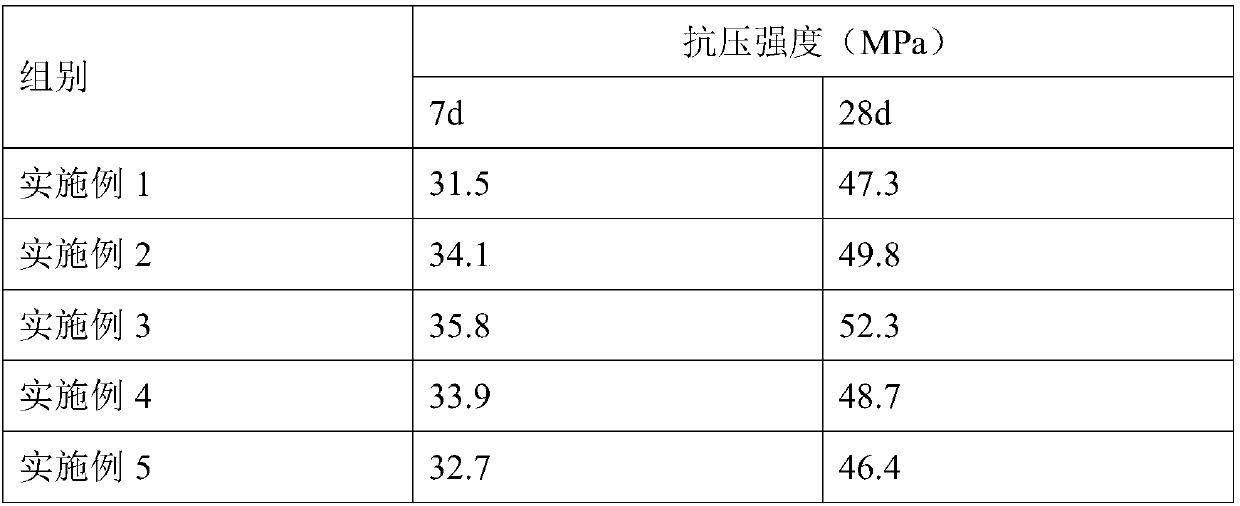

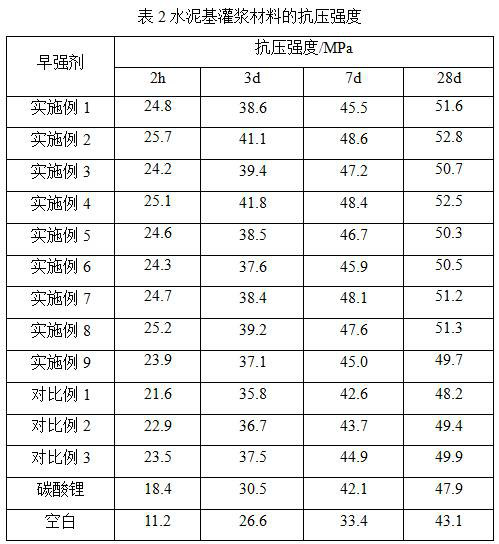

Preparation method of nano ettringite crystal nucleus early strength agent, obtained product and application

The invention discloses a preparation method of a nano ettringite crystal nucleus early strength agent as well as an obtained product and application of the nano ettringite crystal nucleus early strength agent. The nano ettringite crystal nucleus early strength agent is prepared by sequentially and slowly dropwise adding a calcium salt solution and an aluminum salt solution into a polar dispersant aqueous solution at normal temperature, adjusting the pH value to 10.0-12.0 by using a sodium hydroxide solution and synchronously stirring in the dropwise adding process. The nano ettringite crystal nucleus early strength agent prepared by the invention is relatively small in particle size and relatively good in dispersion stability, can greatly improve the mechanical properties of a cement-based grouting material at all ages, and particularly has a remarkable effect of improving the early strength of the cement-based grouting material. Heating and ultrasonic dispersion are not needed during preparation, and the preparation method is simple and suitable for large-scale production.

Owner:UNIV OF JINAN

An ecological cementitious material

ActiveCN102515588BReduce manufacturing costReduce consumptionCinker content reductionSodium metasilicateBrick

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Composite concrete grinding-assistant reinforcing agent

InactiveCN101948268BDoes not affect setting timeActivate mixed materialCement productionCalcium formateCarboxylic acid

The invention discloses a composite concrete grinding-assistant reinforcing agent which is prepared by using the following methods: adding 500kg of polycarboxylic acid copolymer, 90kg of triisopropanolamine, 100kg of triethanolamine, 40kg of propanediol and 70kg of glycol into a reaction container; heating to 50-60 DEG C; stirring for 0.5-1.5 hours to uniformly mix to prepare a mixture No.1; adding 50kg of esterifying agent, 250kg of carbamide, 180kg of calcium formate and 20kg of adjusting solidification agent into 700kg of water; fully stirring for 0.5-1.0 hour at 50 DEG C-60 DEG C to prepare a mixture No.2; and keeping the temperature of the mixture No.1 at 50 DEG C-60 DEG C, slowly pouring the mixture No.2 into the No.1 mixture while stirring; fully stirring for 0.5-1.5 hours to obtain the composite concrete grinding-assistant reinforcing agent which is brown liquid and hardly precipitates. The invention has the advantages of favorable stability performance, no influence on cementcondensation time, electricity saving, chlorine free, enhancement, simple use, low doping content, small investment and the like, improves output table yield of the cement by 15 percent to 30 percentand improves the age strength of the cement.

Owner:衡阳市银利实业有限公司

A low rebound early high strength wet shotcrete and its application

The invention relates to the field of building materials, in particular to a low-rebound early-high-strength wet shotcrete and its application, comprising the following raw materials in parts by weight: 380-500 parts of cement, 800-1000 parts of sand, 650-800 parts of crushed stone, 10-30 parts of quick-setting agent, 160-200 parts of water, 20-30 parts of high-strength ultrafine admixture, 40-50 parts of fly ash, the low-rebound early high-strength wet sprayed concrete prepared by the present invention greatly improves the bonding The strength of the concrete is reduced, and the concrete can be sprayed normally in the water-rich area. The result has reached the domestic leading level. The invention can be directly applied to the initial support construction of the tunnel, opening up a new technical approach for the initial support construction of the tunnel.

Owner:TRANSTECH ENG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com