Calcination-free industrial gypsum byproduct dry-mixed mortar activator

An industrial by-product gypsum and dry-mixed mortar technology, which is applied in the field of dry-mixed mortar additives, can solve the problems of reducing the strength of the mortar in the later stage, cannot fully play its role, and is not suitable for rapid dissolution, so as to shorten the setting time, enhance the strength of the age, and avoid The effect of ubiquinol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

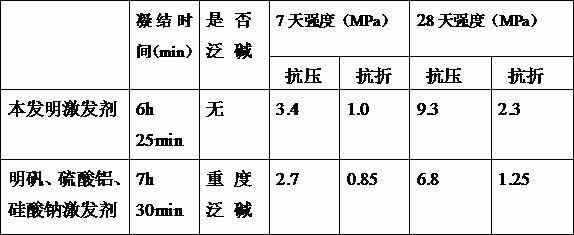

Embodiment 1

[0024] formula:

[0025] Anhydrous Calcium Chloride 15g Calcium Nitrite 5g Triethanolamine 15g

[0026] Triisopropanolamine 5g Industrial sugar residue 40g Water 20g

[0027] Stone powder finer than 200 mesh 900g

[0028] Described triethanolamine is industrial grade 85 mixed amine;

[0029] The sugar content of the sucrose residue is about 48, and the Brix is about 70.

[0030] Preparation:

[0031] Dissolve anhydrous calcium chloride, calcium nitrite, triethanolamine, triisopropanolamine and sucrose residue in water to obtain an intermediate solution, and slowly add the intermediate solution to the stone powder at a weight ratio of 1:9, Add and stir mechanically, and stir evenly to obtain the target activator.

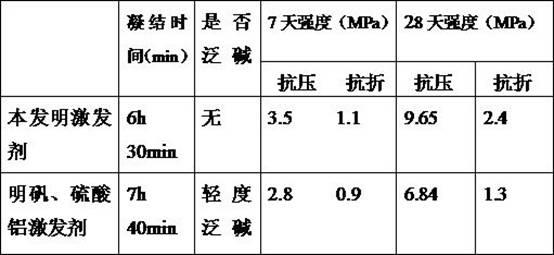

Embodiment 2

[0033] formula:

[0034] Anhydrous Calcium Chloride 20g Calcium Nitrite 4g Triethanolamine 10g

[0035] Triisopropanolamine 10g Industrial sugar residue 30g Water 26g

[0036] Stone powder finer than 200 mesh 900g

[0037] Described triethanolamine is industrial grade 85 mixed amine;

[0038] The sugar content of the sucrose residue is 48, and the Brix is 70.

[0039] Preparation:

[0040] Dissolve anhydrous calcium chloride, calcium nitrite, triethanolamine, triisopropanolamine and sucrose residue in water to obtain an intermediate solution, and slowly add the intermediate solution to the stone powder at a weight ratio of 1:9, Add and stir mechanically, and stir evenly to obtain the target activator.

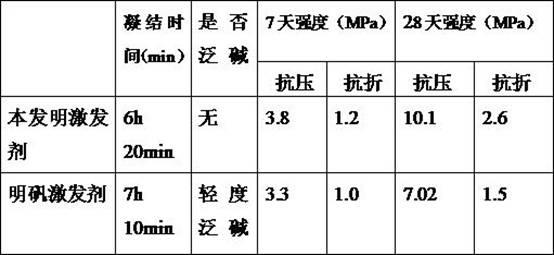

Embodiment 3

[0042] formula:

[0043] Anhydrous Calcium Chloride 15g Calcium Nitrite 7g Triethanolamine 5g

[0044] Triisopropanolamine 5g Industrial sugar residue 45g Water 23g

[0045] Stone powder finer than 200 mesh 900g

[0046] Described triethanolamine is industrial grade 85 mixed amine;

[0047] The sugar content of the sucrose residue is 48, and the Brix is 70.

[0048] Preparation:

[0049] Dissolve anhydrous calcium chloride, calcium nitrite, triethanolamine, triisopropanolamine and sucrose residue in water to obtain an intermediate solution, and slowly add the intermediate solution to the stone powder at a weight ratio of 1:9, Add and stir mechanically, and stir evenly to obtain the target activator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| brix | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com