Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Improved anti-splash effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

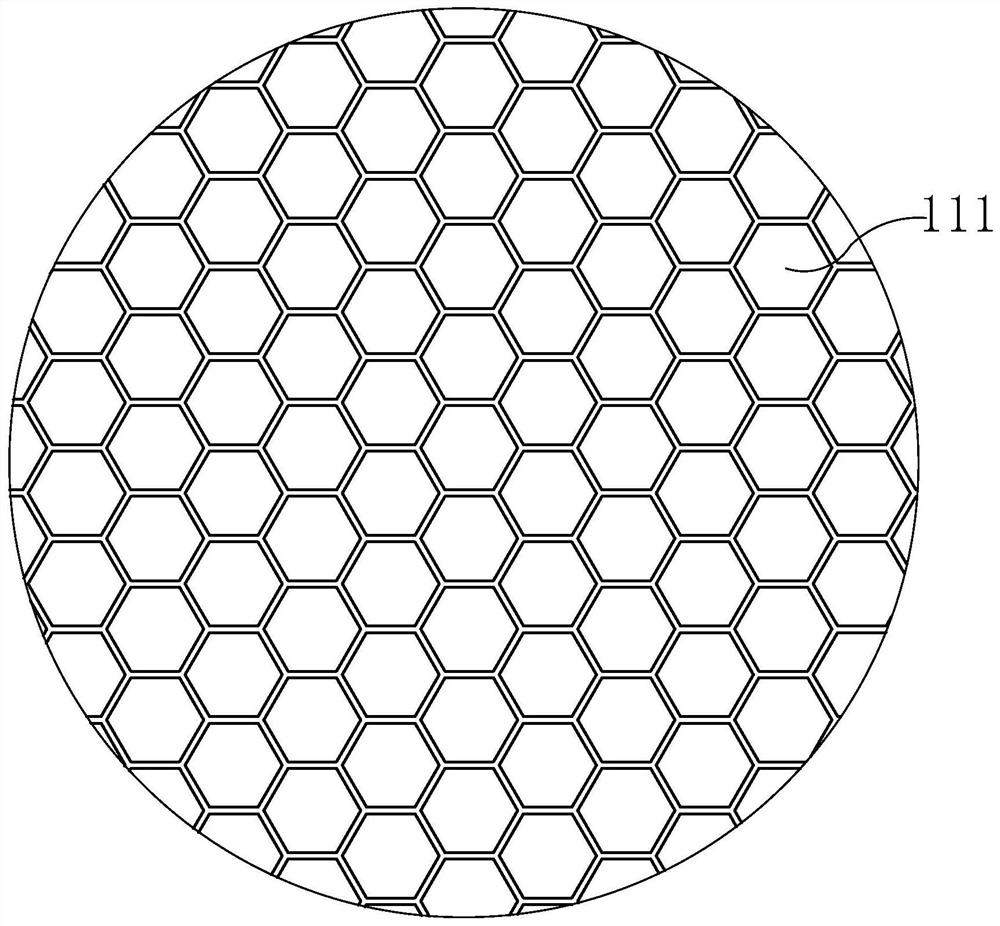

Street floor tile for preventing sewage splashing

ActiveCN109024132APromote circulationReduce volumeSingle unit pavingsSidewalk pavingsNatural stateEngineering

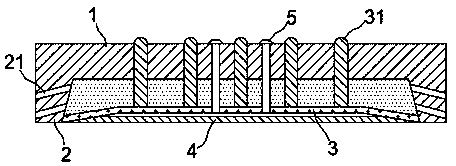

The invention relates to a street floor tile for preventing sewage splashing. The street floor tile for preventing sewage splashing comprises a main body, wherein the edge of the main body is bent downward to form a supporting enclosure edge, and a flow guiding hole is arranged on the supporting enclosure edge. An elastic sealing sheet is arranged below the main body, the edge of the elastic sealing sheet is fixedly connected with the bottom edge of the supporting peripheral edge, and the elastic sealing sheet, the supporting peripheral edge and the main body form an adjusting space; The air guide hole communicates the regulating space and the outside; The elastic sealing sheet protrudes toward the lower surface of the body in a natural state; The elastic sealing sheet is provided with a transmission column, the transmission column is vertically upward and penetrates from the body, and the exposed part of the transmission column forms an anti-slip dot matrix; The transmission column iscapable of reciprocating sliding relative to the body; The street floor tile has novel structure and unique principle, can effectively alleviate the situation of water splashing when walking in rainydays, and can also provide a neat and clean walking street for pedestrians.

Owner:李燕玲

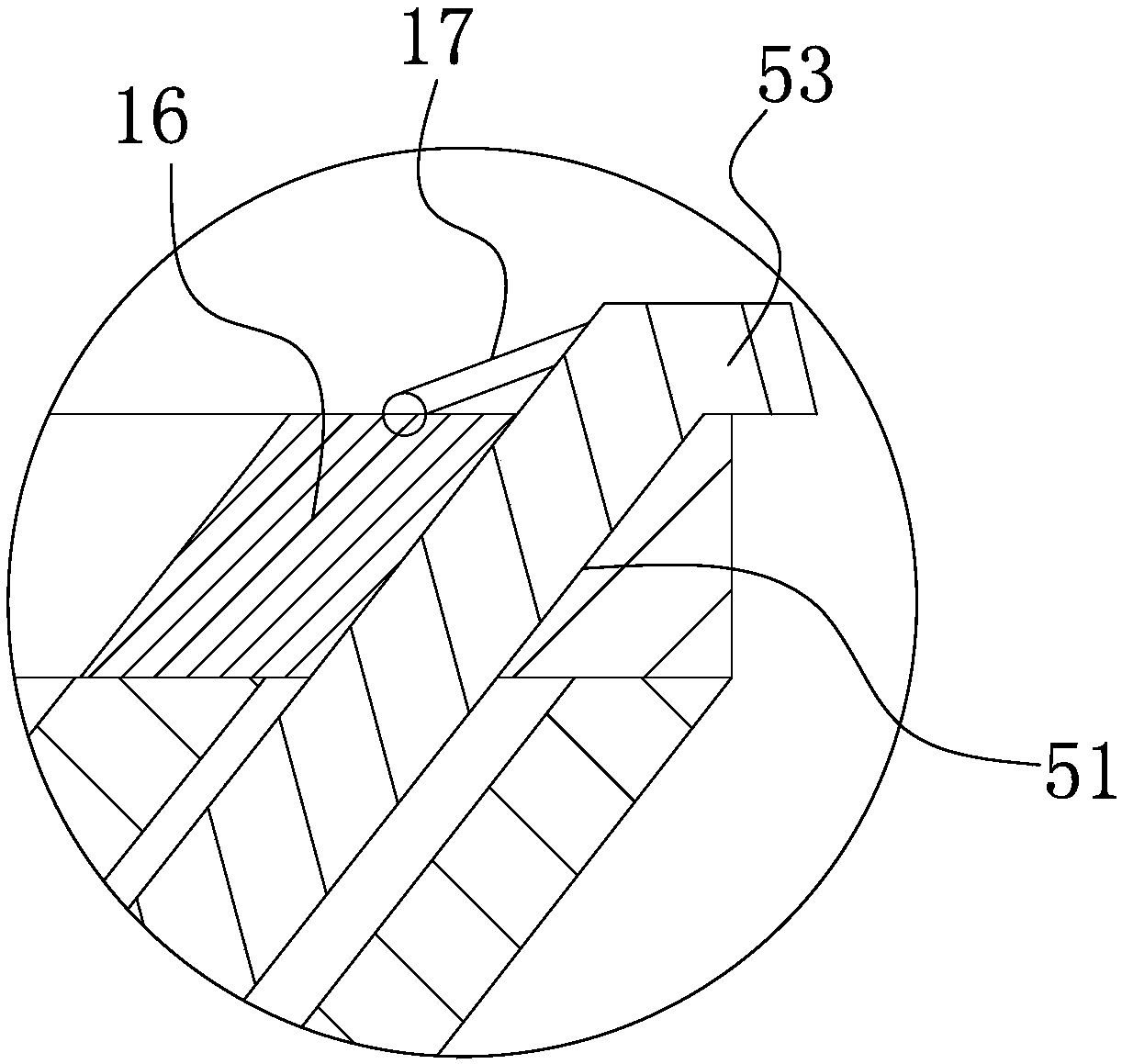

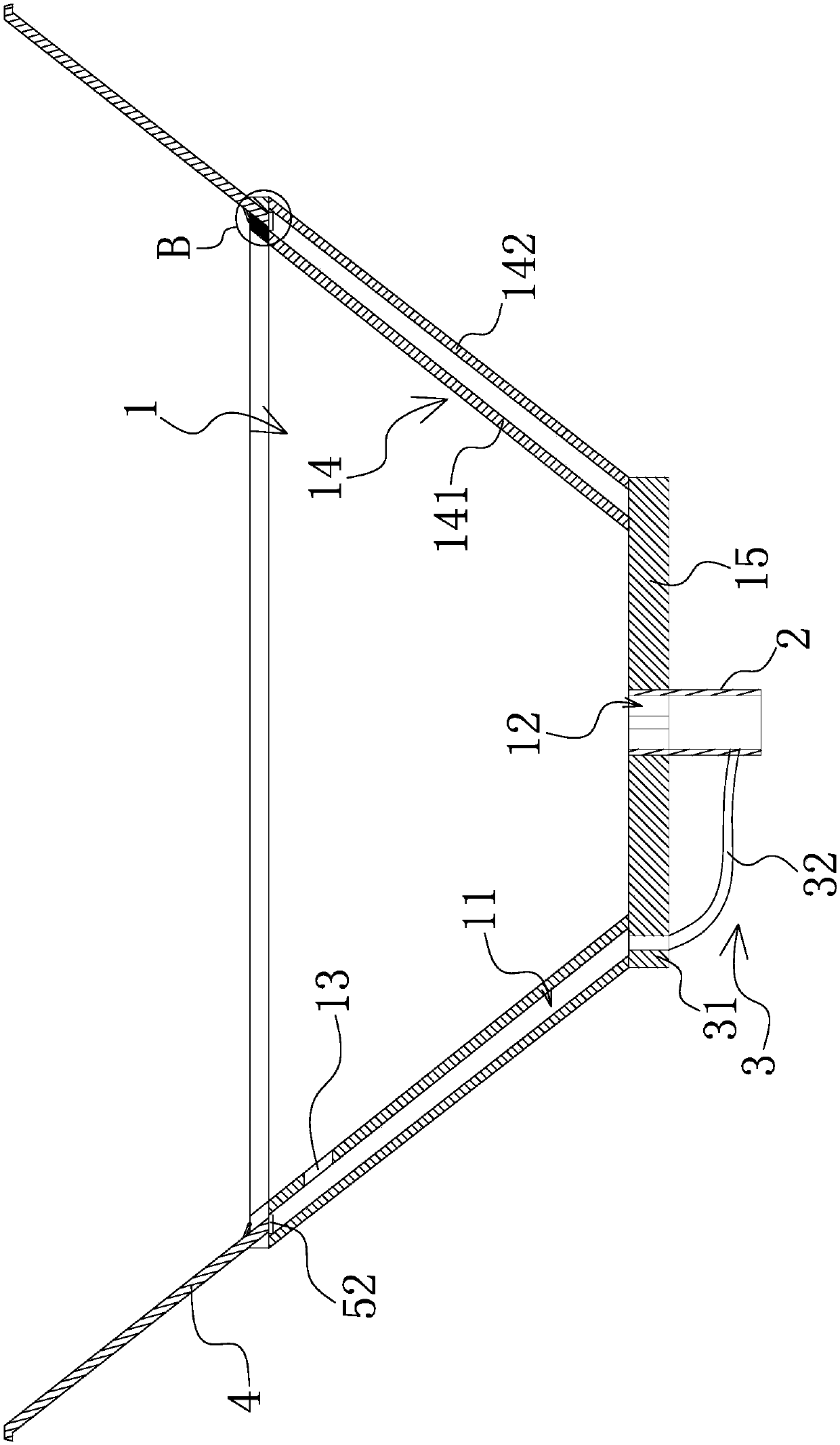

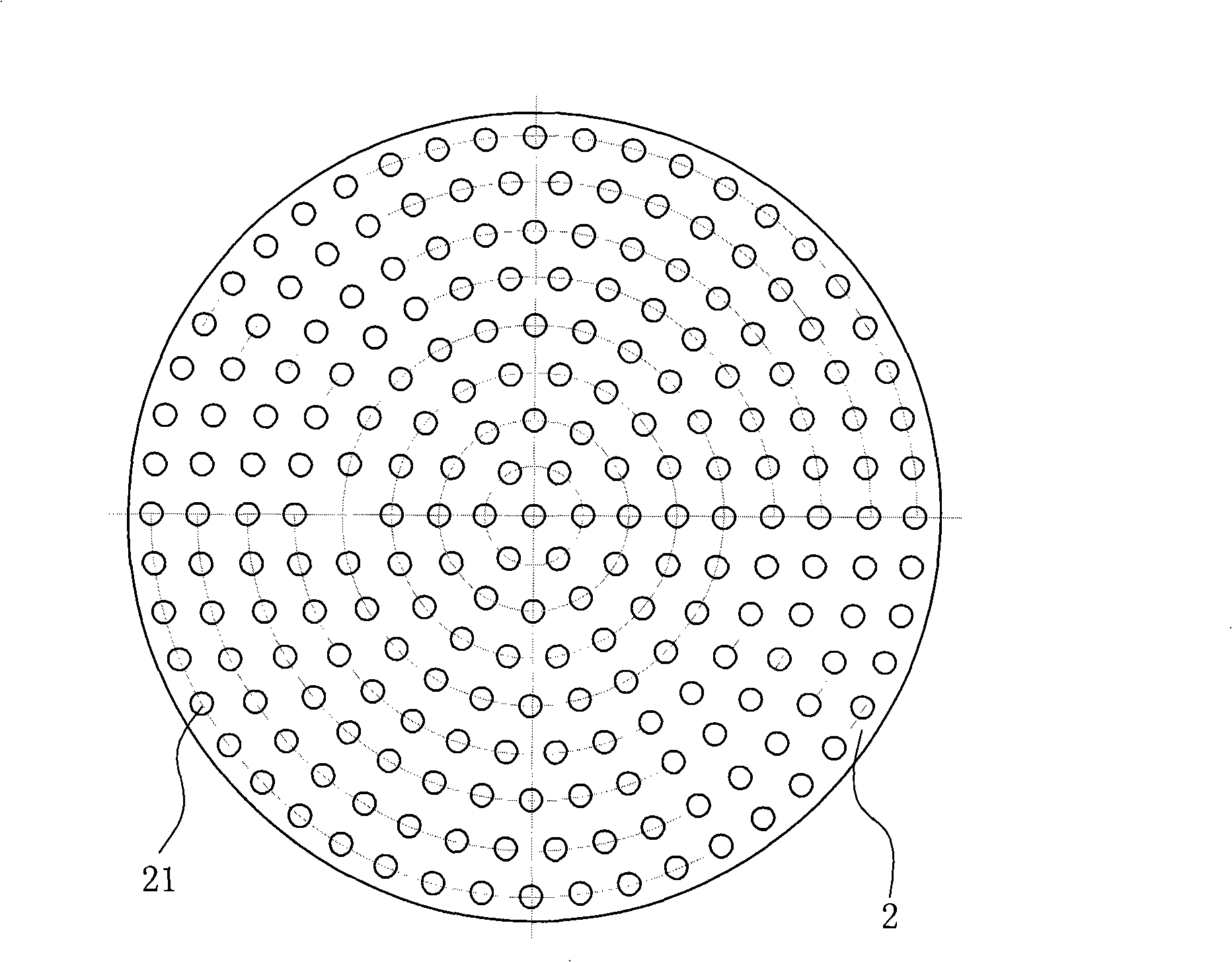

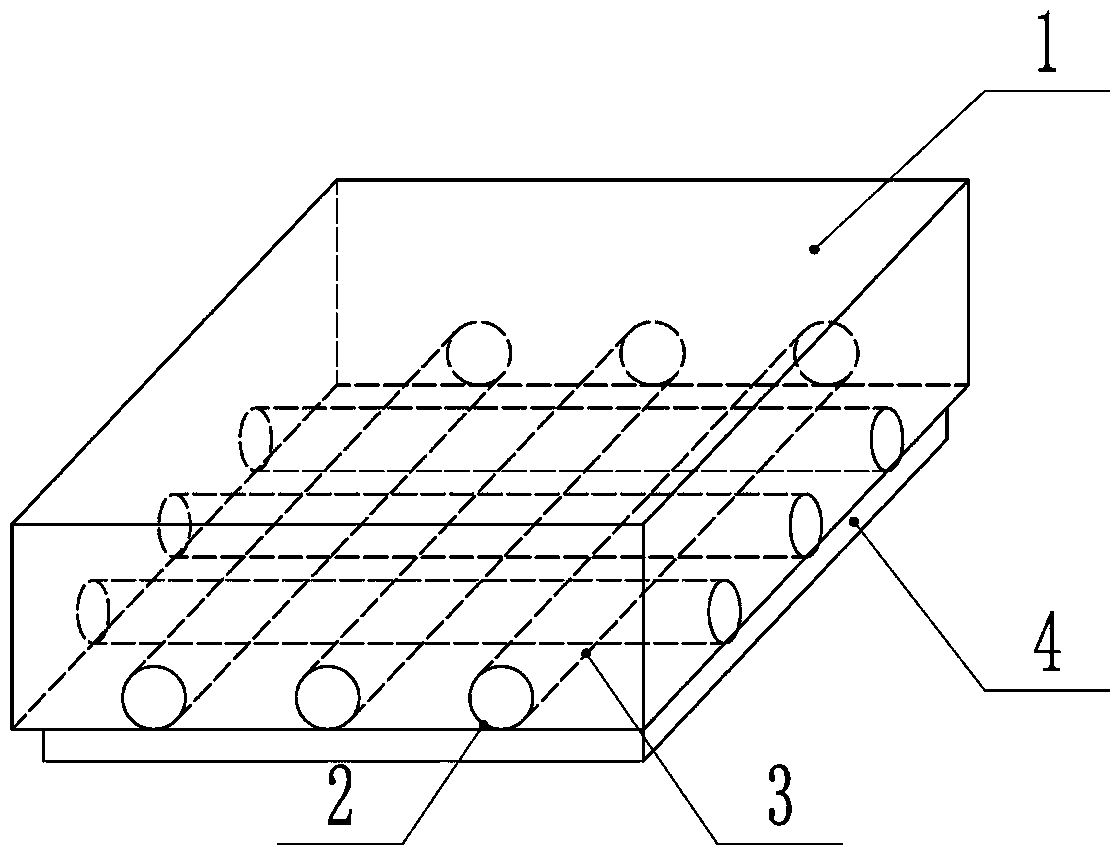

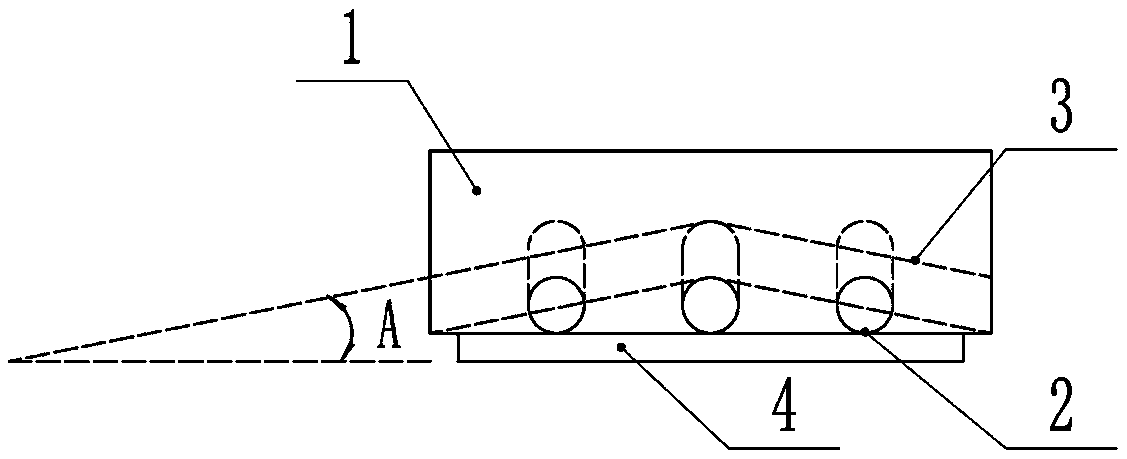

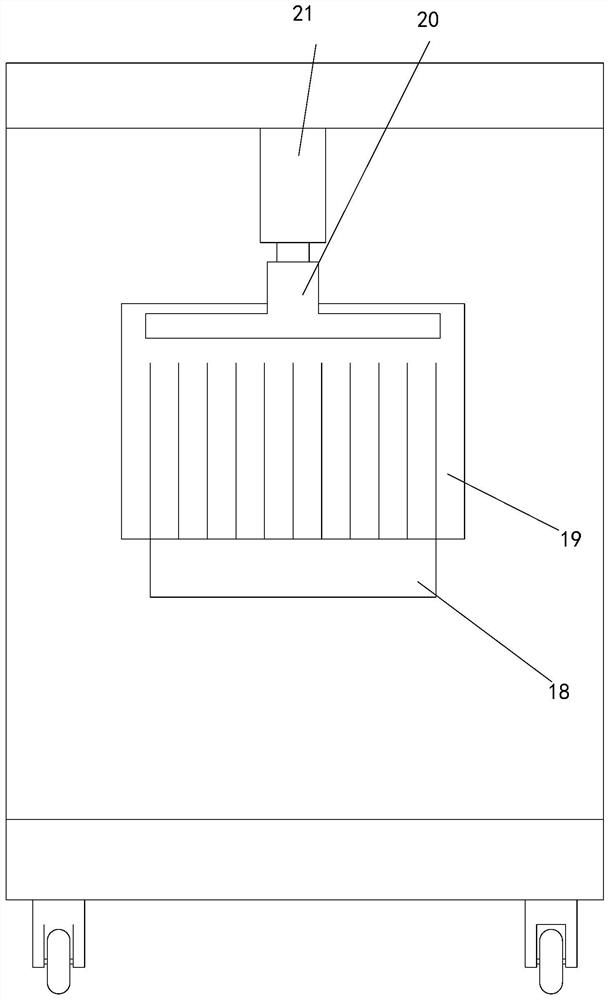

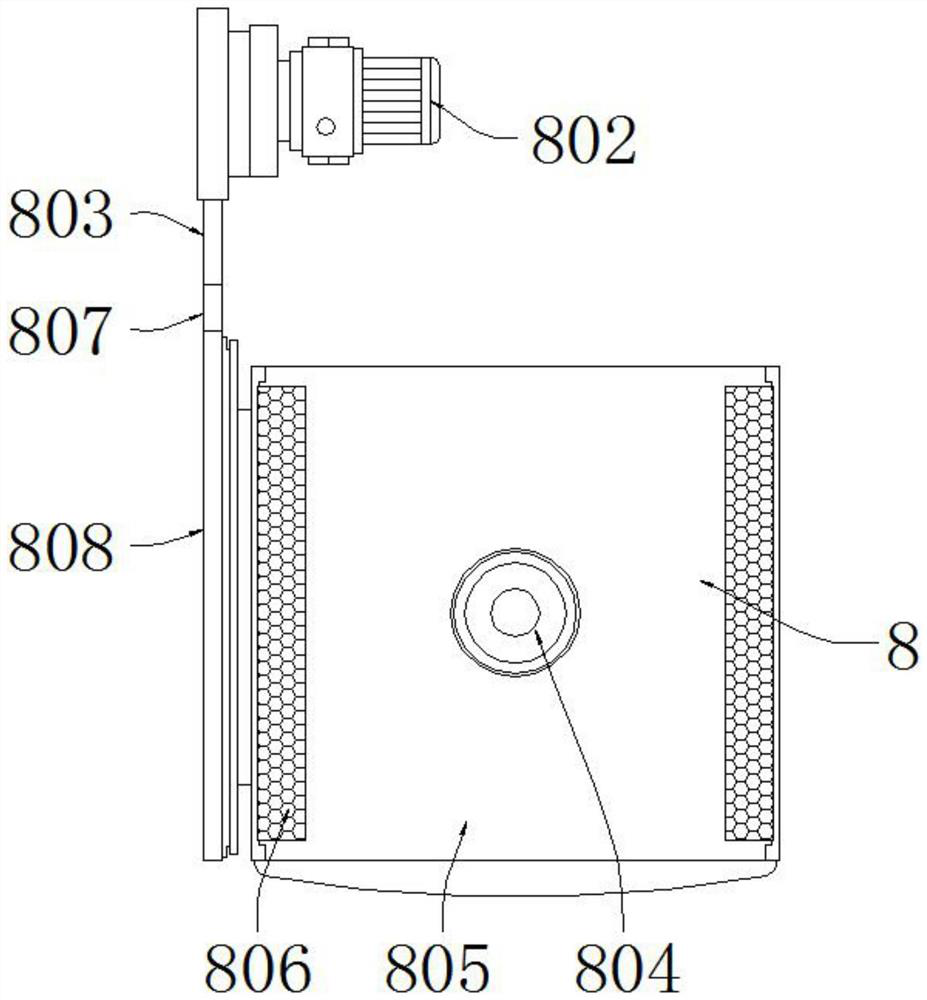

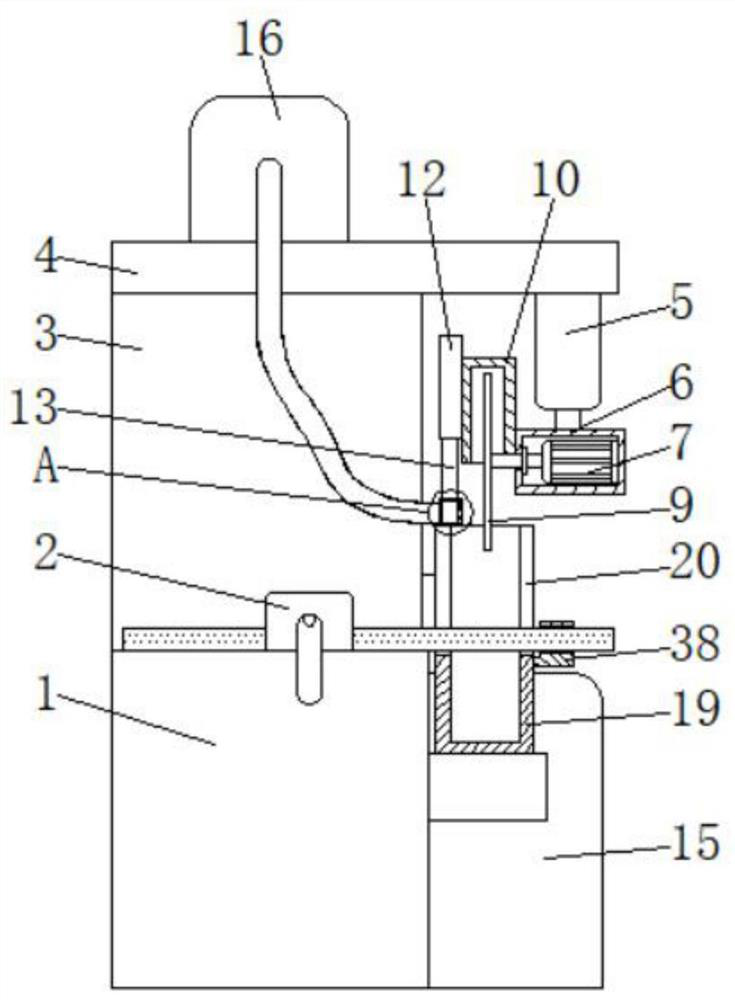

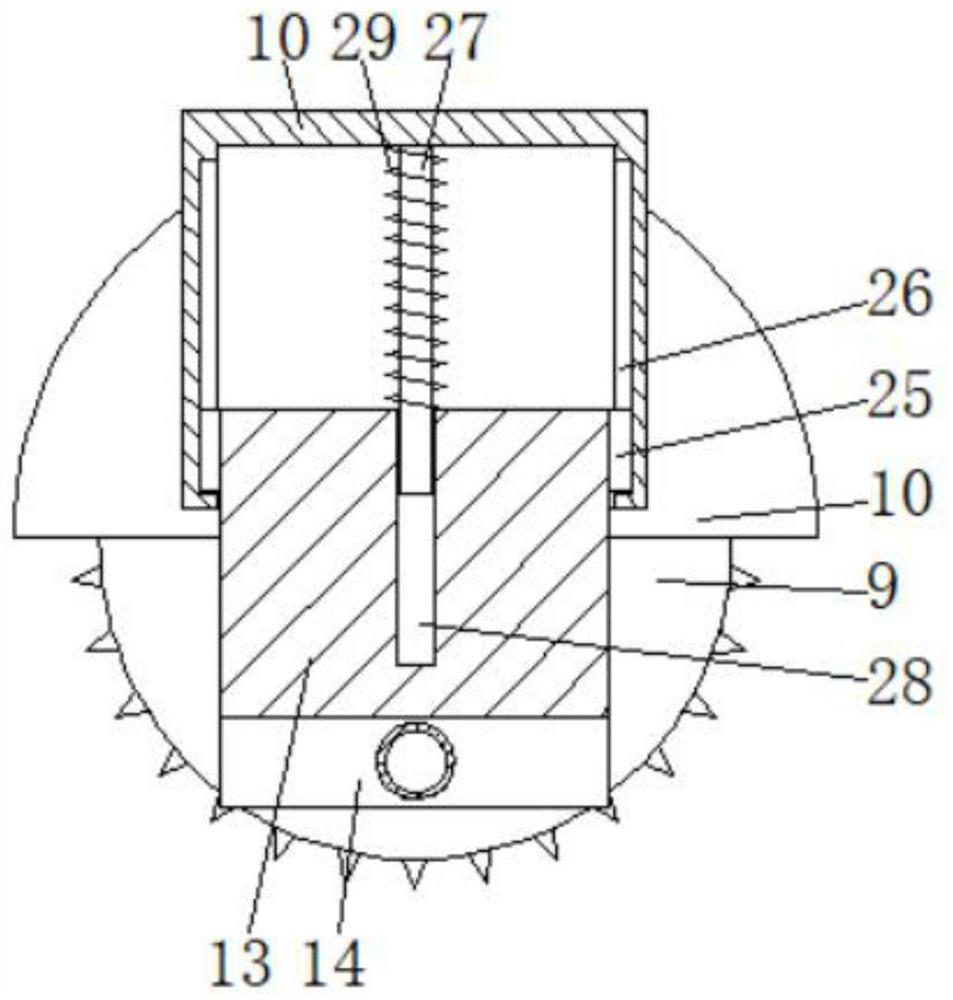

Quartz plate outer circle polishing machine

ActiveCN106166694AAvoid destructionLower bounce heightGrinding carriagesRevolution surface grinding machinesEngineeringGrinding wheel

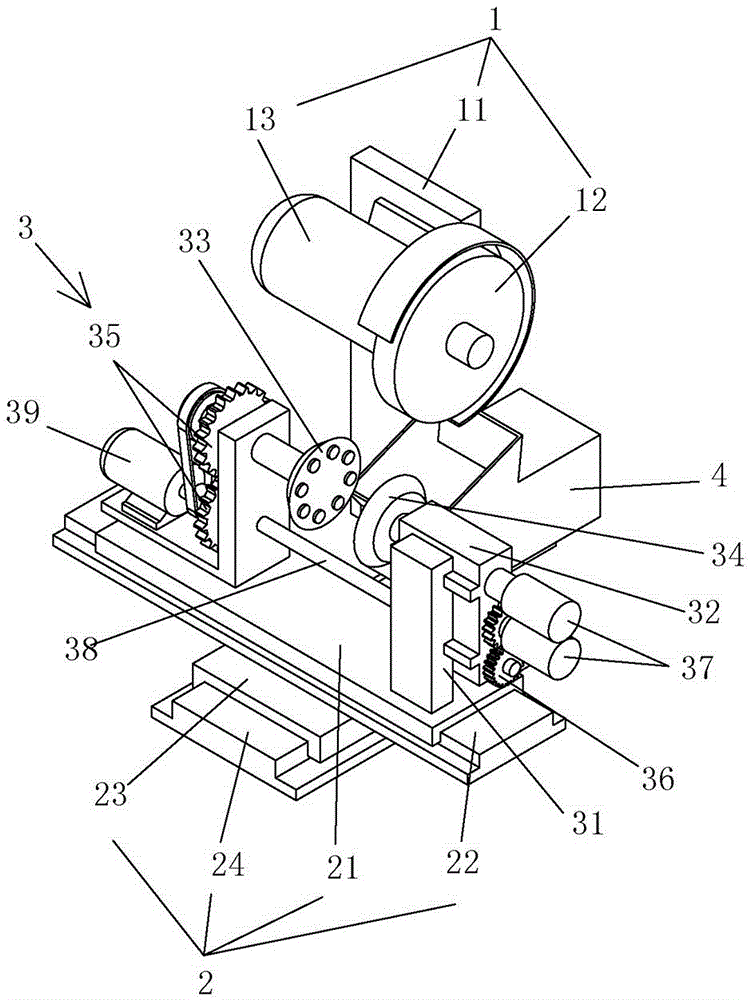

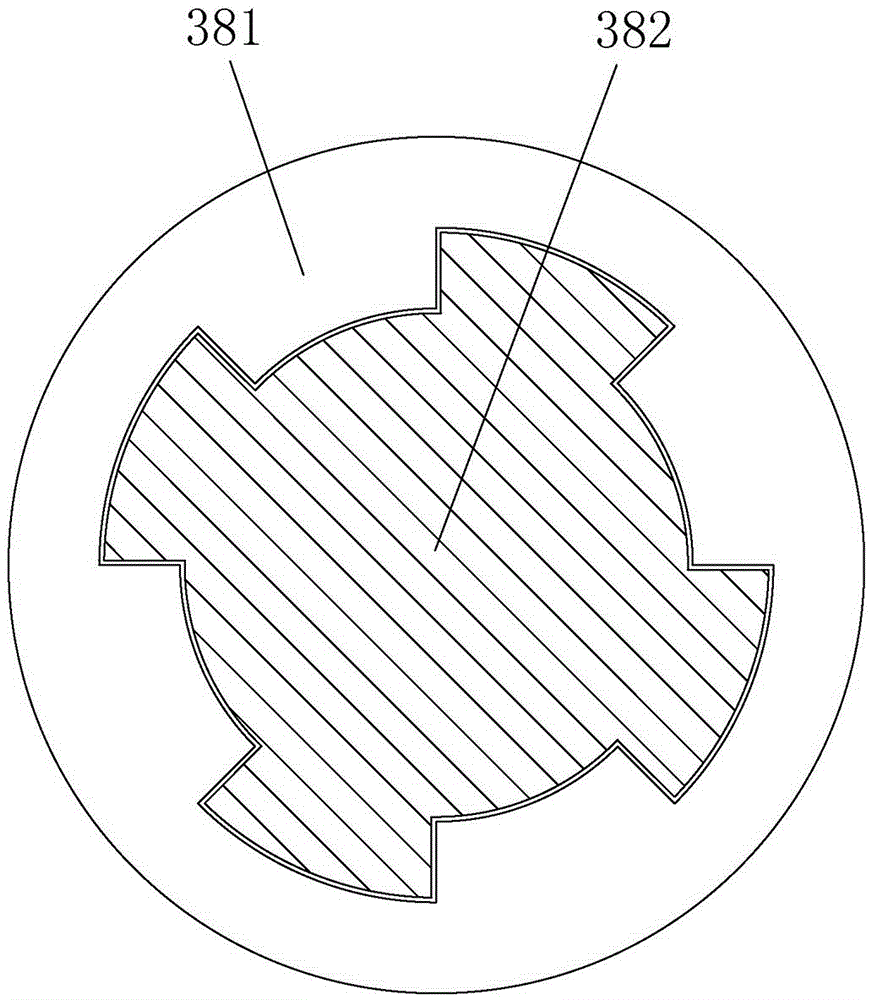

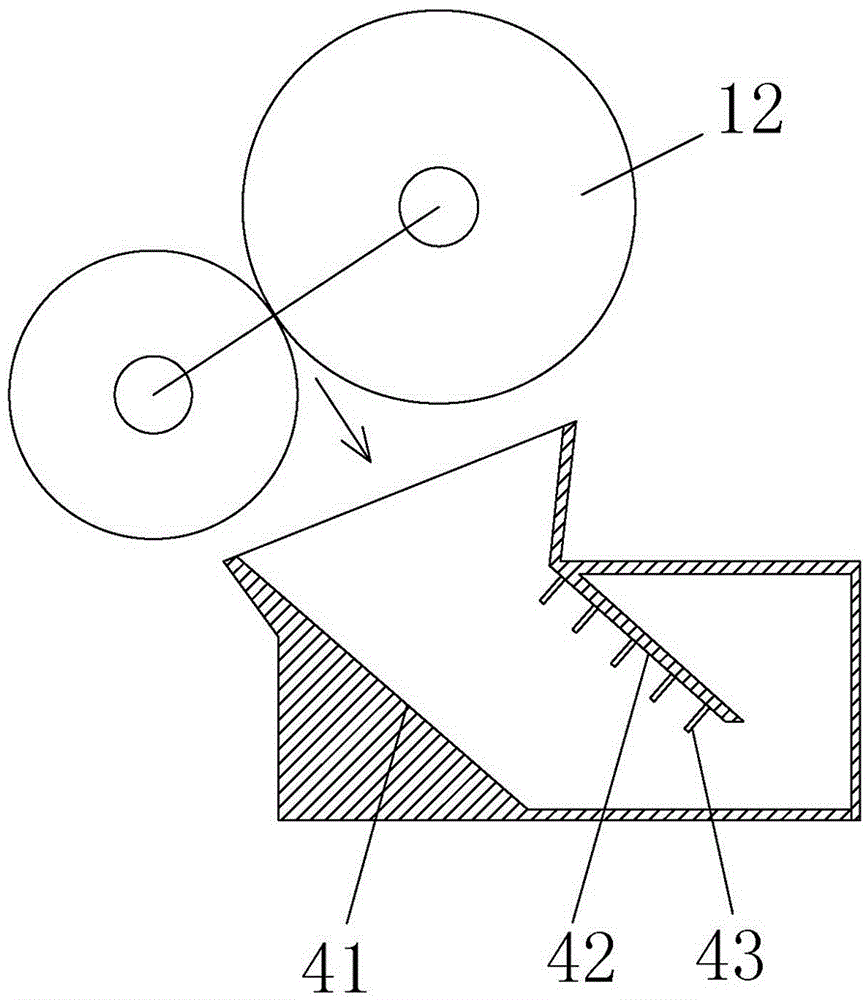

The invention relates to the technical field of outer circle polishing equipment, in particular to a quartz plate outer circle polishing machine. The quartz plate outer circle polishing machine comprises a clamping device, a polishing device and a positioning device; the clamping device comprises clamping discs and a clamping base, the clamping base is arranged on the positioning device, and the clamping discs are rotationally mounted on the clamping base; the clamping discs comprise the driving clamping disc and the driven clamping disc, the driven clamping disc and the driving clamping disc synchronously rotate through a synchronizer, the rotating direction of the clamping discs is identical to that of a grinding wheel, and the clamping discs carry out intermittent rotation. An inclined angle of 45 degrees to 60 degrees is formed between the connecting line between the rotating centers of the clamping discs and the rotating center of the grinding wheel and the horizontal plane. According to the quartz plate outer circle polishing machine, the rebounding height of grindings entering a collecting box relative to the bottom of the collecting box can be effectively reduced, the sputtering preventing effect is good, the clamping discs carry out intermittent rotation, sufficient polishing time can be provided, the polishing effect is good, a quartz plate is firmly clamped, and the surface of the quartz plate is protected against abrasion.

Owner:HUZHOU OPAL QUARTZ TECH

Water-based environment-friendly metal welding base metal protective agent and preparation method thereof

ActiveCN106141501ALow costSimple processWelding/cutting media/materialsSoldering mediaWater basedFilm-forming agent

The invention discloses a water-based environment-friendly metal welding base metal protective agent. The water-based environment-friendly metal welding base metal protective agent is prepared from, by weight percent, 9%-15% of a polymer film-forming agent, 8%-16% of a spreading agent, 5%-10% of a wetting flatting agent, 0.5%-5% of a rust-inhibiting additive, 12%-18% of a cosolvent and 45%-65% of deionized water. The raw materials adopted in the protective agent are environment-friendly, non-poisonous and degradable components; the prepared metal welding base metal protective agent can effectively avoid welding splash adhesion, is easy to clean and moderate in viscosity, and has excellent antirust performance; and the protective agent is suitable for multiple welding positions of flat welding, transverse welding, vertical welding, overhead welding and the like. The invention further discloses a preparation method of the water-based environment-friendly metal welding base metal protective agent. According to the preparation method, no heating is needed, operation is easy, the application range is wide, and cost is low.

Owner:南京尚易环保科技有限公司

Reflective and heat-isolation coating and preparation method thereof

InactiveCN107298886AExcellent reflective insulation performanceEnergy savingFireproof paintsAntifouling/underwater paintsIonEmulsion

The invention relates to a reflective and heat-isolation coating and a preparation method thereof. The reflective and heat-isolation coating is characterized by being prepared from the following raw materials in parts by weight: 40 to 60 parts of macromolecular emulsion, 4 to 8 parts of composite hollow microspheres, 10 to 20 parts of rutile type titanium dioxide, 1 to 3 parts of flame-retardant agent, 0.5 to 2 parts of filming additive, 0.1 to 0.5 part of wetting agent, 0.1 to 0.5 part of dispersant, 0.1 to 0.5 part of preservative, 0.05 to 0.2 part of defoaming agent, 0.01 to 0.2 part of thickening agent, and 10 to 20 parts of deionized water, wherein the macromolecular emulsion is a mixed solution of acrylate emulsion and polyurethane emulsion; the composite hollow microspheres comprise hollow glass microspheres, hollow ceramic microspheres, and fly ash hollow microspheres. The reflective and heat-isolation coating has the advantages that the components are scientifically compounded, the usage amount of the coating is small, the use cost is low, the reflective and heat-isolation effects of the coating thin layer are good, the construction is rapid, the anti-cracking property, anti-dirt property and weather-resistant property are good, and the certain flame-retardant function is realized.

Owner:张聪聪

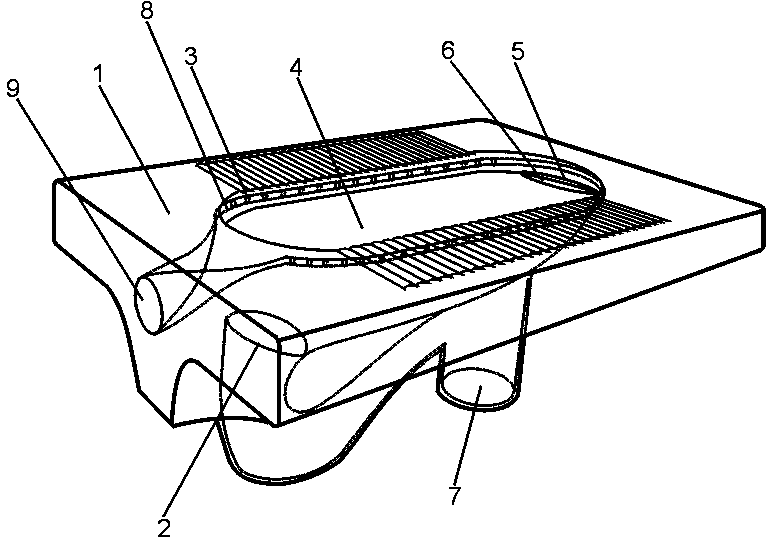

Splash-proof structure of wash basin

The invention relates to a splash-proof structure of a wash basin. By the aid of the splash-proof structure, the technical problems of insufficient reasonableness and the like of designs in the priorcan be solved. The splash-proof structure comprises a wash basin body. The wash basin body is provided with an open upper end and a closed lower end and is of a double-layer hollow structure with a drainage cavity, a drain hole which is communicated with a drain pipe is formed in the lower end of the wash basin body, an overflow hole which is communicated with the drainage cavity is formed in theinner side of the upper end of the wash basin body, the drainage cavity is communicated with the drain pipe via a drainage assembly, a plurality of water barriers are movably arranged on the peripheral outer side of the upper end of the wash basin body, a side of each water barrier is slidably connected with the wash basin body by a slide connecting structure, and the other end of each water barrier is obliquely upwardly arranged away from a side of the wash basin body in an extension manner. The splash-proof structure has the advantages that the water barriers can be withdrawn to stop water flow from splashing, good splashing preventive effects can be realized, and the ground below the wash basin can be prevented from getting wet; the water barriers can be stored in the wash basin withoutoccupying spaces of a bathroom when not used.

Owner:杜盼潇

Composite boiler and method of manufacturing the same

InactiveCN101342048AEmbossed texture is clear and obviousEnsure consistencyCooking-vessel materialsFlangingMetal substrate

The invention relates to a combined pot, which comprises a pot body made of non-magnetic conducive metal substrate and a magnetic conducive heating metal plate which is combined on the exterior bottom surface of the pot body through cold extrusion. A plurality of flanged holes are punched in the magnetic conducive heating metal plate; the magnetic conducive heating metal plate is attached to the exterior bottom surface of the pot body through cold extrusion to extrude the substrate of the pot body in the flanged holes in the magnetic conducive heating metal plate after plastic deformation; at the same time, the flanging of the flanged holes is inserted into the exterior bottom surface of the pot body to fixedly combine the magnetic conducive heating metal plate in the exterior bottom surface of the pot body. The invention is characterized in that imprint patterns matched with the shape of the flanging and the arrangement of the flanged holes of the magnetic conducive heating metal plate are formed through mold punching in the exterior bottom surface of the pot body. The imprint patterns of the combined pot have good stability, repeatability and industrial properties, and the invention has good anti-splashing effect.

Owner:陆意祥

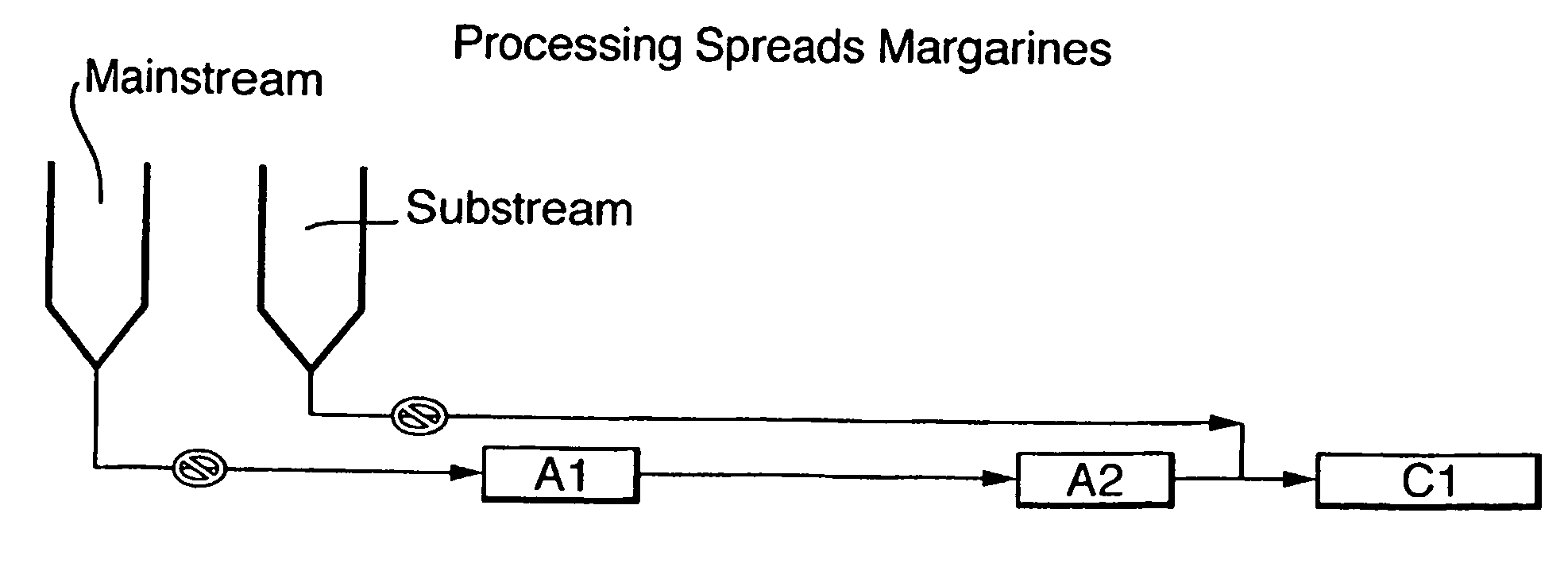

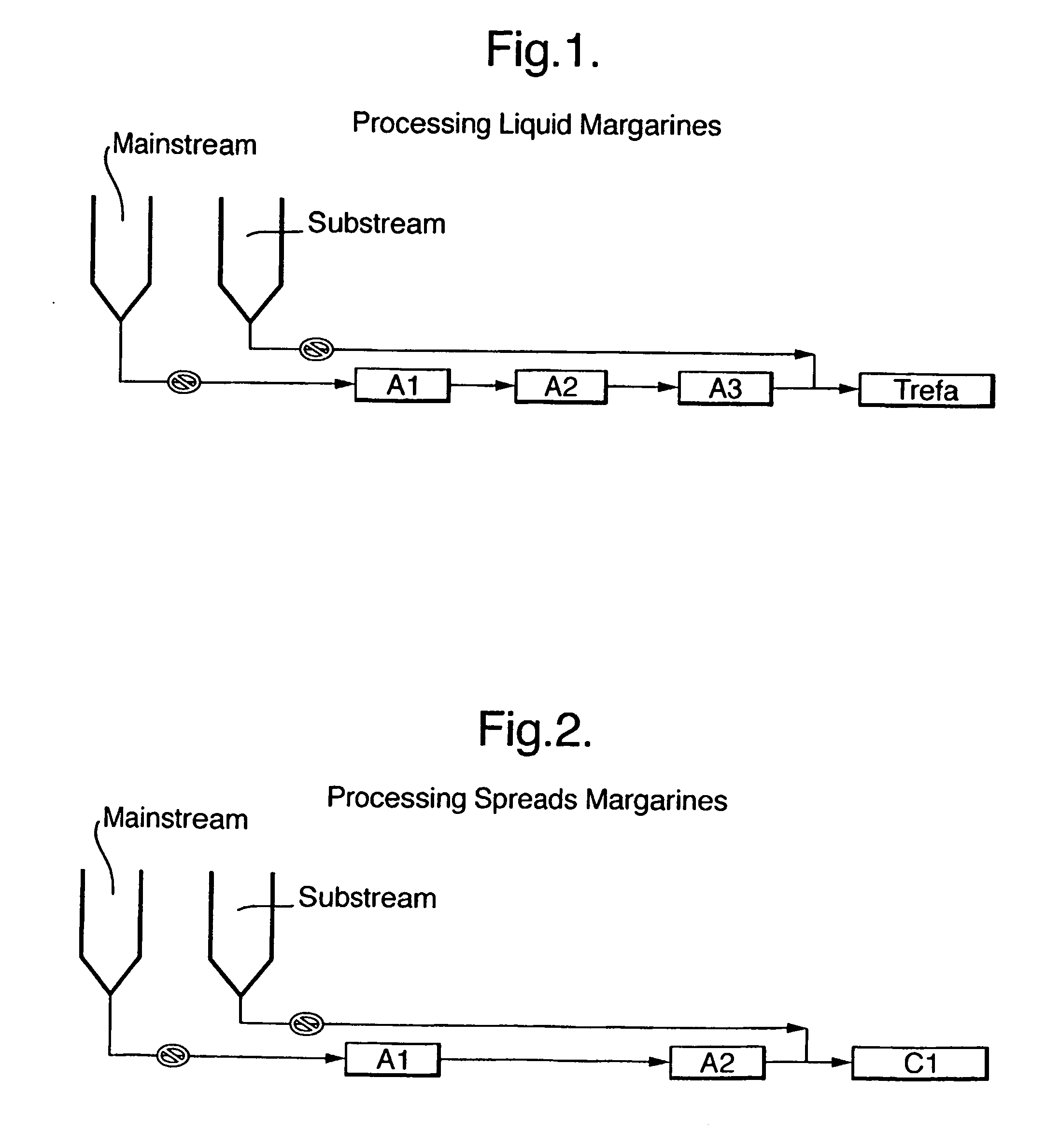

Water-in-Oil Emulsion With Improved Spattering Behaviour

ActiveUS20080305221A1Low in fatImprove performanceEdible oils/fats ingredientsAvicultureCelluloseVegetable matter

The invention relates to a water-in-oil emulsion food product with improved spattering behaviour comprising 0.1-5 wt. % of a porous powderous vegetable matter made from nuts, seeds, kernels, pits and cellulose having a volume weighted mean particle diameter (d4,3) not exceeding 0.5 mm.

Owner:UPFIELD EURO BV

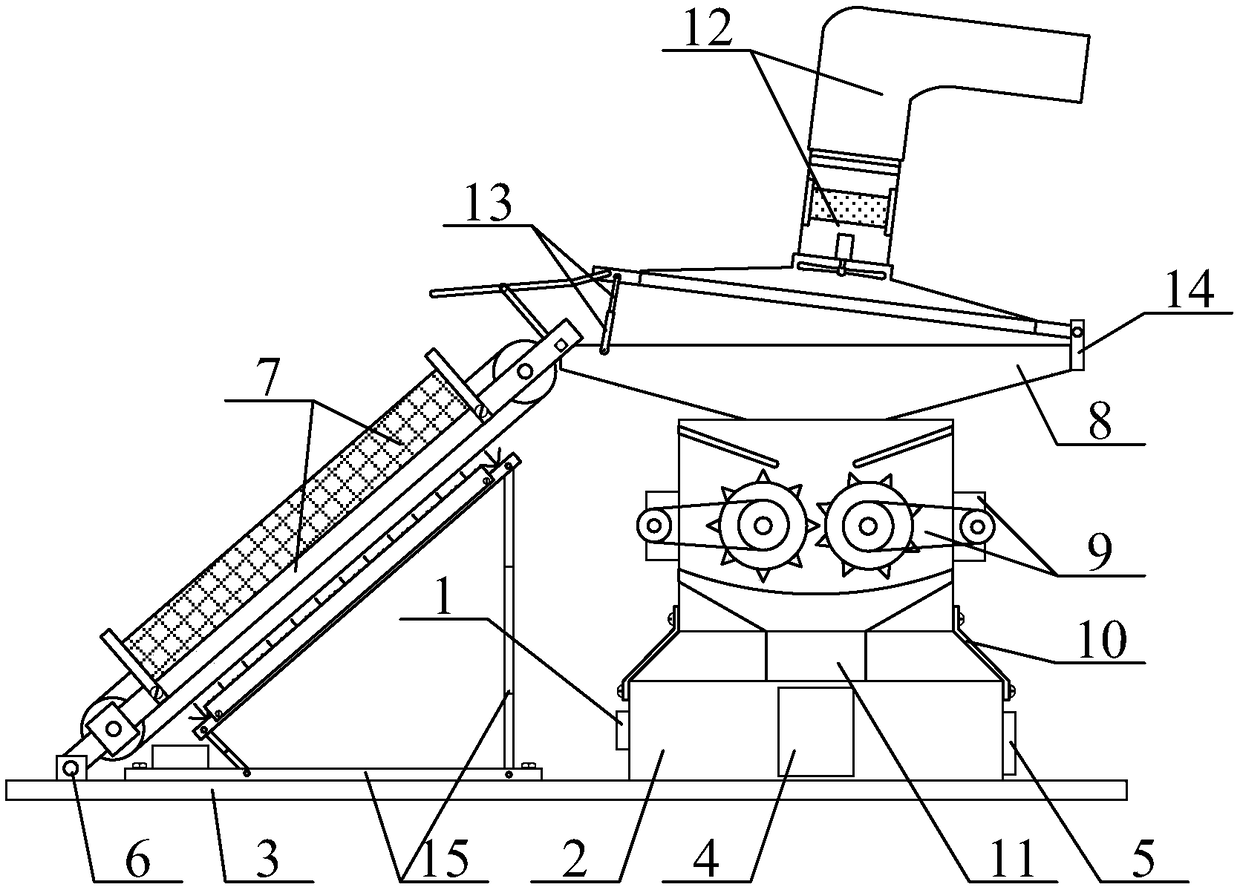

Environment-friendly device for recycling and disposing waste circuit boards

InactiveCN109433314AGood for recycling and crushingPrevent fallingDispersed particle filtrationTransportation and packagingDrive motorAlloy

The invention provides an environment-friendly device for recycling and disposing waste circuit boards. An option switch, a disposing collection box, a base, an observation piece, a clearing door, a fixing seat, a waste circuit board recycling diversion splash-proof net structure, a diversion bucket, a waste circuit board rapid disperser, a supporting plate, a derivation bucket, a waste gas discharge disposable anti-pollution pipe structure, a main telescopic pole, a connecting seat and a conveyor belt surface impurity dust clearing adjustable brush structure are included, and the option switch is connected to the middle position of the left side of the disposing collection box through screws. According to the environment-friendly device for recycling and disposing the waste circuit boards, a diversion seat, a guardrail, a protective net, a driven rotary drum, a driving rotary drum, a driving motor and a conveyor body are arranged, the waste circuit boards are conveniently recycled andcrushed, meanwhile, the problem of falling during recycling can be solved, and the good protective action is played; and a splash-proof adjustment plate and an aluminum alloy supporting seat are arranged, the good splash-proof action is played advantageously, and the fact that slipping of the waste circuit boards affects disposing work is avoided.

Owner:王思琦

Total-pressure toilet bowl capable of realizing clingy surface flushing and internally encircling washing

InactiveCN102505745AIncrease pressureIncrease flow rateWater closetsLavatory sanitoryEngineeringGuide tube

The invention discloses a total-pressure toilet bowl capable of realizing clingy surface flushing and internally encircling washing, which comprises a water inlet hole, a panel, a skirt, an inner ring groove, a pressure guiding tube, an overflow dam, a flushing opening and a blow-off opening. Water is fully filled in the pressure guiding tube continuously, total water supply pressure is transmitted to the flushing opening, the skirt controls a main flow to realize clingy surface flushing to the bottom of a toilet bowl, and seamless synchronous washing of the periphery of the toilet bowl is realized by the inner ring groove. The total-pressure toilet bowl resolves problems that an existing sanitary appliance cannot realize powerful washing, cannot wash edges, is replaced difficultly, is troublesome in production process, and the like.

Owner:谢伟藩 +1

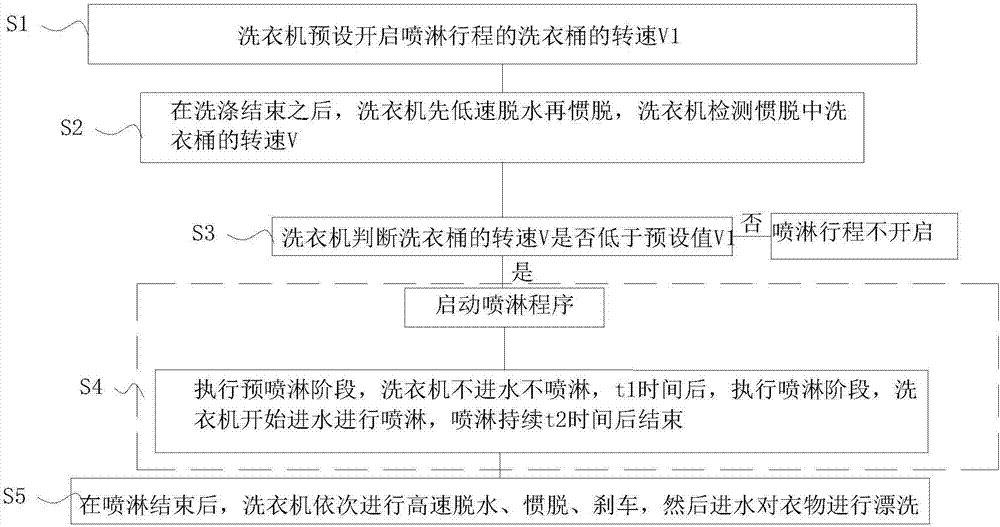

Control method of washing machine and washing machine

ActiveCN107190464AReduce splashImprove the spray effectOther washing machinesControl devices for washing apparatusResonance pointEngineering

The invention belongs to the field of washing machines, and particularly relates to a control method of a washing machine and the washing machine. In the dewatering process before a rinsing procedure, when the washing machine detects that the rotational speed of a washing drum in the dewatering process is reduced to a preset value V1, a spraying procedure is controlled to be started. The control method of the washing machine and the washing machine have the advantages that 1, by detecting the rotational speed of the washing drum, starting of the spraying procedure is controlled according to the rotational speed of the washing drum, spraying is avoided when the rotational speed of the washing drum is near a resonance point, splashing is reduced, and the spraying effect is improved; 2, spraying is conducted in the dewatering process, the cumbersome process of separately setting the spraying procedure is avoided, the dewatering process is fully utilized, and the time is saved; 3, because in the dewatering process, the speed of the washing drum is gradually reduced, the controllability is good, the splash-proof effect is good, and the good spraying effect can be achieved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

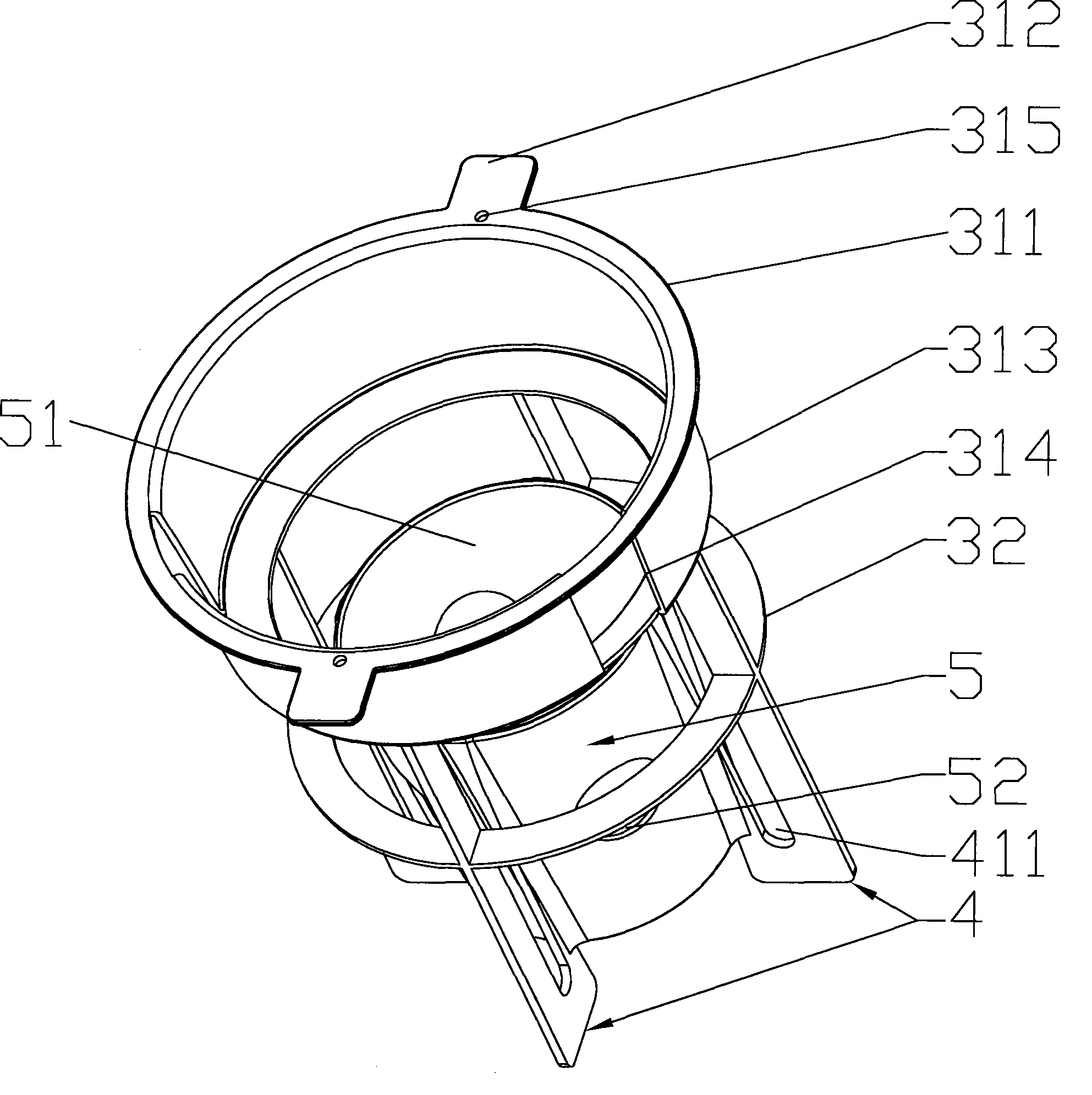

Flow-guiding device of soybean milk machine

InactiveCN101485424AIncreased turbulenceSmash thoroughlyBeverage vesselsFood preparationDischarge rateEngineering

The invention relates to a fluid director for a soybean milk machine. The fluid director provides a diversion cover which is directly sleeved on the upper edge of a cup body of the soybean milk machine and is free from assembly and disassembly, and the diversion cover is provided with a plurality of turbulent flow ribs and an anti-splash baffle plate which can effectively reinforce the turbulent flow while pulping so as to grind bean more thoroughly, prevent splash and improve the pulp discharging rate. The fluid director of the soybean milk machine comprises a machine head of the soybean milk machine and a cup body of the soybean milk machine; a lower cover of the machine head of the soybean milk machine and an electric heating pipe are inserted in the fluid director, and are buckled on the cup body of the soybean milk machine together with the fluid director; and the fluid director consists of a flange positioning structure on the top, the anti-splash baffle plate in the middle part, a diversion cup body on the bottom and the turbulent flow ribs by which the flange positioning structure, the anti-splash baffle plate and the diversion cup body are connected.

Owner:DONGGUAN BBK HOUSEHOLD ELECTRICAL APPLICANCES

Brick for landscaping

InactiveCN107905051APrevent splashSimple structureSingle unit pavingsPaving gutters/kerbsBrickLandscaping

The invention discloses a brick for landscaping and relates to the technical field of building materials. The brick comprises a brick body, water leading holes are formed in the four sides of the brick body correspondingly, and water leading grooves for enabling the water leading holes to communicate with one another are formed in the brick body. According to the brick for landscaping, the problemthat as for an existing brick for landscaping, the accumulated water splashing condition occurs is solved.

Owner:广西金智风工程发展有限公司

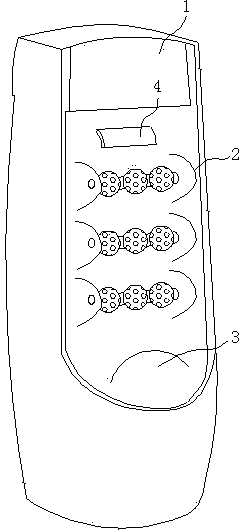

Anti-splashing vertical urinal

The invention belongs to the field of sanitary and bathroom equipment and particularly relates to an anti-splashing vertical urinal which comprises a rear wall, lateral walls, an upper wall and a lower wall of a urinal body, an upper baffle, a lower baffle, a water inlet hole and a drainage ditch. A water saving tank is arranged on the inner side of the upper baffle, the upper wall of the urinal body forms an upper cover of the water saving tank, the rear wall and the lateral walls of the urinal body form a urine region of the urinal body, the bottom of the urine region is in a concave spoon shape, and the drainage ditch is formed in the concave-spoon-shaped bottom. The anti-splashing vertical urinal further comprises a rolling body device arranged on the urine region. The rolling body device comprises a left supporting seat, a right supporting seat and a rotary shaft, wherein the left supporting seat and the right supporting seat protrude out of the surface of the urine region, the rotary shaft is arranged between the left supporting seat and the right supporting seat, and a rolling body capable of rotating for 360 degrees is arranged on the rotary shaft. Due to the fact that the rolling body is arranged on the urine region, urine injected into the urine region of the urinal from the outside is in contact with the rolling body firstly, impact force of the urine drives the rolling body to rotate, the rotating rolling body throws the urine into the urine region, and splashing of urine is prevented well.

Owner:周卫曾

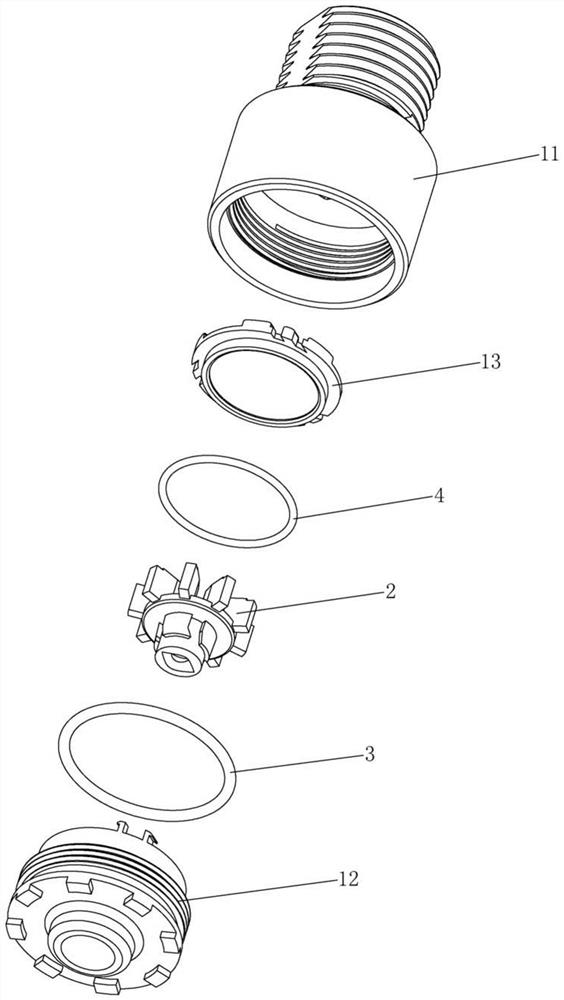

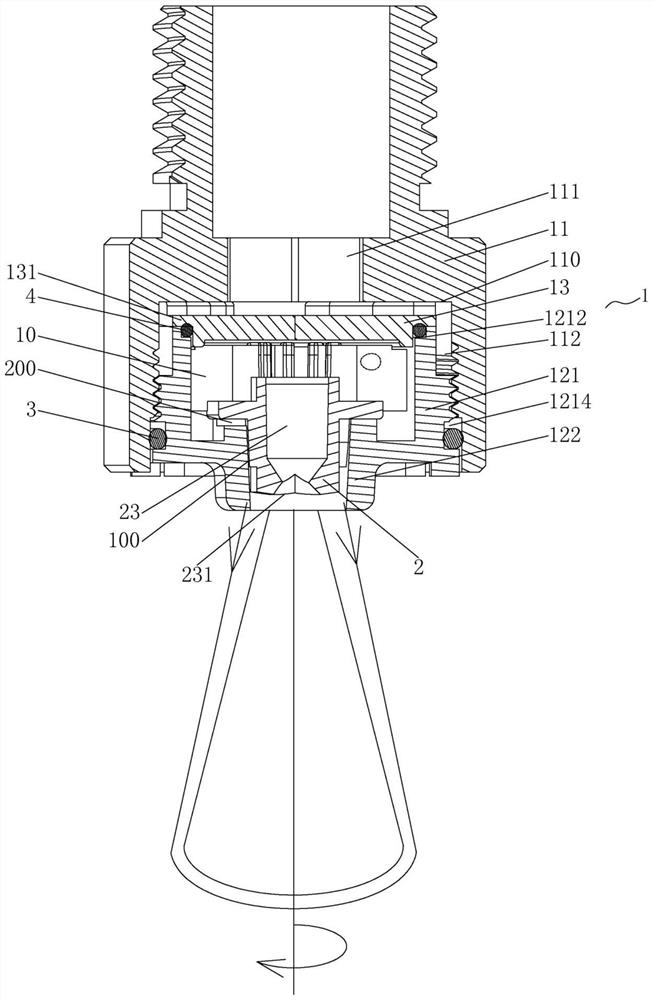

Water outlet device

PendingCN113042235AConcentrated and full water flowReduce opening angleSpray nozzlesHydraulic massageMassageEnvironmental engineering

The invention discloses a water outlet device. In the water outlet device, a body is provided with a water outlet hole; and a rotating piece rotates relative to the axis of the water outlet hole and is provided with a protruding part extending into the water outlet hole. Water outlet gaps are formed between the peripheral wall of the protruding part and the hole wall of the water outlet hole; and the distance between the water outlet gaps is reduced in the water outlet direction. According to the water outlet device, the water outlet initial speed of rotating water spray water outlet in the rotating axis direction can be increased, the field angle of water outlet water spray is reduced, the anti-splashing effect of the rotating water spray is improved, and a user can obtain satisfactory massage washing experience.

Owner:FUJIAN XIHE SANITARY WARE TECH

Invisible-rim veneering potty washing basin

InactiveCN103374959AIncrease pressureIncrease kinetic energyWater closetsMechanical engineeringSewage discharge

The invention discloses an invisible-rim veneering potty washing basin which comprises a potty faceplate, a sewage discharging inlet, washing and brushing holes, a potty bottom, an invisible rim, a main flushing port and a sewage discharging outlet. The invisible rim controls the main flushing port to perform veneered washing and brushing on the potty bottom, so that the problem that existing sanitary appliances are powerless in washing and brushing, non-veneering in brushing and brushing, difficulty in controlling of anti-spattering effect, difficult in replacement, complex in production process and the like.

Owner:GUANGDONG HEGII SANITARY WARES CO LTD

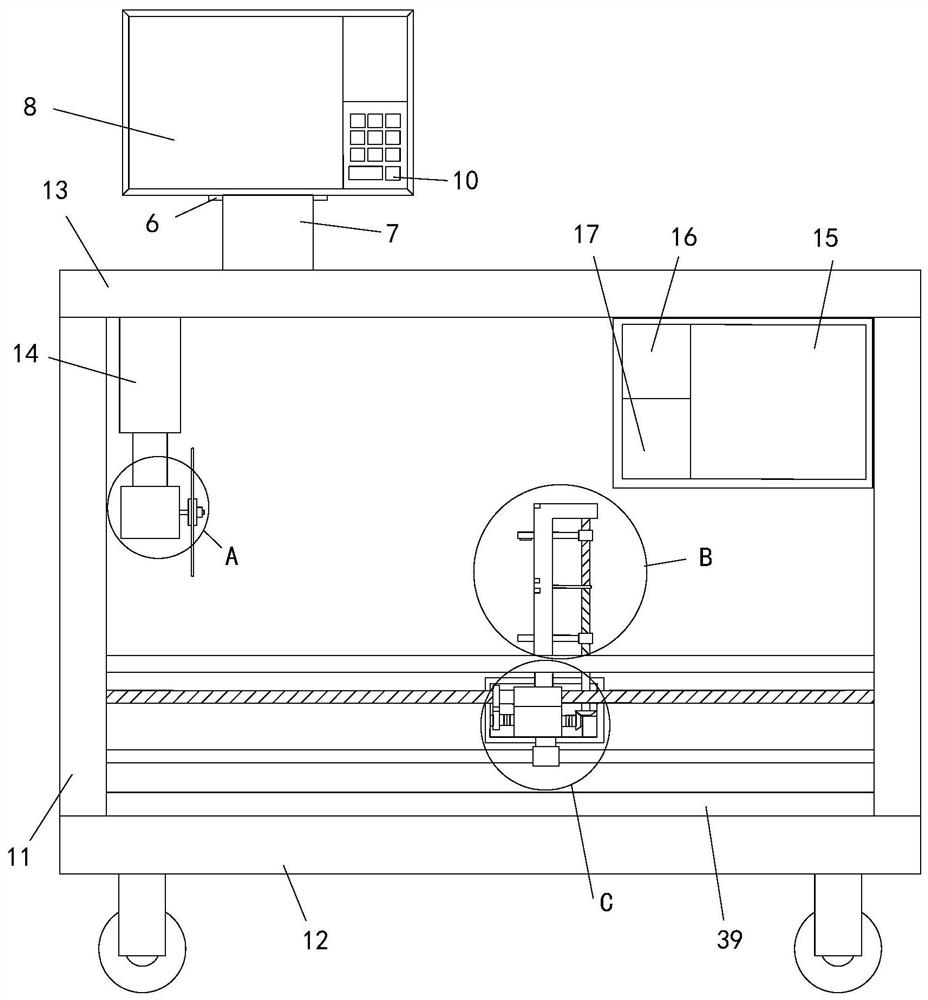

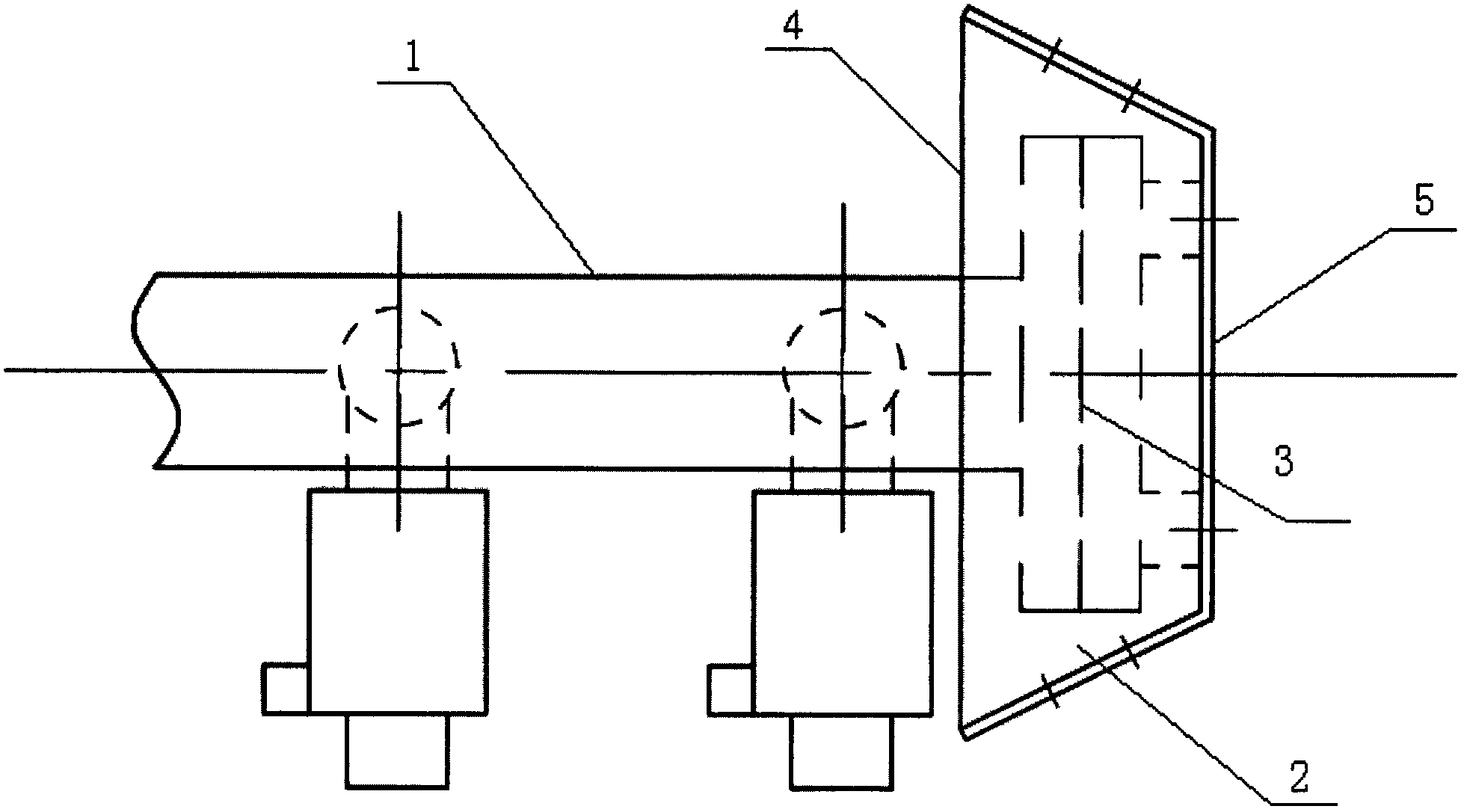

Sectional material sawing device for building decoration and using method thereof

PendingCN112893993ASawing standardComplete sectionMetal sawing devicesElectric machineArchitectural engineering

The invention relates to the technical field of building decoration, in particular to a sectional material sawing device for building decoration and a using method thereof. The sectional material sawing device comprises a bottom plate, wherein vertical plates are arranged on the left side and the right side of the top end of the bottom plate correspondingly, a feeding port is formed in the vertical plate located on the left side, a control panel is arranged at the top end of a rotating ring, an input device is arranged on the control panel, a first telescopic rod is arranged on the left side of the bottom end of a top plate, a motor is arranged at the bottom end of the first telescopic rod, a saw blade is arranged at the output end of the motor, a main machine is arranged on the right side of the bottom end of the top plate, a material pushing controller module and a saw cutting controller module are arranged in the main machine, the vertical plates are connected with each other through a bearing plate, a lead screw and a sliding rail, a sliding groove is vertically formed in the top end of the bearing plate in a penetrating mode, a clamping assembly is slidably connected into the sliding groove, and a movement assembly is arranged on the circumferential outer wall of the lead screw in a sleeving mode. Therefore, the sawing position of a sectional material is accurately positioned, the sawing accuracy and continuity of the sectional material are guaranteed, chippings are isolated, intelligent measurement is adopted, and the error rate is reduced.

Owner:向艳清

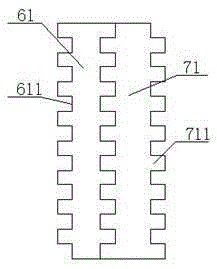

Anti-splashing feed extruder

InactiveCN105396511ASimple structureHigh degree of automationGranulation by material expressionElectric machineryAutomation

The invention discloses an anti-splashing feed extruder. The anti-splashing feed extruder comprises a support, an extruding block a, an extruding block b and an actuating motor, wherein the upper and lower parts of the support are respectively provided with an upper plate and a lower plate which are both provided with chutes; two ends of the chutes are movably provided with rolling balls moving horizontally on the chutes; the extruding block a and the extruding block b are symmetrically arranged between the upper plate and the lower plate via the rolling balls; the middle part of the support is also provided with a sliding guide rail which is provided with two slide blocks; one ends of the slide blocks are respectively fixedly connected with the extruding block a and the extruding block b, and the other ends of the two slide blocks are connected to and installed on the actuating motor on the support. The anti-splashing feed extruder is simple in structure; the actuating motor actuates the slide blocks to move oppositely on the sliding guide rail to extrude the extruding block a and the extruding block b; the automation degree is high; moreover, when the anti-splashing feed extruder operates, concave and convex grooves in the extruding block a and the extruding block b are matched with each other so as to achieve seamless connection; the anti-splashing effect is good; the extrusion surfaces can be cleaned after the separation of the extruding block a and the extruding block b; the operation is convenient.

Owner:TAICANG LUNWEN MACHINERY CO LTD

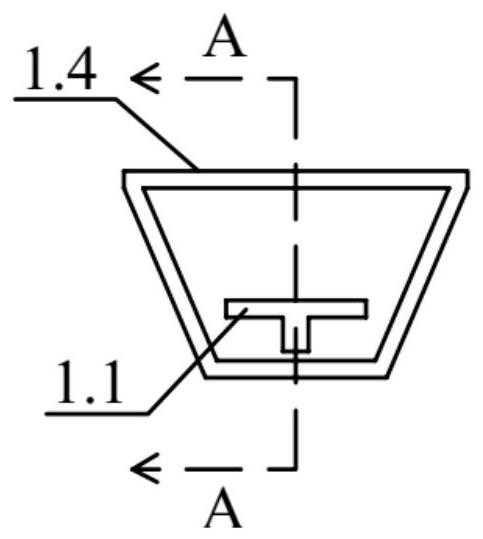

Design method of anti-pollution air knife structure for welding laser lens

The invention discloses a design method of an anti-pollution air knife structure of a welding laser lens. The design method comprises the steps that the mounting position of an air knife main body is determined, the position of the reference surface of an air knife air outlet is determined, the shape and the size of the air knife air outlet are designed, the air knife air outlet is a T-shaped air outlet, the reference surface of the air knife air outlet is the plane where the top of the T-shaped air outlet is located, the size of the T-shaped air outlet is designed according to the parameters of the laser lens and the distance H between the reference surface of the air knife air outlet and the plane where the laser focusing lens is located, and the height h1 and the width w1 of the upper portion of the T-shaped air outlet and the height h2 and the width w2 of the lower portion of the T-shaped air outlet need to meet the following formula, w1h1 = w2h2. By means of the design method, design of an anti-lens pollution air knife can be rapidly and conveniently realized, and the designed air knife has an excellent lens protection effect.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD +1

Metal cutting equipment with anti-splashing function

PendingCN114309768AWith anti-splash functionGradient JudgmentFeeding apparatusTube shearing machinesPipe fittingMetal machining

The invention relates to the technical field of metal processing, and discloses metal cutting equipment with an anti-splashing function, which comprises a bottom plate, a mounting frame is fixedly connected to the upper surface of the bottom plate, two first sliding grooves are formed in the upper surface of the mounting frame, and second sliding seats are movably connected to the interiors of the first sliding grooves; a second electric telescopic rod is fixedly connected to the upper surface of the mounting frame, the second electric telescopic rod is fixed to a second sliding seat, and a rotating plate is movably connected to the inner wall of one side of the second sliding seat. According to the device, the inclination of a metal pipe fitting can be accurately judged through matched use of a rotating plate and a stress plate, the detection effect of the device is improved, the metal pipe fitting can be supported after being cut through matched use of an auxiliary plate and a first sliding seat, the protection effect of the device is improved, and the device is convenient to use. And through cooperative use of a protective shell and a baffle, splashing residues generated during cutting can be blocked, and the anti-splashing effect of the device is improved.

Owner:佛山东涵智能科技有限公司

High heat stability welding splashing preventing agent

InactiveCN109822261AAvoid stickingThe degree of condensation increasesWelding/cutting media/materialsSoldering mediaBULK ACTIVE INGREDIENTSe element

The invention discloses a high heat stability welding splashing preventing agent and belongs to the field of metal welding splashing preventing chemical additives. Organic selenium compounds are addedin the high heat stability welding splashing preventing agent, a metal selenide film is generated, and adhesion between splashing metal particles and weldment can be avoided while stability of oily substances is improved; and acid leaching is performed on vermiculite to remove acid-soluble components in the vermiculite and break through pores, citrate can be adsorbed, isocyanate is mixed in, pressurizing mixing treatment is performed, pores are broken through, the adsorbing effect is improved, the vermiculite expands due to heat, and the adsorbed metal particles can be treated in a concentrated manner conveniently; and acrylic acid, acrylamide and the like are used for making polymer gel to serve as a colloidal condition stable component of active ingredients of the high heat stability welding splashing preventing agent, and the splashing preventing effect can be effectively stabilized. The high heat stability welding splashing preventing agent solves the problem that a welding splashing preventing agent commonly used at present is not good in stability and splashing preventing effect under high temperature.

Owner:王若梅

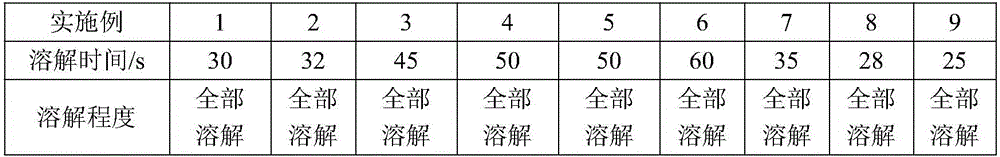

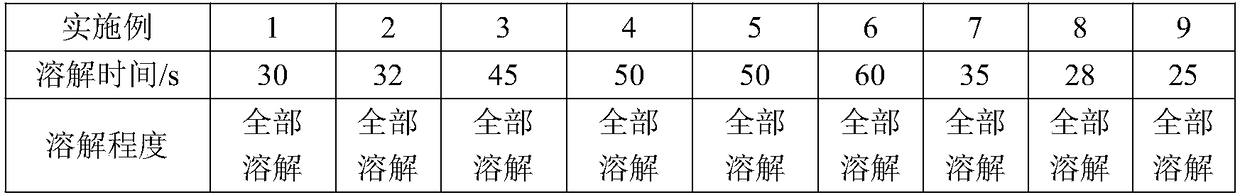

Preparation method of fluxing agent coverage piece

ActiveCN106706387AReduce meltingAvoid lostPreparing sample for investigationMaterials preparationLithium metaborate

The invention relates to a preparation method of a fluxing agent coverage piece. According to technical scheme, material preparation is performed according to the mass ratio 1: (1-5) of a solid fluxing agent to an ash-free binding agent, and even mixing is performed to obtain a mixture; then, pure water is added to the mixture, the adding amount of the pure water is 10-50% of the weight of the mixture, and even mixing is performed to obtain a plastic material; the plastic material is transferred to a cylindrical mold to make a cylindrical green body through molding, then the cylindrical green body is sliced, and drying is performed to obtain the fluxing agent coverage piece. The solid fluxing agent is one of lithium carbonate, lithium tetraborate, lithium metaborate, sodium carbonate and boric acid, the purity of the solid fluxing agent is 99.9% or above, and the particle size is smaller than 0.5 mm. The ash-free binding agent is one of polyvinyl alcohol, polyethylene, polypropylene and polyacrylate. The ash content of the ash-free binding agent is smaller than 0.01% by weight. The preparation method has the advantages of being simple and convenient to operate, good in splash preventing effect, saving time and high in efficiency.

Owner:宁波飞创制药设备有限公司

Lathe capable of preventing cut article from flying

InactiveCN107627147APrevent splashSimple structureMaintainance and safety accessoriesAgricultural engineeringEngineering

The invention discloses a lathe capable of preventing cut articles from flying. The lathe comprises a lathe body, wherein a cutting part is arranged on the lathe body; a protection cover for preventing the cut articles from flying is arranged on the cutting part. A mounting groove is formed in the cutting part; the protection cover is embedded into the mounting groove and is fixed with the cuttingpart. The outer side wall of the mounting groove is higher than the inner side wall of the mounting groove; the height that the outer side wall of the mounting groove is higher than the inner side wall of the mounting groove is equal to the thickness of the protection cover, and then the upper end surface of the cutting part is kept flat when the protection cover is embedded into the mounting groove. Cut articles are prevented from flying by mounting the protection cover on the cutting part of the lathe, and the lathe is simple in structure, easy to implement and good in flying prevention effect.

Owner:广东湘凯办公家具有限公司

Fender

InactiveCN112644590AImprove space utilizationEasy to shapeSuperstructure subunitsFenderIndustrial engineering

The invention provides a fender, and relates to the technical field of fenders. According to the fender, a restraining plate is arranged on the side, close to a wheel, of the fender, a plurality of restraining units are arranged on the restraining plate, and an overlapping part is arranged between every two adjacent restraining units. Due to the fact that every two adjacent restraining units have the common edge, the space utilization rate of the restraining plate is high, the anti-splashing effect is good, and the production cost is low.

Owner:宁波联华汽车部件有限公司

A kind of water-based environment-friendly metal welding base metal protective agent and preparation method thereof

ActiveCN106141501BLow costSimple processWelding/cutting media/materialsSoldering mediaWater basedFilm-forming agent

The invention discloses a water-based environment-friendly metal welding base metal protective agent. The water-based environment-friendly metal welding base metal protective agent is prepared from, by weight percent, 9%-15% of a polymer film-forming agent, 8%-16% of a spreading agent, 5%-10% of a wetting flatting agent, 0.5%-5% of a rust-inhibiting additive, 12%-18% of a cosolvent and 45%-65% of deionized water. The raw materials adopted in the protective agent are environment-friendly, non-poisonous and degradable components; the prepared metal welding base metal protective agent can effectively avoid welding splash adhesion, is easy to clean and moderate in viscosity, and has excellent antirust performance; and the protective agent is suitable for multiple welding positions of flat welding, transverse welding, vertical welding, overhead welding and the like. The invention further discloses a preparation method of the water-based environment-friendly metal welding base metal protective agent. According to the preparation method, no heating is needed, operation is easy, the application range is wide, and cost is low.

Owner:南京尚易环保科技有限公司

Metal cutting equipment for metal can machining

ActiveCN114260514AImprove clamping stabilityPrevent splashPositioning apparatusMaintainance and safety accessoriesRocker armMaterials science

The invention discloses metal cutting equipment for metal can machining and relates to the technical field of metal cutting, the metal cutting equipment comprises a base and a machining table, a support is mounted at the top of the base, a sliding rod is mounted at the top of the support, a rocker arm is slidably connected to the outer surface of the sliding rod, and a hydraulic telescopic rod is mounted at the top of the rocker arm; a sliding rail is installed on the surface of the rocker arm, a cutting assembly is connected to the surface of the sliding rail, and an auxiliary assembly is connected to the bottom of the cutting assembly. According to the multi-surface cutting device, the multiple assemblies are arranged in a matched mode, the protection performance during machining can be improved, splashing of chippings can be stopped, meanwhile, the cutting angle can be adjusted through the adjusting assembly, the convenience of multi-surface cutting machining is improved, the transparent baffle can automatically follow to change the shielding angle during adjustment, and the machining efficiency is improved. And through the arrangement of the limiting assembly, the clamping firmness of the machined workpiece can be improved, the application range of the clamping device can be widened, and the universality of the clamping device is improved.

Owner:SHENZHEN MEIXINLONG CAN CO LTD

A Design Method of Anti-pollution Air Knife Structure for Welding Laser Lens

The invention discloses a design method of an anti-pollution air knife structure for a welding laser lens, which includes determining the installation position of the main body of the air knife, determining the reference plane position of the air outlet of the air knife, and designing the shape and size of the air outlet of the air knife. It is a T-shaped air outlet, and the reference plane of the air knife outlet is the plane where the top of the T-shaped air outlet is located. The size of the T-shaped air outlet is based on the parameters of the laser lens and the distance H between the reference plane of the air knife outlet and the plane where the laser focusing lens is located. Design, the height h of the upper part of the T-shaped air outlet 1 , width w 1 and the height h of the lower part of the T-shaped air outlet 2 , width w 2 The following formula needs to be satisfied: w 1 h 1 =w 2 h 2 , the design method can quickly and easily realize the design of the anti-lens pollution air knife, and the designed air knife has excellent lens protection effect.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD +1

Outer hanging type lateral sputtering prevention device

The invention discloses an outer hanging type lateral sputtering prevention device, which comprises a spreading and distributing rod, wherein the two ends of the spreading and distributing rod are provided with protection devices, and the spreading and distributing rod is connected with the protection devices through flanges. The outer hanging type lateral sputtering prevention device has the advantages that the spreading and distributing rod and the protection devices are connected through the flanges, so the mounting and the dismounting of the spreading and distributing rod and the protection devices are convenient, the cleaning and the equipment maintenance are convenient, the multi-direction regulation of the protection devices can also be convenient through the flange connection, an outer support frame and rubber are light in material, the protection devices are arranged at two sides of the spreading and distributing rod so that the sputtering prevention effect is good, the cleaning and the quality maintenance of road and spreading and distributing vehicle equipment are favorably realized, the construction efficiency is ensured, and the equipment cost is saved.

Owner:NANTONG SOUTHEAST HIGHWAY ENG

Cooling liquid sputtering prevention device for polymer synthetic new material processing

PendingCN112427730ASolve the problem of protection and poor protection effectGood anti-splash effectMetal sawing devicesMaintainance and safety accessoriesEngineeringMaterials processing

The invention discloses a cooling liquid sputtering prevention device for polymer synthetic new material processing. The cooling liquid sputtering prevention device for polymer synthetic new materialprocessing comprises a workbench, a clamping mechanism is arranged in the workbench, a first supporting plate is fixedly connected to the back surface of the workbench, a second supporting plate is fixedly connected to the top of the front surface of the first supporting plate, and an air cylinder is fixedly connected to the right side of the bottom of the second supporting plate. According to thecooling liquid sputtering prevention device for polymer synthetic new material processing, an electric box and a protective sleeve are driven by the air cylinder to move downwards, the protective sleeve can protect cooling liquid through a baffle while pressing a metal material through a square spray head, therefore, the advantage of being good in sputtering prevention effect is achieved, and theproblems that a cooling liquid sputtering prevention device of an existing cutting device only protects cooling liquid through a spacer sleeve on a cutting disc, and the protection effect is poor aresolved; and the phenomenon that in the protection process, more cooling liquid still splashes out, and consequently waste is caused is avoided, and use is convenient for people.

Owner:诸暨伍凯机械有限公司

Water-based rustproof splash proof adherent for metal welding

InactiveCN1272141CAvoid stickingReduce cleanup workloadWelding/cutting media/materialsSoldering mediaWater basedAlkylphenol

The water-based rustproof splashproof adherent for metal welding consists of C12-C18 fatty acid polyethenoxy ether, C3-C9 alkylphenol ethoxylate, C10-C18 alkyl diethanolamide and water. It can prevent the welded product from becoming rust within 7 days, prevent the splashed matter produced in welding from adhering to the surface of the workpiece, reduce the post-welding processing of the welded workpiece, and raise the surface smoothness and the overall quality of the welded product. The water-based rustproof splashproof adherent has high splashproof effect, no toxicity, no environmental pollution, high welding quality and other advantages, and may be used widely in metal welding.

Owner:西安昌泰化工厂

An inlet-immersed energy conduction squatting pan

The invention provides an inlet-immersed energy conduction squatting pan comprising a panel, a rinsing hole, a water guide ring, a defecation pan, a sewage draining exit, and a water inlet. The height of the upper edge of the water inlet is lower than the height of the lower edge of the water guide ring, so that the whole water inlet is immersed in water for a long time and thus the problem of kinetic energy attenuation caused by air flow of the rinsing hole during flushing is solved, so that the objectives of powerful rinsing, powerful replacement, water saving and splashing prevention are achieved.

Owner:GUANGDONG HEGII SANITARY WARES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com