Metal cutting equipment for metal can machining

A technology of metal cutting and metal cans, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of easily soiling the clothes of the processing personnel, debris mixed with water splashes, and easy accidental injury to the staff, etc. , to achieve the effect of improving the protection ability, improving the anti-splash ability, and improving the firmness of the clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

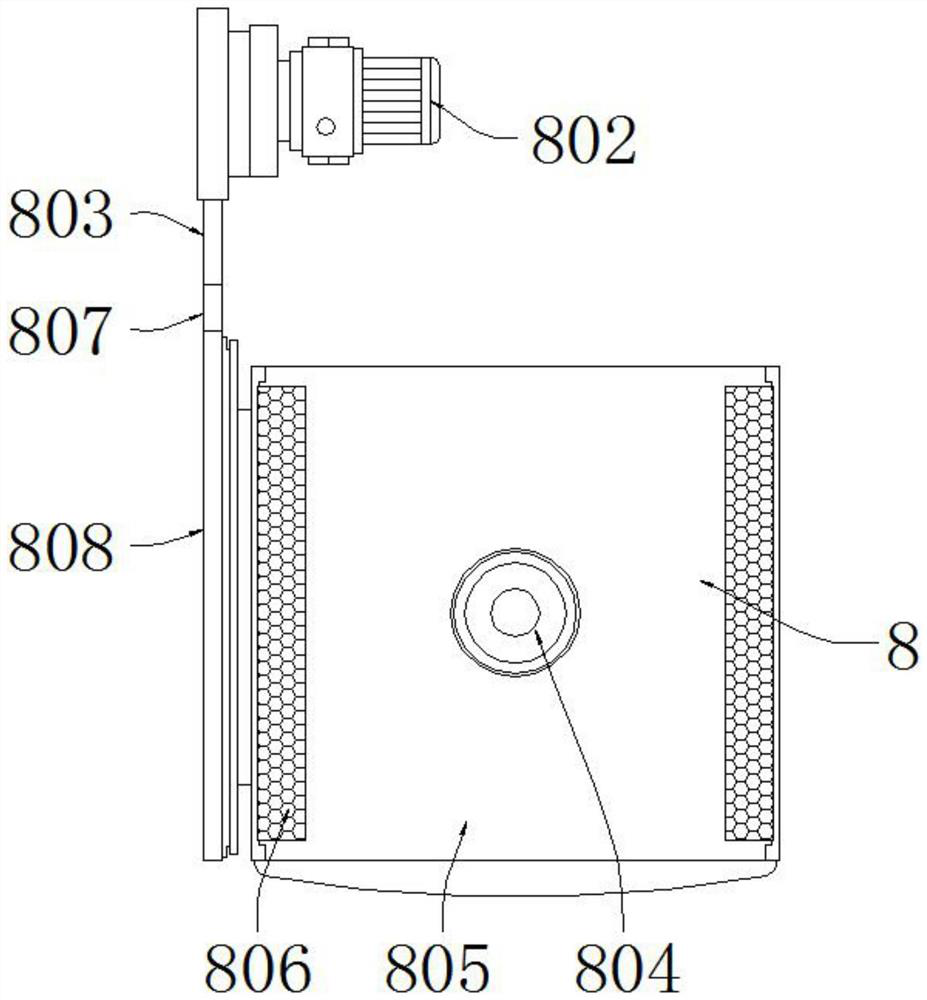

[0026] see Figure 1-5 , the present invention provides a technical solution: a metal cutting equipment for metal can processing, including a base 1 and a processing table 9, a bracket 2 is installed on the top of the base 1, and a slide bar 3 is installed on the top of the bracket 2, and the outer surface of the slide bar 3 is A rocker arm 4 is slidingly connected, and a hydraulic telescopic rod 5 is installed on the top of the rocker arm 4, a slide rail 6 is installed on the surface of the rocker arm 4, and a cutting assembly 7 is connected to the surface of the slide rail 6, and an auxiliary assembly 8 is connected to the bottom of the cutting assembly 7. The processing table 9 is installed on the right side of the base 1, and the top of the processing table 9 is connected with an adjustment assembly 10, and the auxiliary assembly 8 includes an auxiliary table 801, an adjustment motor 802, a connecting arm 803, a rotary spring 804, a transparent baffle 805 and a magnet plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com