Environment-friendly device for recycling and disposing waste circuit boards

A technology for waste circuit boards and processing equipment, applied in grain processing, transportation and packaging, chemical instruments and methods, etc., can solve the problems of inability to remove impurities on the surface of the conveyor belt, unsatisfactory crushing effect, waste gas and air pollution, etc., and achieve good environmental protection. , improve the crushing effect and avoid environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

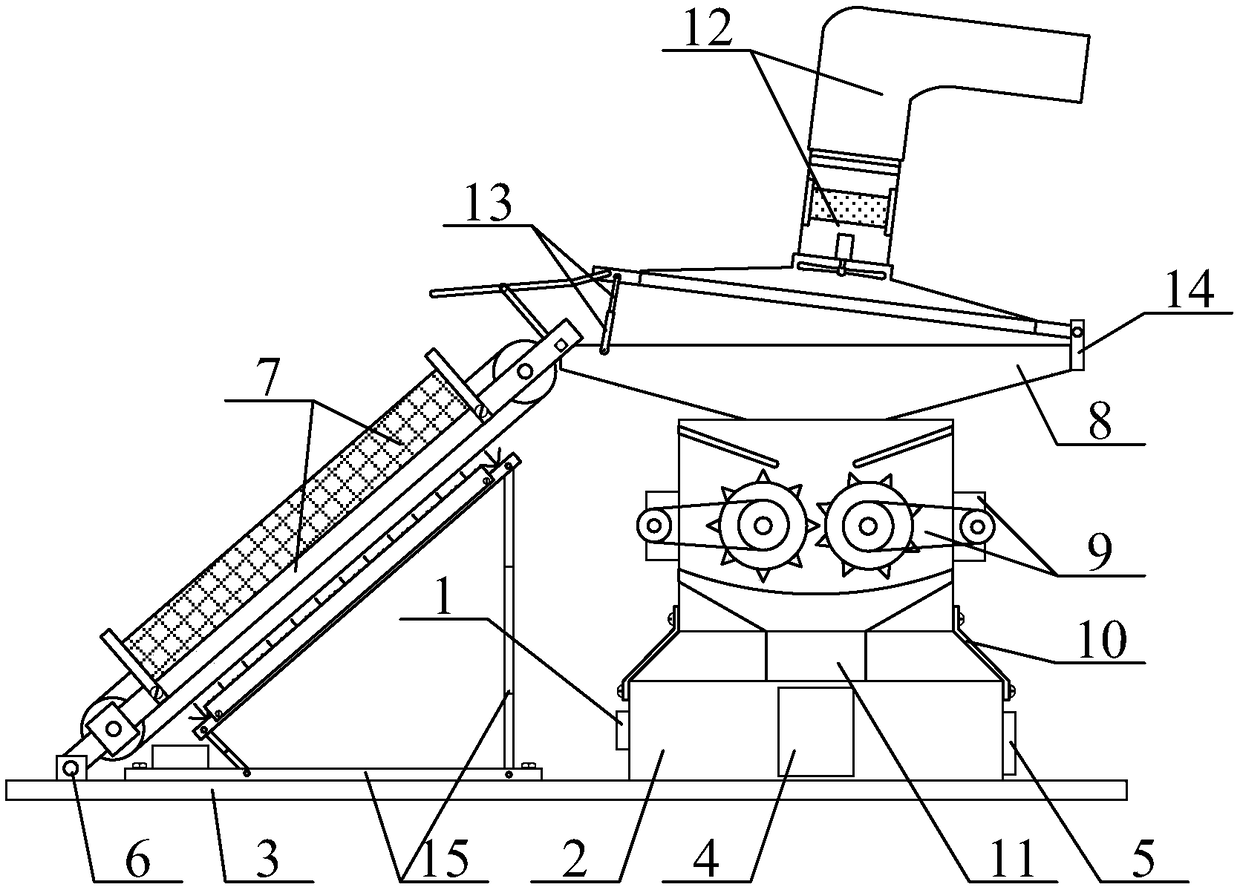

[0065] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, an environment-friendly waste circuit board recycling and processing equipment includes a selection switch 1, a processing collection box 2, a base 3, an observation piece 4, a cleaning door 5, a fixing seat 6, and a waste circuit board recycling diversion and splash-proof net structure 7. Diversion bucket 8, waste circuit board quick shredder 9, support plate 10, export bucket 11, exhaust gas discharge can handle pollution prevention pipe structure 12, main telescopic rod 13, connecting seat 14 and adjustable brush for cleaning impurities and dust on the surface of the conveyor belt Structure 15, the selector switch 1 is screwed to the left middle position of the processing collection box 2; the bottom bolt of the processing collection box 2 is installed at the upper right middle position of the base 3; the observation sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com