Anti-splashing feed extruder

An extrusion device and anti-splash technology, which is applied in the direction of extrusion and granulation of raw materials, can solve the problems of low degree of automation, reduced economic benefits, and large cost input, and achieve the effect of high degree of automation, anti-splash effect and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

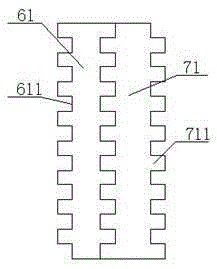

[0016] Such as figure 1 and figure 2 A kind of anti-splash feed extruding device shown, comprises bracket 1, extruding block a6, extruding block b7 and driving motor 10, upper and lower parts of bracket 1 are respectively provided with upper plate 2 and lower plate 3, upper and lower plate Both 2 and 3 are provided with a chute 4, and both ends of the chute 4 are movable with a rolling ball 5 moving horizontally on the chute 4, and the extrusion block a6 and the extrusion block b7 are symmetrically arranged on the top of the chute 4 through the rolling ball 5. , between the lower plates 2 and 3, the middle part of the bracket 1 is also provided with a sliding guide rail 8, and the sliding guide rail 8 is provided with two sliders 9, and one end of the two sliders 9 is respectively fixedly connected to the extrusion blocks a6, b7, and the two The other end of each slide block 9 is connected with the driving motor 10 installed on the support 1, and the upper and lower plates 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com