Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Improve solder joint quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

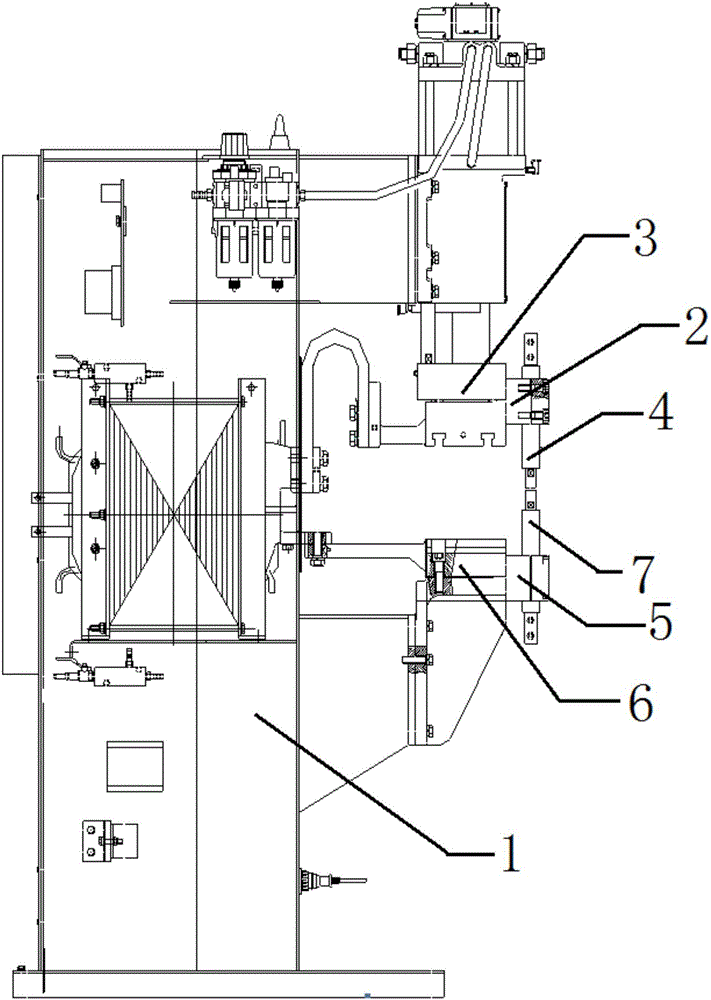

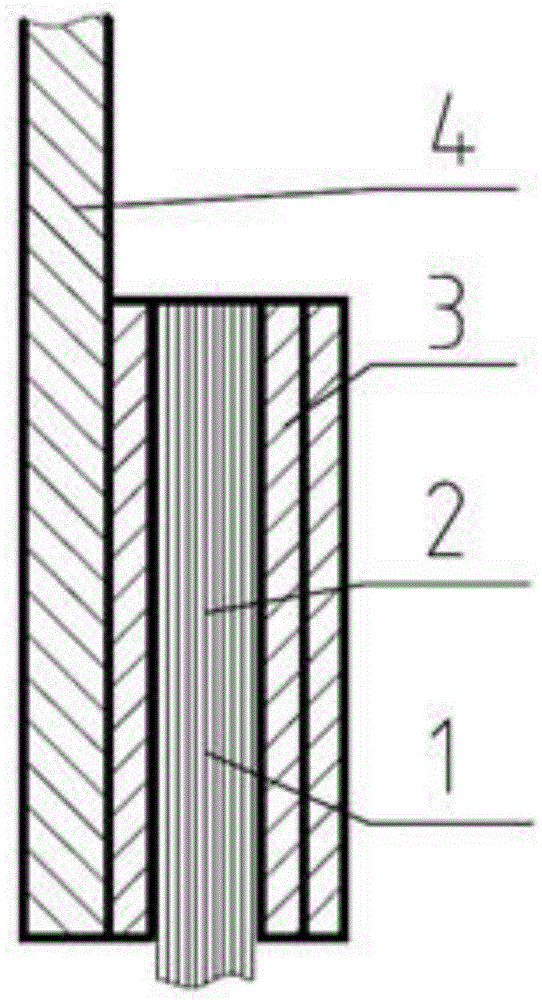

Steel meshwork automatic welding device and production technology thereof

InactiveCN101913020AMeet the work intensityMeet job requirementsWelding electric supplyProgramme control in sequence/logic controllersNumerical controlTransformer

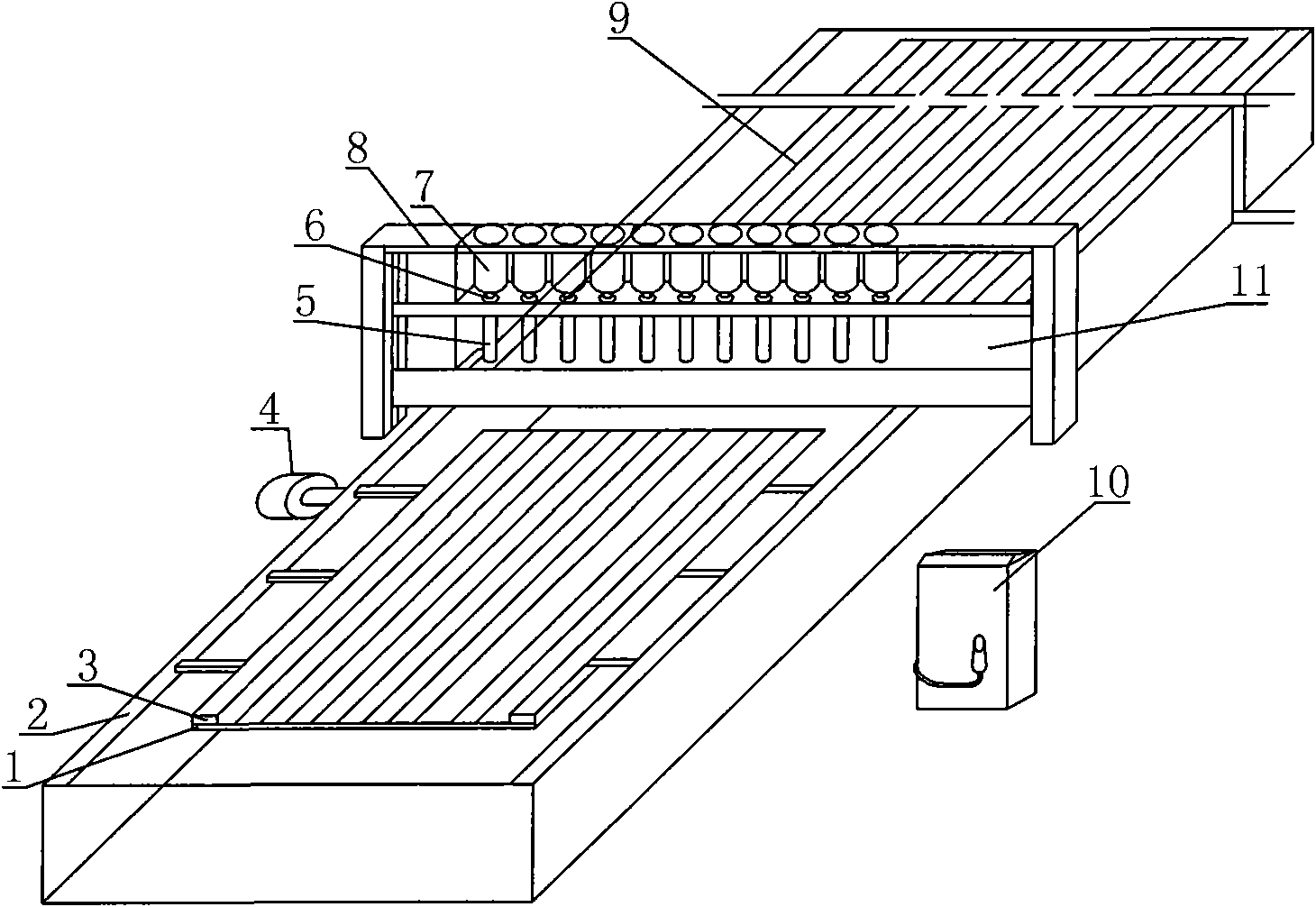

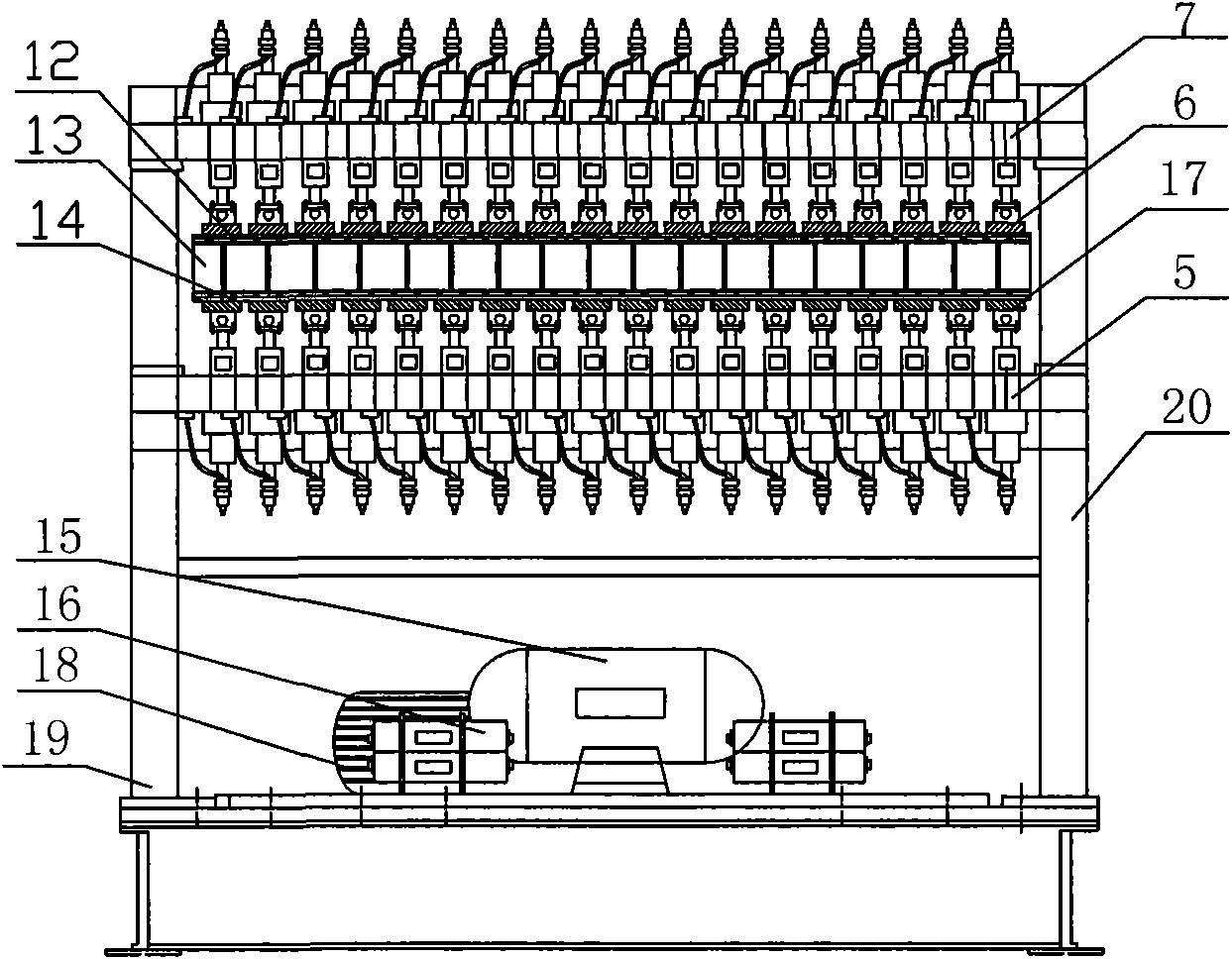

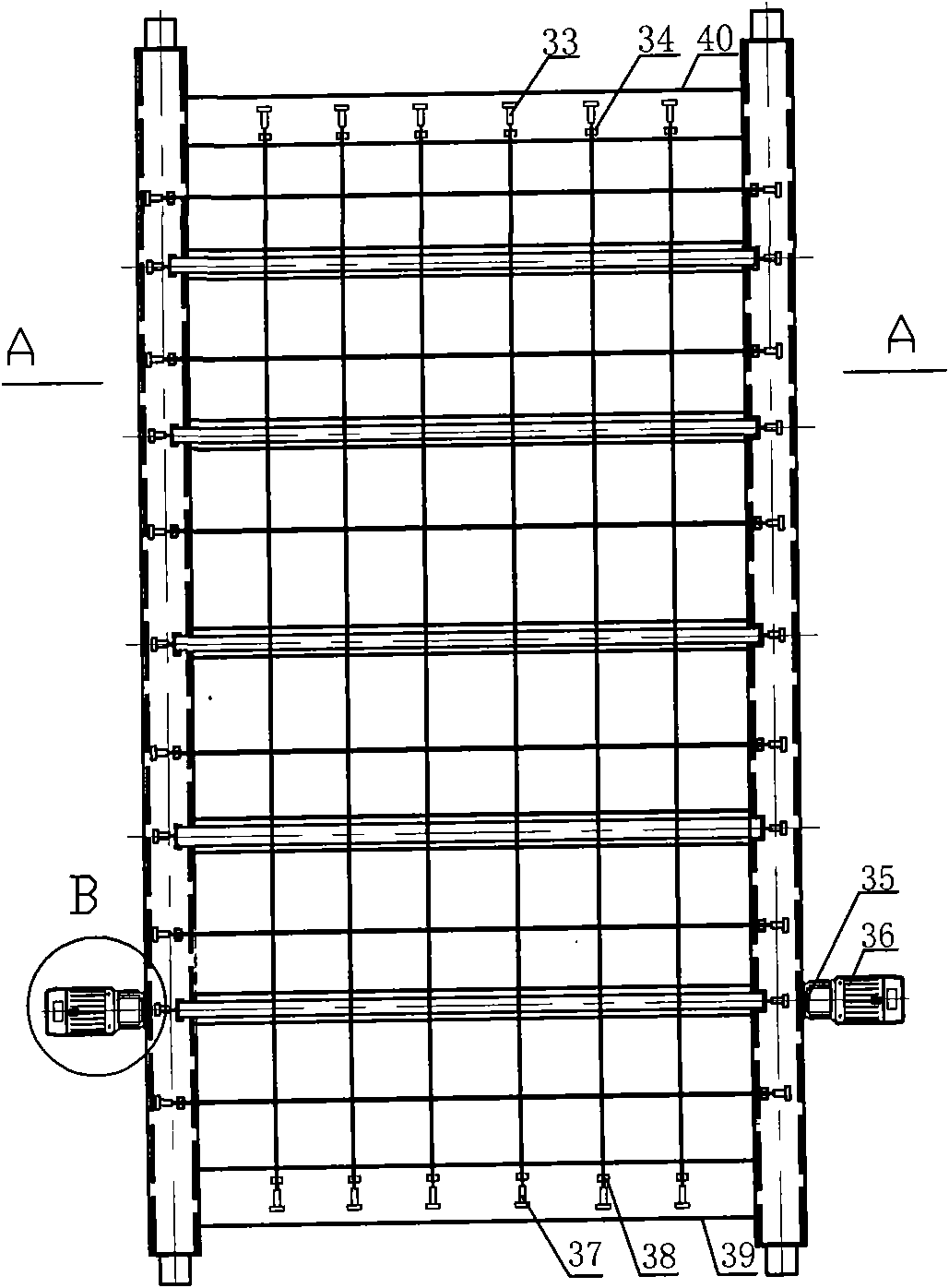

The invention belongs to the technical field of mechanical-electrical integration and particularly relates to a steel meshwork automatic welding device and production technology thereof. The device of the invention comprises a gantry pressure welding frame, a numerical control pressure welder, a pressurizing mechanism, a resistance welding transformer, an electric control cabinet, a resistance welding controller, a trolley track, a mould base trolley, a step trolley, a demountable welding fixture and a servo drive device, wherein the mould base trolley contains a mould base cross beam, a mould base left end beam, a mould base right end beam, mould base trolley wheels, a left lateral overturning and positioning frame, a right lateral overturning and positioning frame, a left lateral overturning cylinder, a right lateral overturning cylinder, positioning frame pins, an upper positioning block, a lower positioning block, a mould base front end beam, a mould base back end beam, a front lateral overturning positioning frame, a back lateral overturning positioning frame, a front lateral overturning cylinder, a back lateral overturning cylinder, and positioning frame pins. The device of the invention and the welding technology thereof have high degree of automation, higher work efficiency, good consistency of the product and high quality of the product; and the device and technology are especially suitable for the engineering with short construction time and high demand on the construction period.

Owner:EAST STEEL STRUCTURE BRIDGE

Environmental-friendly water-soluble flux and preparation method thereof

InactiveCN101850483AImprove the insulation resistance valueReduce corrosionWelding/cutting media/materialsSoldering mediaPolyvinyl alcoholSolvent

The invention relates to an environmental-friendly water-soluble flux which is matched with lead-free solder; the environmental-friendly water-soluble flux comprises anhydrous citric acid, DL-malic acid, triethanolamine, modified polyvinylalcohol, polymethyl acrylate, vinyl acetate-ethylene copolymer powder, hydroxyethyl methyl cellulose ether, surfactant, benzotriazol, phenol and mixed solvent; the anhydrous citric acid, the DL-malic acid, the triethanolamine, the modified polyvinylalcohol, the polymethyl acrylate, the vinyl acetate-ethylene copolymer powder and the hydroxyethyl methyl cellulose ether are prepared into a complex active substance A through microencapsulated coating treatment; and the mixed solvent, the surfactant, the benzotriazol, the phenol, the modified polyvinylalcohol, the polymethyl acrylate and the complex active substance A are uniformly mixed by weight ratio to obtain the environmental-friendly water-soluble flux. The environmental-friendly water-soluble flux can effectively assist lead-free solder, particularly applicable to Sn-Ag-Cu lead-free solder, can enhance the solderability of the lead-free solder, can adapt to the high welding temperature requirement on the lead-free solder, has small action to the corrosion of lead-free solder alloys and little residue after welding, can be cleaned by water, has good welding point quality, clean surface and strong stability, and a dried circuit board has higher insulation resistance value.

Owner:NINGBO YINYANG TIN SOLDER

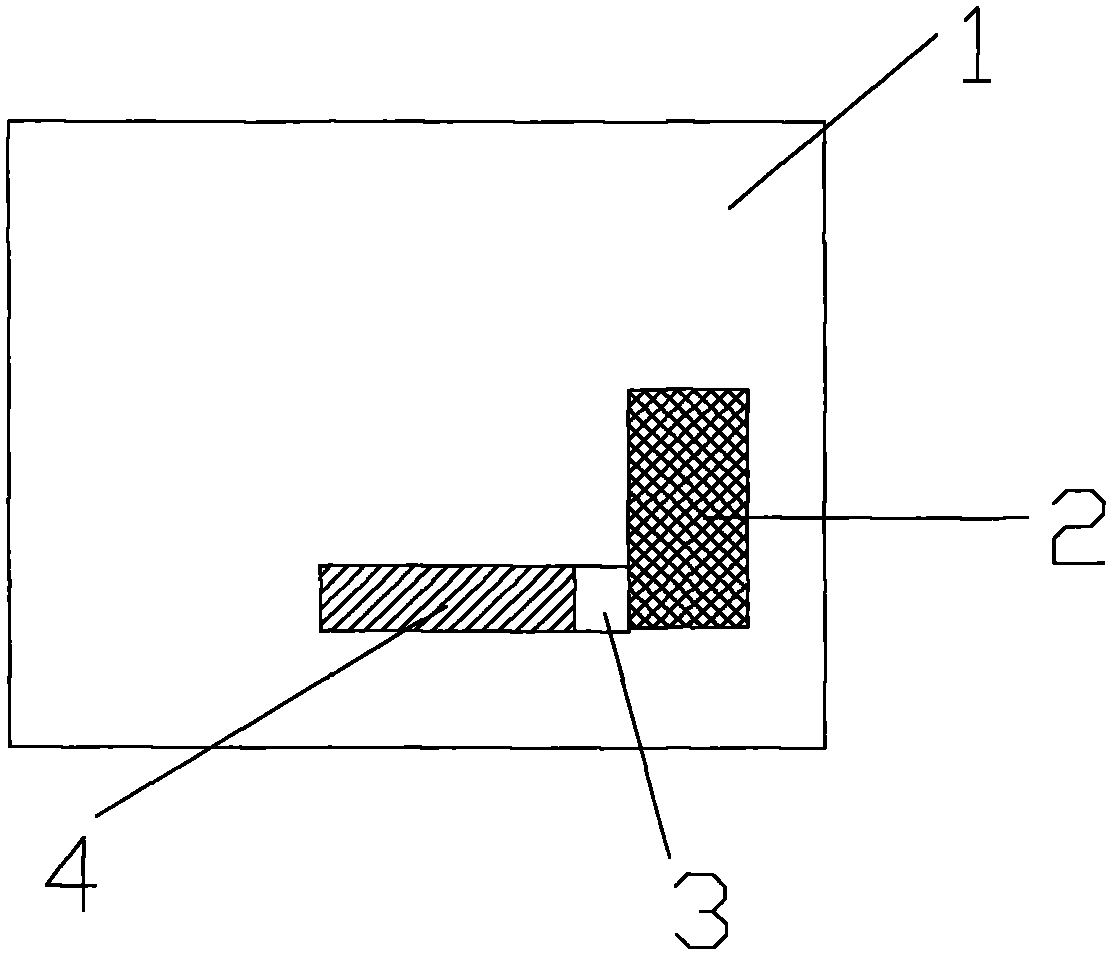

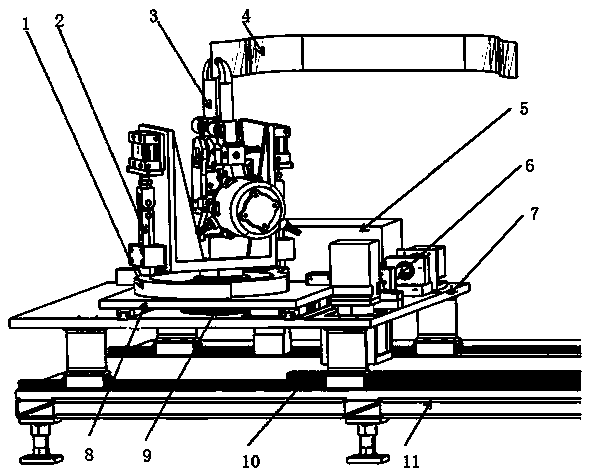

Full-automatic visual spot-welding robot

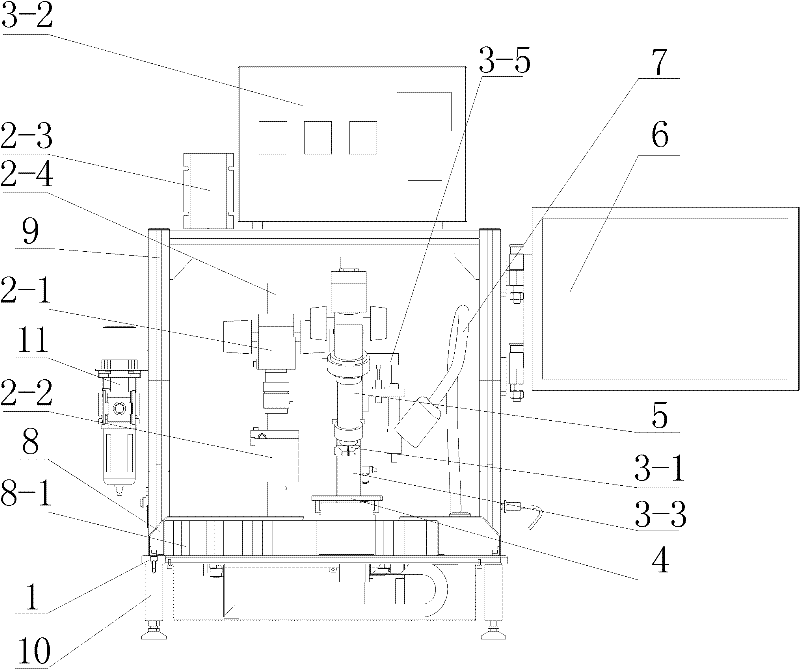

ActiveCN102528337AIn line with the operating processReduce fatigueWelding/cutting auxillary devicesAuxillary welding devicesSimulationComputer module

The invention relates to a full-automatic visual spot-welding robot which comprises a bottom plate mechanism, as well as a visual identification system, an automatic spot-welding system, a motion platform system and an industrial personal computer (IPC) which are arranged on the bottom plate mechanism, wherein the visual identification system comprises an industrial camera, a light source and a light source controller; the industrial camera and the light source are connected with the bottom plate mechanism by virtue of a lifting table, and the light source is positioned under the industrial camera; the automatic spot-welding system comprises a micro-spot-welding mechanism and a micro-spot-welding controller; the micro-spot-welding mechanism is connected with the bottom plate mechanism by virtue of a lifting mechanism; the motion platform system comprises an X-axis module and a Y-axis module; the Y-axis module is slidably connected to the X-axis module; and the motion platform system is positioned below the visual identification system and the micro-spot-welding mechanism. The robot capable of realizing a full-automatic spot-welding function has the functions of automatically locating the spot-welding position of a workpiece in a visual way, guaranteeing the precise translational motion of the workpiece, welding in an automatic micro-spot-welding way, and the like.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

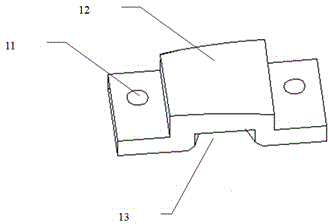

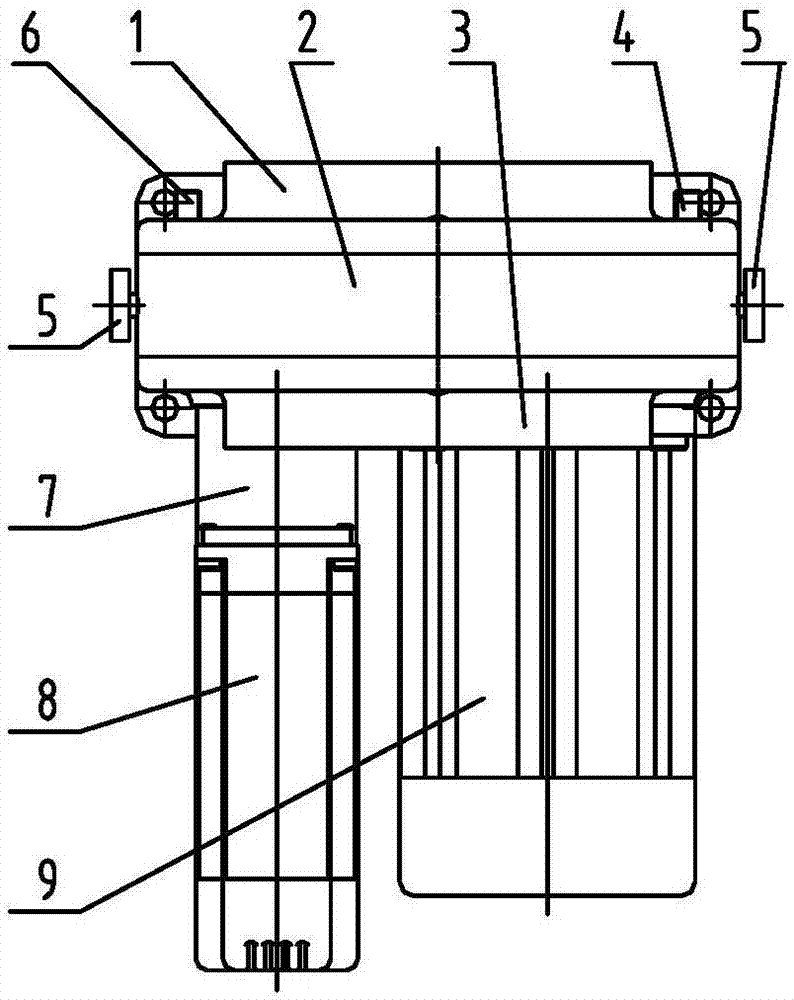

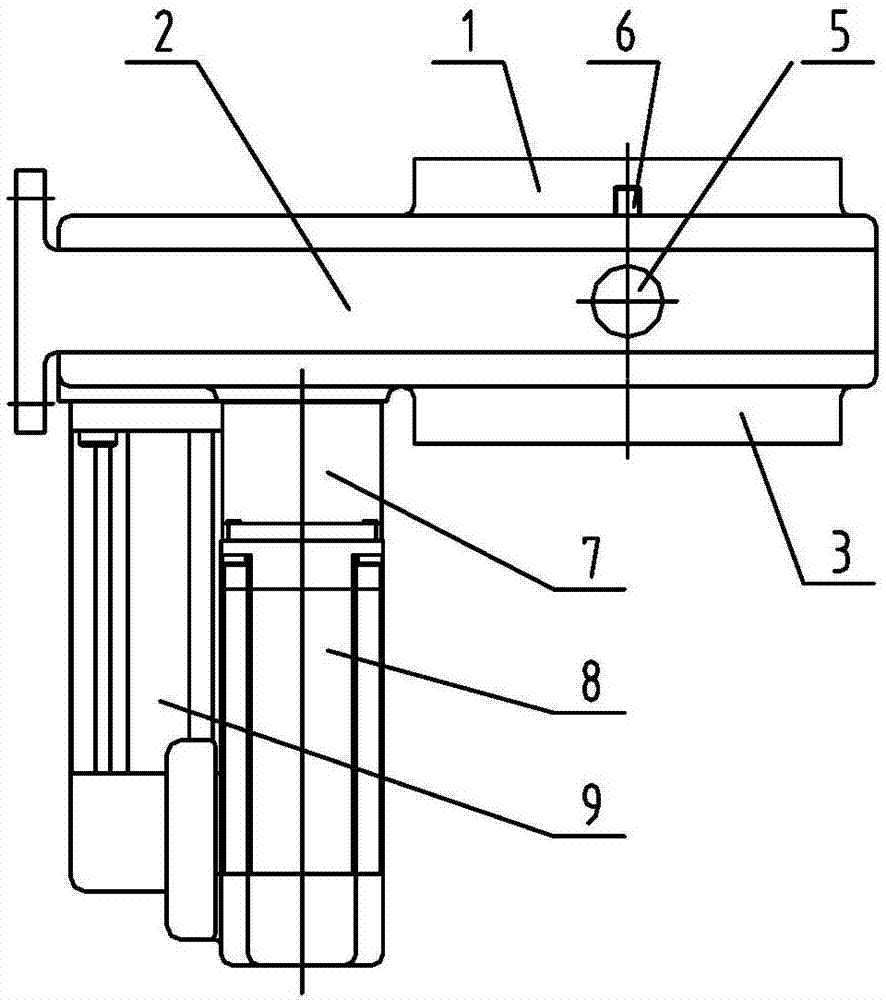

Spot soldering fixture and spot soldering process

InactiveCN102581458APrecise positioningHeight adjustableResistance welding apparatusEngineeringSoldering process

The invention belongs to the technical field of soldering, and particularly relates to a spot soldering fixture, which is used in a spot soldering process capable of avoiding pseudo soldering, false soldering and bursting, and is high in soldering efficiency. The spot soldering fixture comprises a fixture body, a cell storage area and a fuse storage area, and an avoidance hole is reserved between the cell storage area and the fuse storage area. Compared with the prior art, the spot soldering fixture has the advantages that a fuse and a metal strap can be effectively positioned, the height of a soldering pin can be adjusted, spot soldering quality can be improved, soldering reject ratio can be decreased, production efficiency can be improved, and cost can be saved. Besides, the invention further discloses the spot soldering process using the spot soldering fixture.

Owner:DONGGUAN NVT TECH

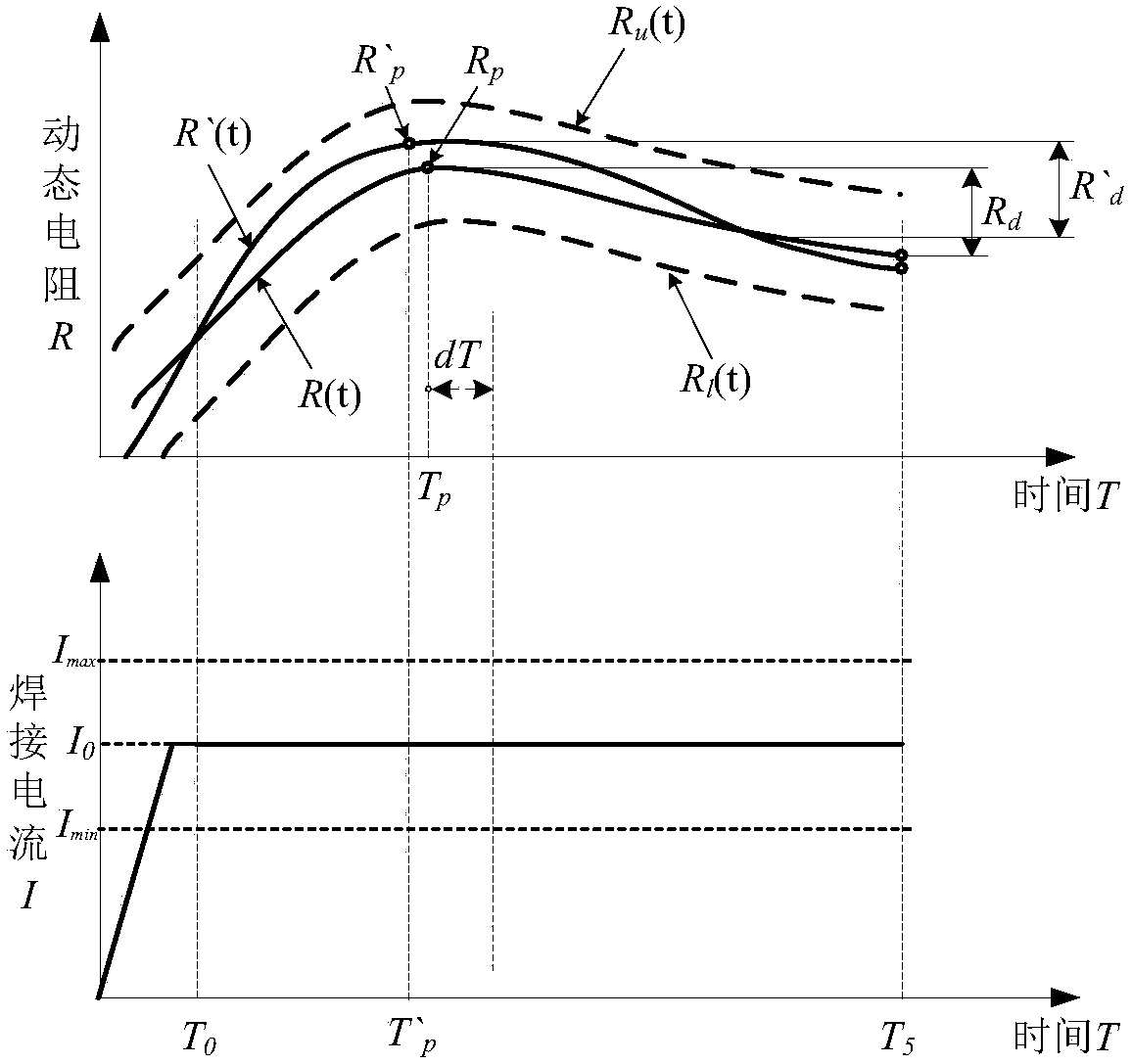

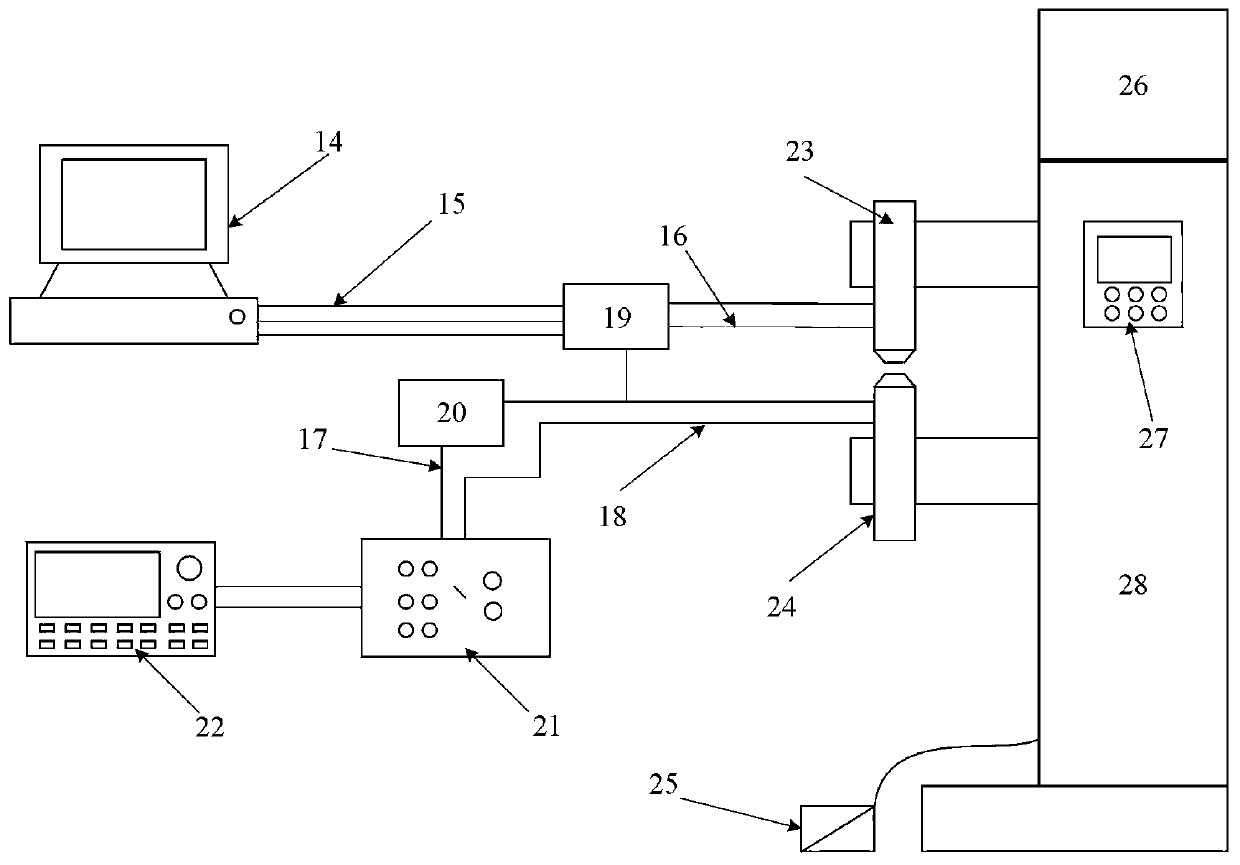

Direct-current resistance spot-welding multi-mode feedback control method

ActiveCN107671406AImprove solder joint qualitySuppress splashWelding monitoring devicesElectrical resistance and conductanceEngineering

The invention relates to a direct-current resistance spot-welding multi-mode feedback control method, which comprises the steps of (1) carrying out test weld under a standard welding condition, wherein a welding current magnitude is I0; and building a template dynamic resistance curve R (t), an upper tolerance zone curve Ru (t) and a lower tolerance zone curve R1 (t) of a welding spot, wherein a peak value of the template dynamic resistance curve is Rp, the moment corresponding to the Rp is Tp, the declining volume of the template dynamic resistance curve after the peak value is Rd, and the maximum conduction time is T5; (2) welding a material to be welded, wherein an initial welding current magnitude is I0; and drawing an actual dynamic resistance curve R' (t), wherein a peak value of theactual dynamic resistance curve is R'p, the moment corresponding to the R'p is T'p, and the declining volume of the actual dynamic resistance curve after the peak value is R'd; and (3) entering different control modes, and dynamically adjusting an actual welding current and actual conduction time. According to the direct-current resistance spot-welding multi-mode feedback control method providedby the invention, the welding spot quality and a welding process are controlled in real time, the welding spot quality of a key station is remarkably improved, the spattering during the welding process is effectively inhibited, the stability of the welding quality is improved, and a lot of technological parameter adjusting time aiming at different working conditions is saved.

Owner:SHANGHAI JIAO TONG UNIV

Cleaning-free scaling powder for tin-silver-zinc series lead-free solder

InactiveCN101327556AImprove solderabilityImprove wettabilityWelding/cutting media/materialsSoldering mediaSolderabilityZinc

The present invention relates to a wash-free soldering flux used by Sn-Ag-Zn leadless solder. Based on the total weight of the soldering flux, the ingredients of the soldering flux include 0.1 percent to 15 percent of activating agent, 0.1 percent to 15 percent of wetting agent, 0.1 percent to 5 percent of thixotropic agent, 0.1 percent to 2 percent of corrosion inhibitor and 0.1 percent to 5 percent of oxidation inhibitor, and the rest is deionized water. The non-corrosive soldering flux can be perfectly cooperated with the Sn-Ag-Zn leadless solder and adapted to the soldering temperature requirement of the leadless solder and can increase the wetting property and the inhibiting ability of the leadless solder and enhance the solderability of the leadless solder, a small quantity of residues are left, washing is not needed, soldering spots can have good quality, bright and clean surfaces and strong stability, and a dried circuit board can have a large insulation resistance value. In addition, the soldering flux is environment-friendly and produces no pollution, moreover, a washing process can be omitted, and the cost is reduced.

Owner:太仓市南仓金属材料有限公司

Water-soluble scaling powder for lead-free solder of tin silver zinc series

InactiveCN101347876AImprove the insulation resistance valueReduce corrosionWelding/cutting media/materialsSoldering mediaSolderabilityWater soluble

The invention relates to a water-soluble soldering flux which is suitable for tin, silver and zinc series lead-free solder. The weight percentage of all the components is as follows: 0.1-22 % of activating agent, 0.1-25 % of wetting agent, 0.1-5% of thixotropic agent, 0.1-2 % of corrosion inhibitor, 0.1-5 % of oxidation inhibitor and solvent for the rest. The invention aims at the problem that the existing soldering flux of leaded solder is not suitable for lead-free solder and provides the water-soluble soldering flux which can be effectively matched with lead-free solder, especially applicable to tin, silver and zinc series lead-free solder; the water-soluble soldering flux can improve wettability, antioxidant ability and solderability of lead-free solder, can meet the requirements of welding temperature of lead-free solder, and causes little corrosion to lead-free solder alloy; postwelding residue is little and can be washed away by water; welding spots have good quality, smooth surfaces and strong stability; a dried circuit board has high insulation resistance value.

Owner:TIANJIN UNIV

Appearance welding spot protecting device

ActiveCN104625507AGood dispersionGuaranteed not to distortWelding/cutting auxillary devicesAuxillary welding devicesChinese charactersEngineering

The invention provides an appearance welding spot protecting device. The appearance welding spot protecting device comprises a protecting copper pad, a connecting plate, guide pins with springs and a supporting seat; the protecting copper pad is shaped like a Chinese character 'ji', the top surface of the protecting copper pad is a sheet metal contact surface attached to a sheet metal molded surface, the bottom surface corresponding to the top surface is an electrode holder electrode contact surface, and the electrode holder electrode contact surface is close to the sheet metal contact surface; the two ends of the protecting copper pad are connected with the connecting plate through the guide pins with springs; the connecting plate is of a door type structure which is placed horizontally, the two edges of the door type structure are connected with the two ends of the protecting copper pad, an electrode holder avoiding channel is left between the door type structure and the protecting copper pad, the door top edge of the connecting plate is connected with the supporting seat, the supporting seat is provided with fastening bolt connecting via holes fixedly connected with a fixture, and the fastening bolt connecting via holes are used for fixing the whole device on the fixture. According to the appearance welding spot protecting device, an electrode on one side of the protected surface preferentially makes contact with the protecting copper pad, and then the protecting copper pad makes contact with sheet metal; because the contact area of the protecting copper pad with the sheet metal is much larger than the contact area of the electrode with the sheet metal, pressure can be dispersed well, and therefore it is guaranteed that a welding spot is not distorted, and the welding spot indentation can meet the appearance quality requirements.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

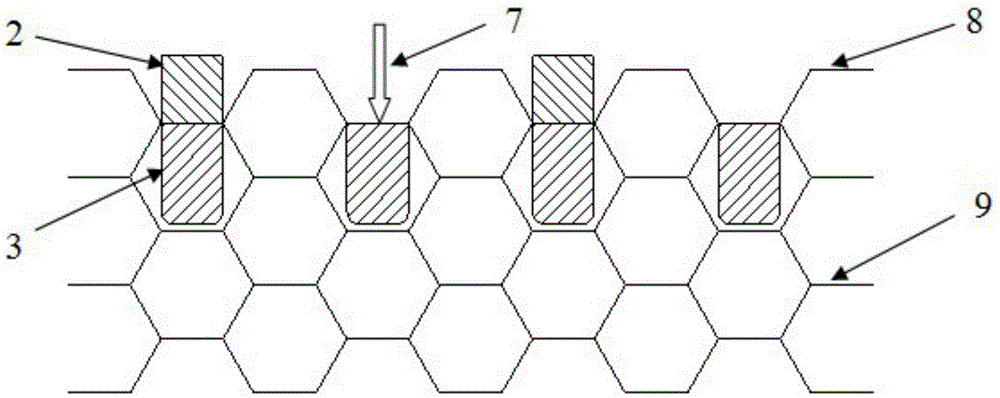

Small size honeycomb structural member spot welding movable electrode and welding method

A movable electrode for the point welding on sall cellular member is made up of a segment of high-strength enamelled wire, flattening and bending its upper segemnt, and removing the enamel from its contact surface and electric conducting surface. Its welding method includes such steps as inserting said movable electrode in the cellular member, making electric conducting and pressing block on the inner surface of welding tongs in contact with the point to be welded, and closing the power switch for electric point welding.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

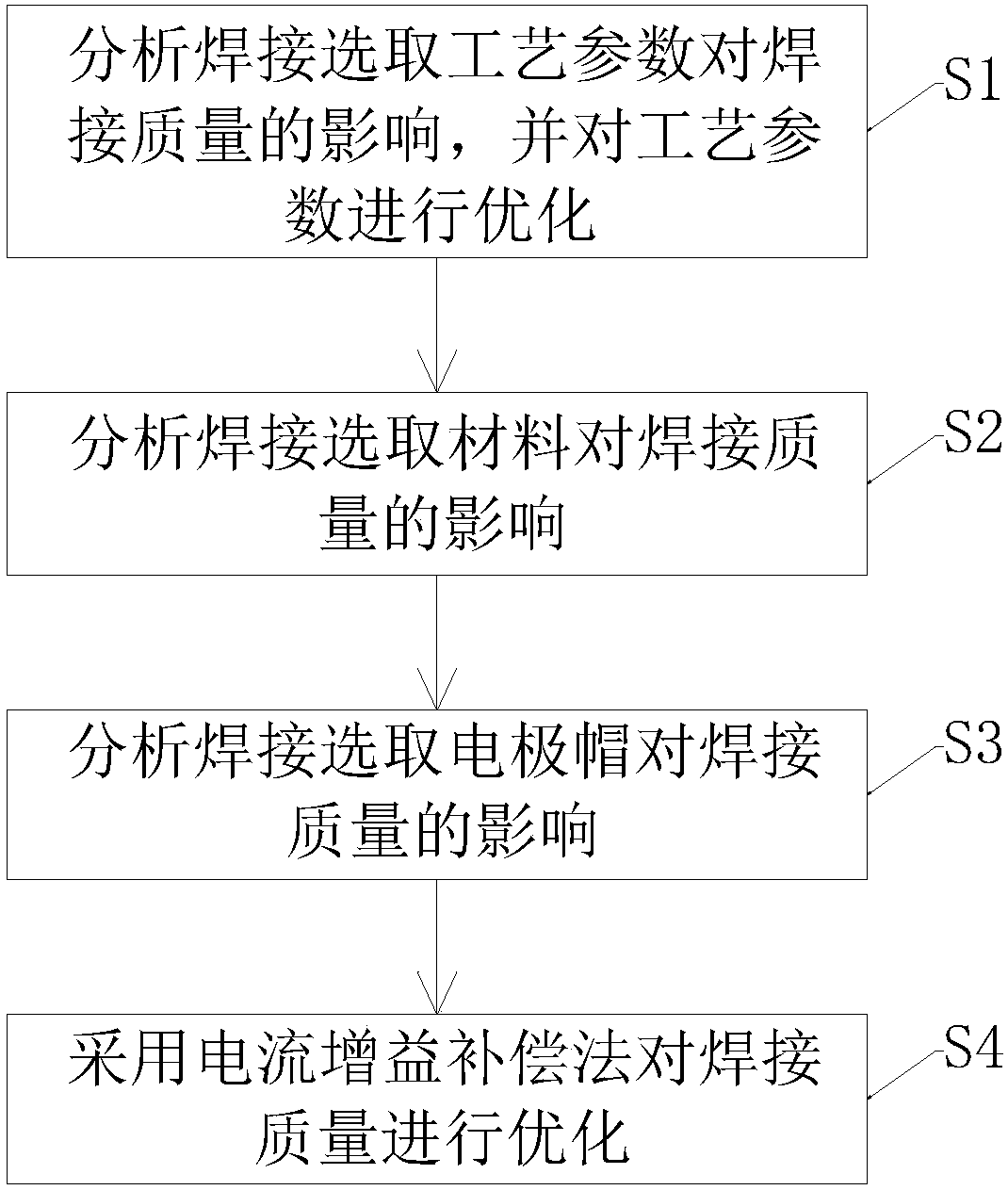

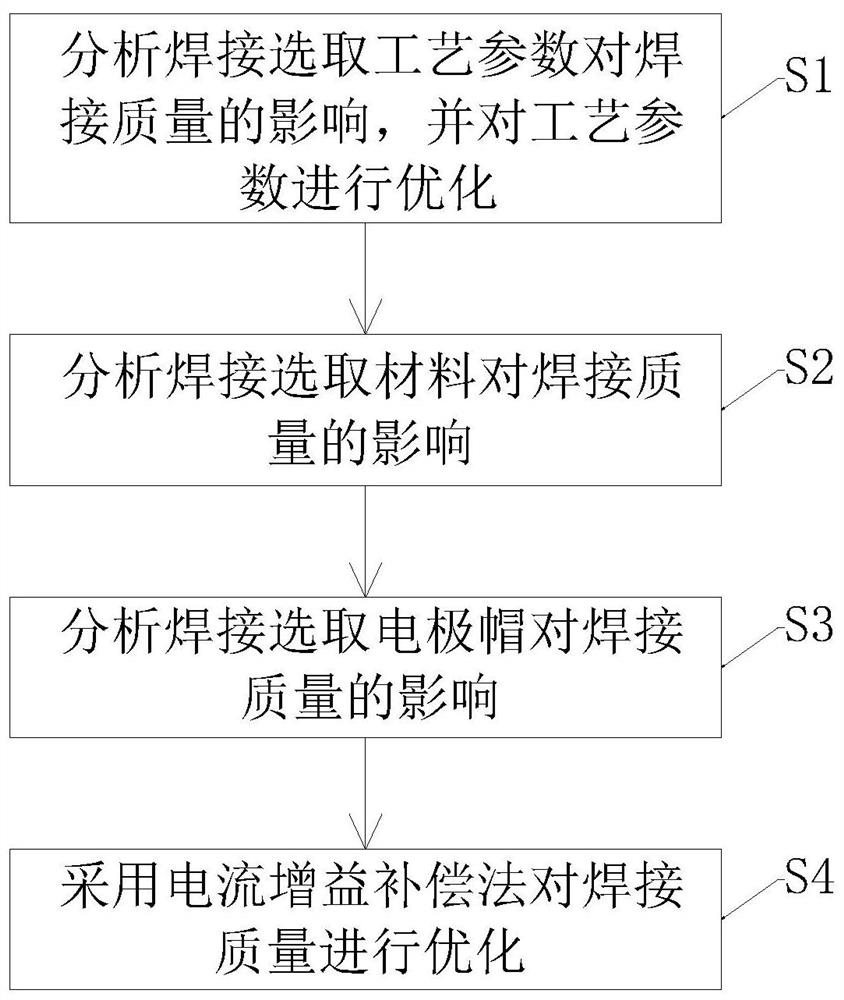

Spot welding quality control method for galvanized steel plate for automobile

ActiveCN108857010AAvoid stickingQuality improvementResistance welding apparatusSheet steelQuality control

The invention relates to a spot welding quality control method for a galvanized steel plate for an automobile. The spot welding quality control method comprises the following steps that S1, the influence of welding selection process parameters on the welding quality is analyzed, and the process parameters are optimized; S2, the influence of welding selection materials on the welding quality is analyzed; S3, the influence of a welding selection electrode cap on the welding quality is analyzed; and S4, the welding quality is optimized by adopting a current gain compensation method. According tothe spot welding quality control method, the influence of the welding process parameters, welding base materials, spot welding electrodes and the like on the welding quality is studied, and the spot welding quality is controlled by an appropriate method, so that the welding spattering and burrs are reduced, the welding spots are prevented from being over-burnt, the electrodes are prevented from being adhered, and the purposes of improving the strength and the appearance surface quality of the welding spot welding spots and improving the quality of the whole vehicle are achieved; and meanwhile,the production environment of a workshop is also improved, the labor intensity of workers is relieved, the production period is shortened, the production cost is reduced, resources are saved, and themarket competitiveness of enterprises is improved.

Owner:WUHAN JIEZHONG AUTO PARTS CO LTD

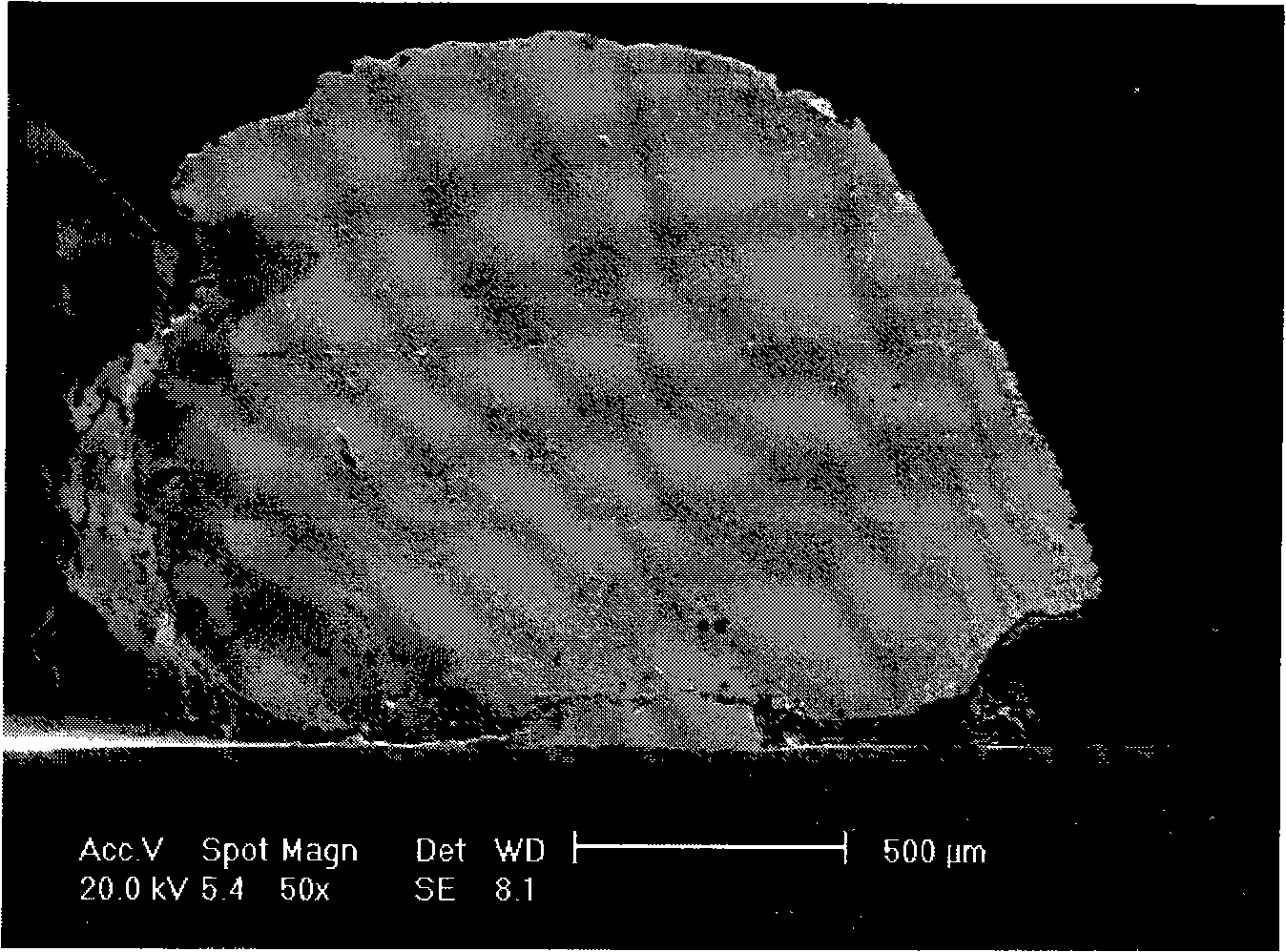

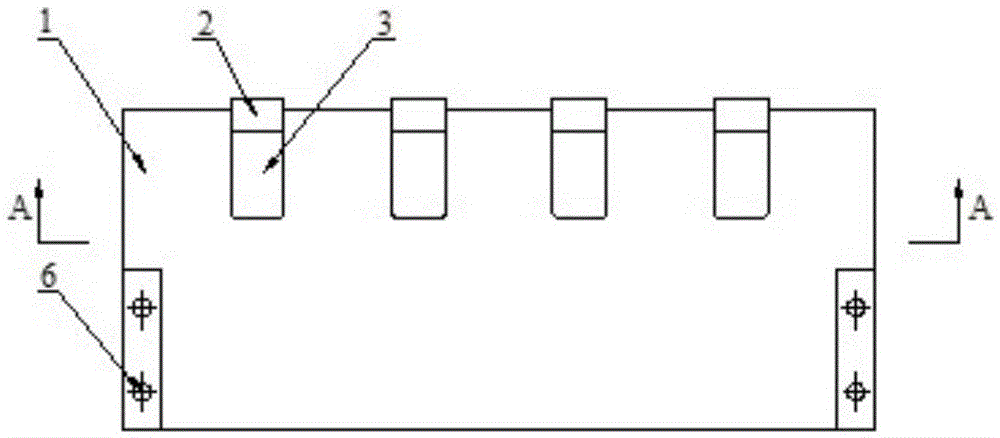

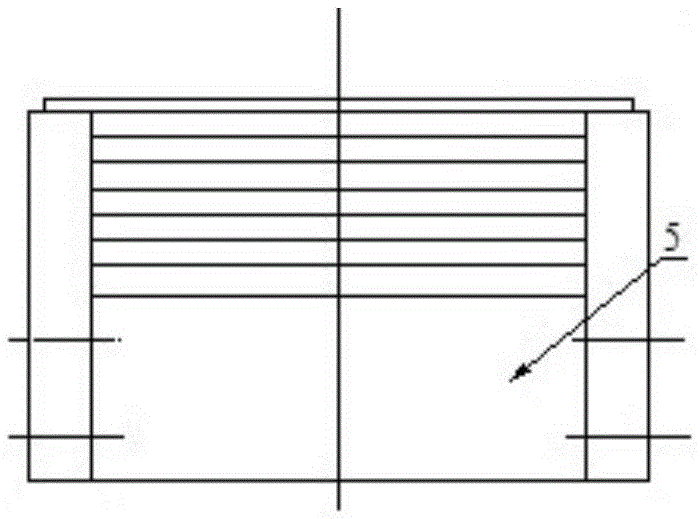

Spot welding method for metal honeycomb core

InactiveCN105583512AImprove solder joint qualityImprove welding efficiencyMetal working apparatusResistance welding apparatusHoneycombEngineering

The invention discloses a spot welding method for a metal honeycomb core and relates to a determining method for the spot welding parameter of the metal honeycomb core and a spot welding clamp for the honeycomb core. The spot welding method includes the steps that firstly, a similar formula converting calculation method is used for preliminarily obtaining preliminarily-selected parameters of corresponding welding materials; and then a spot welding test is conducted according to the preliminarily-selected parameters, and the optimal spot welding parameter is determined through fine turning and correcting. The spot welding clamp of the honeycomb core is characterized by comprising two supporting plates, two connecting plates, compressing blocks and supporting rods, wherein the number of the compressing blocks is equal to that of the supporting rods. When the spot welding clamp is used, the honeycomb core is put on the spot welding clamp, and spot welding is conducted on the honeycomb core according to the determined spot welding parameter. The spot welding method has the beneficial effects that the spot welding parameter of the honeycomb core is easy and convenient to determine, and the welding clamp is simple in structure and convenient to operate; and high-quality and high-efficiency welding of the honeycomb core is achieved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Composite aluminum belt for air cooling of power station and manufacturing method thereof

ActiveCN111304497AAvoid formingReduce energy consumptionMetal rolling arrangementsPower stationEnergy consumption

The invention discloses a composite aluminum belt for air cooling of a power station. The composite aluminum belt is of a composite structure formed by a core layer and a single-face composite layer thereof. The composite aluminum belt is an important component of an air cooling direct-cooling system pipe fin type heat exchanger of the power station. The composite layer and the core layer are prepared by utilizing a cast rolling and cold rolling production manner, and by means of cold rolling compositing, two layers of metal are combined together closely. The invention further discloses a manufacturing method of the composite aluminum belt for air cooling of the power station. The technological process of the method comprises the steps of smelting, cast rolling, rough rolling, homogenizingannealing, cold rolling compositing, rough rolling and edge cutting, finish rolling, finished product annealing, slitting, checking and packaging. Compared with a material produced through a traditional hot rolling method, indexes such as strength obtained before and after brazing, the welding spot quality, the shaving razor blowing pressure and the upright degree after welding are equivalent, however, the technologic process is short, energy consumption is low, the production efficiency is high, the composite rate in the plate and strip material width direction is uniform, the yield is high,the cost input is low, the risk is low, and formation of intermetallic brittleness compounds can be avoided.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

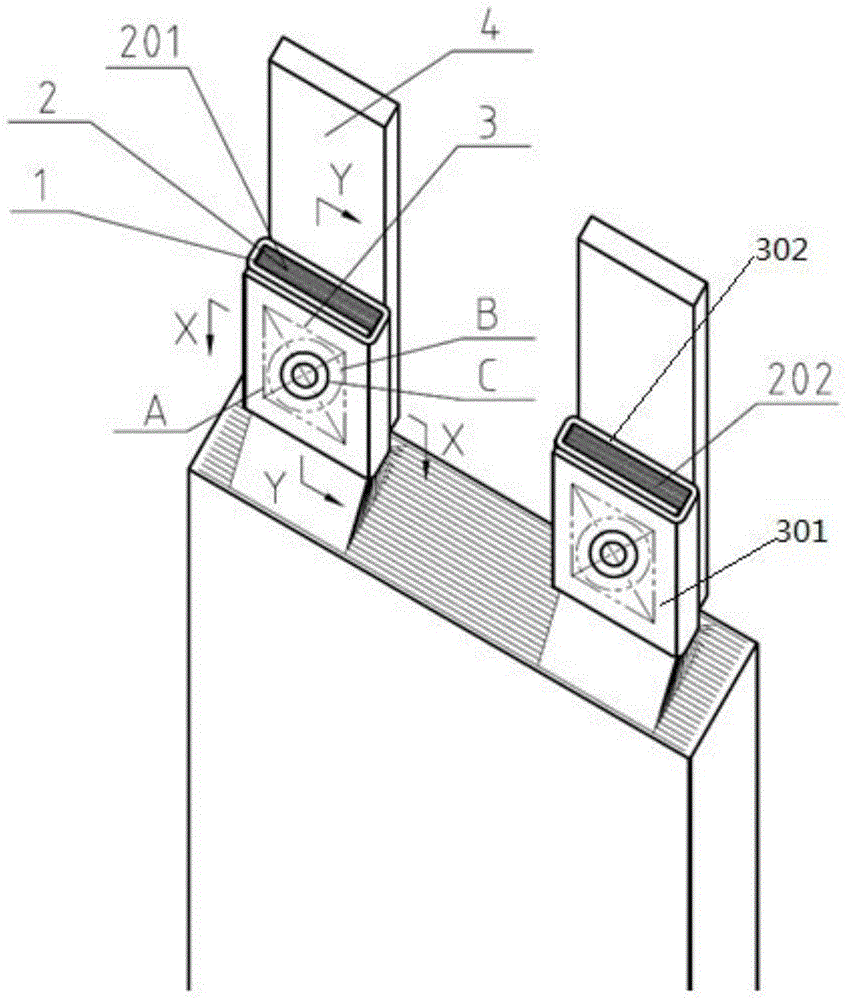

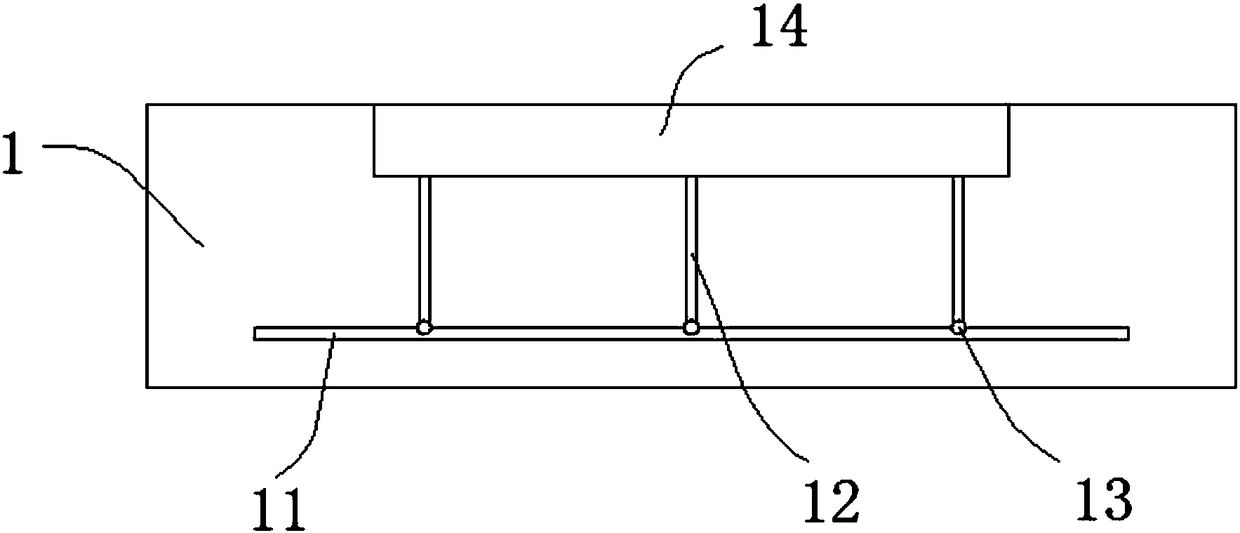

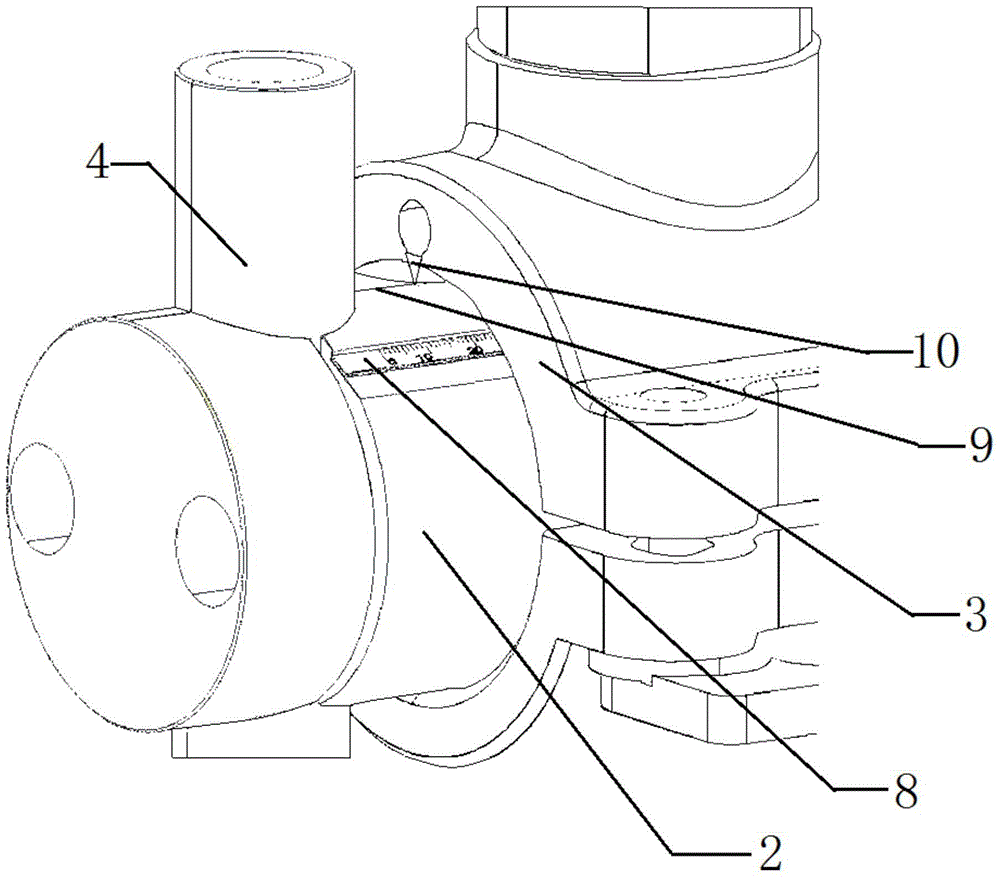

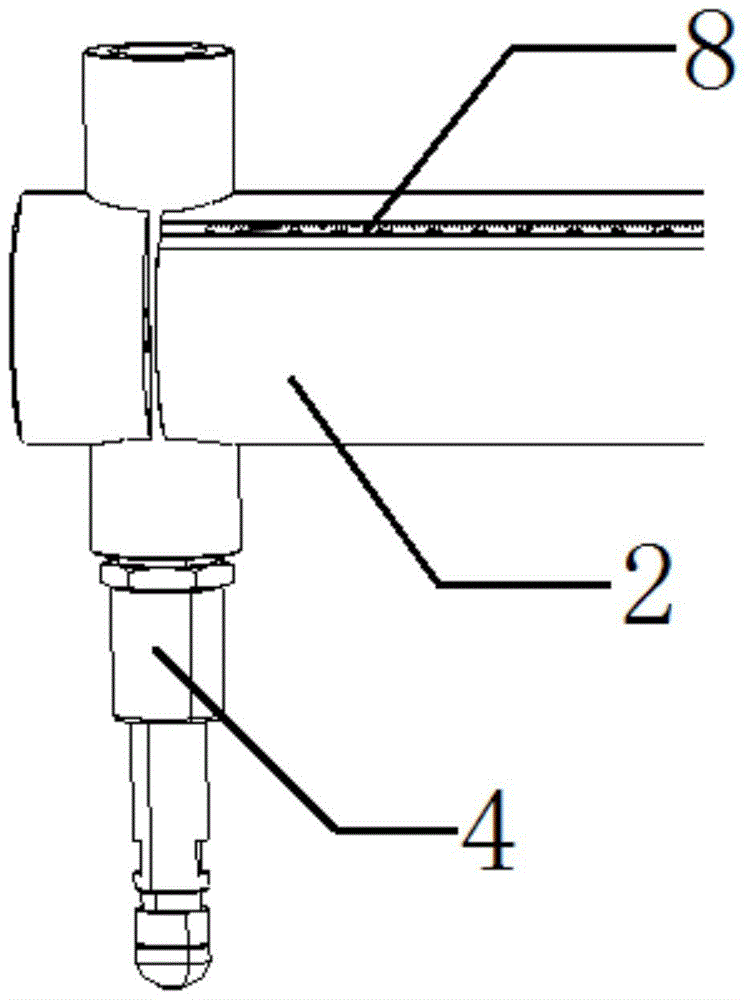

Structure and method for rapid centering of fixed spot welding machine electrode arms

The invention relates to a structure for rapid centering of fixed spot welding machine electrode arms. The structure comprises a machine body, the upper electrode arm, an upper working tabletop, an upper electrode holder, the lower electrode arm, a lower working tabletop and a lower electrode holder. One end of the upper electrode arm is movably installed on the upper working tabletop. The upper electrode holder is fixedly installed at the other end of the upper electrode arm. One end of the lower electrode arm is movably installed on the lower working tabletop. The lower electrode holder is fixedly installed at the other end of the lower electrode arm. The upper electrode arm and the lower electrode arm are each transversely provided with a dividing ruler. The upper electrode arm and the lower electrode arm are each transversely provided with a reference line. The upper working tabletop and the lower working tabletop are each provided with a reference point. In the welding process, the adjusting time for replacing the electrode holders can be shortened, and the production efficiency can be improved; and welding electrode centering is ensured, and the welding spot quality is improved.

Owner:DIGITAL DIE STAMPING TECH WUHAN

Connecting structure of lithium battery plate lugs and poles and manufacturing method thereof

ActiveCN104466075AAvoid it happening againPlay the role of security protectionCell component detailsUltrasonic weldingButt joint

The invention discloses a connecting structure of lithium battery plate lugs and poles. The connecting structure comprises lugs of a multi-layer foil sheet structure formed by superposing a plurality of layers of foil sheets, wherein the plate lugs comprise a positive electrode plate lug and a negative electrode plate lug; the plate lugs are pressed and packaged by virtue of buffer foil sheet machinery; butt-joint side foil sheets of the buffer foil sheets packaging the plate plugs are superposed and pressed; the plate lugs and the buffer foil sheets are mechanically pressed for pre-connected by virtue of ultrasonic welding; poles are arranged at single-layer sides of the buffer foil sheets; the poles, the plate plugs and the buffer foil sheets are connected by welding; and the adopted welding mode is a filling type stirring friction spot-welding mode. The connecting structure of lithium battery plate lugs and poles manufactured by the manufacturing method disclosed by the invention has the advantages of good reliability and conductivity, capacity of improving the battery consistency, beautiful appearance, and relatively strong processing suitability.

Owner:昆山斯格威电子科技有限公司

Apparatus and method for providing an inerting gas during soldering

InactiveUS20150209885A1Easy transitionImprove scalabilityPrinted circuit assemblingWelding/cutting media/materialsEngineeringAtops

Described herein is an apparatus and method for providing an inerting gas during the application of soldering to a work piece. In one aspect, there is provided an apparatus that is placed atop of a solder reservoir and comprises a plurality of porous diffuser tubes that are in fluid communication with an inerting gas. In another aspect, there is provided a method for providing an inerting gas to a wave soldering apparatus comprising the steps of, among other things, placing an apparatus atop at least one edge of the solder reservoir wherein the apparatus comprises a plurality of tubes comprising one or more openings in fluid communication with an inerting gas source. In a further aspect, at least one of the diffuser tubes comprises a porous protective sheath surrounding at least part of the length of the tube.

Owner:AIR PROD & CHEM INC

Brazed flat pipe composite aluminum strip for high-frequency welding, and manufacturing method of brazed flat pipe composite aluminum strip

ActiveCN111421013AExcellent compound rate uniformityAvoid formingMetal rolling arrangementsSurface cleaningPipe

The invention provides a brazed flat pipe composite aluminum strip for high-frequency welding. The brazed flat pipe composite aluminum strip comprises a middle layer, a brazing layer and a water contact layer, wherein the brazing layer and the water contact layer are respectively composited on an upper surface and a lower surface of the middle layer, the brazing layer, the middle layer and the water contact layer are prepared in a cast rolling and cold rolling production mode, and three layers of metal are tightly combined together through cold rolling compositing. The invention further discloses a manufacturing method of the brazed flat pipe composite aluminum strip for high-frequency welding. The technological process comprises the steps of smelting, cast rolling, rough rolling, homogenizing annealing, cold rolling compositing, diffusion annealing, rough rolling trimming, finish rolling, surface cleaning, finished product pre-annealing, finish rolling, surface cleaning and plate shape straightening, slitting inspection and packaging and the like. Compared with materials produced through a traditional hot rolling method, the strength before and after brazing, the welding spot quality, the pressure bearing performance after welding, the corrosion resistance and other indexes are equivalent, but the technological process is short, energy consumption is low, the production efficiency is high, the compositing rate of plate and strip materials in the width direction is uniform, the yield is high, the investment fund is small, and the risk is low.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

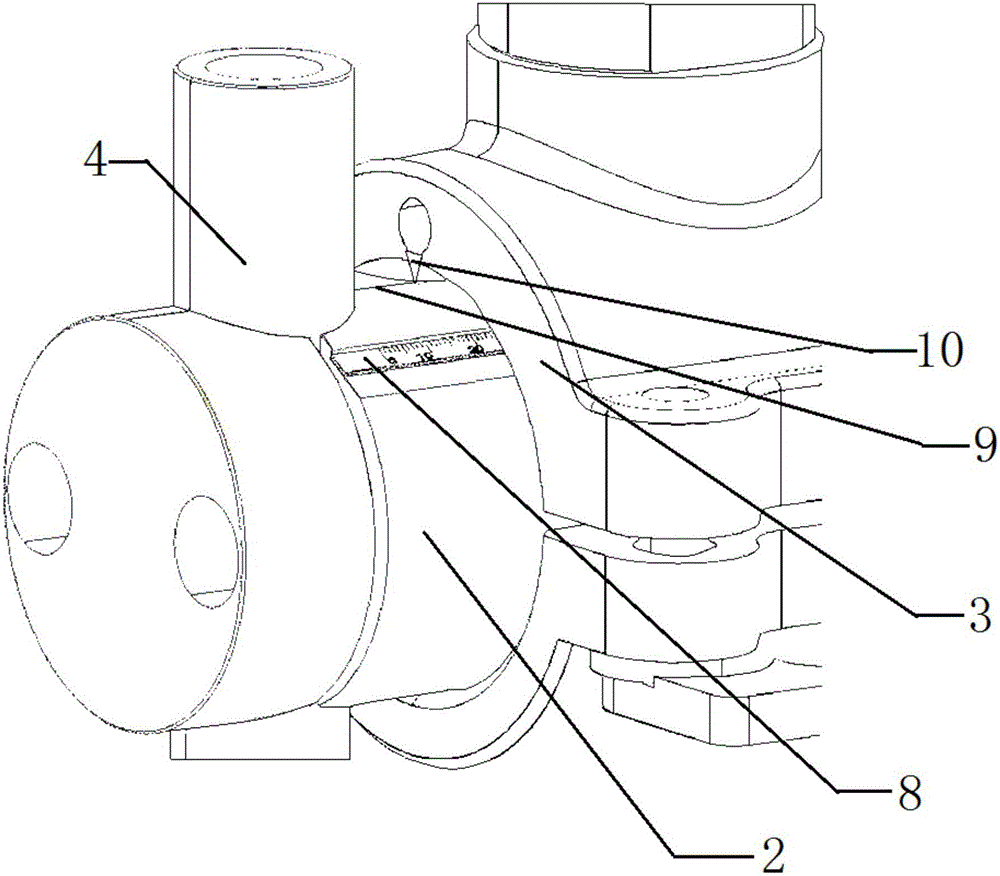

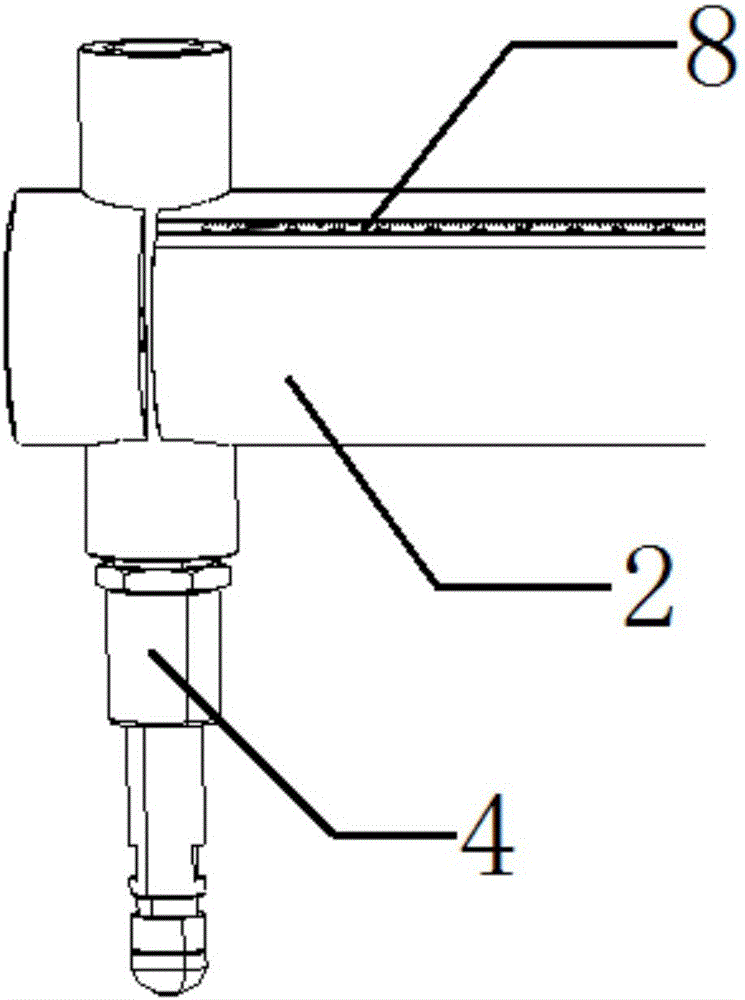

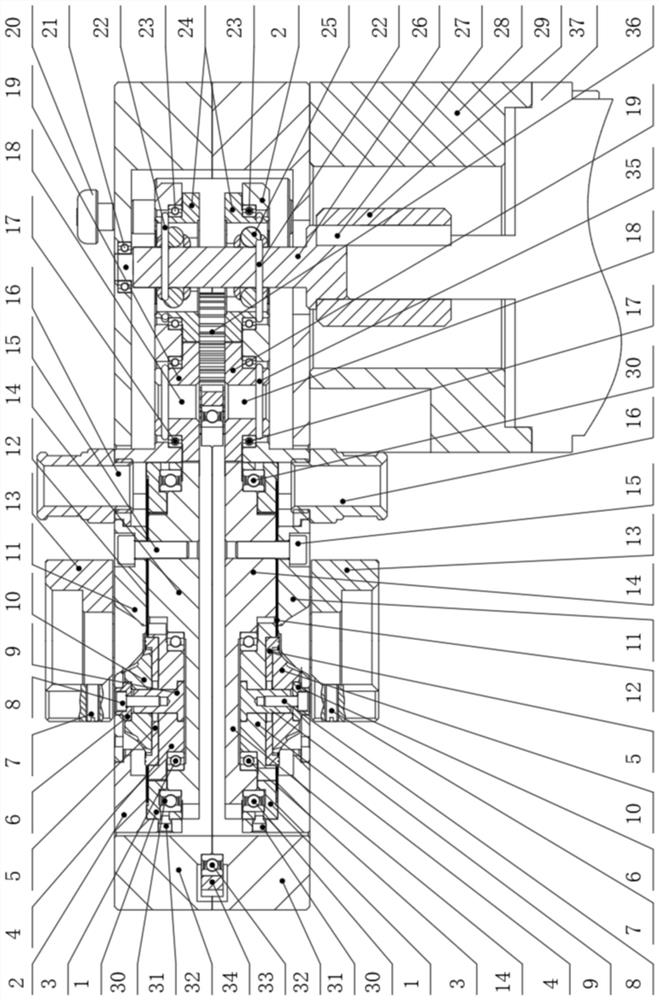

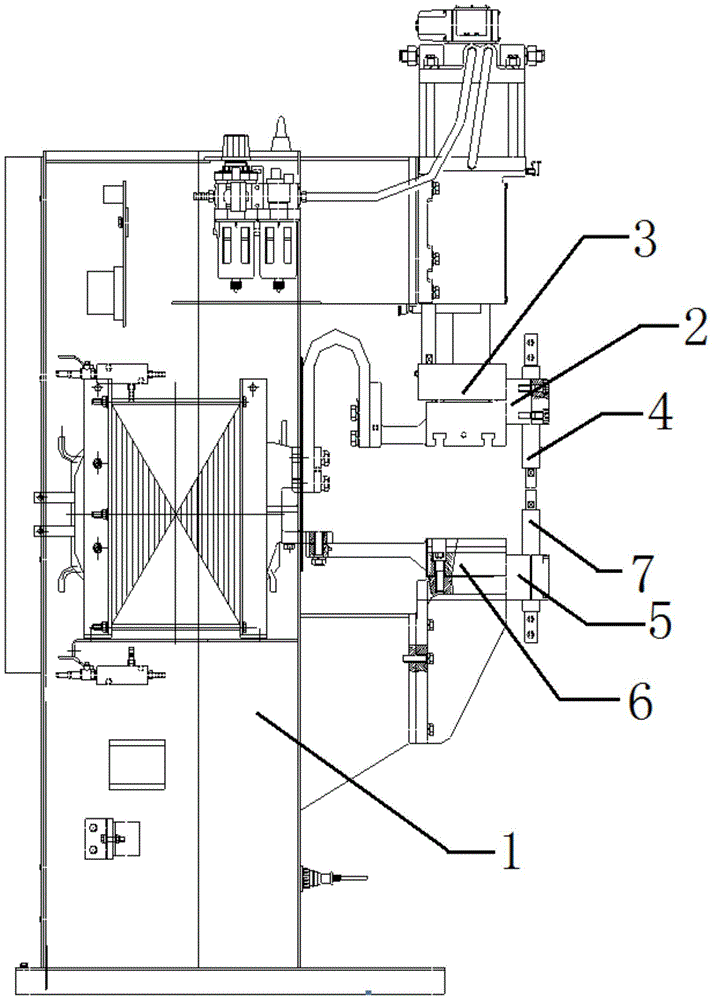

Automatic repair-grinding device for resistance spot-welding electrodes

ActiveCN107262902AEliminate negative attributesLimit roughness valueElectrode maintenanceElectrical resistance and conductanceGear wheel

The invention discloses an automatic repair-grinding device for resistance spot-welding electrodes. The automatic repair-grinding device comprises a main frame body, a cutting system, a cutting displacement moving system and a positioning reference adjusting mechanism; the cutting system comprises a rotating power input gear, a first transition gear and a tool rest which are driven by a rotating power alternating current motor sequentially; the tool rest carries combined cutting tools; the cutting displacement moving system comprises a speed reducer, a power input gear and a second transition gear which are driven by a servo motor sequentially; the second transition gear meshes with the power input gear; the second transition gear and a third transition gear which are assembled coaxially and adopt identical structures mesh with circular cam gear rings on two sides respectively and interact with cam discs on the two sides respectively through cam slopes; with the positioning reference adjusting mechanism, the positioning reference is adjusted through adjustment of the position relationships of two independent gear shafts and two sliding sleeve gears and the upper and lower cam discs. Through the micro-cutting-quantity fixed-displacement cutting and repair-grinding manner, the device can have the remarkable positive effects in the aspects of the product spot-welding quality, the spot-welding technology cost and the like during spot-welding production.

Owner:天津市扬帆科技开发有限公司

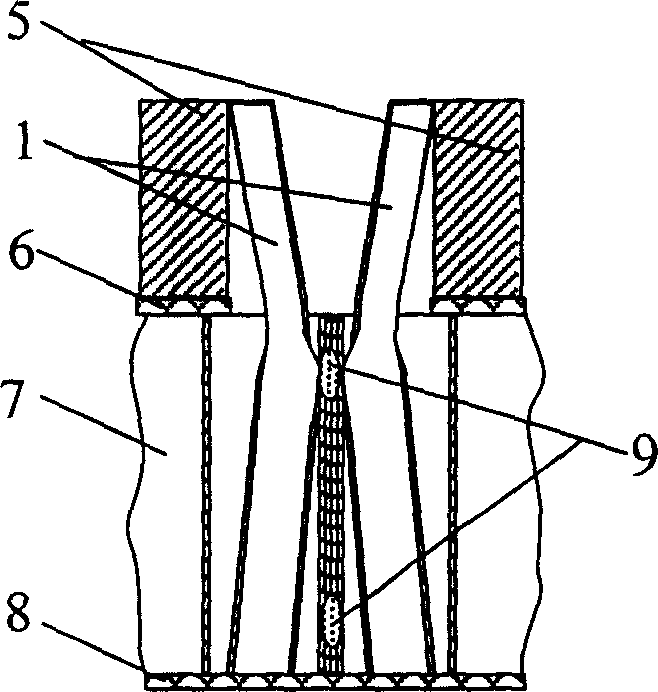

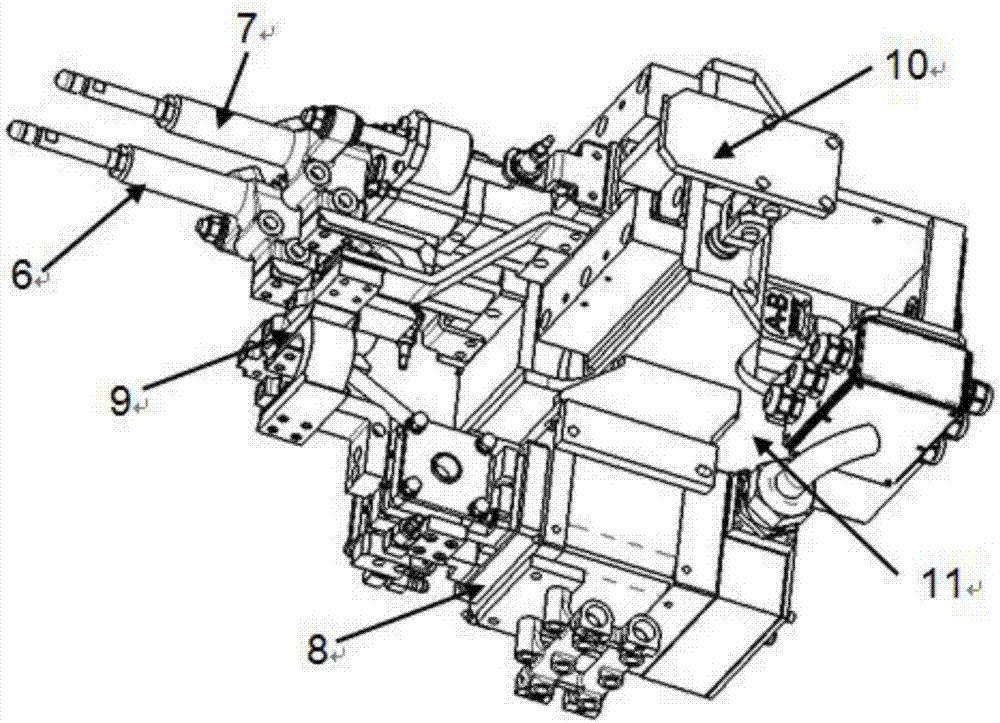

Novel flexible single-face double-point spot welding system and technology

PendingCN107322155APrevent reverse displacementImprove the cushioning forceResistance electrode holdersProgramme-controlled manipulatorTransformerSpot welding

The invention provides a novel flexible single-face double-point spot welding system and technology. The novel flexible single-face double-point spot welding system comprises a robot rack, a plurality of robots, an electrode holder, an electric cylinder and a welding clamp. The robots are arranged on the robot support. The welding clamp is fixedly arranged on the ground and used for clamping a workpiece and transmitting welding current. The electrode holder is arranged at the lower ends of the robots. The electrode holder comprises a static electrode and a dynamic electrode. The preset distance of the static electrode and the dynamic electrode is adjusted under driving of the electric cylinder, series air cylinders drive the static electrode and the dynamic electrode to a welding point, a welding transformer provides welding current, and welding work of a to-be-machined workpiece is finished. A parallel structure is adopted in the installing robots, pressure is directly applied to the electrode holder, the structure rigidity of the whole machine is very high, very large welding counter acting force can be borne, reverse movement of the motor is effectively prevented, the position of the motor is stable, the welding pressure is stable, and the welding efficiency and the welding quality are greatly improved.

Owner:天津七所高科技有限公司

Solder wire soldering flux capable of reducing splashing and preparation method thereof

ActiveCN111906472AStrong viscous resistanceEffective protectionWelding/cutting media/materialsSoldering mediaCompound organicOrganic acid

The invention relates to a solder wire soldering flux capable of reducing splashing and a preparation method thereof. The soldering flux is composed of the following components in percentage by weightof 1.0-10.0% of compound organic acid, 0.2-5.0% of compound activator, 0.1-1.0% of compound defoamer, 2.0-10.0% of compound solvent, 0.1-1.0% of antioxidant, 0.1-1.0% of corrosion inhibitor and the balance of compound rosin. The preparation method comprises the following steps of heating, stirring and melting the compound rosin, adding the compound organic acid and the low-melting-point indissolvable activator, adding the solution dissolved with the high-melting-point dissolvable activator, the antioxidant and the corrosion inhibitor, finally adding the compound defoamer, performing continuous stirring at the constant temperature of 145-165 DEG C, performing full dissolving, and performing uniform mixing, thereby obtaining the soldering flux. The soldering flux is high in activity, easy to tin during welding, low in corrosion, small in residue and high in insulation resistance, the splashing number and the splashing distance of the soldering flux and tin beads in the welding process of a lead-free tin wire can be greatly reduced, the RoHS instruction is met, and the reliability of electronic and electrical products after welding is guaranteed.

Owner:云南锡业新材料有限公司

Ultrasound electric resistance welding welder

InactiveCN102615441AQuality improvementImprove solder joint qualityWelding apparatusElectrical resistance and conductanceTinning

An ultrasound electric resistance welding welder is characterized in that a welding head is used for overlapping ultrasonic shock energy onto welding points on the base of electric resistance welding at the time of electrified welding and a time interval around the electrified welding, namely formation of the welding points relies on current energy and ultrasonic wave shock energy together. Ultrasonic shock enables surfaces of objects to be welded to abraded mutually to effectively remove paint of enameled wires on the welding points, current passes through conductors to be welded which are extruded together to enable the conductor to be heated and bonded together even melted together. Therefore, circuit boards of electronic products and tinning face or non-tinning face can obtain reliable high-quality welding points. A machine head with pressure locking enables pressure to be accurately controlled and further improves welding quality. The ultrasonic shock is used for removing paint, prestress point electric welding electrodes is not required, and the ultrasonic shock removes paint and pollution, reduces manual repairing and polishing of electrodes, thereby improving working efficiency, saving labor and enabling the electrodes to be durable in use.

Owner:珠海微点焊电子工业有限公司

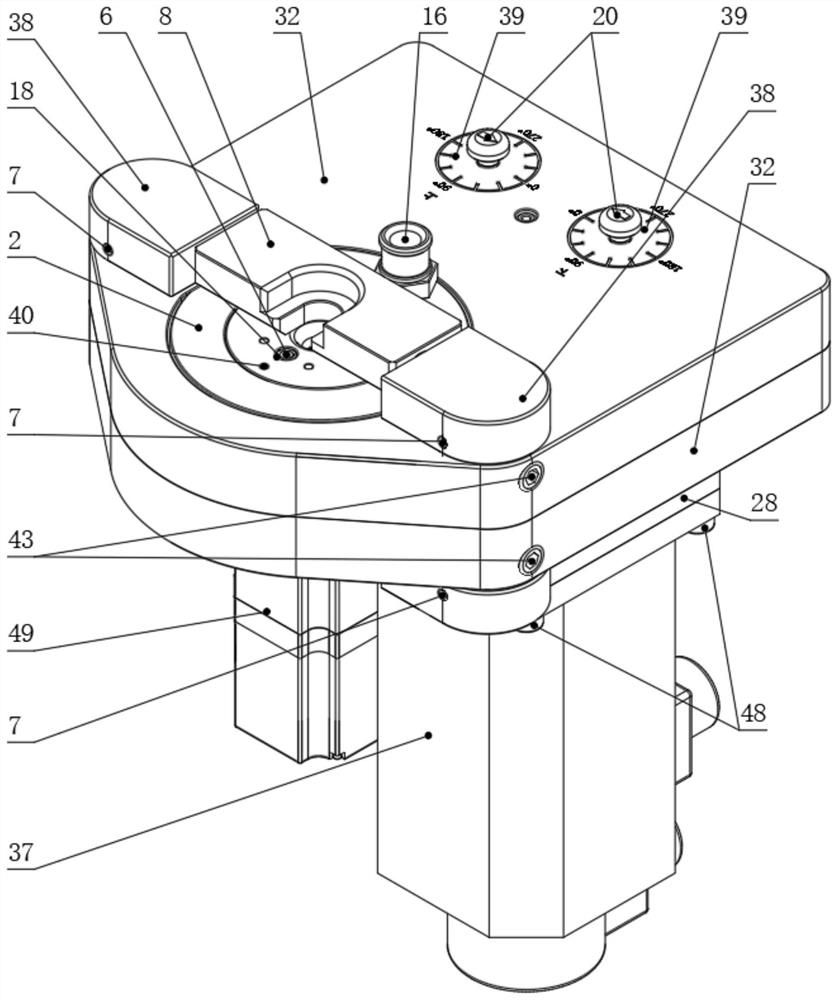

Symmetric automatic electrode grinding device with grinding displacement controllability and grinding angle adjustability

PendingCN112809098AReduce the amount of unnecessary grindingReduce consumptionDriving apparatusMaintainance and safety accessoriesLinear motionElectric machine

The invention discloses a symmetric automatic electrode grinding device with grinding displacement controllability and grinding angle adjustability. The symmetric automatic electrode grinding device with grinding displacement controllability and grinding angle adjustability comprises a closed shell consisting of a left shell and a right shell, wherein main body parts of functional mechanisms for electrode cutting and grinding, cutting displacement control, grinding angle adjustment and the like are arranged in the closed shell. An electrode cutting and grinding mechanism drives a combined cutting tool to work in a revolution and rotation mode through different combination modes of a gear, a gear ring and the like. A cutting displacement control mechanism converts the rotating power of a stepping motor into micro-distance linear motion of cutting displacement by utilizing a positive and negative threaded shaft. A grinding angle adjusting mechanism is used for compensating deflection of the electrode working surface caused by welding deflection deformation and the like of an electrode holder machine arm. According to the symmetric automatic electrode grinding device with grinding displacement controllability and grinding angle adjustability provided by the invention, through the multi-edge combined cutting tool, the revolution and rotation grinding principle of the multi-edge combined cutting tool, and the functional characteristics such as a fixed-displacement grinding mode and grinding angle adjustment without external force, the remarkable positive effects can be achieved in the aspects of prolonging the service life of the cutting tool, reducing unnecessary electrode cutting, improving the welding spot quality, reducing the spot welding process cost and the like.

Owner:扬帆研华(天津)科技发展有限公司

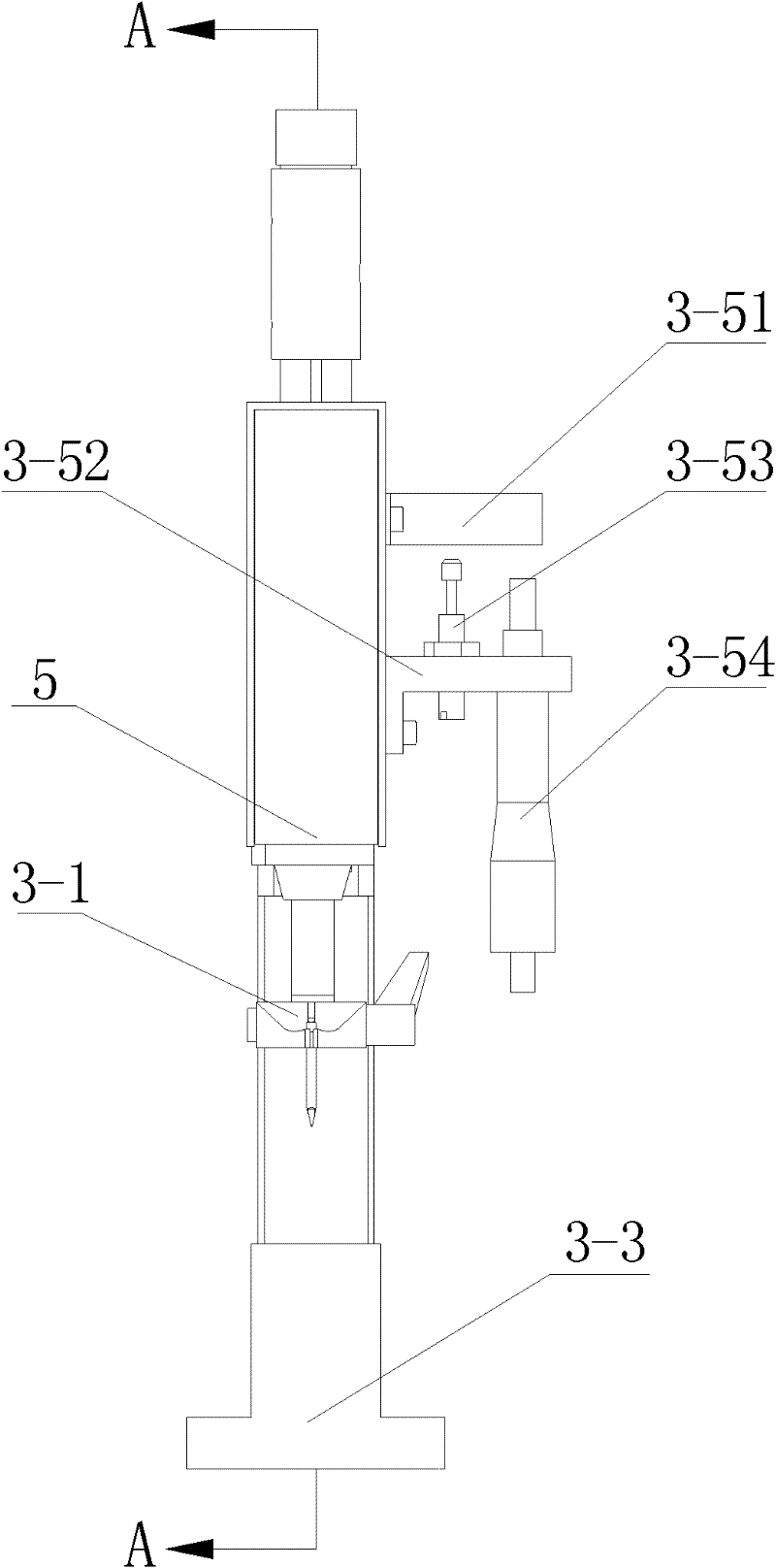

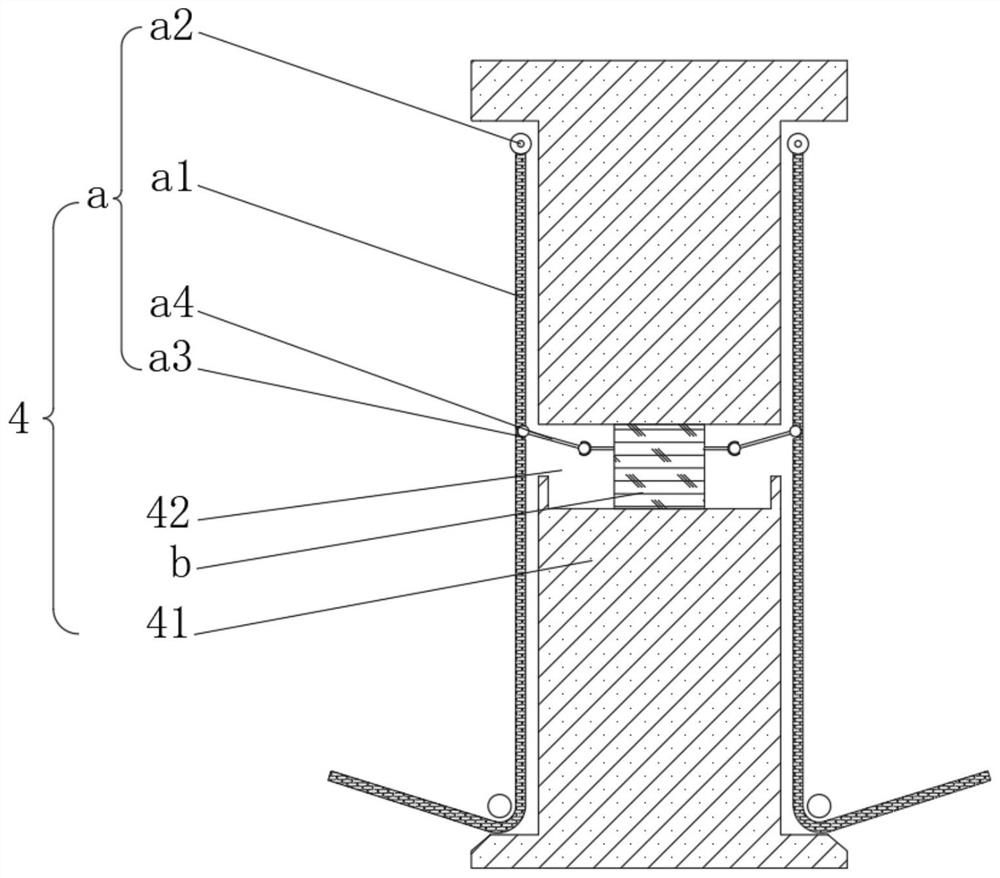

Single working end swing type automatic electrode grinder for resistance spot welding

ActiveCN108161202AEliminate helix angleImprove solder joint qualityWork clamping meansMilling cuttersElectrical resistance and conductanceGear wheel

The invention discloses a single working end swing type automatic electrode grinder for resistance spot welding. The automatic electrode grinder comprises a bracket and a working end frame arranged onthe bracket; the working end frame is internally provided with a working end and a grinding angle compensation system, and the outer side of the working end frame is provided with an electrode positioning mechanism used for electrode grinding; a working end frame floating mechanism is arranged between the bracket and the working end frame; a power input gear, a spline gear, a spline shaft, a ballcage, a gear shaft and a tool rest gear composed of a tool rest and a combined cutting tool are driven by an AC motor in sequence during grinding and cutting; during the cutting displacement of the cutting tool in the grinding process, a screw ball nut, a connecting plate, a support base and the working end are driven by the servo motor in sequence; and the grinding angle compensation system comprises a stepping motor, a worm gear, a bolt tie rod, a connecting block, a hinge pin and so forth. The automatic electrode grinder disclosed by the invention has the abilities of positioning and micro-grinding for the electrode surface, gradually increasing compensation of grinding angles and accurate positioning of electrode grinding positions.

Owner:天津市昊源吉高机械零部件股份有限公司 +1

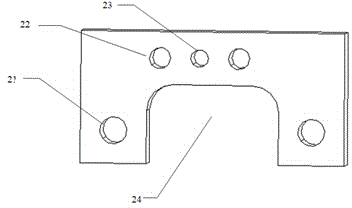

Robot spot welding tool and method for antenna array

InactiveCN108237302AImprove consistencyImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention provides a robot spot welding tool and method for an antenna array, and relates to the field of welding tools. The robot spot welding tool for the antenna array comprises a bottom boardprovided with a long round groove and a plurality of short round grooves; a long rod and short rods of the antenna array are arranged on the long round groove and the short round grooves; the long round groove and the short round grooves correspond to the long rod and the short rods in the antenna array in position; and one ends of the short round grooves communicate with the long round groove. The welding uniformity of the long rod and the short rods of the antenna array can be greatly improved, and the welding efficiency and quality are improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Shelf supporting frame and refrigerator with same

ActiveCN102901318ASmall amount of deformationDoes not affect surface flatnessLighting and heating apparatusSupportEngineeringRefrigerated temperature

The invention discloses a shelf supporting frame and a refrigerator with the same. The shelf supporting frame comprises a first framework piece body, a second framework piece body and a supporting rod, wherein a first welding projection is arranged on the inner side face of the first framework piece body, and a second welding projection is arranged on the inner side face opposite to the inner side face of the first framework piece body, of the second framework piece body; and the first welding projection and the second welding projection are welded on the two ends of the supporting rod respectively. According to the shelf supporting frame disclosed by the embodiment of the invention, the first welding projection and the second welding projection are arranged on the first framework piece body and the second framework piece body, during the welding process, the supporting rod is welded with the first welding projection and the second welding projection without affecting the surface levelness of the first framework piece body and the second framework piece body, and the deformation of the first framework piece body and the second framework piece body is small, thereby not only improving the welding point quality and preventing rust, but also facilitating the production assembly and improving the product quality.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

Automatic welding mechanism for curved surface of car body

InactiveCN103624386ASimple structureEasy to operateVehicle componentsMetal working apparatusEngineeringWelding

The invention provides an automatic welding mechanism for a curved surface of a car body. The automatic welding mechanism comprises a base, a carrying platform, a worktable and a pair of welding tongs, wherein the carrying platform is installed on the base, the carrying platform can slide along the lateral direction of the base, the worktable is installed on the carrying platform, the worktable can longitudinally slide on the carrying platform, the welding tongs can be installed on the worktable, and the welding tongs can rotate on the worktable. The automatic welding mechanism has the beneficial effects that the automatic welding mechanism is simple in structure, convenient to operate, labor-saving, high in working efficiency, high in quality of welding point and high in stability.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Resistance welding method adopting piezoelectric actuator to assist pressure applying

ActiveCN109807444AGuaranteed welding pressureRich parameter combinationsResistance welding apparatusGas cylinderPressure.drive

The invention discloses a resistance welding method adopting a piezoelectric actuator to assist pressure applying. The piezoelectric actuator pushes a motion end head to realize another-level pressurepushing device except from conventional gas cylinder / servo / other pressure applying ways, and the pressure pushing device is coaxially arranged in a ring-shaped electrode; and a parallel / series pressure applying way is regulated through length of the motion end head, and the motion end head extends out from the inner part of the ring-shaped electrode, so that a resistance spot-welding method adopting two-stage pressure drive is formed. The method can control welding quality in stages, and the piezoelectric actuator vibrates at high frequency at a pre-pressure stage to realize effect of clearing an oxide film; at an electrifying welding stage, the piezoelectric actuator vibrates at high frequency at an electrifying welding stage to realize molten pool stirring effect and crystalline grain refining effect; at a power-off forging and pressing stage, the piezoelectric actuator vibrates at high frequency to realize stress relief effect, so that quality of a welding spot can be effectively strengthened; and meanwhile, the resistance welding method easily realizes automation, and improves production efficiency.

Owner:BEIJING UNIV OF TECH

Structure and method for rapid centering of electrode arms of a fixed spot welder

The invention relates to a structure for rapid centering of fixed spot welding machine electrode arms. The structure comprises a machine body, the upper electrode arm, an upper working tabletop, an upper electrode holder, the lower electrode arm, a lower working tabletop and a lower electrode holder. One end of the upper electrode arm is movably installed on the upper working tabletop. The upper electrode holder is fixedly installed at the other end of the upper electrode arm. One end of the lower electrode arm is movably installed on the lower working tabletop. The lower electrode holder is fixedly installed at the other end of the lower electrode arm. The upper electrode arm and the lower electrode arm are each transversely provided with a dividing ruler. The upper electrode arm and the lower electrode arm are each transversely provided with a reference line. The upper working tabletop and the lower working tabletop are each provided with a reference point. In the welding process, the adjusting time for replacing the electrode holders can be shortened, and the production efficiency can be improved; and welding electrode centering is ensured, and the welding spot quality is improved.

Owner:DIGITAL DIE STAMPING TECH WUHAN

Welding fixing device

PendingCN112355429AEliminate inner wall crushReinforced outer surface elasticWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWeld seam

The invention discloses a welding fixing device. The welding fixing device comprises a welding fixing device body composed of a tray, a base and a supporting rod, wherein the top of the tray is fixedly connected with the bottom of the base; a groove is formed in the top of the base; the bottom of the inner wall of the groove is fixedly connected with the bottom of the supporting rod; the supporting rod is sleeved with a first welding piece; a second welding piece is connected into the first welding piece in a sliding manner; the supporting rod comprises a rod body; a fixing mechanism and a correcting mechanism are arranged in the rod body; the fixing mechanism comprises a rotating rod; and a sliding mechanism is arranged on the top of the rotating rod. The invention relates to the technical field of welding. The welding fixing device solves the problems that due to transverse welding, welding defects such as unsmooth welding seams on the surface of a welding part, uneven and full fillet filling, base metal corrosion, over-burning blackening, undercut (pipe opening burning), overlap height, cracks, air holes and impurities are caused.

Owner:雒明伟

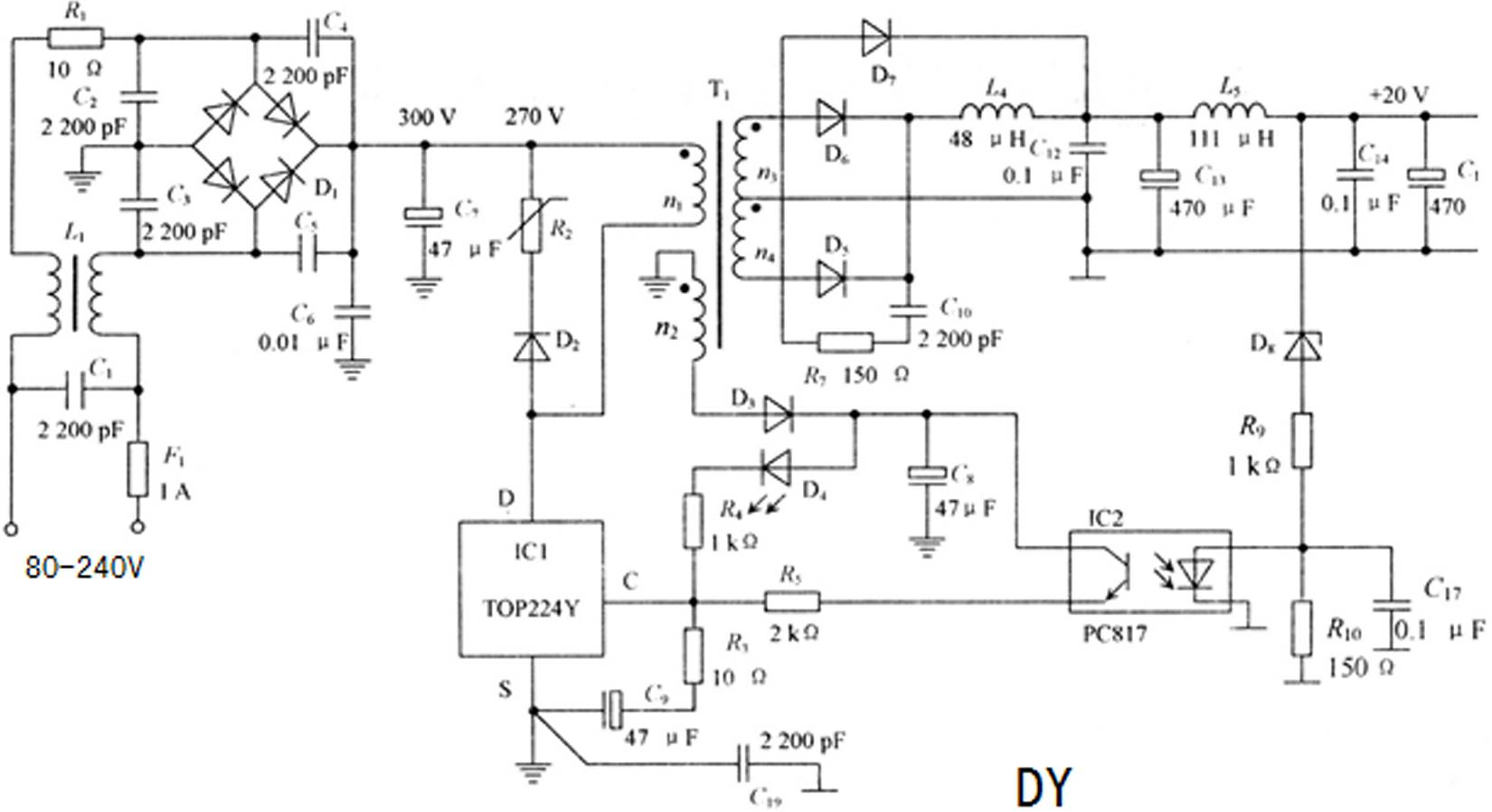

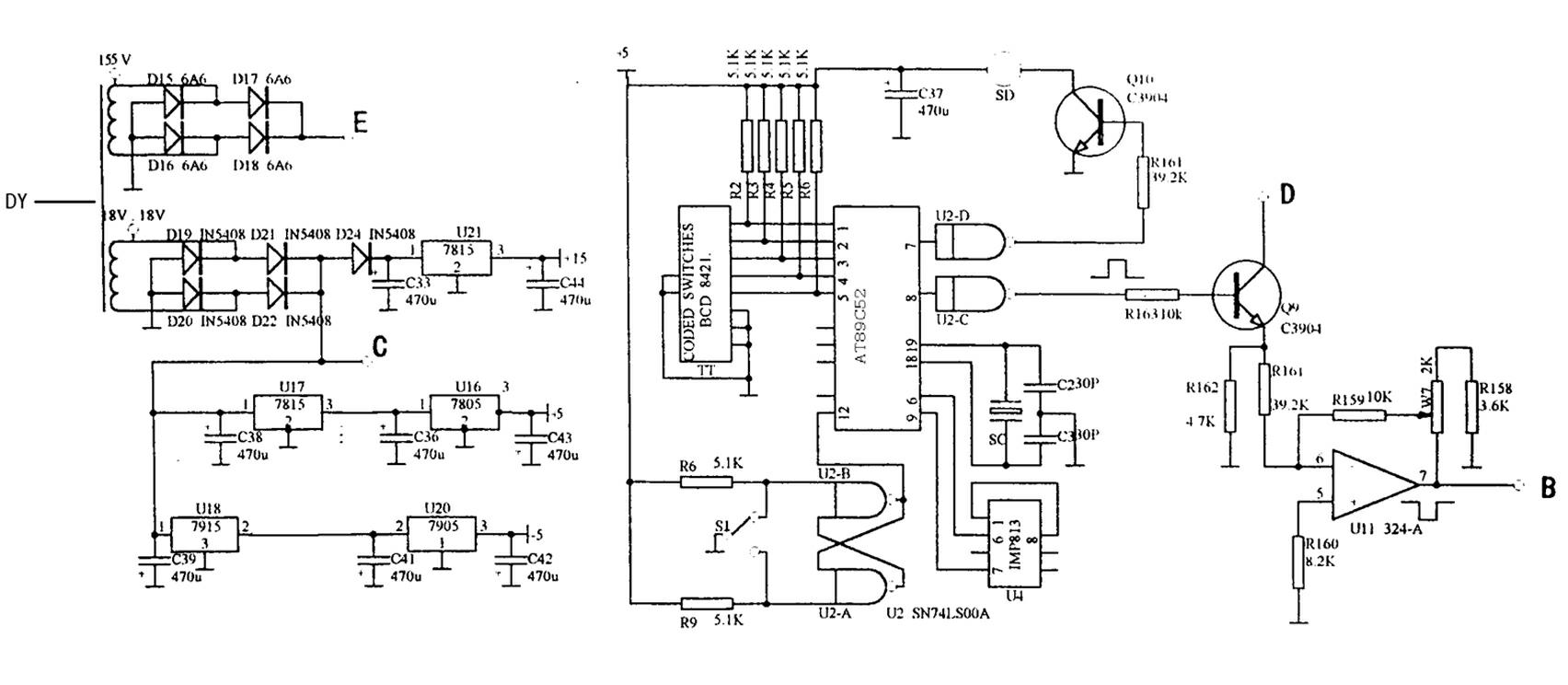

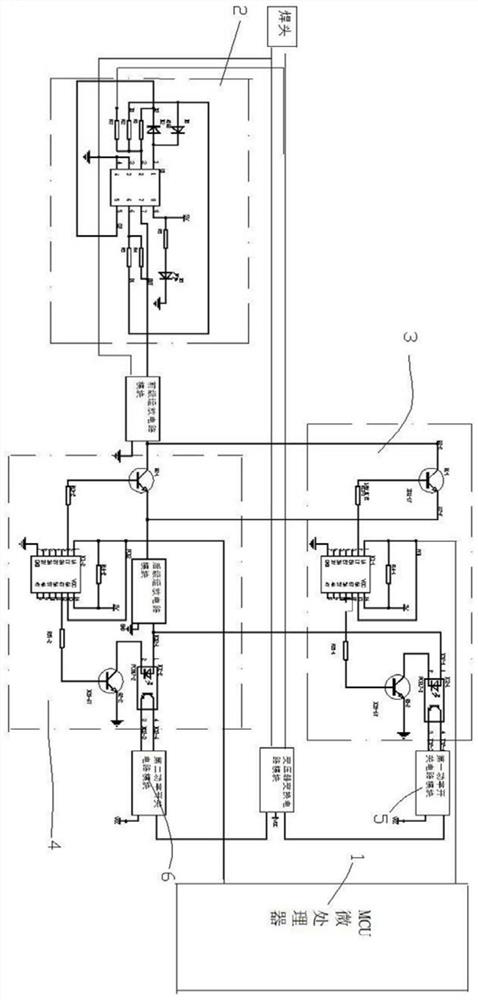

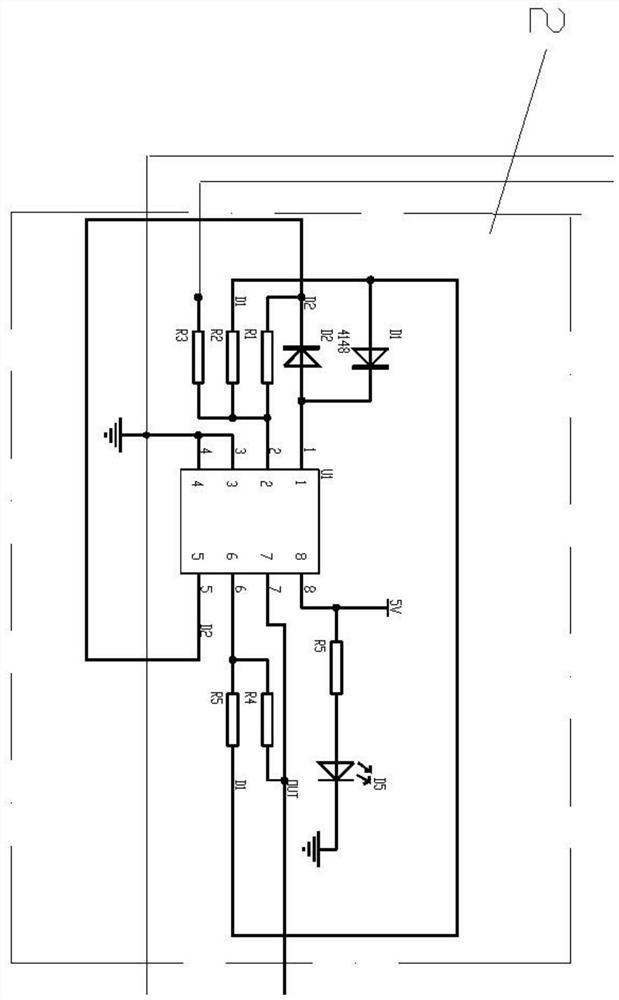

A kind of output current forward and reverse DC welding machine control circuit

ActiveCN111774709BAddressing Polarity EffectsExtended service lifeWelding electric supplyTransformerElectrical polarity

The invention discloses a forward and reverse DC welding machine control circuit with output current, which is characterized in that it includes an MCU microprocessor, a polarity processing circuit module, a first power driving circuit module, a second power driving circuit module, a first power A switch circuit module, a second power switch circuit module and a transformer conversion circuit module. The invention outputs electric signals with different current directions through circuit control in two welding cycles before and after, which solves the polarity effect of the welding head, prolongs the service life of the welding head and improves the quality of welding points.

Owner:珠海微点焊电子工业有限公司

A method for spot welding quality control of galvanized steel sheets for automobiles

ActiveCN108857010BAvoid stickingQuality improvementResistance welding apparatusSpot weldingUltimate tensile strength

Owner:WUHAN JIEZHONG AUTO PARTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com