Appearance welding spot protecting device

A technology for protection devices and solder joints, applied in welding protection devices, auxiliary devices, welding accessories, etc., can solve problems such as single copper plate surface, small effective welding space, and difficult electrode maintenance, so as to reduce requirements, facilitate maintenance, and ensure The effect of surface conformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further illustrate structure of the present invention below in conjunction with accompanying drawing:

[0017] see figure 1 , The present invention consists of a protective copper pad 1, a connecting plate 2, a spring-type guide pin 3 and a support seat 4.

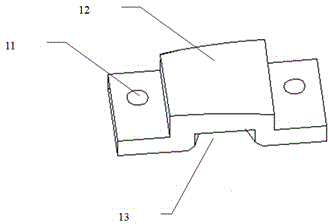

[0018] see figure 2 The protective copper pad 1 is made of chromium-zirconium copper (CuCrZr), and its shape is a few characters. The top surface is the sheet metal contact surface 12 that fits the sheet metal surface, and the bottom surface corresponding to the top surface is the electrode contact surface 13 of the welding tongs. , the sheet metal fitting surface 12 is required to be processed to be consistent with the sheet metal profile data, and the bonding electrode contact surface 13 is required to be similar to the sheet metal profile surface to prevent the electrodes of the welding tongs from sliding. Both ends of the protective copper pad 1 have guide pin holes 11 respectively.

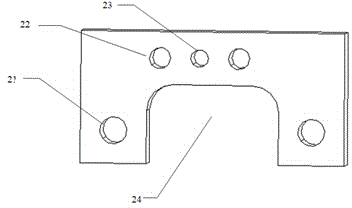

[0019] see image 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com