Cleaning-free scaling powder for tin-silver-zinc series lead-free solder

A technology of lead-free solder and flux, applied in the direction of welding/cutting media/materials, welding media, welding equipment, etc., can solve problems such as moisture absorption, impact, poor mechanical and electrical properties of the workpiece, and achieve cost reduction and surface Effects of smoothness, wettability improvement and anti-oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

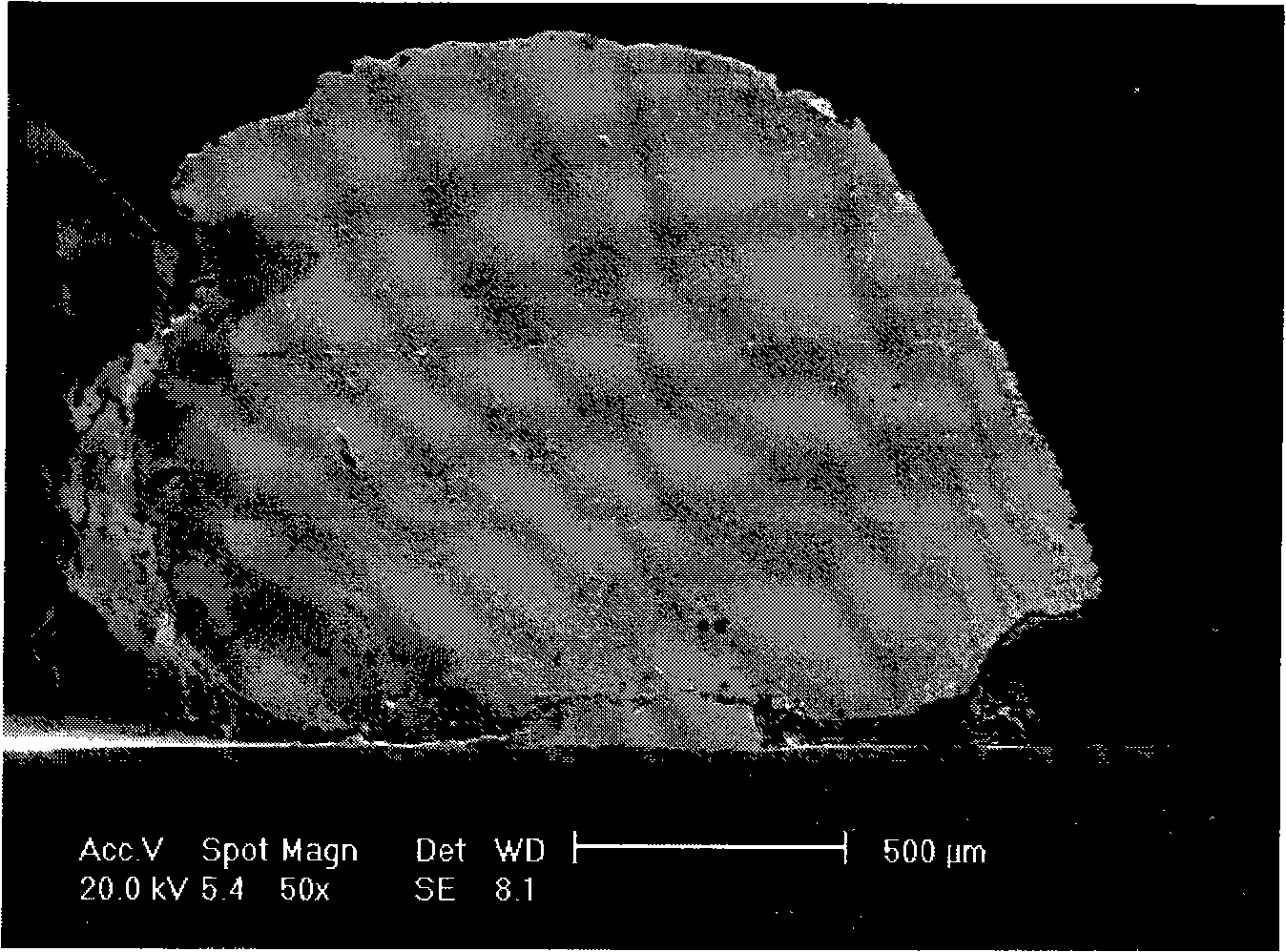

Image

Examples

Embodiment 1

[0022] The no-cleaning flux for tin-silver-zinc lead-free solder according to the present embodiment consists of the following components in parts by weight:

[0023] Adipic acid 8

[0024] Glycerin 10

[0025] Ethylene glycol methyl ether 5

[0026] Hydrogenated castor oil 1

[0027] Benzimidazole 0.1

[0028] Polyphenolic resin 1.4

[0029] Deionized water 74.5

[0030] The preparation process of the flux of this example is:

[0031] At room temperature, add 50 parts of deionized water and 5 parts of ethylene glycol methyl ether into a reaction kettle with a stirrer, add 1 part of hydrogenated castor oil and 1.4 parts of polyphenolic resin under stirring, and after dissolving, add 24.5 parts Deionized water and 10 parts of glycerin, then add 0.1 part of benzimidazole, and stir until the solids are completely dissolved. After the materials are evenly mixed, stand and filter to remove impurities mixed therein, and retain the filtrate to become the no-cleaning flux of the...

Embodiment 2

[0033] The no-cleaning flux for tin-silver-zinc lead-free solder according to the present embodiment consists of the following components in parts by weight:

[0034] Glyceric acid 12

[0035] Glycerin 15

[0036] Hydrogenated castor oil 2

[0037] Benzimidazole 0.3

[0038] Modified Cellulose 1.2

[0039] Deionized water 69.5

[0040] Its preparation is with embodiment 1.

Embodiment 3

[0042] The no-cleaning flux for tin-silver-zinc lead-free solder according to the present embodiment consists of the following components in parts by weight:

[0043] Acetic acid 2

[0044] Lactic acid 8

[0045] Glycerin 5

[0046] Hexylene glycol 8

[0047] Hydrogenated castor oil 3

[0048] Mebenzimidazole 1

[0049] Modified Cellulose 2

[0050] Deionized water 71

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com