Connecting structure of lithium battery plate lugs and poles and manufacturing method thereof

A technology of connecting structure and manufacturing method, applied in the direction of structural parts, battery pack parts, circuits, etc., can solve the problems of large battery internal resistance, reduce battery charge and discharge performance and life, pierce the diaphragm, etc., and achieve smooth and bright surface. High quality solder joints and consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

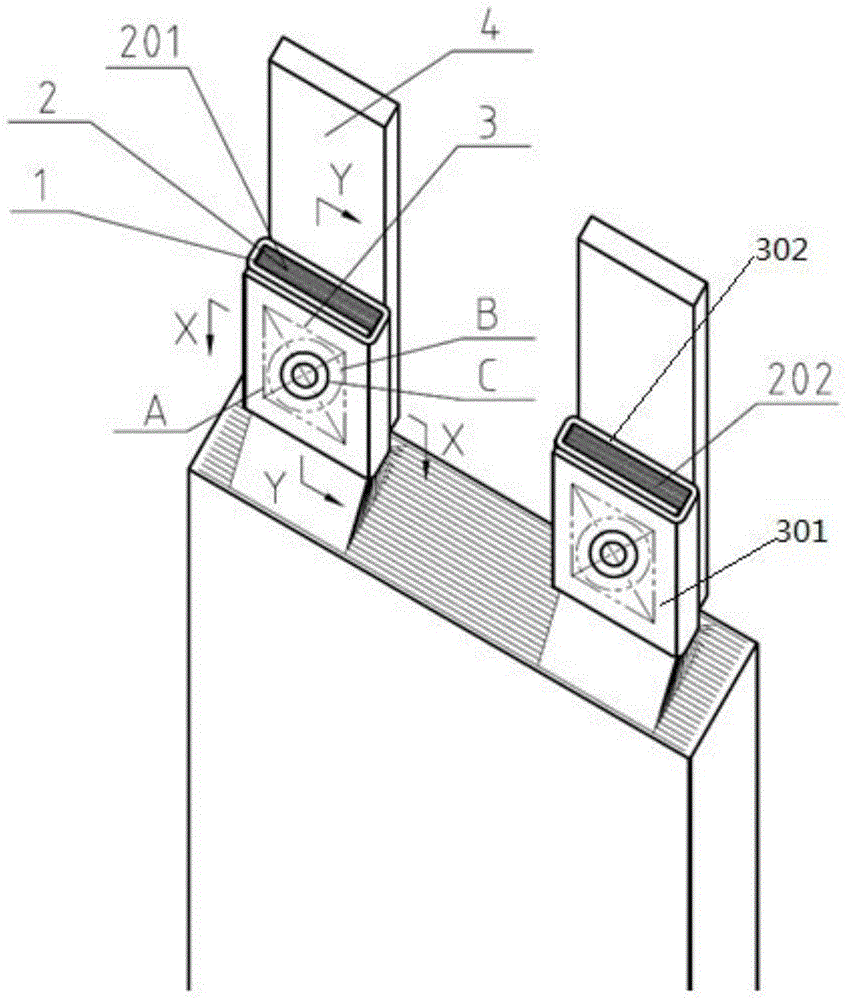

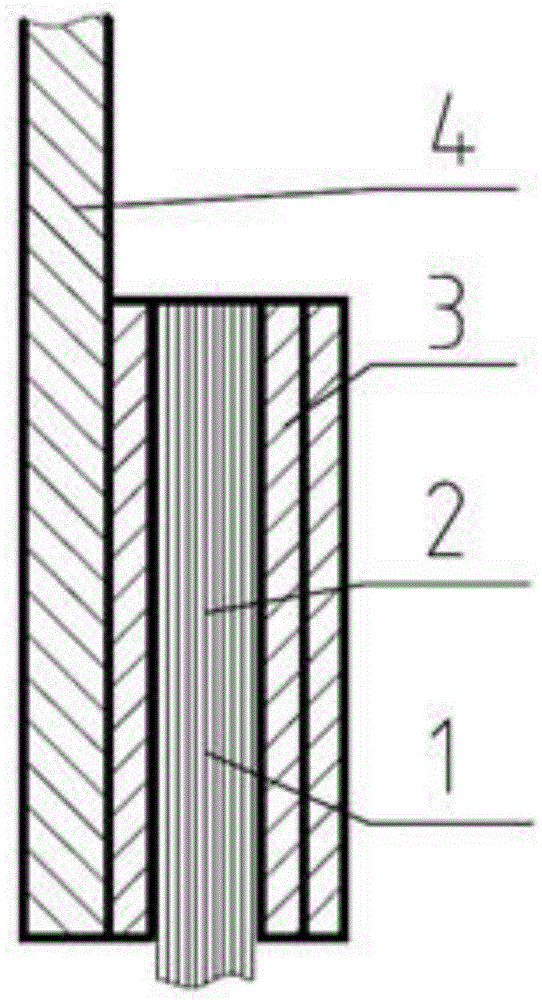

[0043] Such as figure 1 As shown, a connection structure between a tab and a pole of a lithium battery includes a tab 2, a buffer foil 3 and a pole 4. The tab 2 is a laminated structure of multi-layer foils, and the tab 2 passes through the buffer foil 3 Wrapped, the buffer foil 3 has a butt side 301 and a single-layer side 302, the butt side 301 is two or three layers of foil laminated; the pole 4 is set in contact with the single-layer side 302, the pole 4, the buffer foil 3, the pole Ear 2 solder connection.

[0044] Such as Figure 1-Figure 4 The connection structure between a tab and a pole of a lithium battery shown includes a tab 2 composed of 40 layers of foil, and the tab 2 includes a positive electrode tab 201 and a negative electrode tab 202, wherein the positive electrode tab 201 adopts ultra-thin electrolytic aluminum foil with a thickness of 0.02mm, and the negative electrode tab 202 adopts ultra-thin electrolytic copper foil with a thickness of 0.012mm.

[00...

Embodiment 2

[0055] Such as Figure 5-Figure 8 The connection structure between a tab and a pole of a lithium battery shown includes a tab 2 composed of 70 layers of foil, and the tab 2 includes a positive electrode tab 201 and a negative electrode tab 202, wherein the positive electrode tab 201 adopts ultra-thin electrolytic aluminum foil with a thickness of 0.02mm, and the negative electrode tab 202 adopts ultra-thin electrolytic copper foil with a thickness of 0.012mm. The positive electrode tab 201 and the negative electrode tab 202 are respectively wrapped by the buffer foil 3, and the butt side foils of the buffer foil 3 wrapping the positive electrode tab 201 and the negative electrode tab 202 are overlapped and pressed together; A pole 4 is provided on the single-layer side of the face where the butt side is located.

[0056] Such as Image 6 , Figure 7 As shown, the tab 2 is mechanically pressed and wrapped by the buffer foil 3. The foil on the butt side of the buffer foil 3 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com