Spot welding method for metal honeycomb core

A technology of metal honeycomb core and honeycomb core, applied in metal processing, metal processing equipment, welding equipment, etc., can solve the problems of large error and small material sensitivity coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

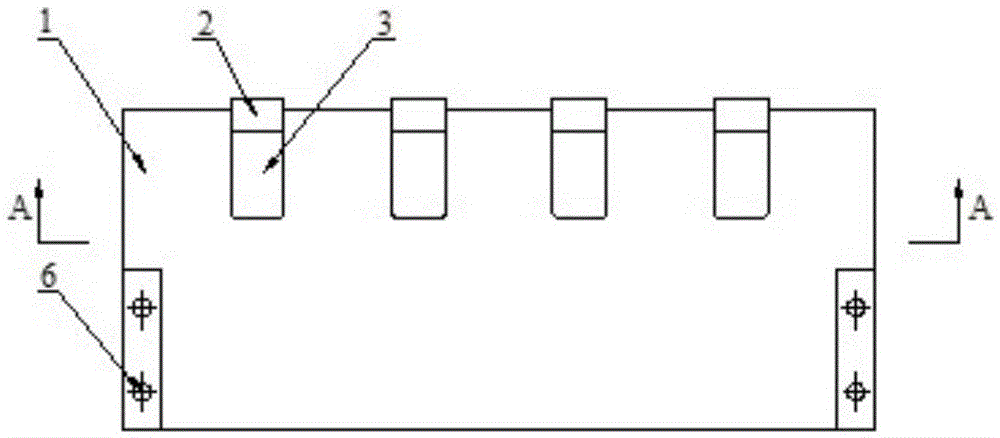

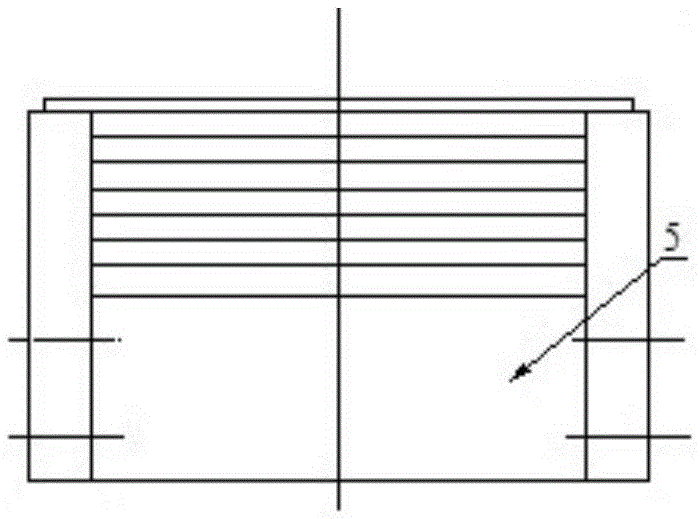

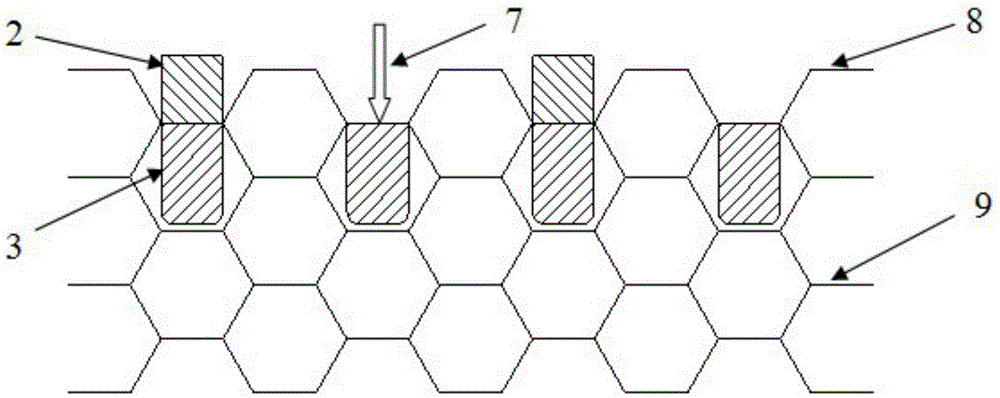

[0020] In this embodiment, at first the honeycomb core spot welding parameters are determined, the method is as follows:

[0021] Firstly, the primary selection parameters of the corresponding welding consumables are preliminarily obtained by applying the formula similar conversion method. The parameters of the same or similar material as the material to be welded are selected as the standard, and the primary parameters are converted by the similar conversion formula (1):

[0022] I x = I 0 ( d x d 0 ) 0.8 ; t x = t 0 ( d x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com