Automatic welding mechanism for curved surface of car body

An automatic welding and driving mechanism technology, applied in welding equipment, vehicle parts, resistance welding equipment, etc., can solve the problems of equipment complexity, many fault points, and inability to use large areas, so as to improve the quality and stability of solder joints, The effect of improving work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

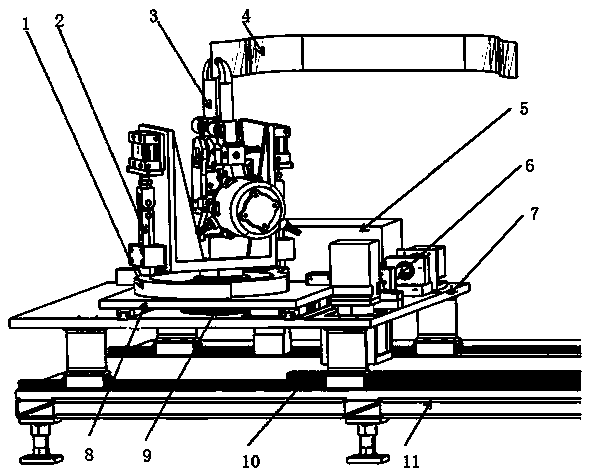

[0019] Such as figure 1 As shown, the present invention discloses an automatic welding mechanism for a curved surface of a car body, comprising a base 11, a bearing platform 7, a workbench 8, and a welding tongs 3, the bearing platform 7 is installed on the base 11, and the bearing platform 7 can slide laterally along the base 11, the workbench 8 is installed on the bearing platform 7, and the workbench 8 can slide longitudinally on the bearing platform 7, and the welding tongs 3 are installed on on the workbench 8 and the welding tongs 3 can rotate on the workbench 8 .

[0020] The base 11 is provided with a base slide rail, and the bearing platform 7 is provided with a bearing platform slider, and the bearing platform slider is installed on the base slide rail, and the automatic welding mechanism also includes driving the bearing platform slider A platform driving mechanism 10 for laterally sliding on the slide rail of the base.

[0021] The bearing platform 7 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com