Ultrasound electric resistance welding welder

A resistance welding machine and ultrasonic technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing labor costs, reducing work efficiency, affecting the quality of solder joints, etc., to reduce labor costs, improve work efficiency, and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The existing micro-spot welding machines in the industry have precise control over the parameters of spot welding. The ultrasonic vibration required by ultrasonic resistance welding is only an auxiliary supplement to improve the quality of solder joints. That is to say, ultrasonic resistance welding does not require ultrasonic machines. It is high and easy to manufacture. The ultrasonic host can be incorporated into the chassis of the welding host to make it together, or it can be added to the existing welding host as a self-contained body.

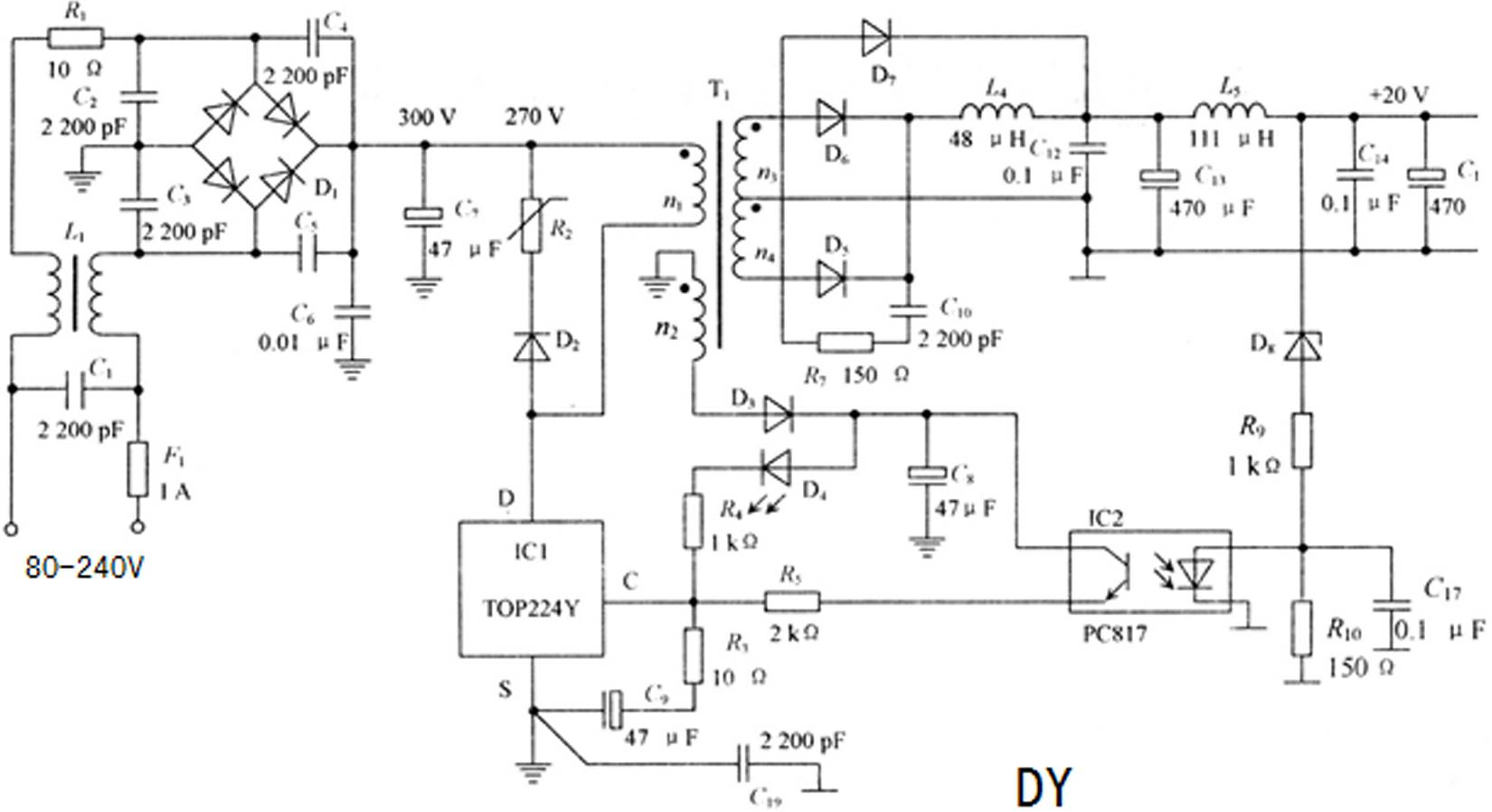

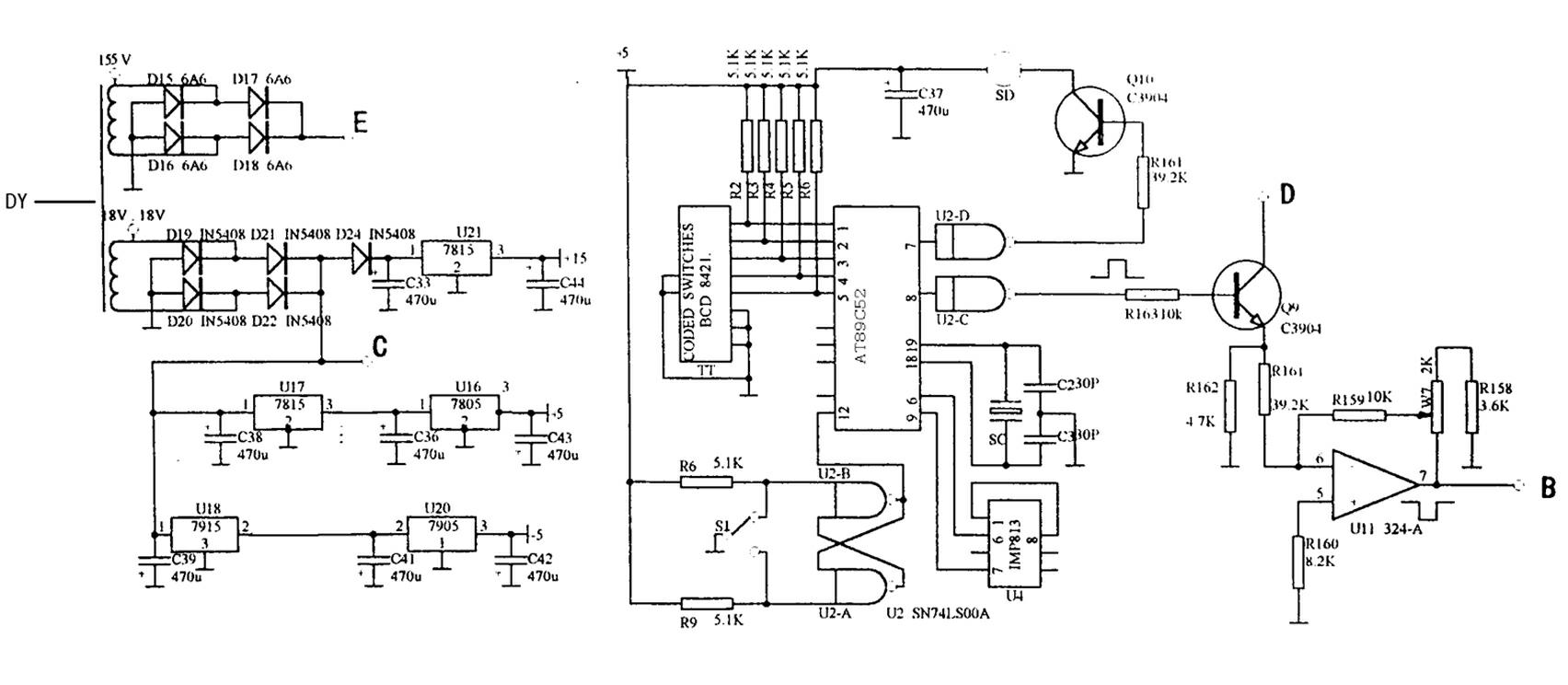

[0070] The ultrasonic resistance welding machine of the present invention comprises an ultrasonic host, a machine head, an ultrasonic vibrator and an electric welding host.

[0071] The oscillating circuit of the ultrasonic host produces high-frequency oscillations of 10KHz-50KHz, and the ultrasonic power and waveform meet the requirements through the post-stage and shaping amplifier integrated circuit and shaping integrated circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com