Direct-current resistance spot-welding multi-mode feedback control method

A DC resistance and feedback control technology, applied in resistance welding equipment, welding monitoring devices, welding power sources, etc., can solve the problem of inability to compensate for the impact, and achieve the effect of saving adjustment time, improving the quality of solder joints, and suppressing spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

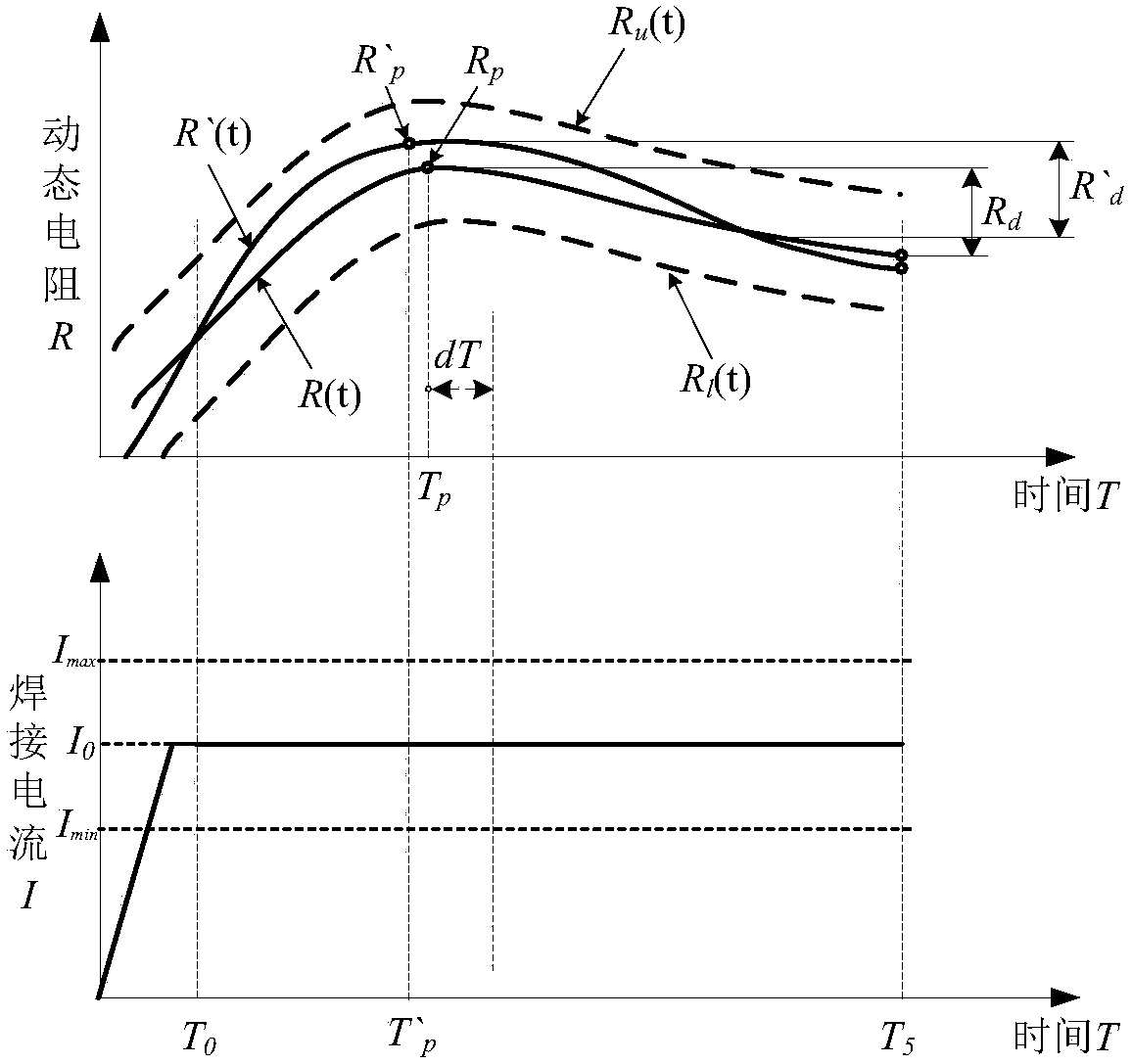

[0050] Such as figure 1 As shown, this embodiment specifically includes the following steps:

[0051] 1) Test welding is carried out under standard welding conditions, and the welding current is I 0 , measure the dynamic resistance during the test welding process, establish the template dynamic resistance curve R(t) of the solder joint, and its upper tolerance zone curve R u (t) and lower tolerance zone curve R l (t), the template dynamic resistance curve peak value is R p , R p The corresponding moment is T p , the drop of template dynamic resistance curve after the peak value is R d , the maximum power-on time is T 5 .

[0052] 2) The material to be welded is welded, and the initial welding current is I 0 , measure the dynamic resistance during the actual welding process, draw the actual dynamic resistance curve R′(t), and the peak value of the actual dynamic resistance curve is R′ p , R' p The corresponding moment is T′ p , the actual dynamic resistance curve dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com