Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Improve smudge quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

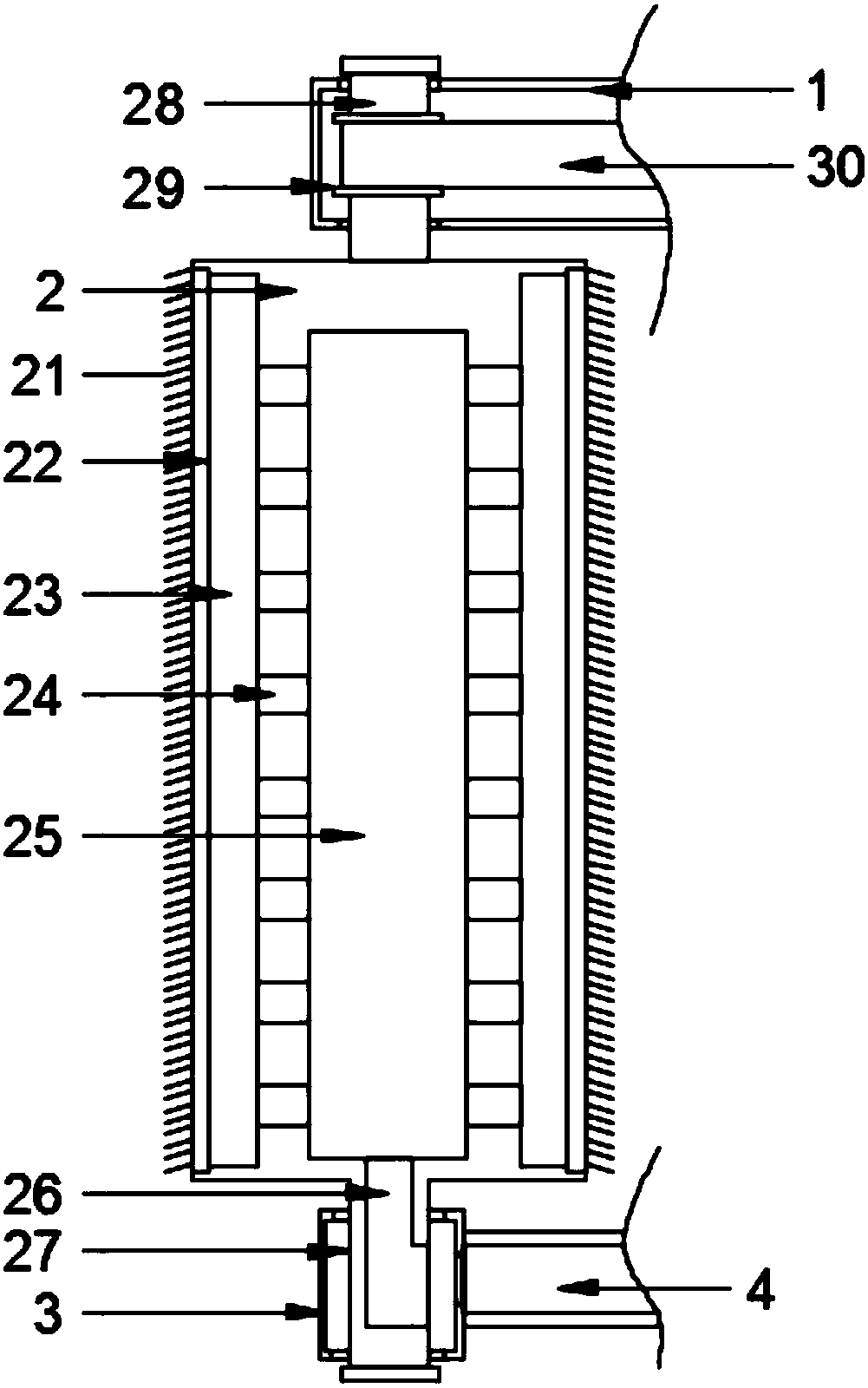

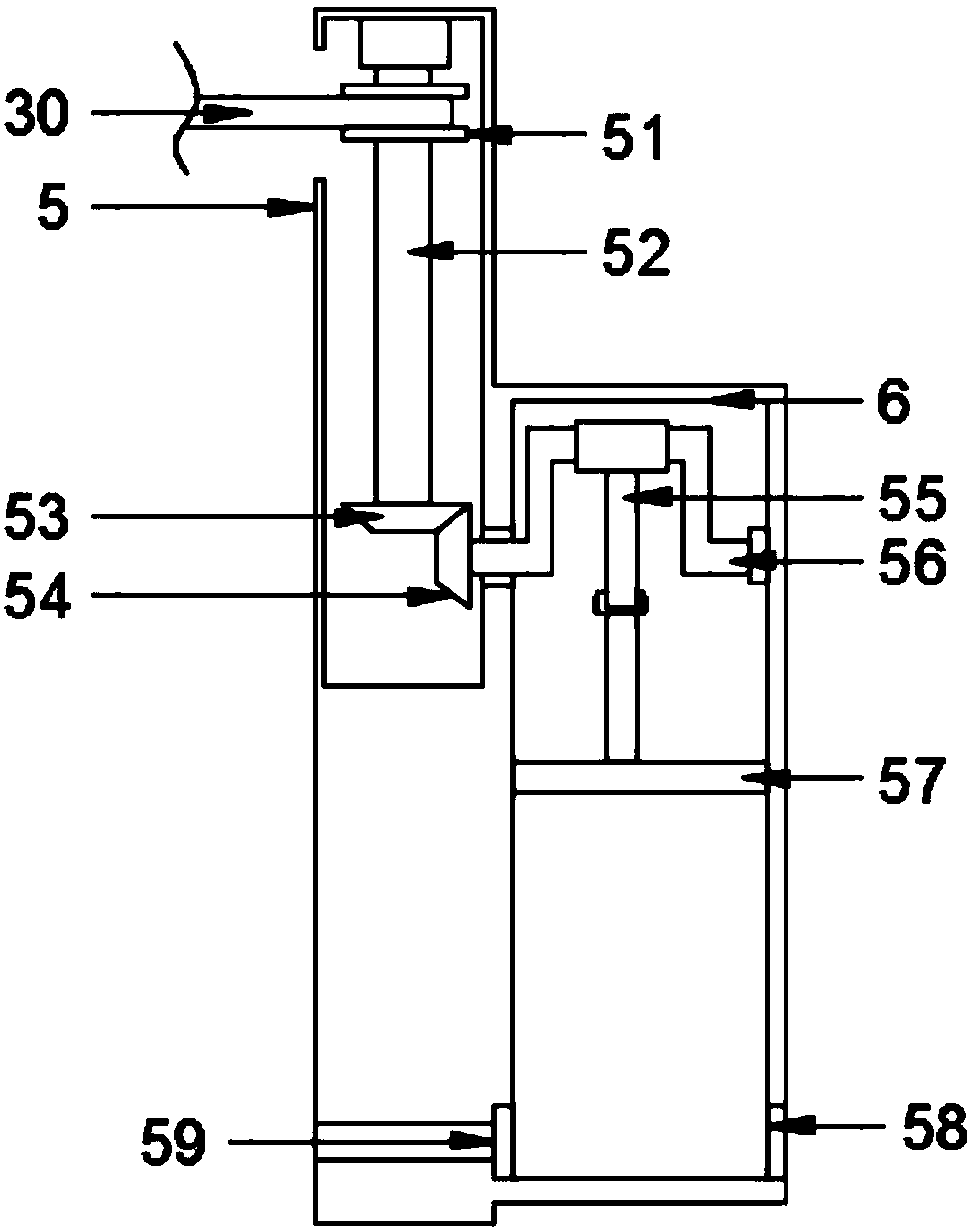

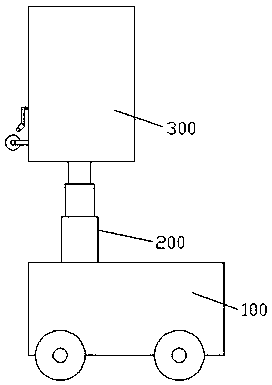

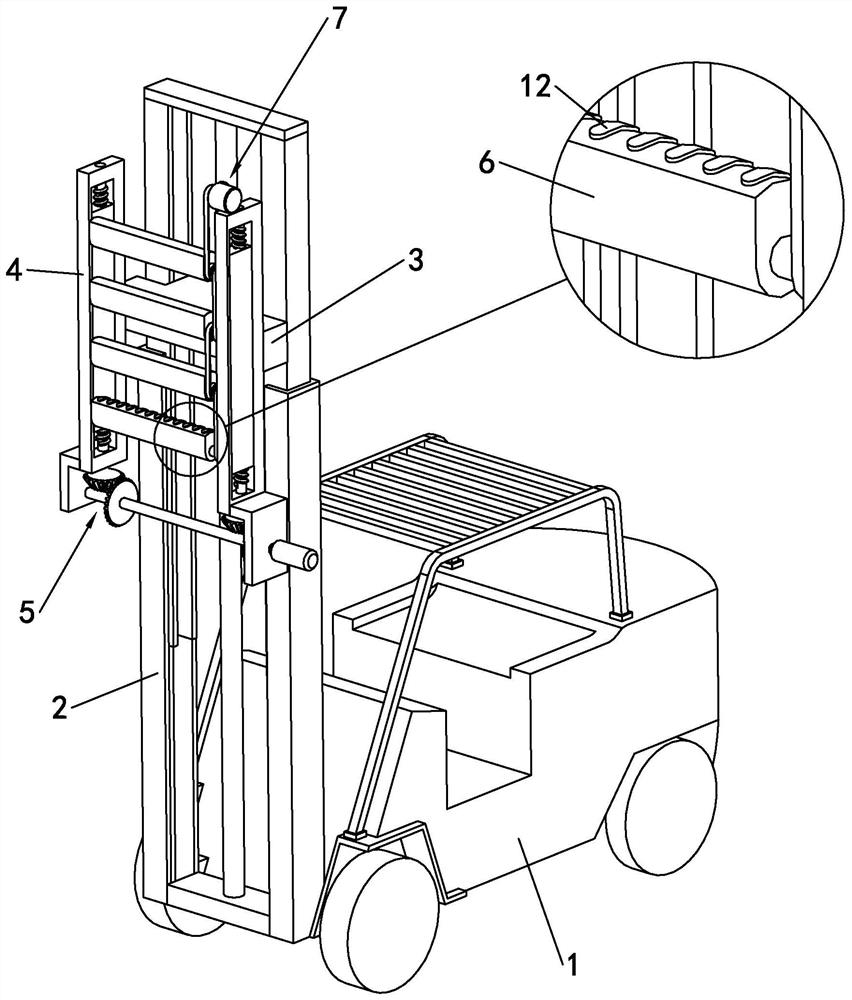

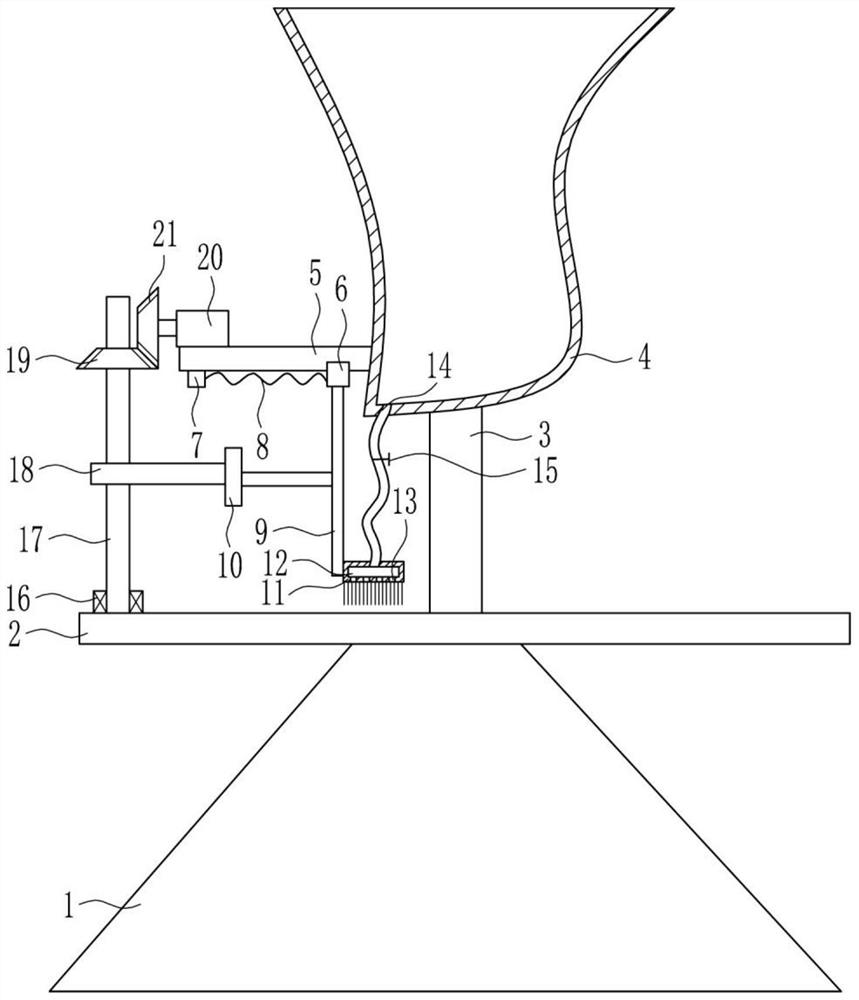

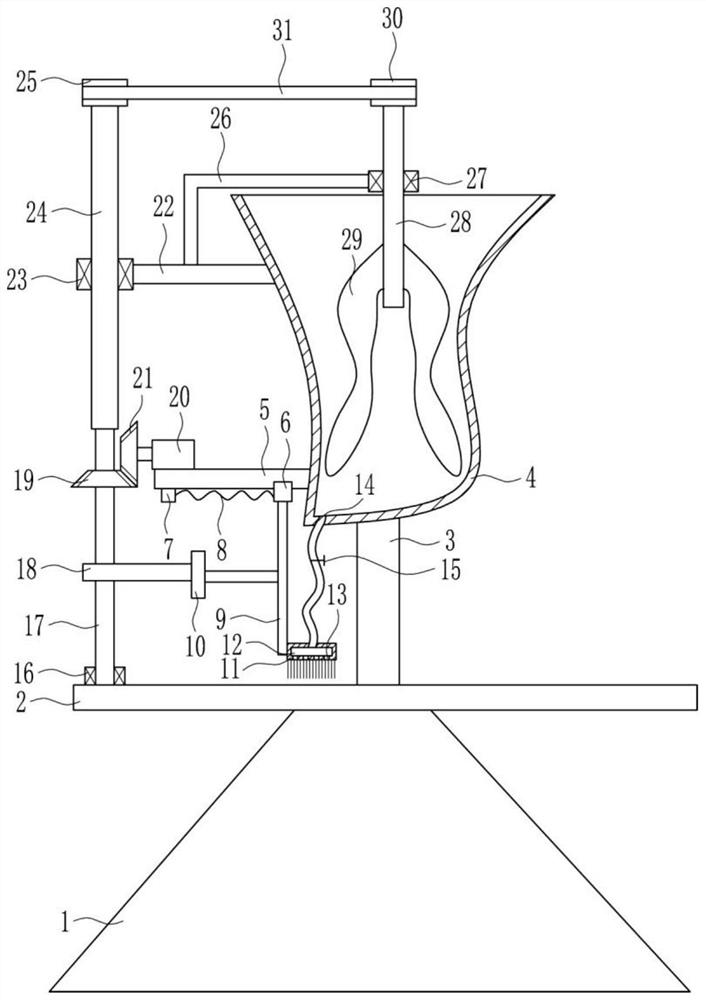

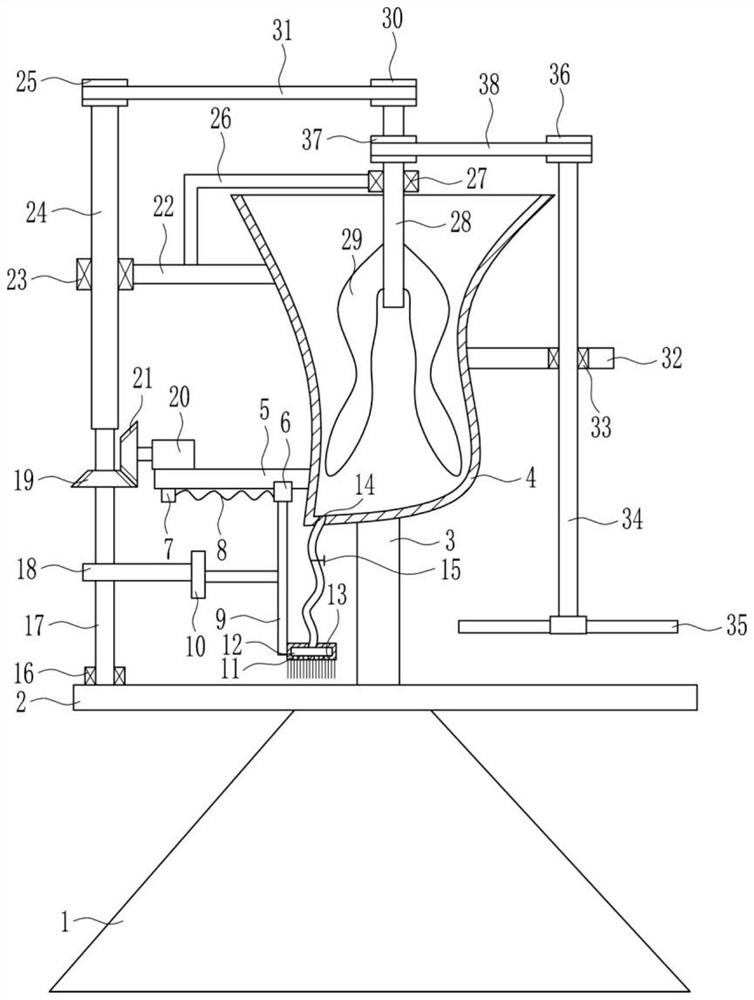

Automatic wall surface mortar painting machine

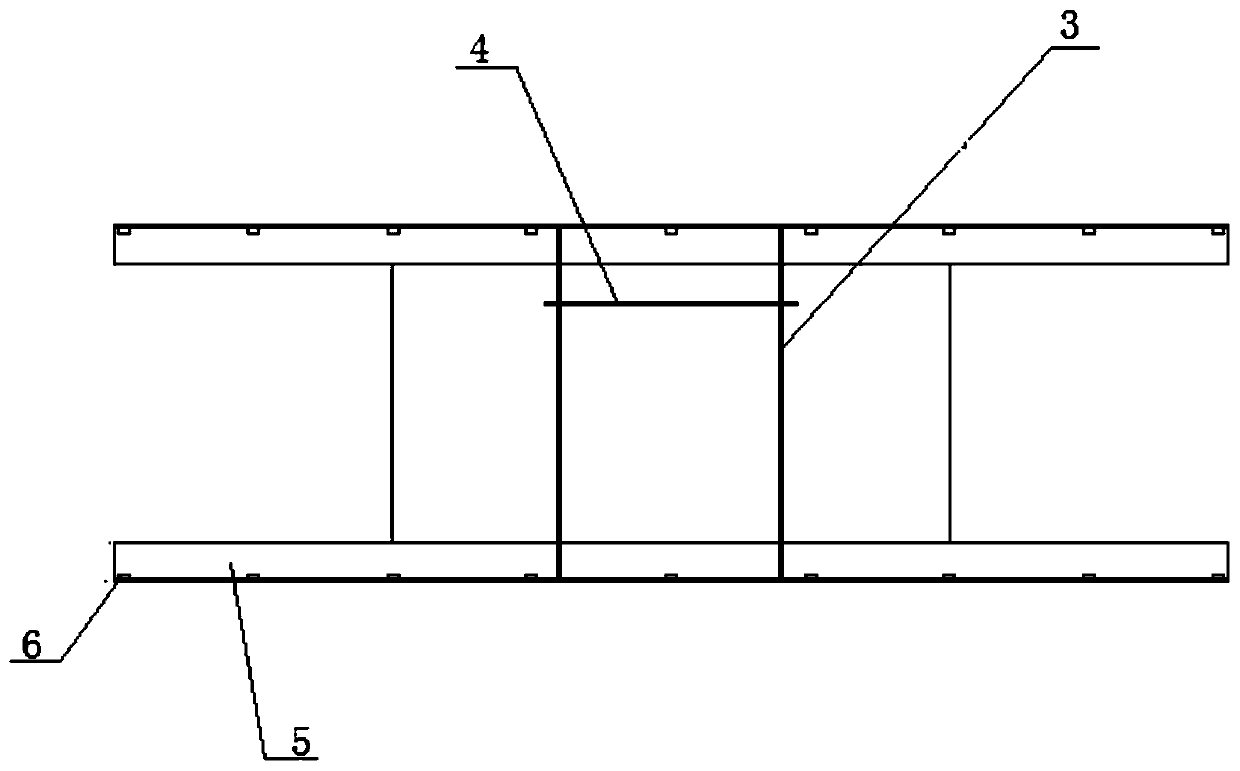

InactiveCN102817465AOperational securityEasy to operateBuilding constructionsAutomatic controlVertical plane

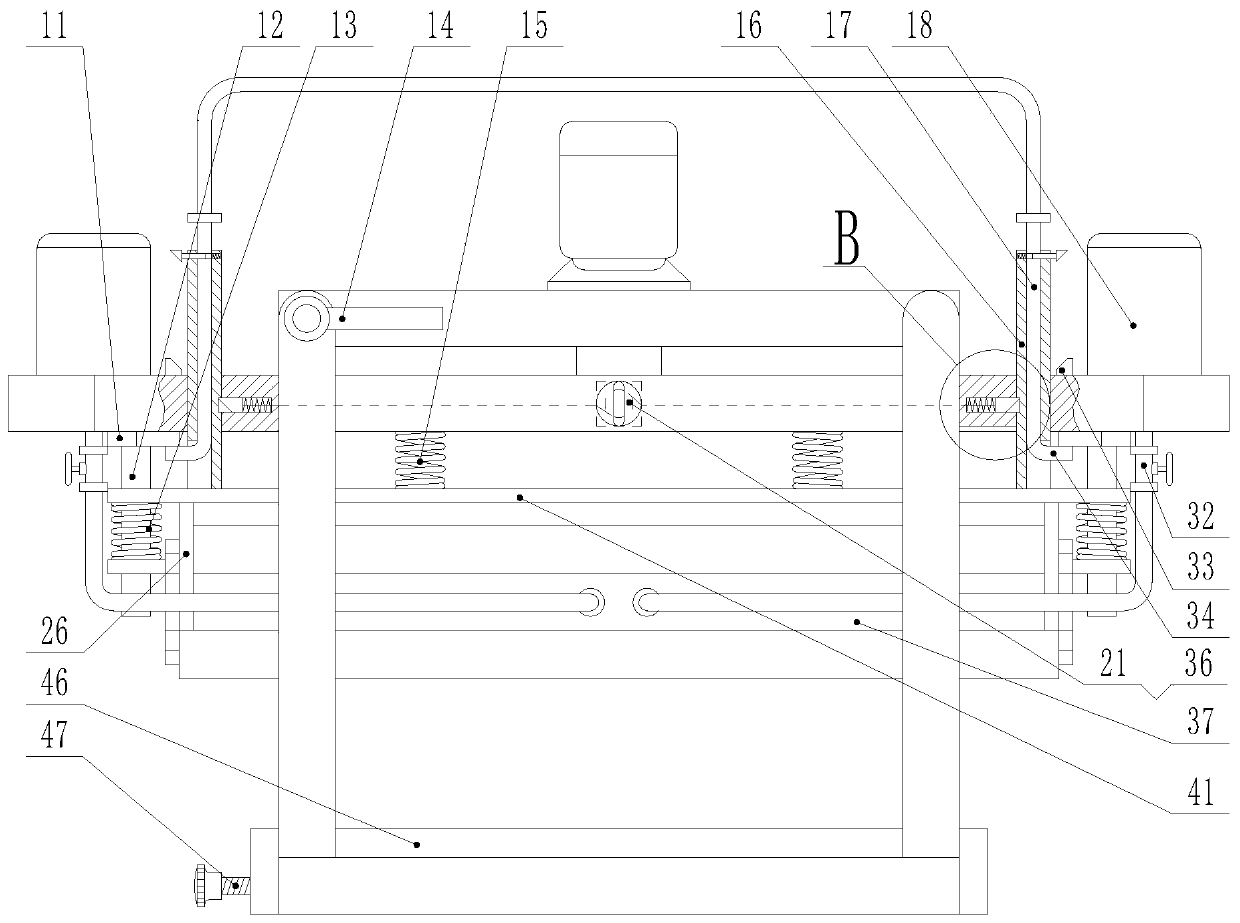

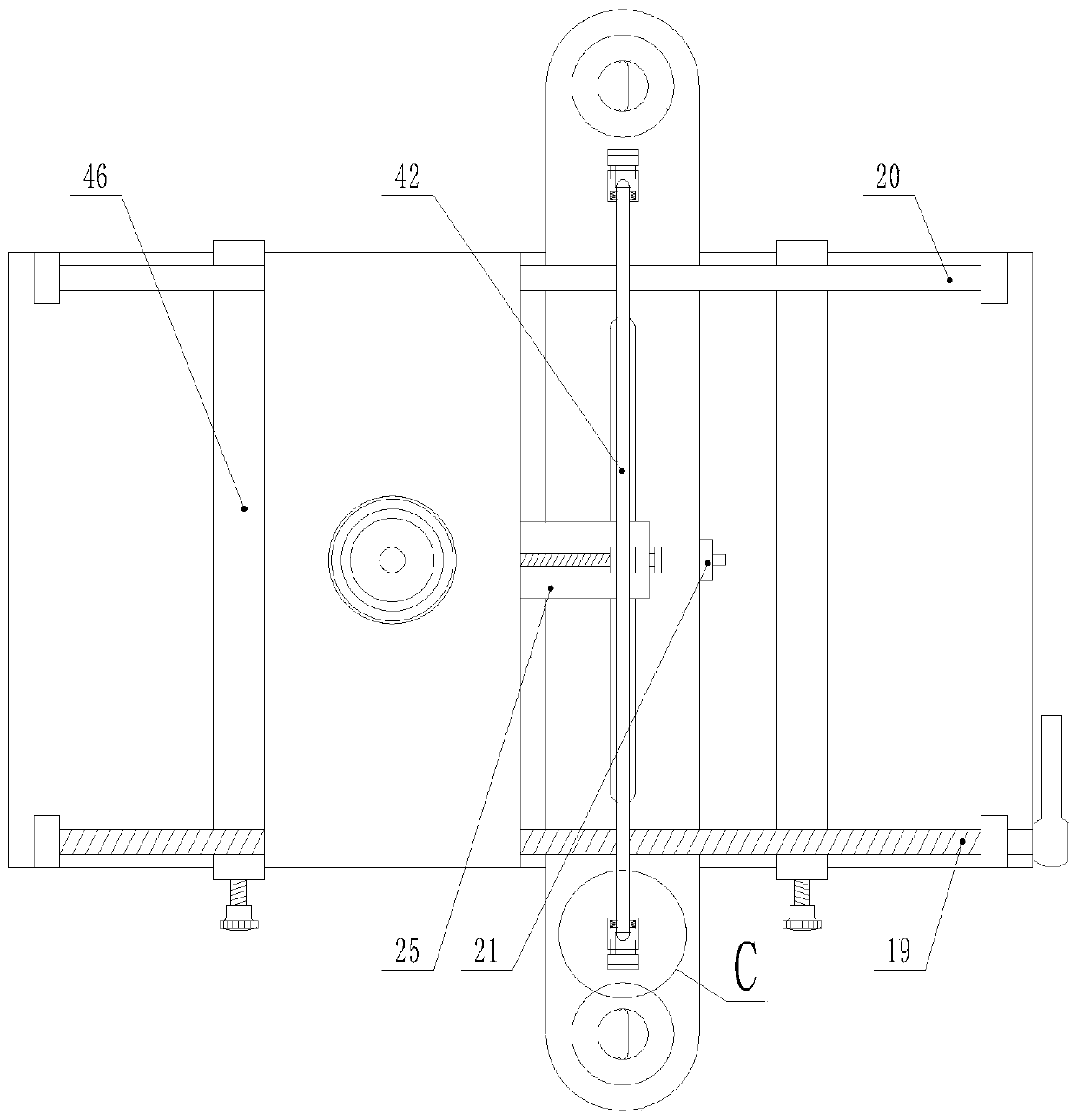

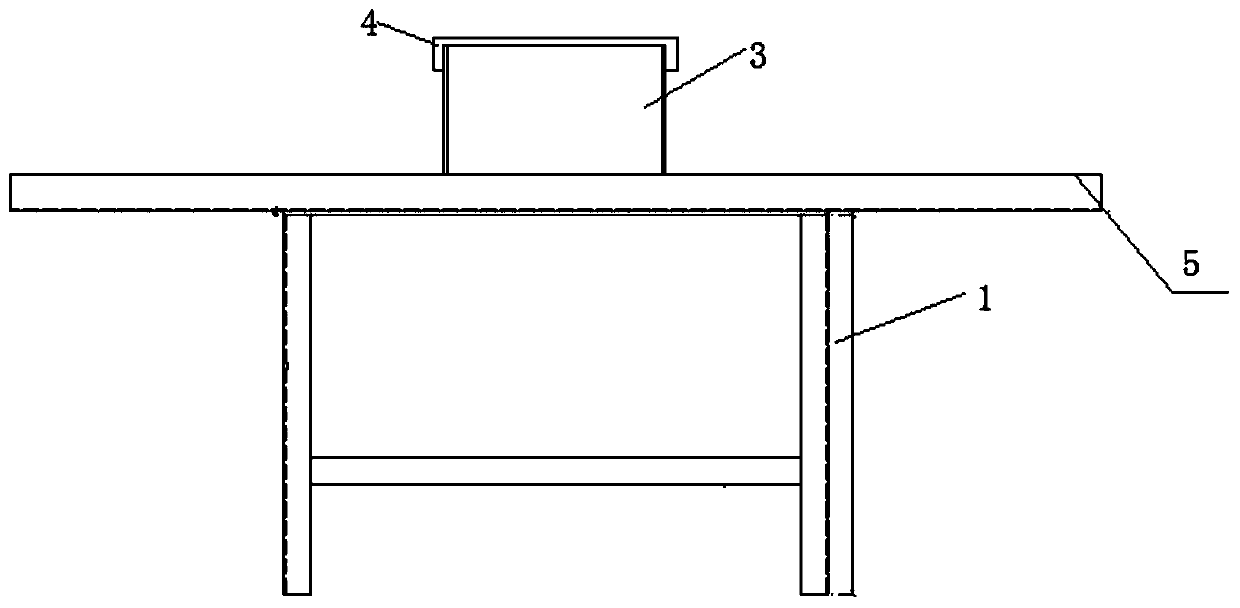

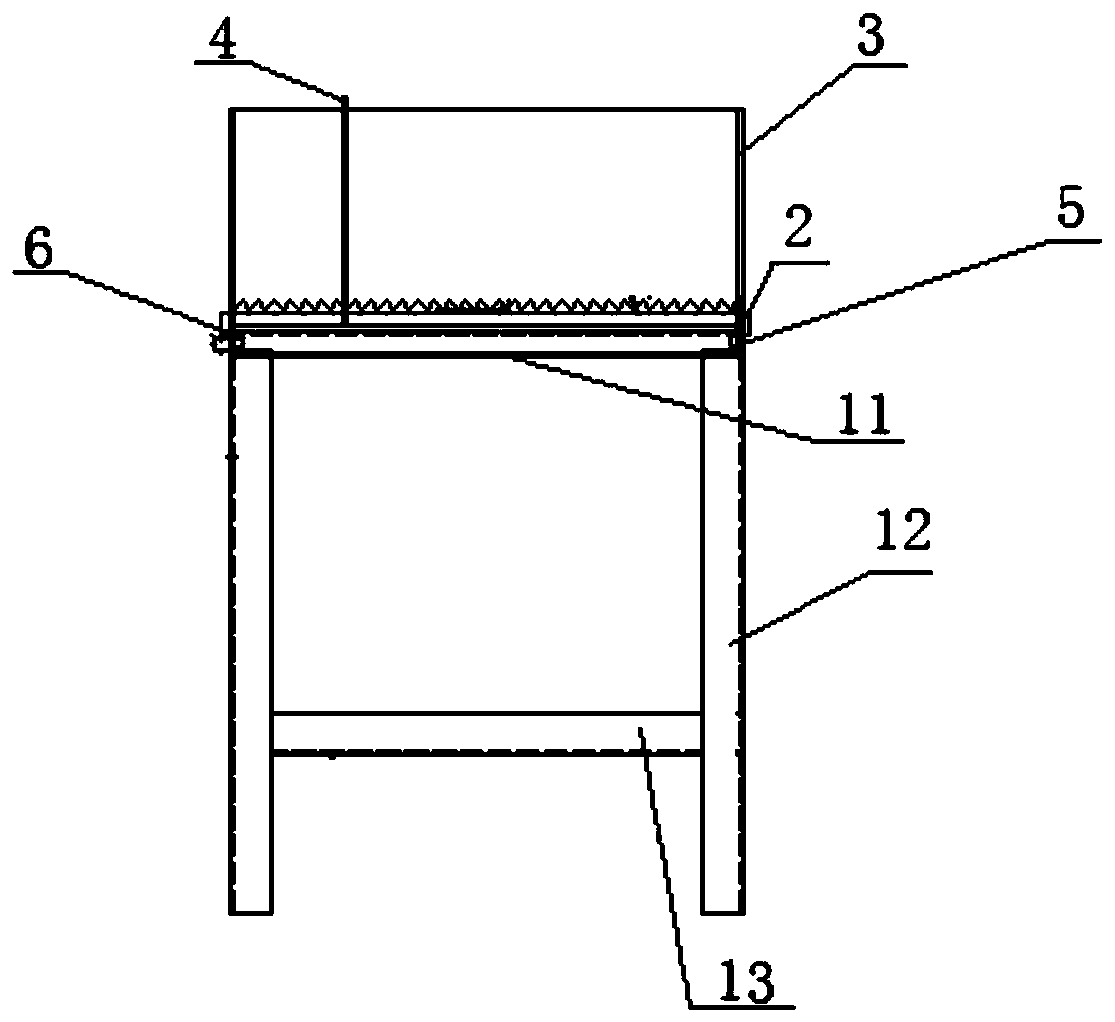

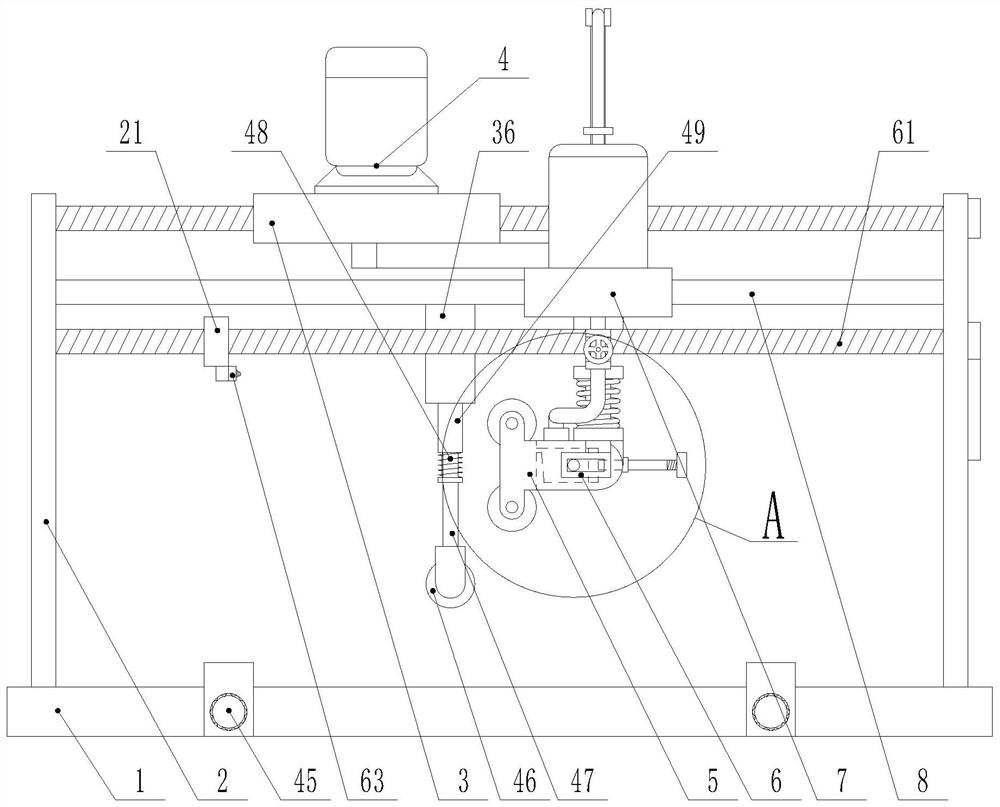

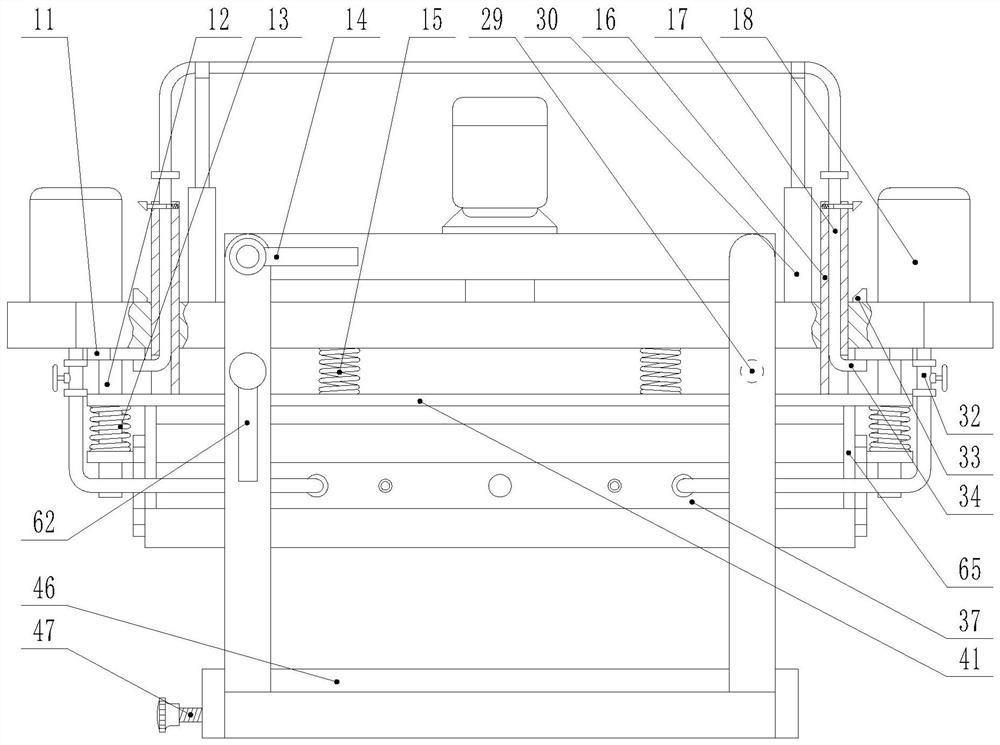

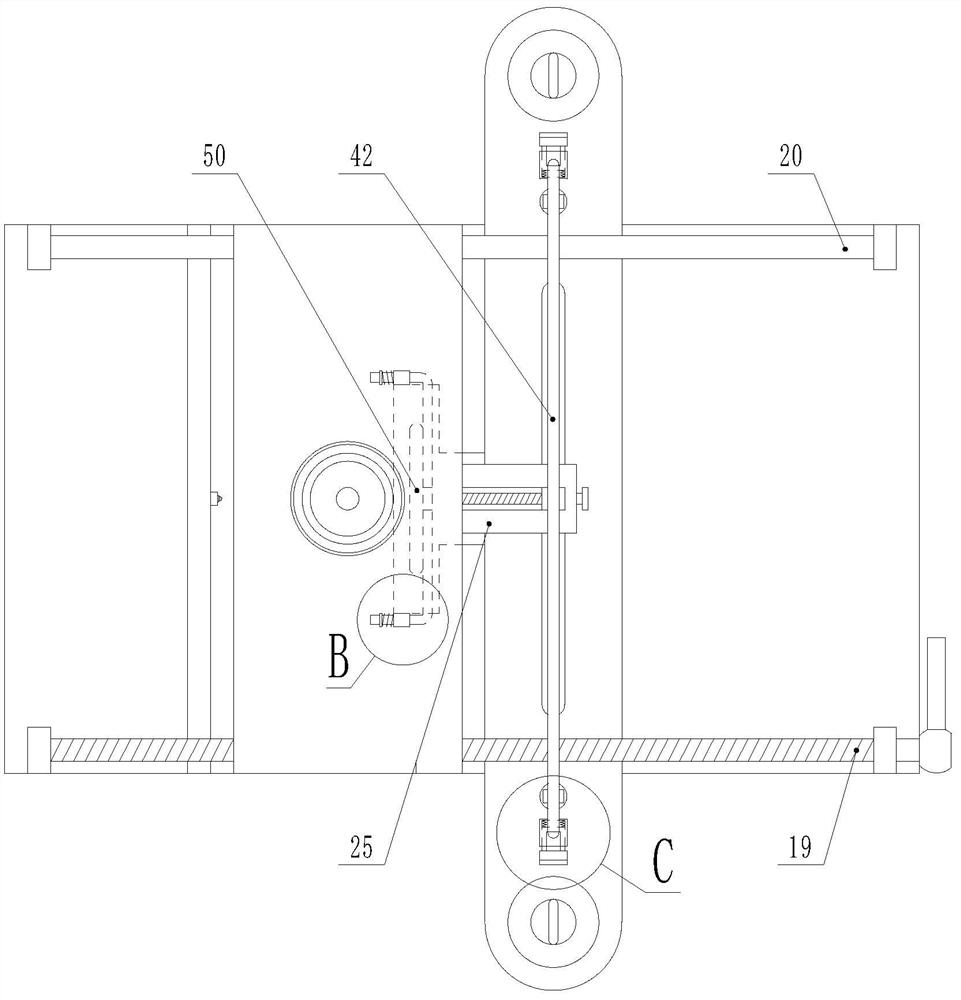

An automatic wall surface mortar painting machine is composed of an A part and a B part, wherein the A part is a mortar painting machine, and the B part is a lifting car. The mortar painting machine is fixed in a lift in the lifting car so that lifting of the mortar painting machine can be achieved, mortar painting is automatically finished along with lifting of the mortar painting machine, and lifting of the mortar painting machine is controlled by an electronically-controlled panel automatically. Along with moving of the lifting car, all the walls are coated by mortar. A vibration rod in the mortar painting machine can extrude the mortar in crevices and concave surfaces of the wall body so as to improve the adhesion between the mortar and the wall surface and improve the structure of the wall body. After the mortar is performed with flat panel treatment by the mortar painting machine, the surface of the wall can be flat. A lifting car positioning baffle is installed left under the lift car body, the baffle is arranged next to a blocking rod which is arranged next to the wall, and the distance between the blocking rod and the wall is adjusted, so that the aim of controlling the thickness of the painted mortar is achieved. A horizontal adjusting bolt can adjust a lifting platform to be horizontal, and accordingly, the mortar painting machine can be ensured to move on the vertical plane.

Owner:韩存雪

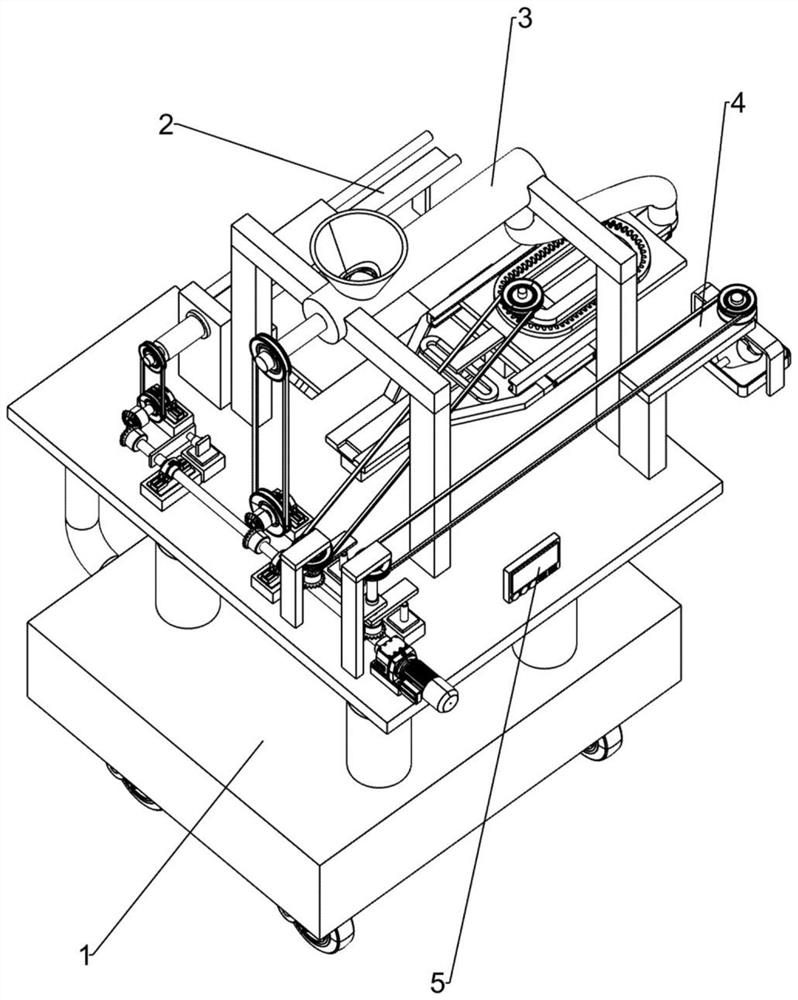

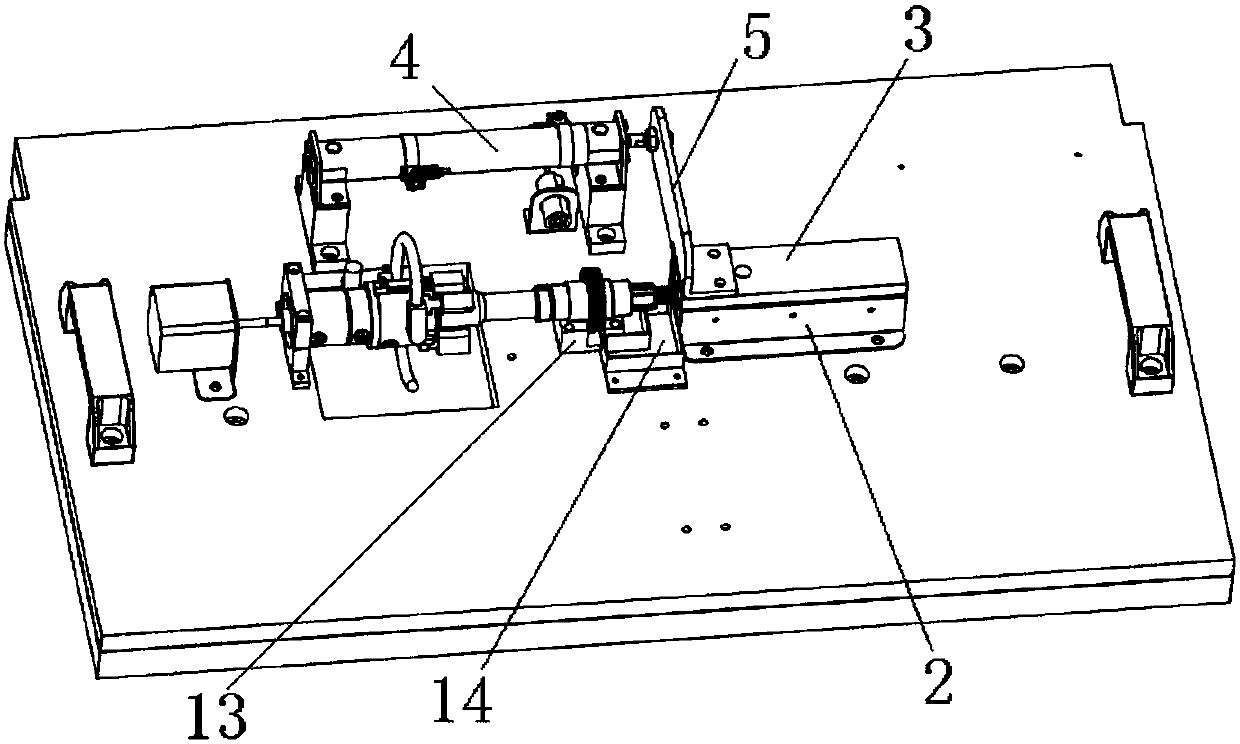

Semi-automatic pencil sharpener for answer sheet pencil

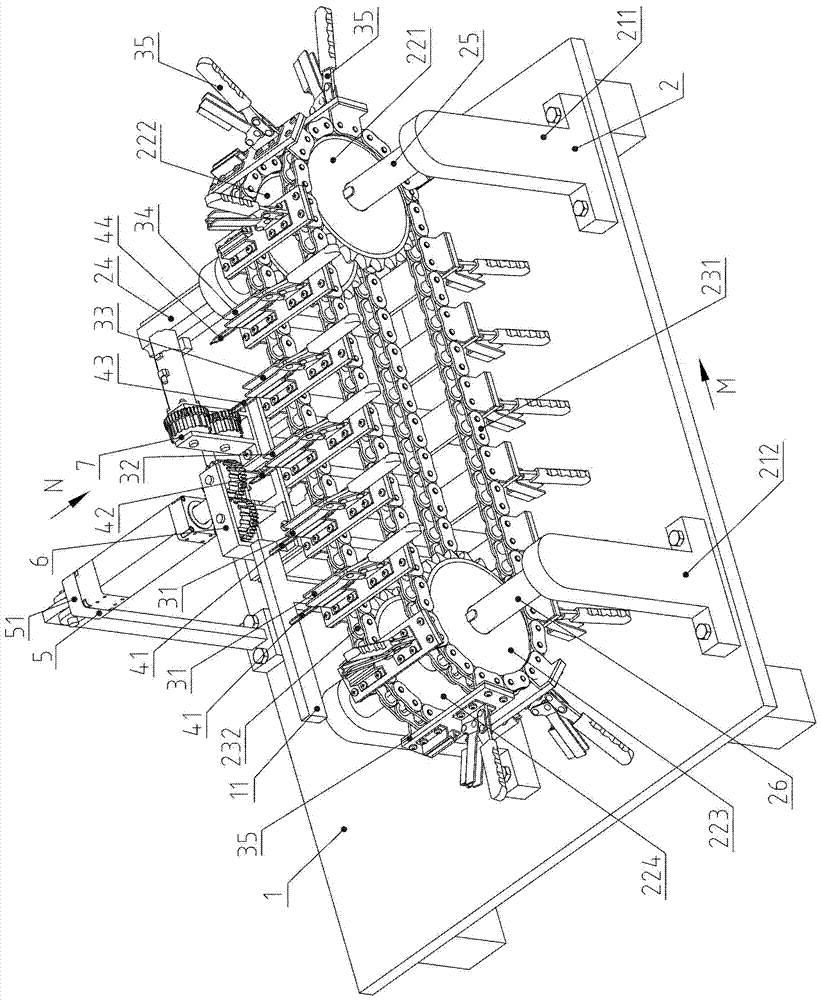

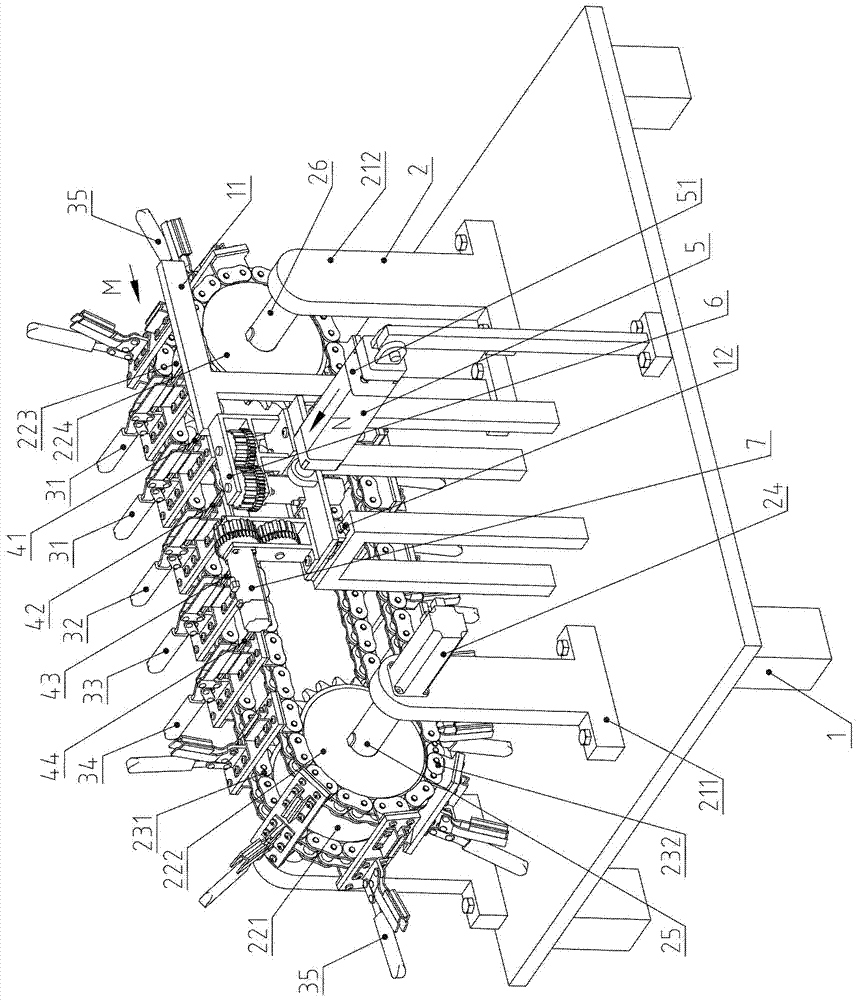

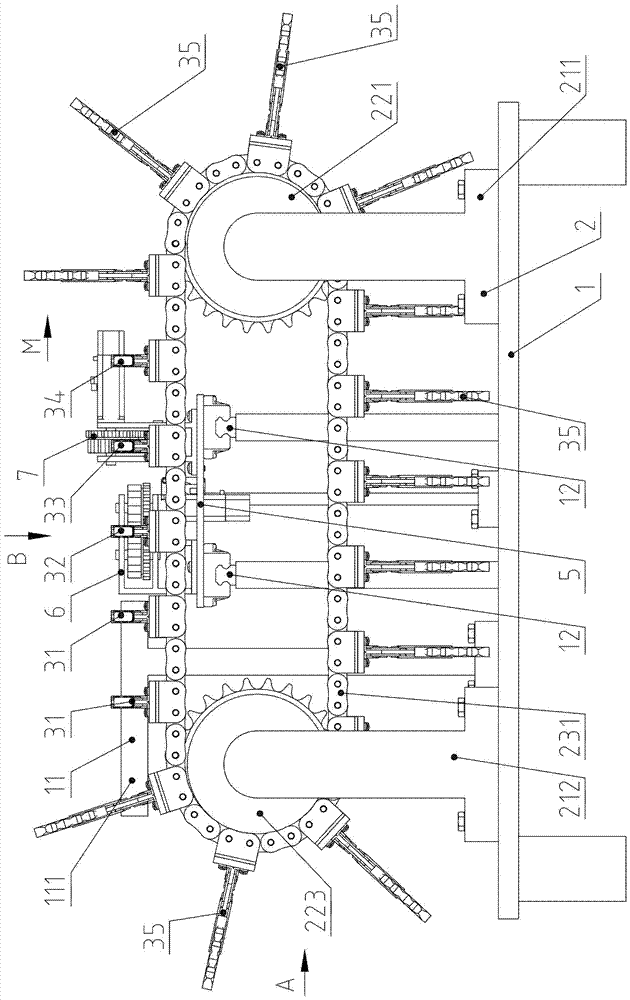

The invention belongs to the technical field of teaching tools, and relates to a semi-automatic pencil sharpener for an answer sheet pencil. The semi-automatic pencil sharpener comprises a machine frame, a chain transmission device, a plurality of clamps, a movable assembly, a front and rear cutting assembly as well as an upper and lower cutting assembly, wherein the chain transmission device drives the clamps, the clamps drive the pencil to do intermittent forward movement, the front and rear cutting assembly comprises a front cutter disc and a rear cutter disc which rotate at high speeds, the upper and lower cutting assembly comprises an upper cutter disc and a lower cutter disc which rotate at high speeds, and the movable assembly drives the front and rear cutting assembly as well as the upper and lower cutting assembly to get close to the pencil and cut the pencil. According to the semi-automatic pencil sharpener, the cutting action is completed in a semi-automatic mode, the cutting sizes of the pencils are totally the same, the cutting face is very smooth and tidy, and the precious time of the examinee can be saved.

Owner:嘉兴华飞鹏科技有限公司

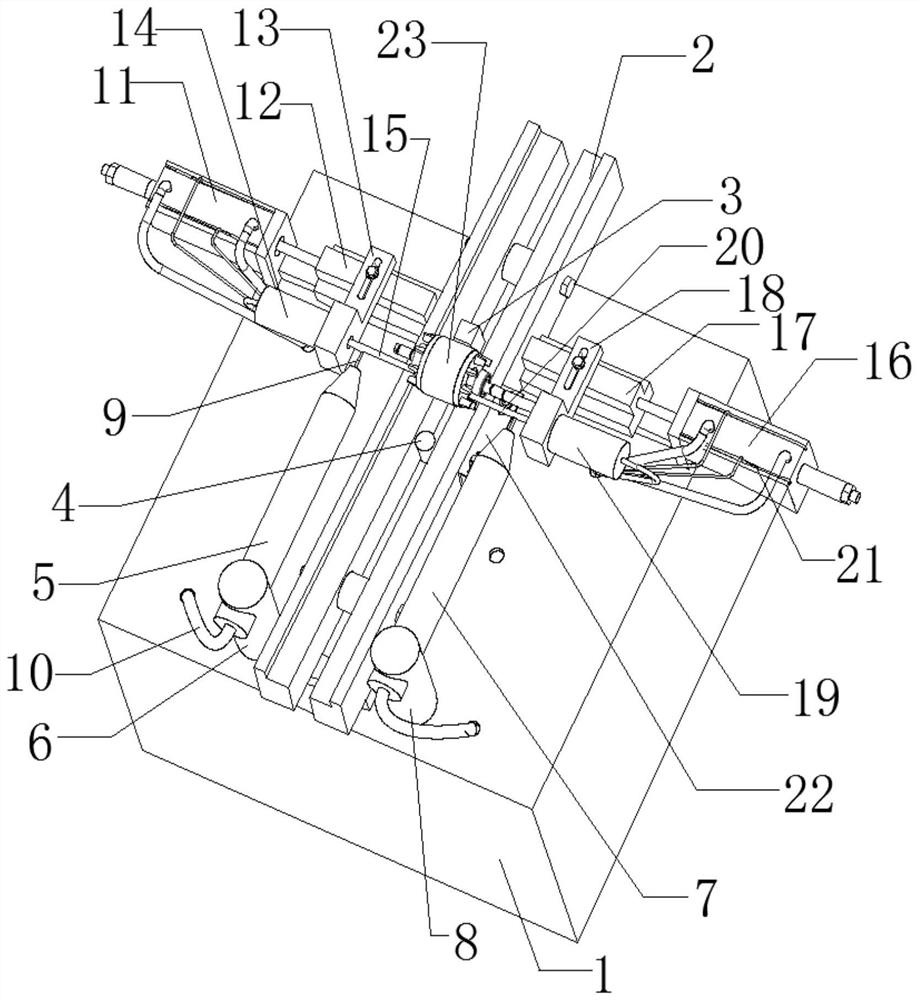

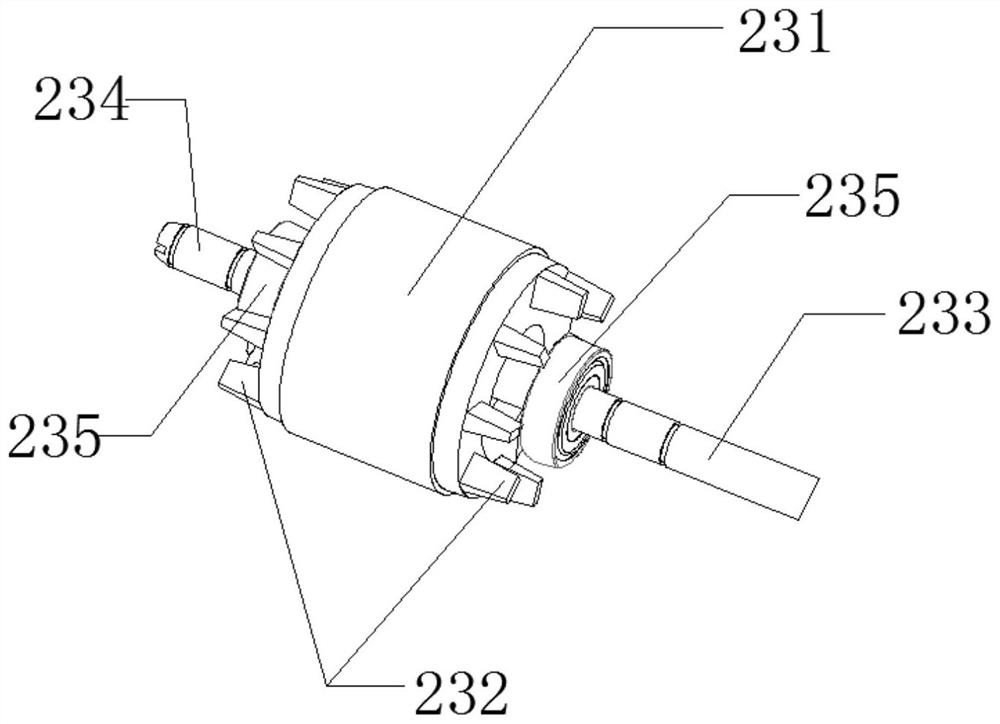

Automatic oiling device for motor rotor bearing

ActiveCN111774234AOil evenlySmooth rotationLiquid surface applicatorsCoatingsElectric machineryOil quality

The invention belongs to the technical field of automatic equipment processing and manufacturing, and particularly relates to an automatic oiling device for a motor rotor bearing. The main structure of the automatic oiling device comprises a rack, a rotor supporting plate, a blocking sliding block, a magnet sliding block, a first oil injector, a first oil injector fixing seat, a second oil injector, a second oil injector fixing seat, an oil injection needle head, an oil injector pushing air pipe, a first fixed sliding block driving air cylinder, a first fixed sliding block, a first oiling motor seat, a first oiling driving motor, a first oiling rod, a second fixed sliding block driving air cylinder, a second fixed sliding block, a second oiling motor seat, a second oiling driving motor, asecond oiling rod, an action counter, an induction device and a rotor. The automatic oiling device is ingenious in design concept, the requirement for oiling the rotor bearing in cooling air teeth andoutside the cooling air teeth of a rotor body can be met at the same time, the motor rotor bearing can be rapidly and evenly oiled, the oiling quality of the motor rotor bearing is improved, the service life of a motor is prolonged, and the production efficiency is improved.

Owner:青岛成信马达有限公司

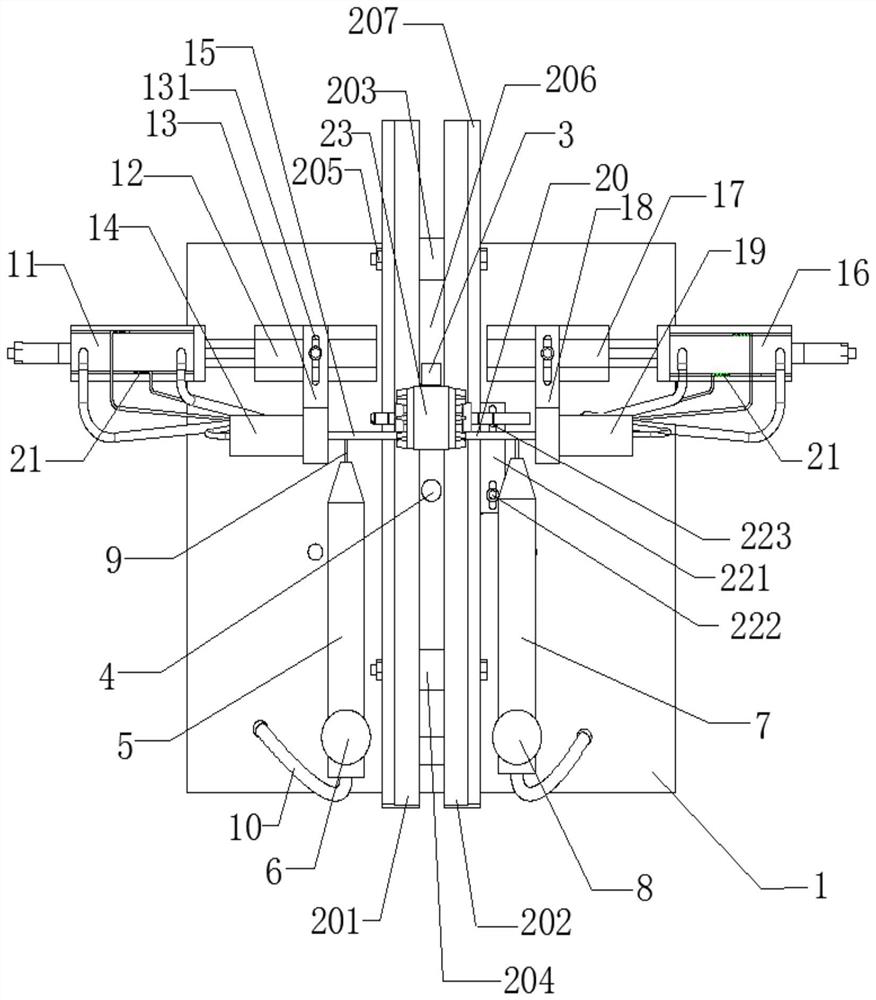

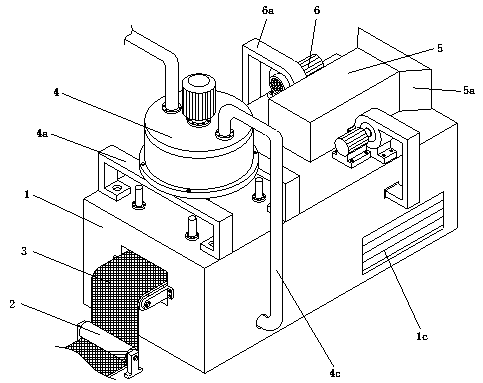

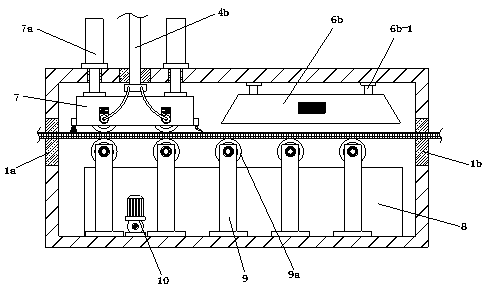

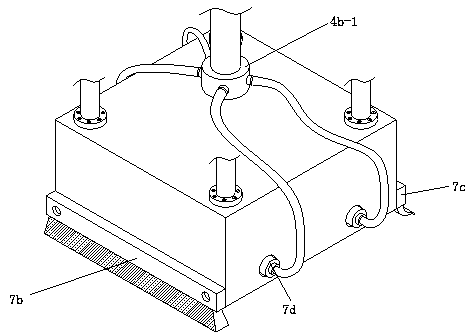

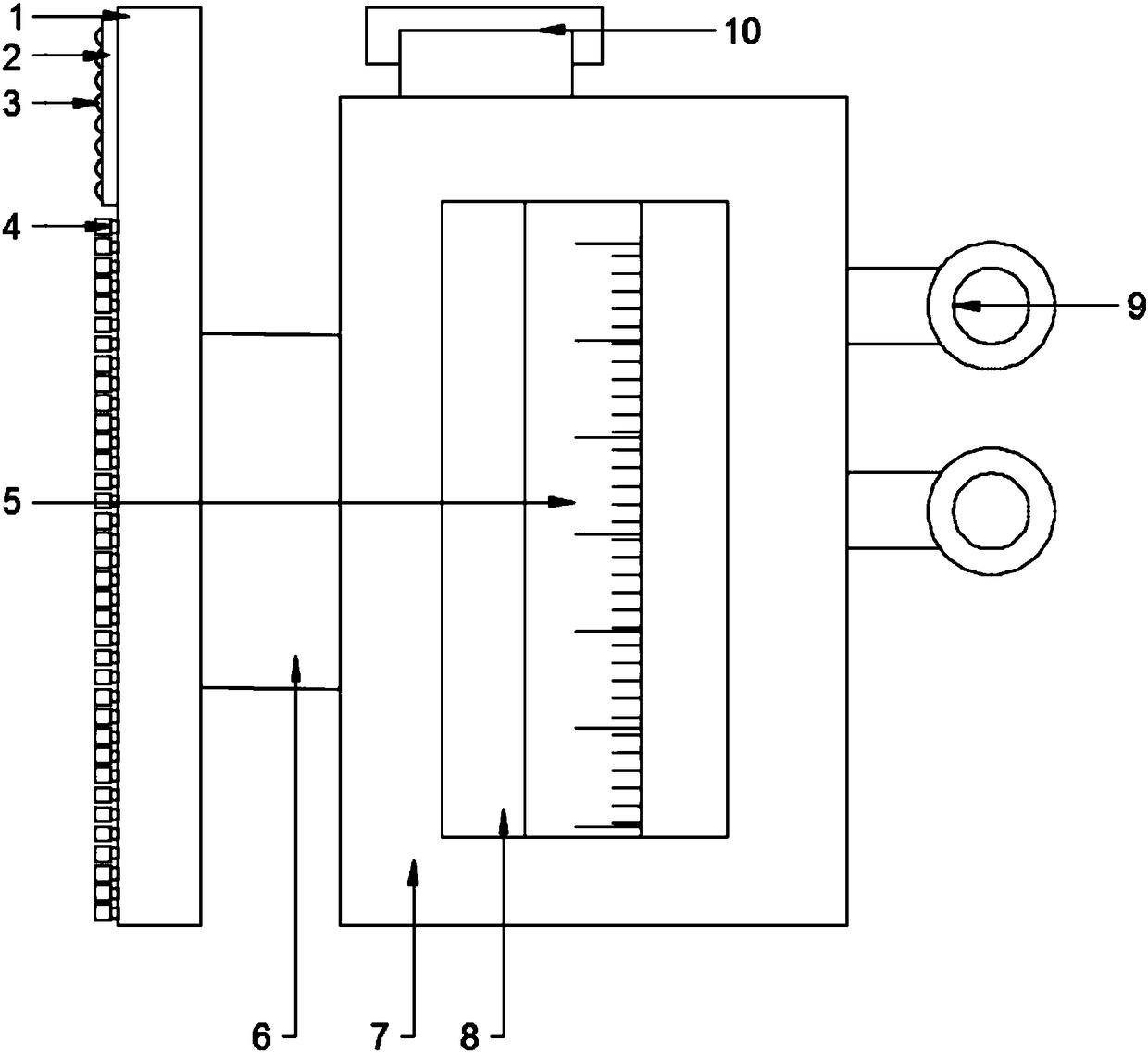

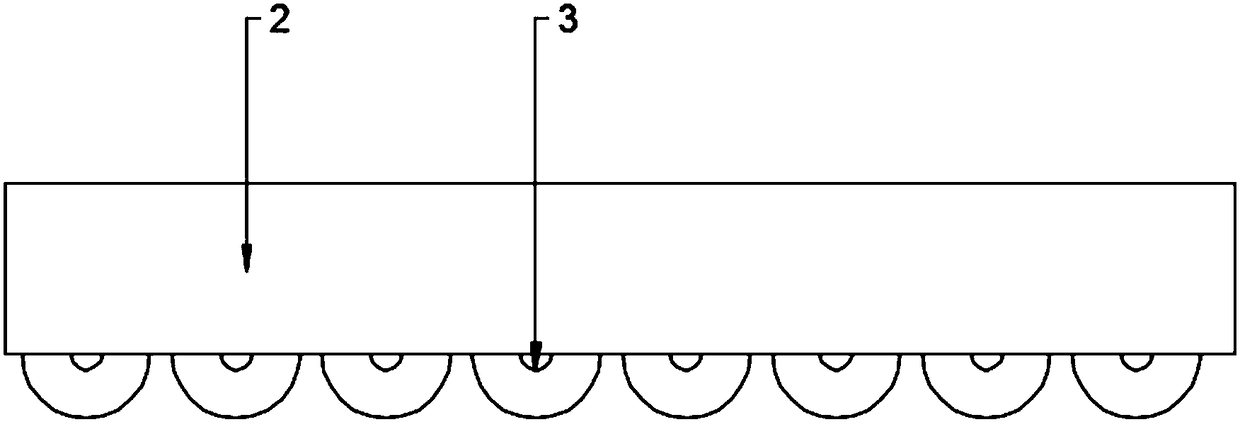

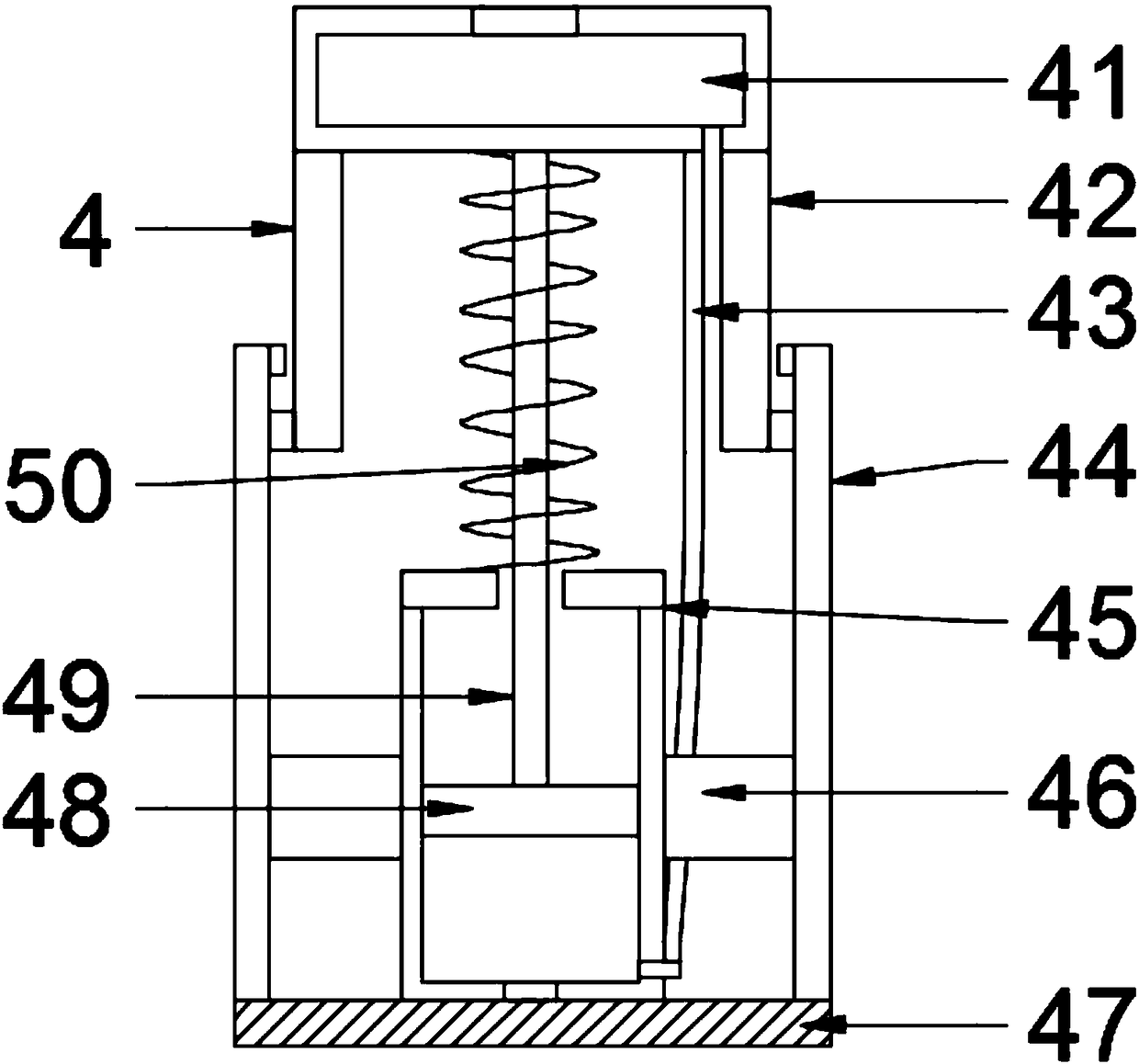

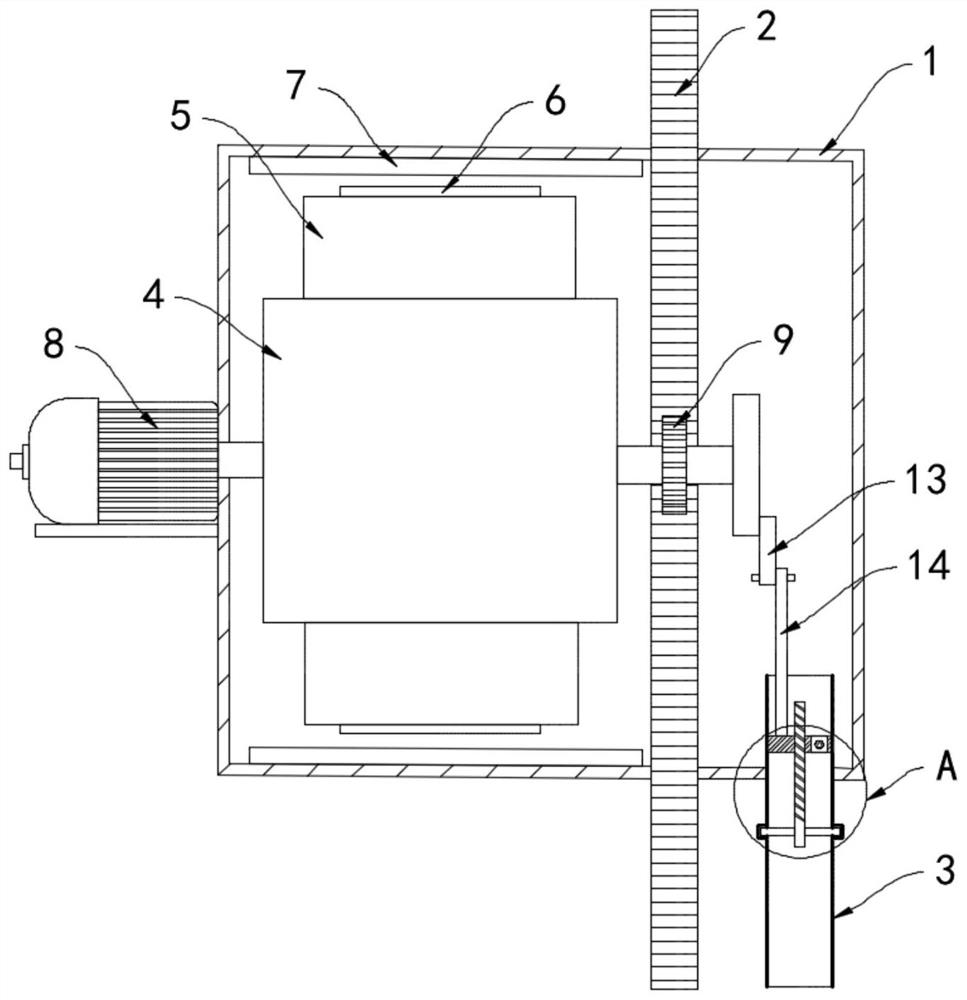

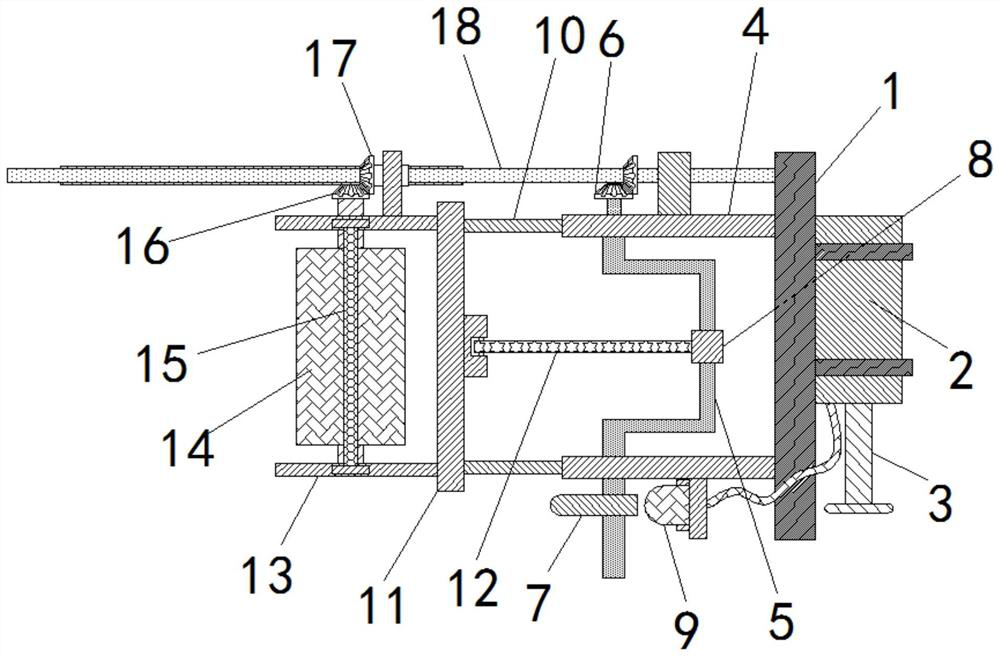

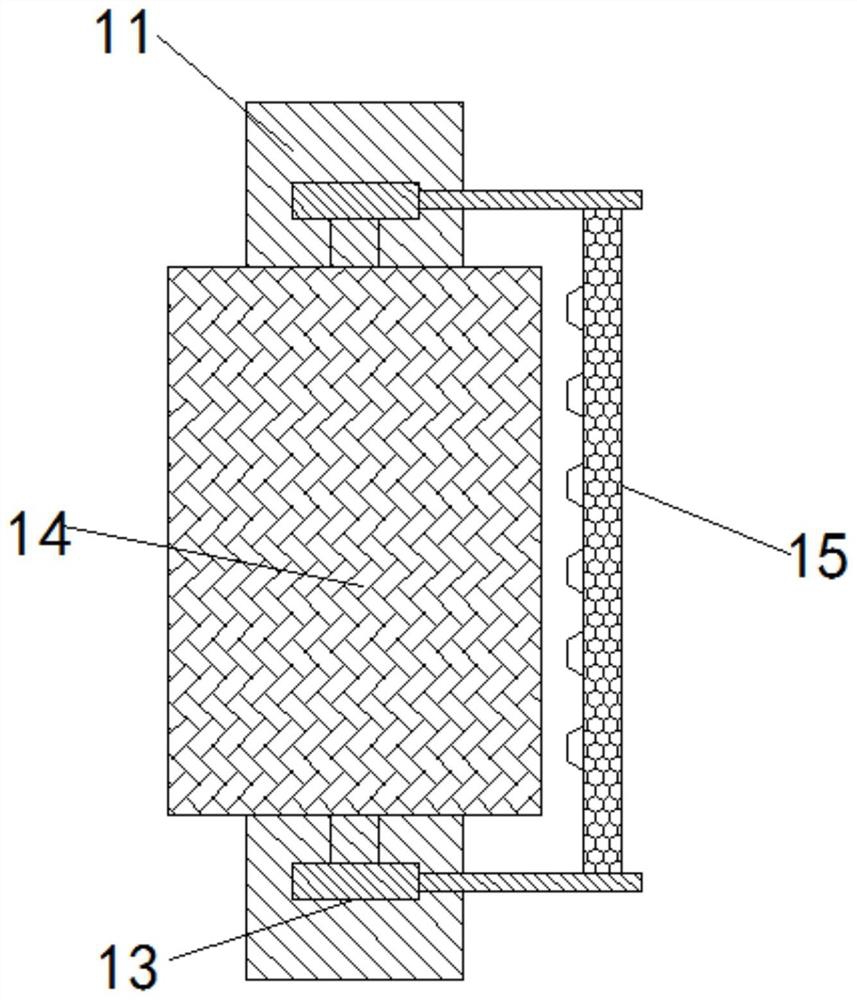

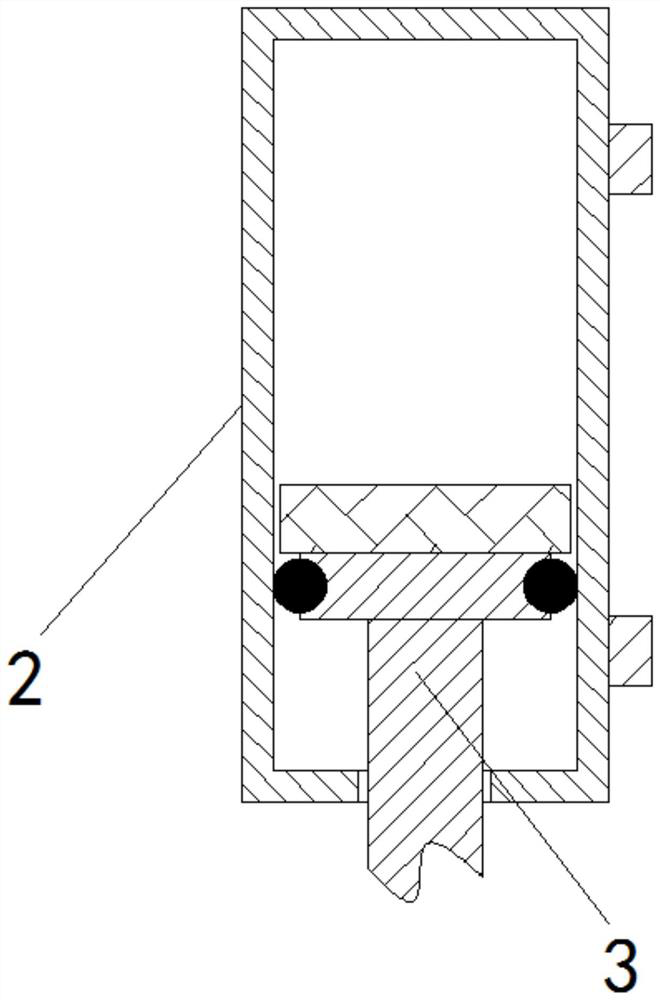

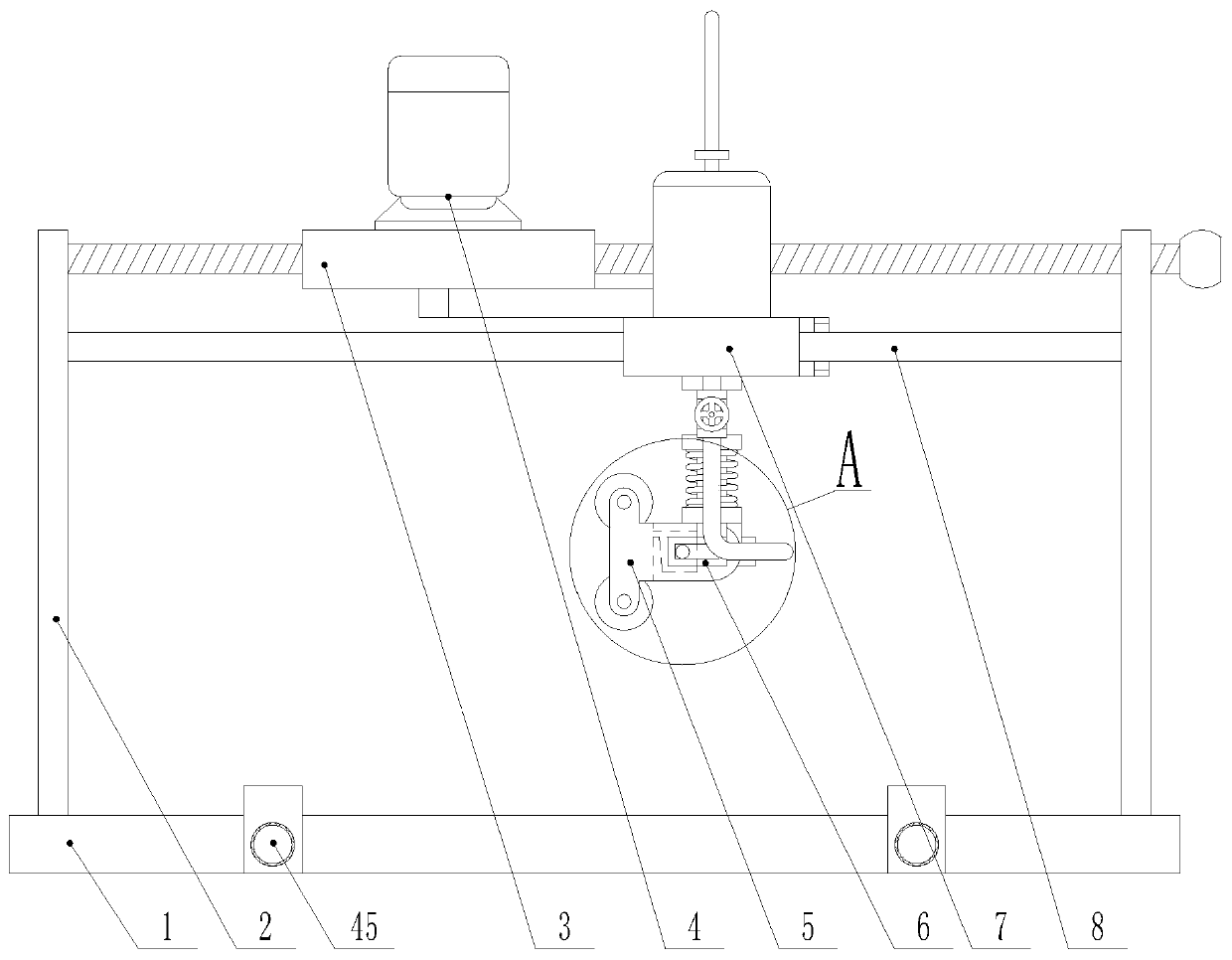

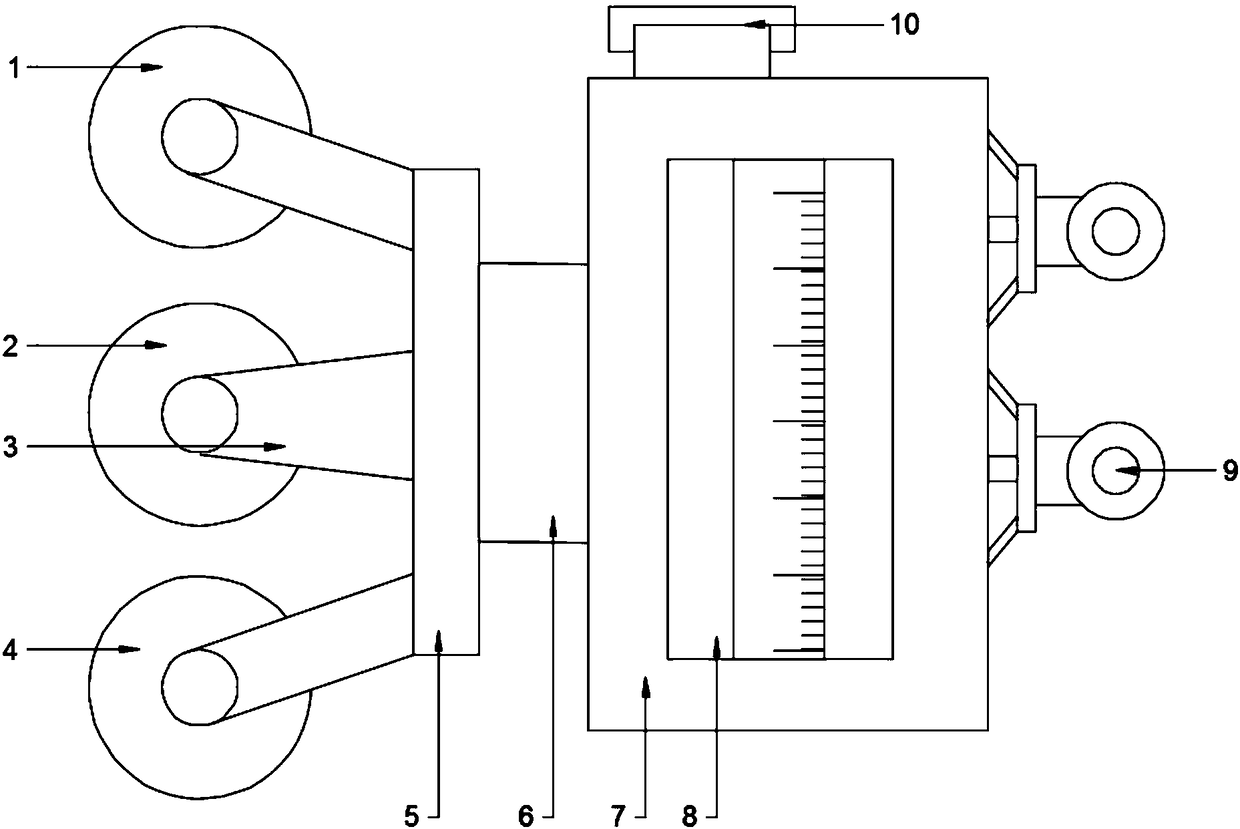

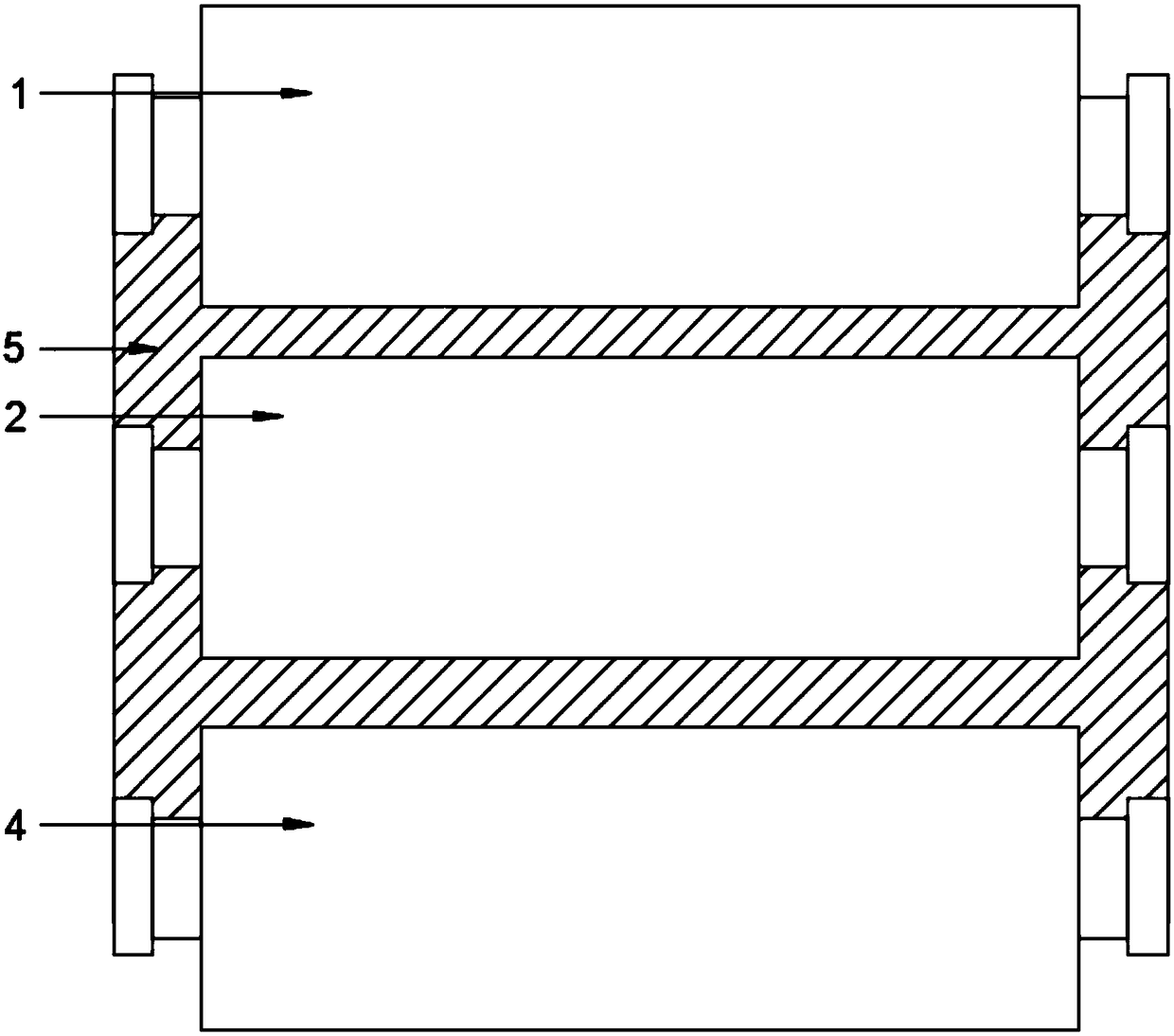

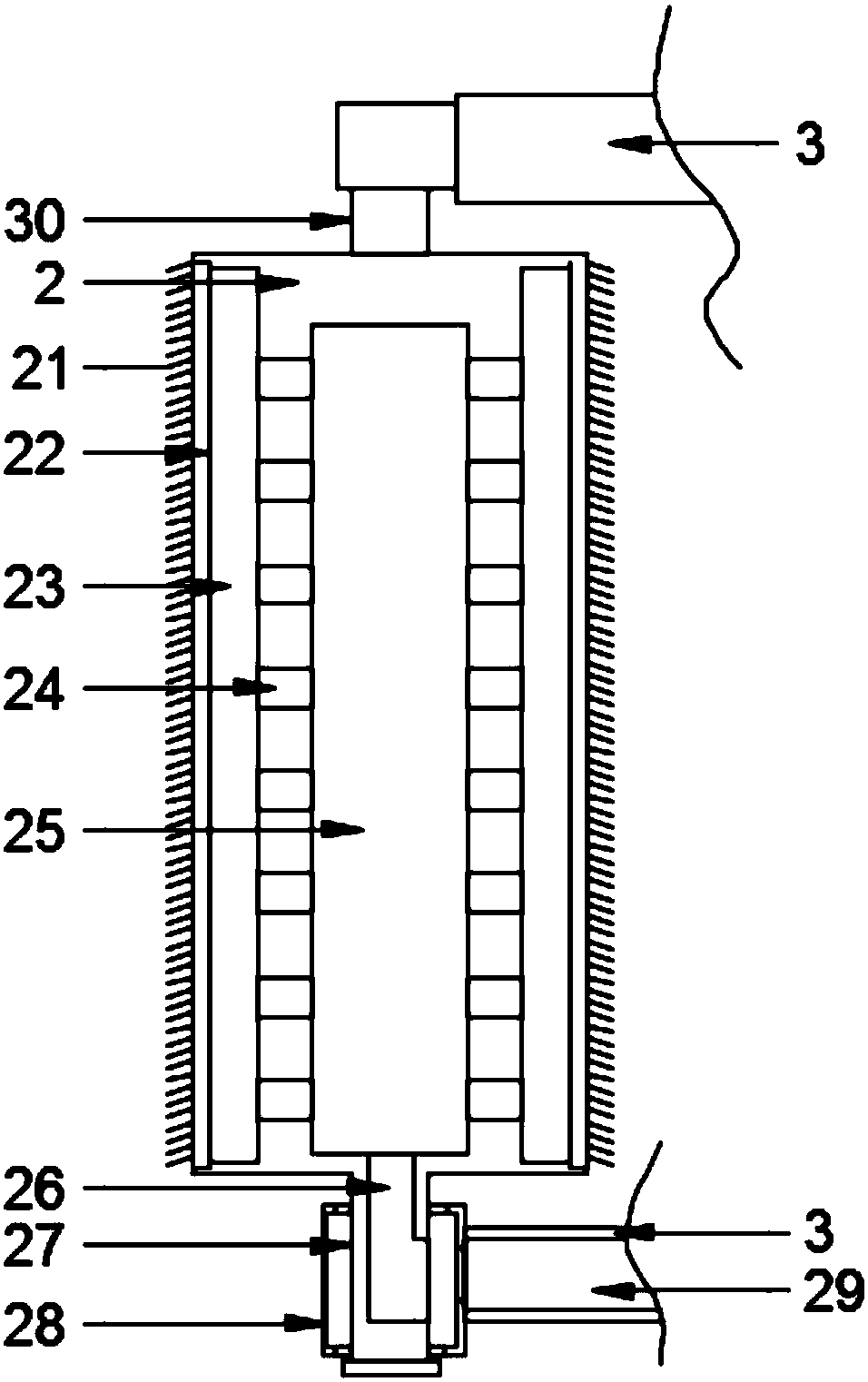

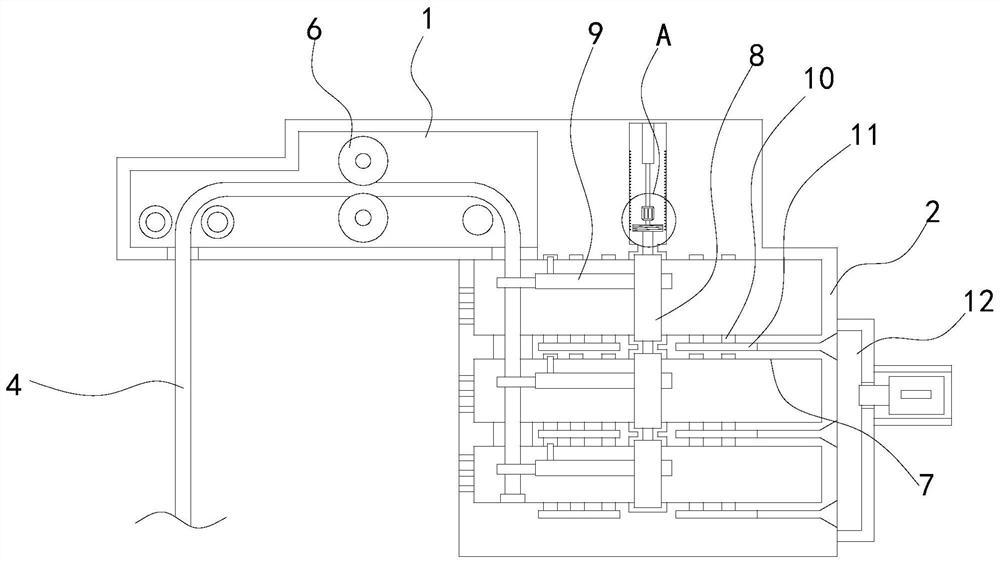

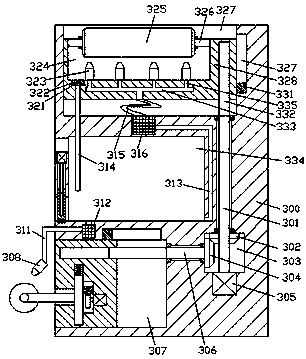

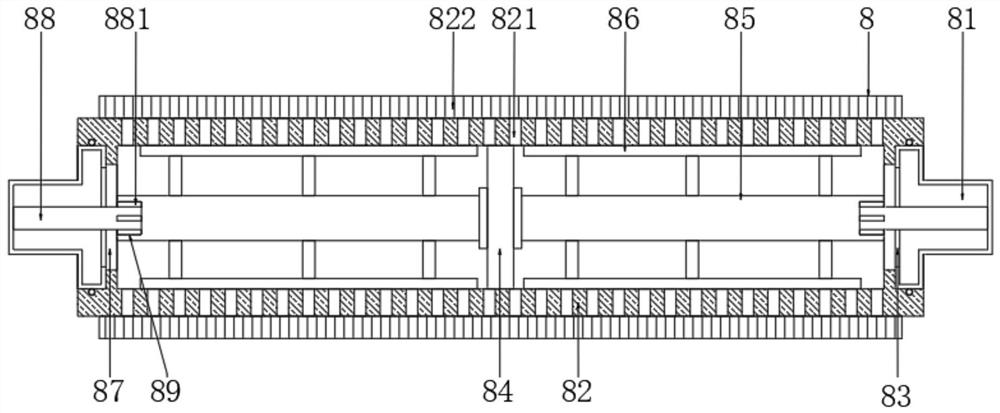

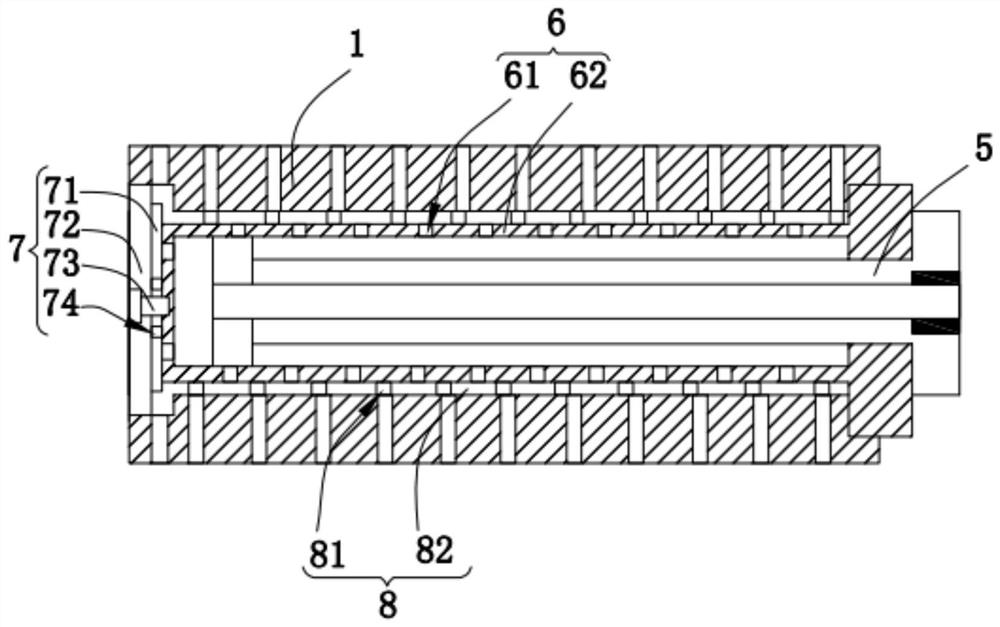

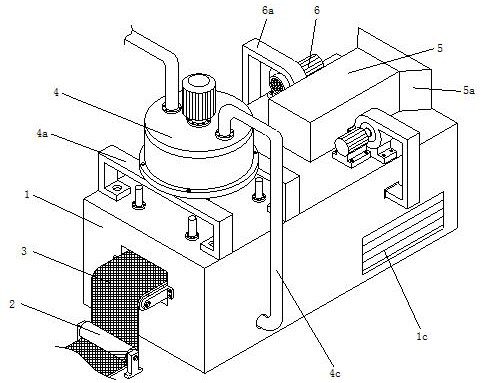

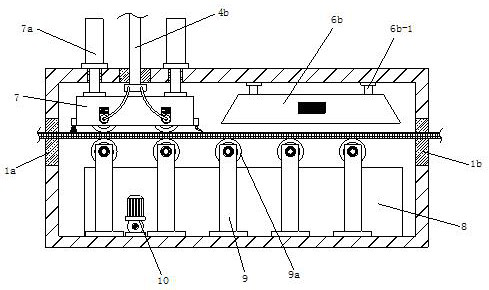

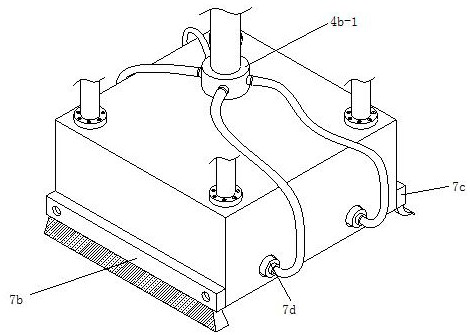

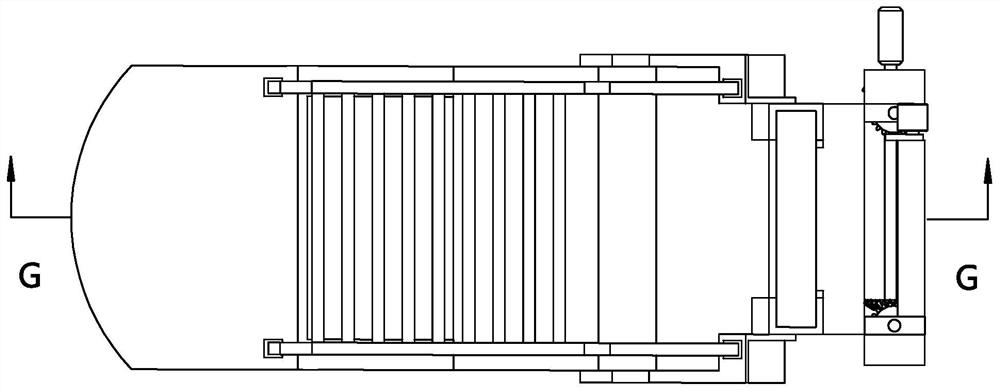

Efficient sheet coating machine for processing lead-acid storage battery grid

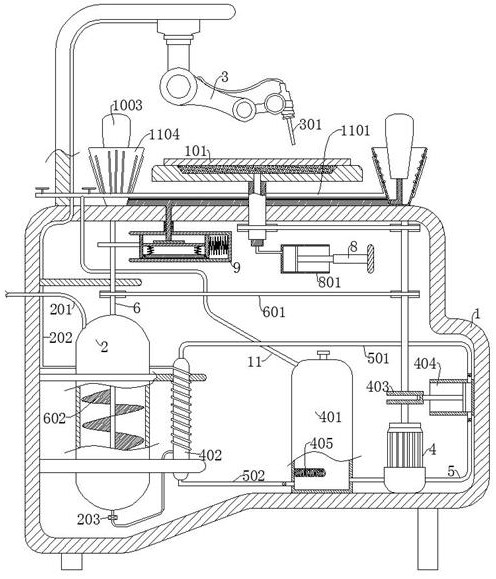

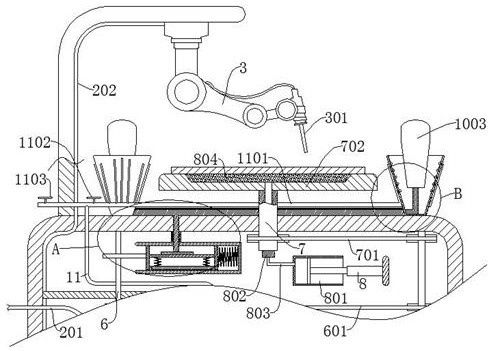

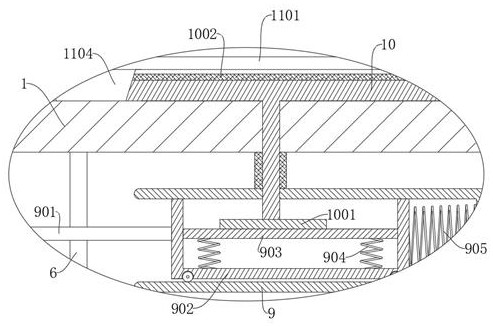

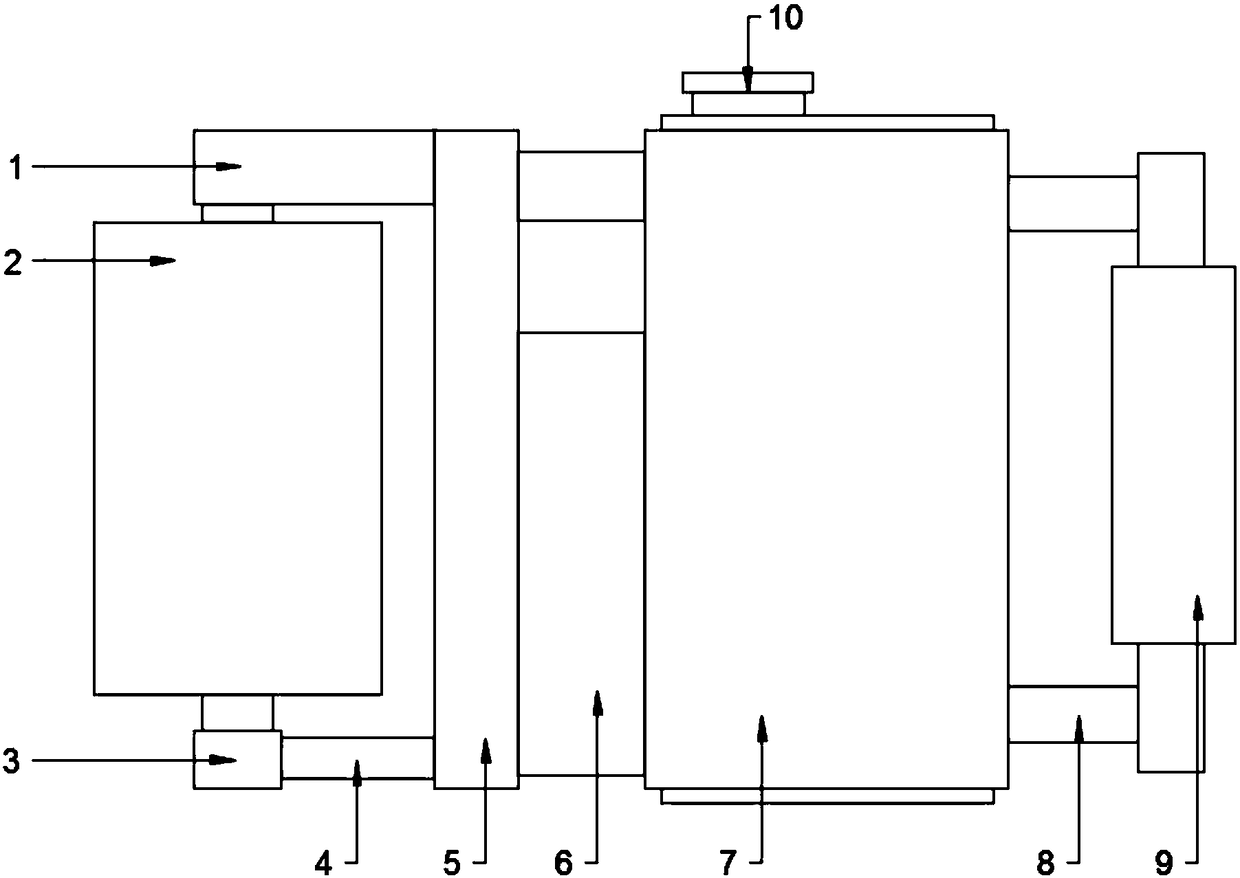

ActiveCN110787953AImprove smudge qualityGuaranteed elastic contactLiquid surface applicatorsElectrode carriers/collectorsEngineeringInternal connection

The invention discloses an efficient sheet coating machine for processing a lead-acid storage battery grid. The efficient sheet coating machine comprises a working machine box. A feeding port and a discharging port are formed in the side walls of the two ends of the working machine box correspondingly. A roller feeding linkage mechanism and a roller discharging linkage mechanism are arranged at the lower ends of the outer sides of the feeding port and the discharging port and are provided with grid sheets which are in a stretched state. A material storing and stirring barrel is mounted at oneend, close to the feeding port, of the top of the working machine box, and the other end is provided with a heating device box. The two sides of the heating device box are provided with fan units correspondingly. The two ends of air pipes on the two fan units are connected with the two sides of the heating device box and the two side shells of the working machine box and extend to the interior ofthe working machine box to be connected with an air outlet cover. The interior of the working machine box is provided with a coating mechanism box vertically under the material storing and stirring barrel. Two porous pressing rollers are arranged in the coating mechanism box. By means of the efficient sheet coating machine, the coating quality of the battery grid sheets is effectively improved, and the production efficiency is remarkably improved as well.

Owner:ANHUI YONGHENG STORAGE BATTERY

Pressing type feeding and smearing device

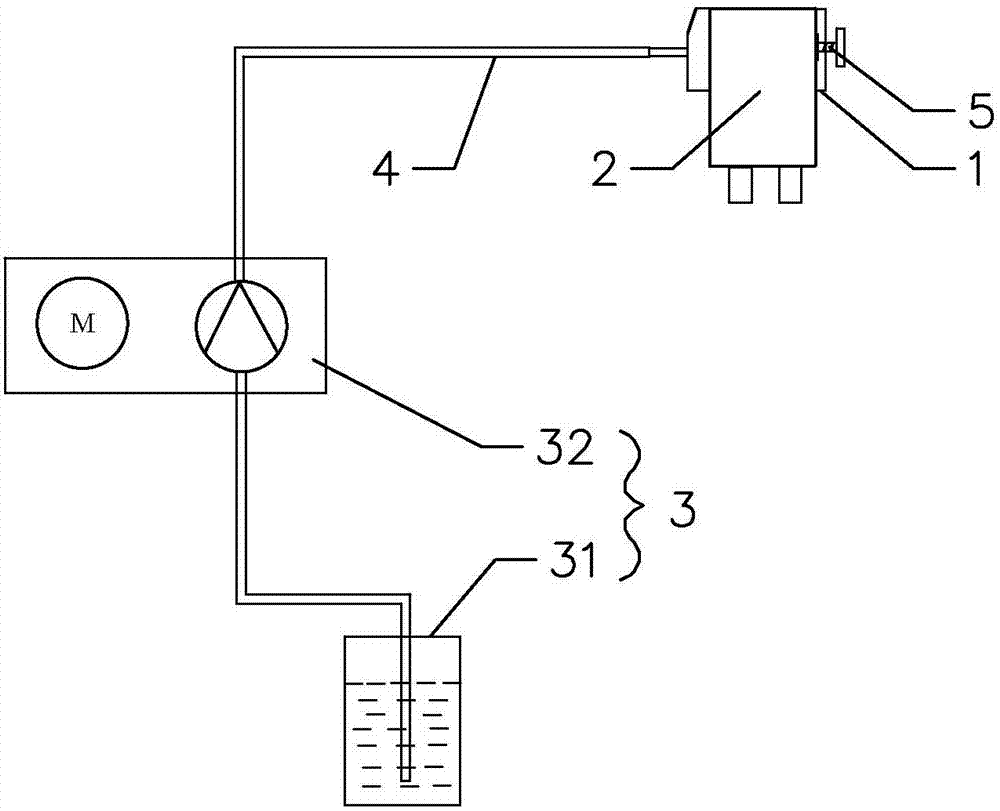

InactiveCN108607782ADoes not affect normal compressionApply evenlyLiquid surface applicatorsCoatingsPeristaltic pumpBiochemical engineering

The invention discloses a pressing type feeding and smearing device. The pressing type feeding and smearing device comprises a fixing board and a liquid storage box; a fixing column is fixed to the left end of the liquid storage box and internally provided with a peristaltic pump; the fixing board is fixed to the left end of the fixing column; an even smearing board is fixed to the upper end of the left side of the fixing board; an even smearing roller distributed in an array mode is arranged on the even smearing board; and smearing heads distributed in an array mode are arranged at the position, at the lower end of the even smearing board, of the fixing board. The pressing type feeding and smearing device is even in smearing and high in smearing quality.

Owner:武汉思异汇创科技有限公司

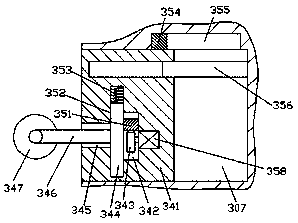

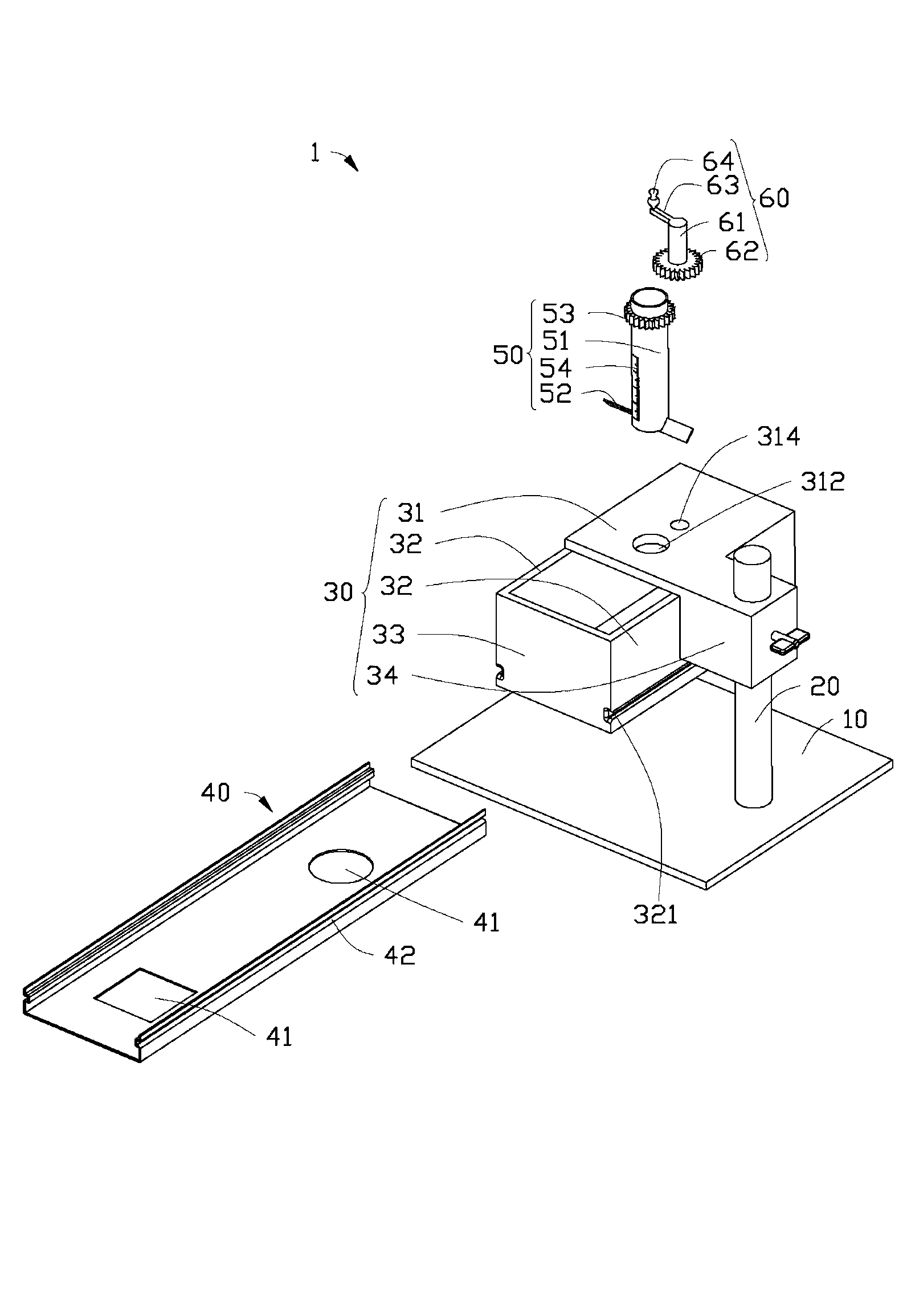

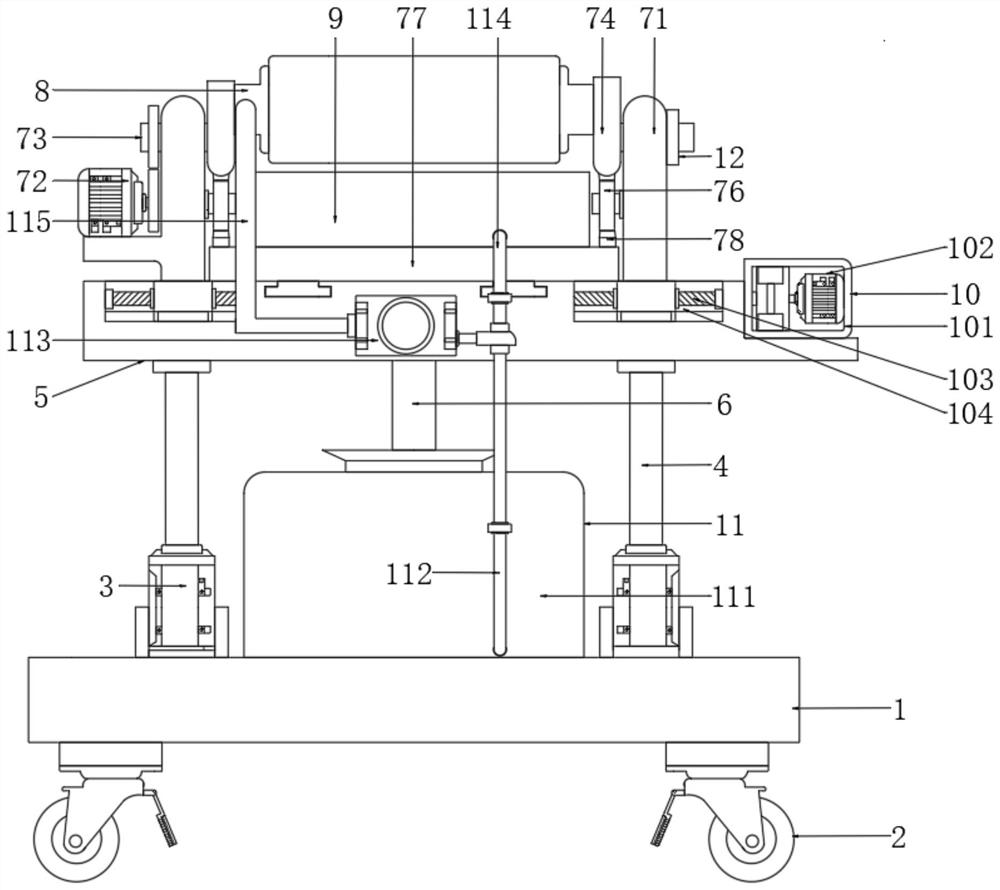

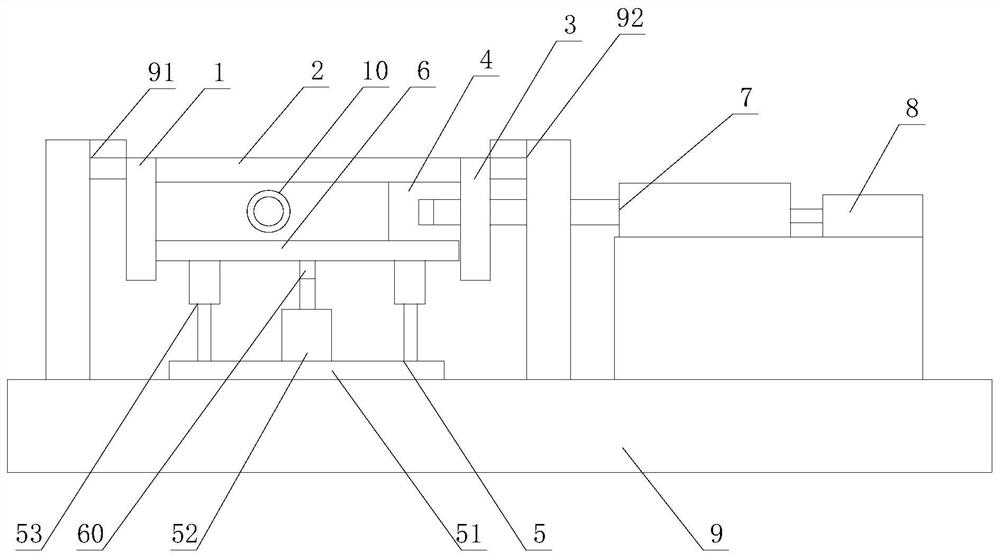

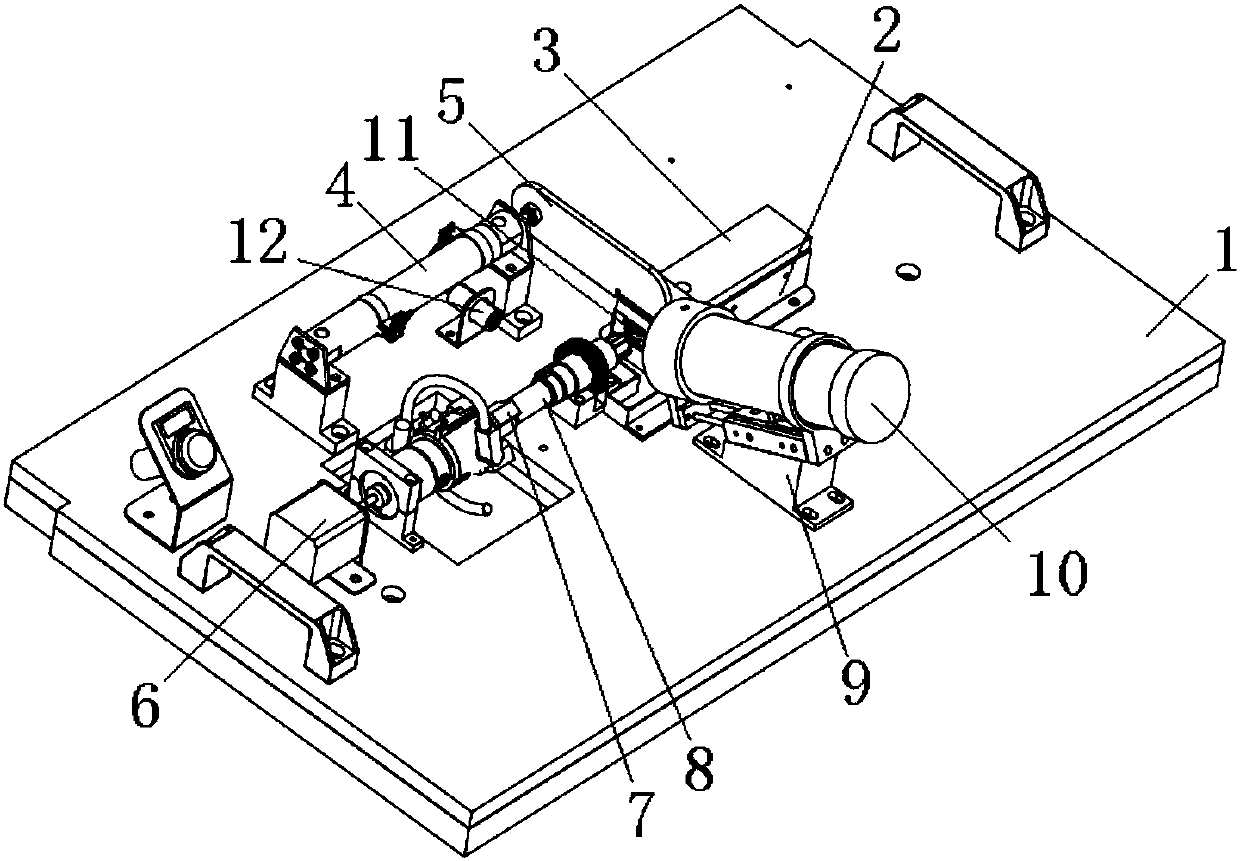

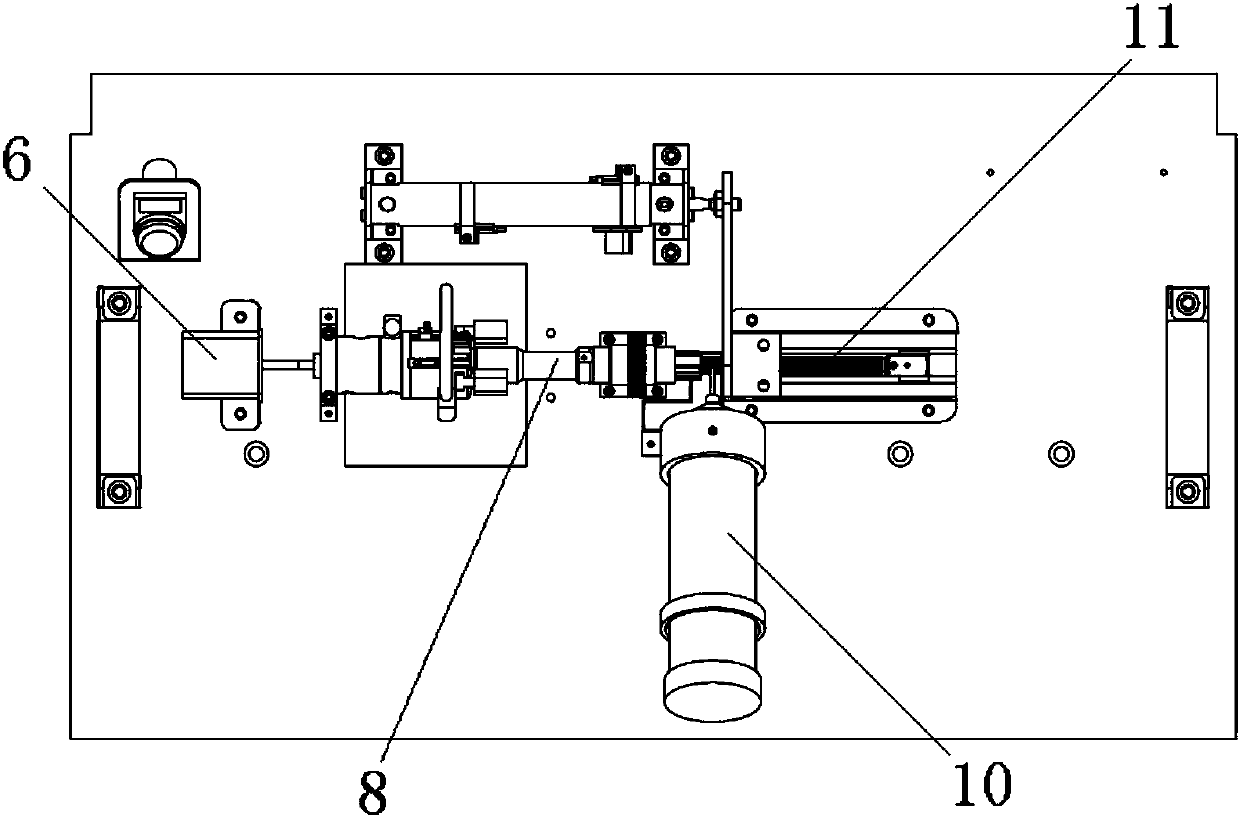

Method for Applying Grease on Screw Rod Assembly

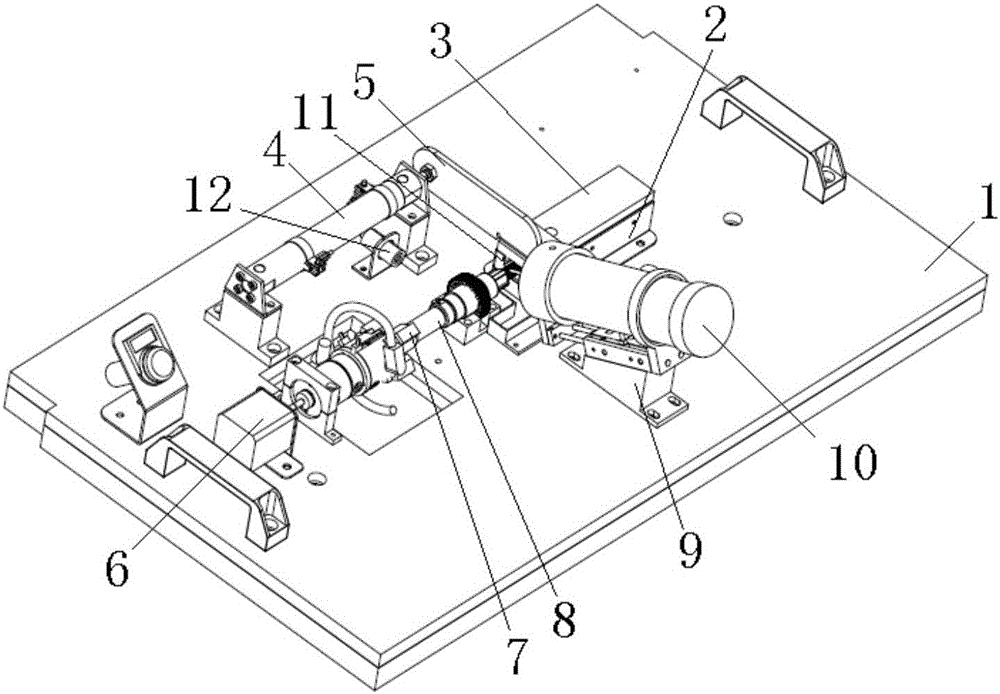

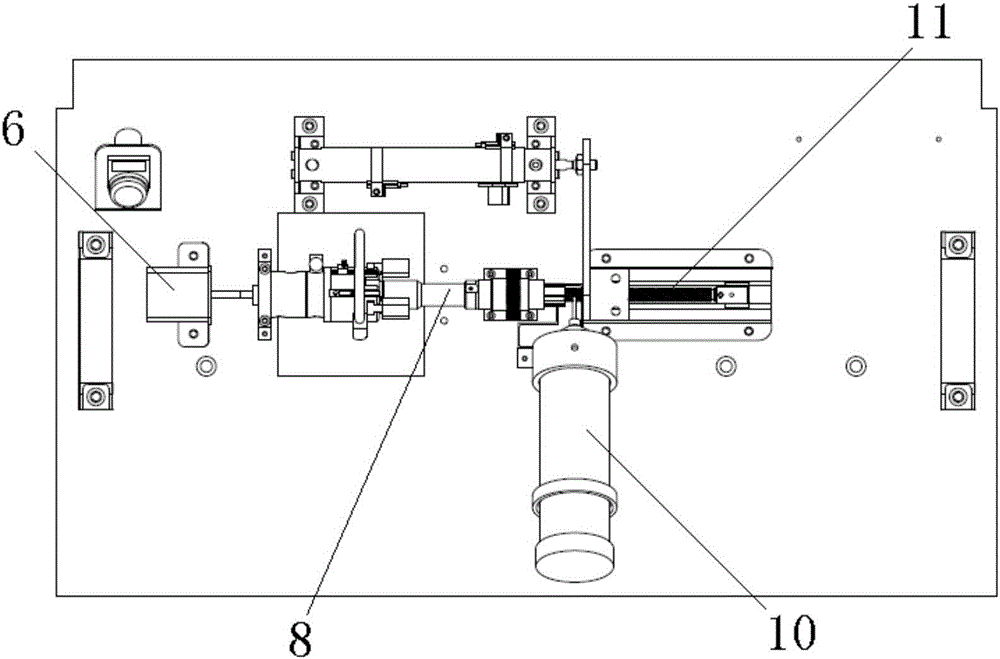

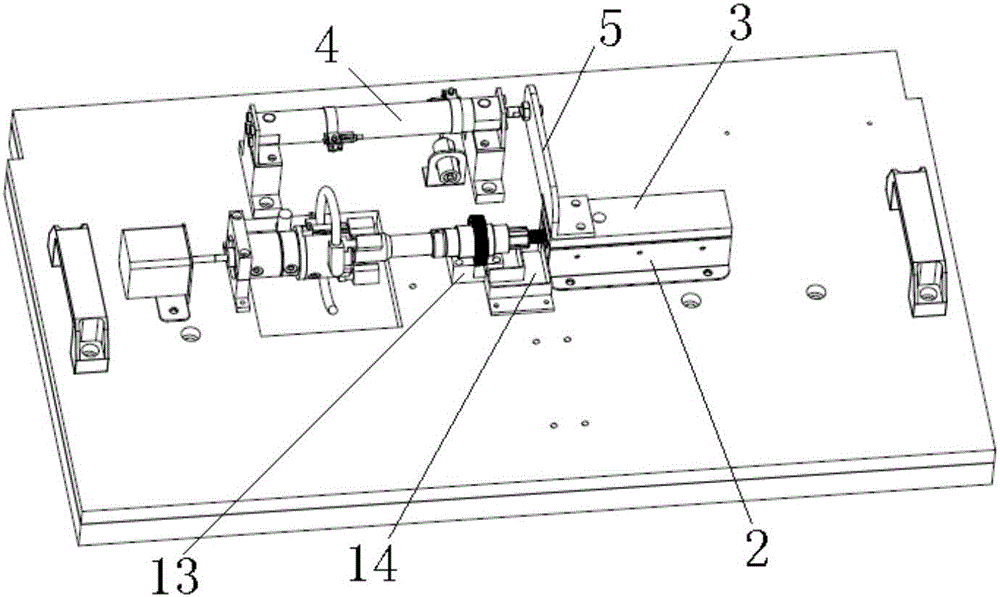

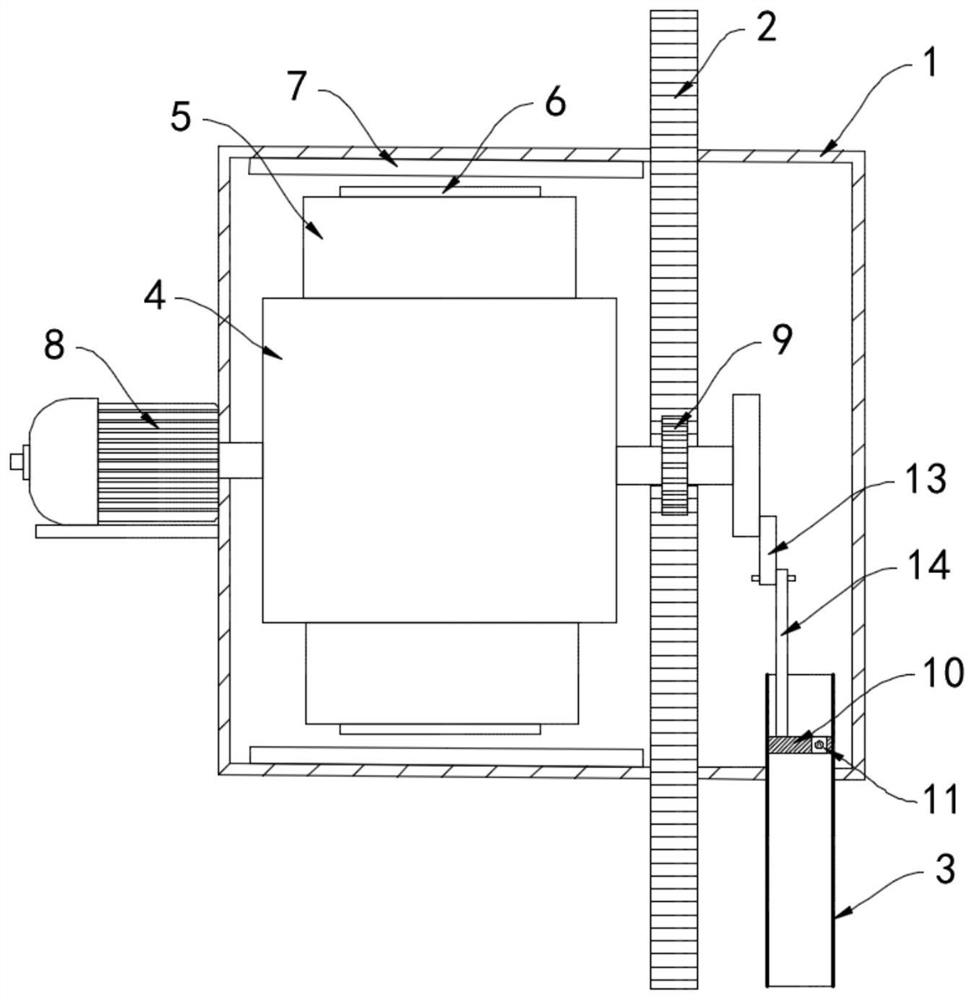

ActiveCN106334661AReasonable tooling structure designReasonable structural designLiquid surface applicatorsCoatingsMotor driveGear wheel

The invention discloses a method for applying grease on screw rod assembly, including following operating procedures: 1) switch in the supply of power and gas source correctly; 2) the lead screw and screw inserts corresponding to the model and gears are screwed into initial pre- tightening state manually, and the lead screw is placed in the chute of lead screw bearing; 3) push the air cylinder to work, move a cover plate to the upward side of lead screw bearing and cover it, then a gas pawl firmly grasps the end of screw inserts, and a needle cylinder is run to lead screw to match with screw inserts; 4) rotating motor drives screw inserts for rotation, and lead screw is moved horizontally by spiral force, and grease is coated on the lead screw by the needle cylinder; 5) after completing rotation, motor rotates reversely and is reset to specified assembling position, to push the air cylinder to work and cover plate is removed, and the gas pawl unclamps screw inserts; 6) the screw components are taken out by an operator. Therefore, the invention is high efficiency, low cost and improvement of application quality.

Owner:WUHU QUAN CHENG INTELLIGENT TECH

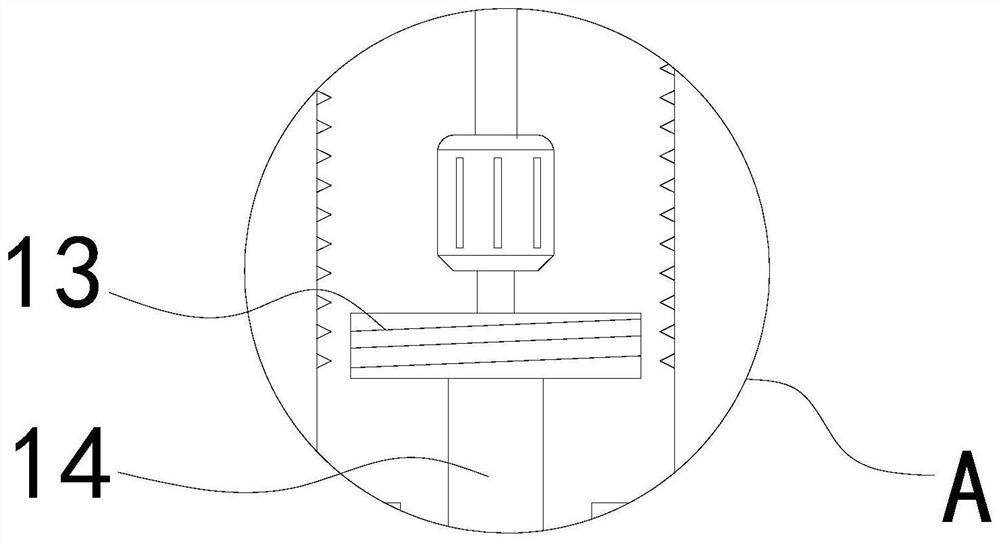

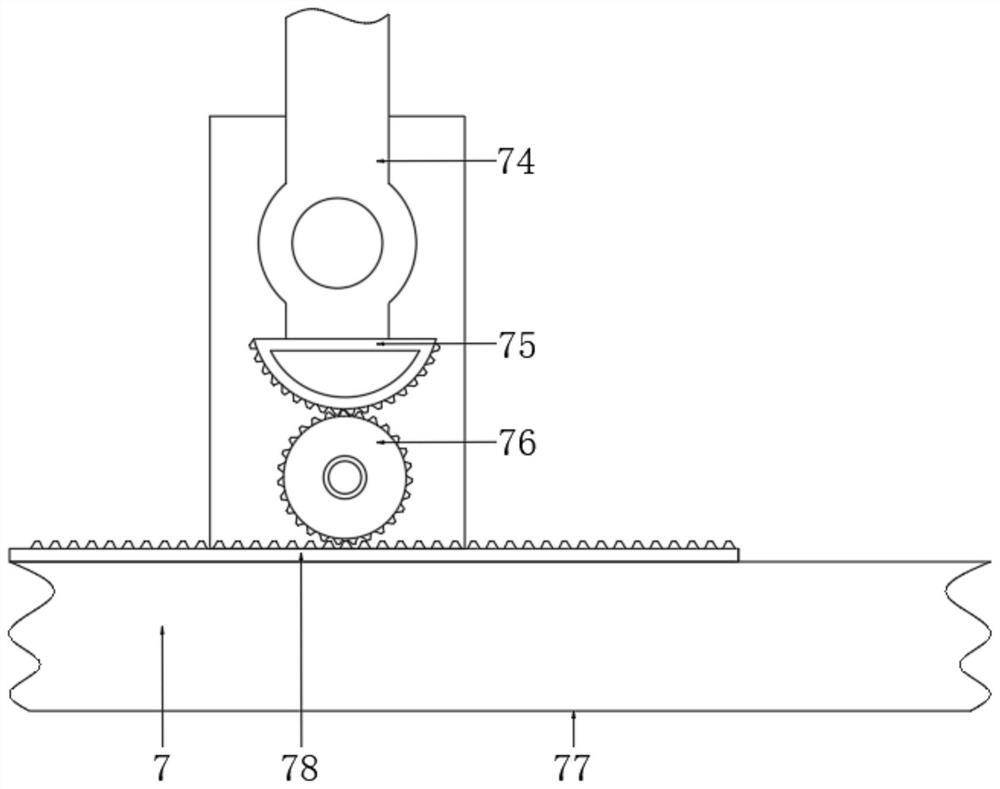

Automatic wall coating device for building construction

InactiveCN111719827AApply evenlyNot easy to dropBuilding constructionsGear wheelArchitectural engineering

The invention belongs to the field of building construction equipment, and particularly relates to an automatic wall coating device for building construction. The automatic wall coating device comprises a housing and a rail rod, wherein the rail rod penetrates through the housing; a toothed slot is formed in the side wall of the rail rod; the lower end of the housing fixedly communicates with a charge tube; a rotary roller is rotatably arranged in the housing; a plurality of bearing plates which are arranged in the form of a ring-shaped array are arranged on the peripheral side wall of the rotary roller; the bearing plates are rubber elastic plates; ends, away from one another, of the bearing plates are equipped with permanent magnetic stripes; permanent magnet pieces which are repellent to same electrodes of the permanent magnetic stripes are arranged on the side wall of the housing; a motor is mounted on the side wall of the housing; the rotary roller is fixedly and coaxially connected to the output shaft of the motor; the other end of the rotary roller is coaxially and fixedly equipped with a gear; and the gear is engaged with a rail rod. The housing slowly moves upwards along awall body, so that cement is uniformly coated onto a wall surface, and a cement layer is coated uniformly and flatly. Moreover, the automatic wall coating device is safe and reliable, and greatly improves work efficiency.

Owner:肖永永

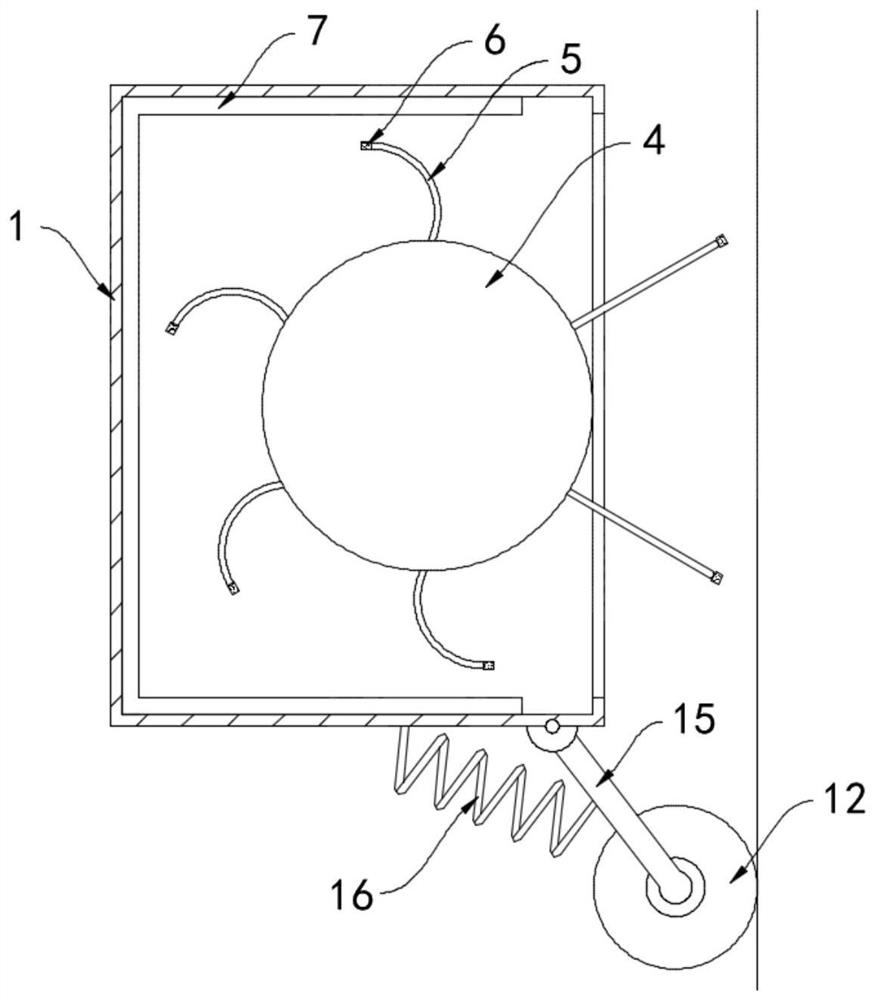

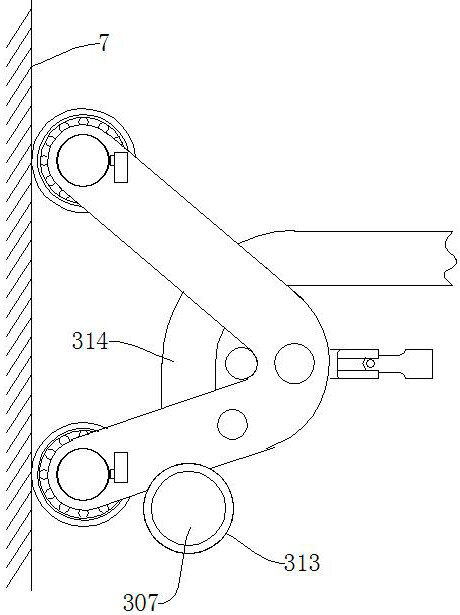

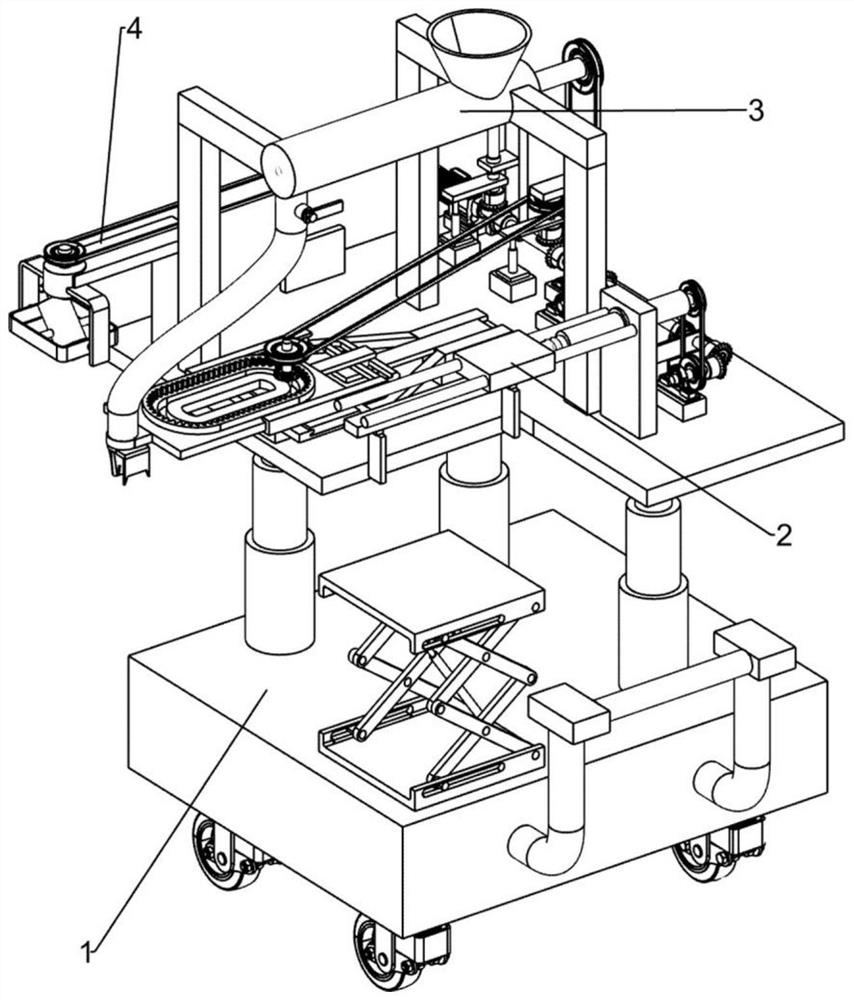

Smearing assembly and smearing robot

InactiveCN112814338AImprove efficiencyImprove smudge qualityRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a smearing assembly used for smearing paint on a smearing face. The smearing assembly comprises a smearing plate, a feeding device and a walking mechanism, wherein the feeding device is at least provided with a paint spraying barrel, and at least one row of spraying holes extending towards the two ends are formed in the outer circumferential face of the paint spraying barrel and used for spraying the paint in the paint spraying barrel to the smearing plate or the smearing face; and the walking mechanism comprises an installing frame with a rolling body, the smearing plate and the paint spraying barrel are arranged on the installing frame, the rolling body rolls along the smearing face to drive the smearing plate to move so that the paint can be evenly smeared on the smearing face, and the moving direction of the smearing plate is parallel to the smearing face. According to the technical scheme, the smearing assembly is used for conducting smearing work on the wall face, a ceiling, the ground and the slope of a staircase, and therefore manual smearing is completely replaced, the smearing work efficiency and the smearing quality are improved, the smearing cost is remarkably reduced compared with manual smearing, and market prospects are wide.

Owner:常家有

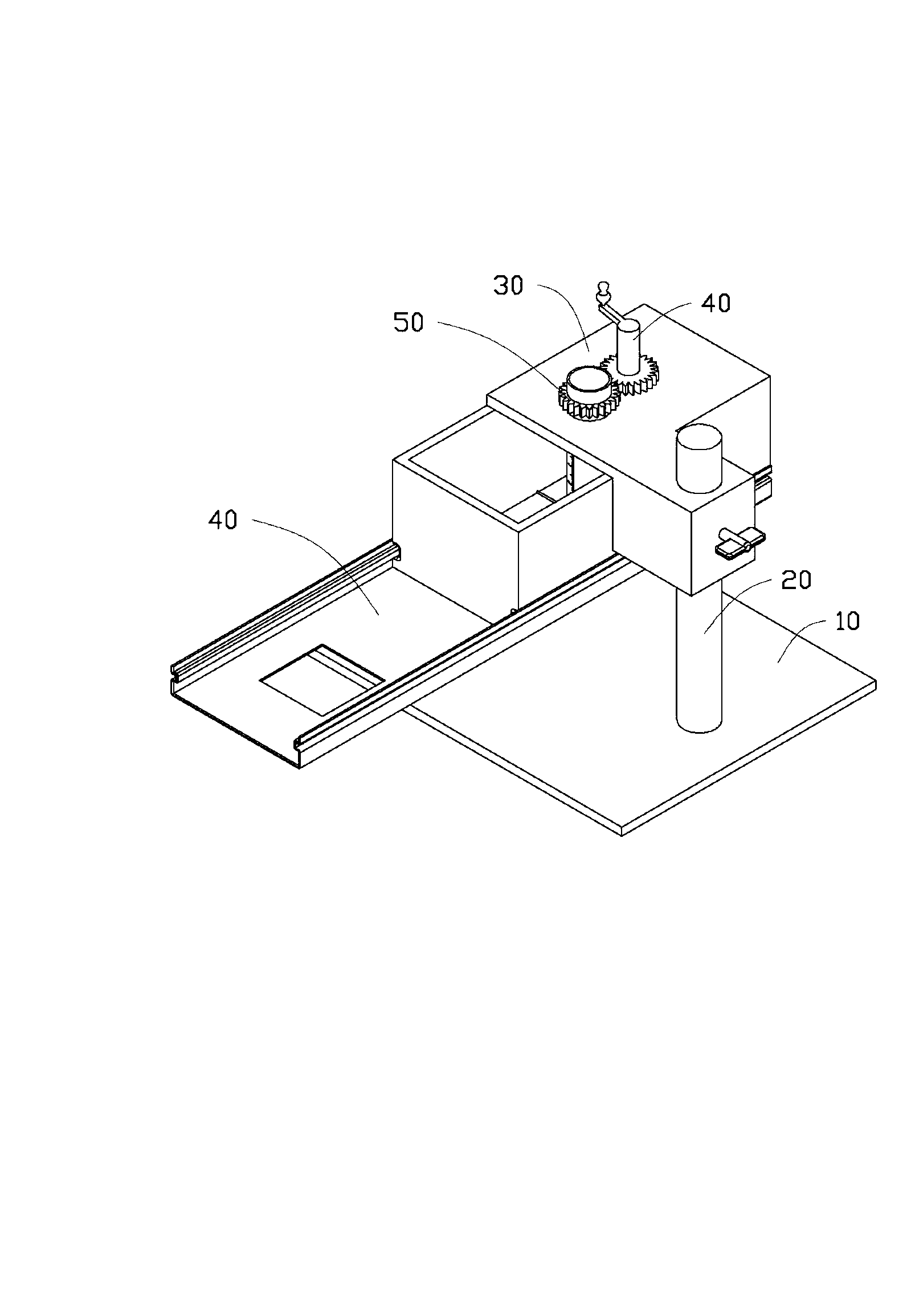

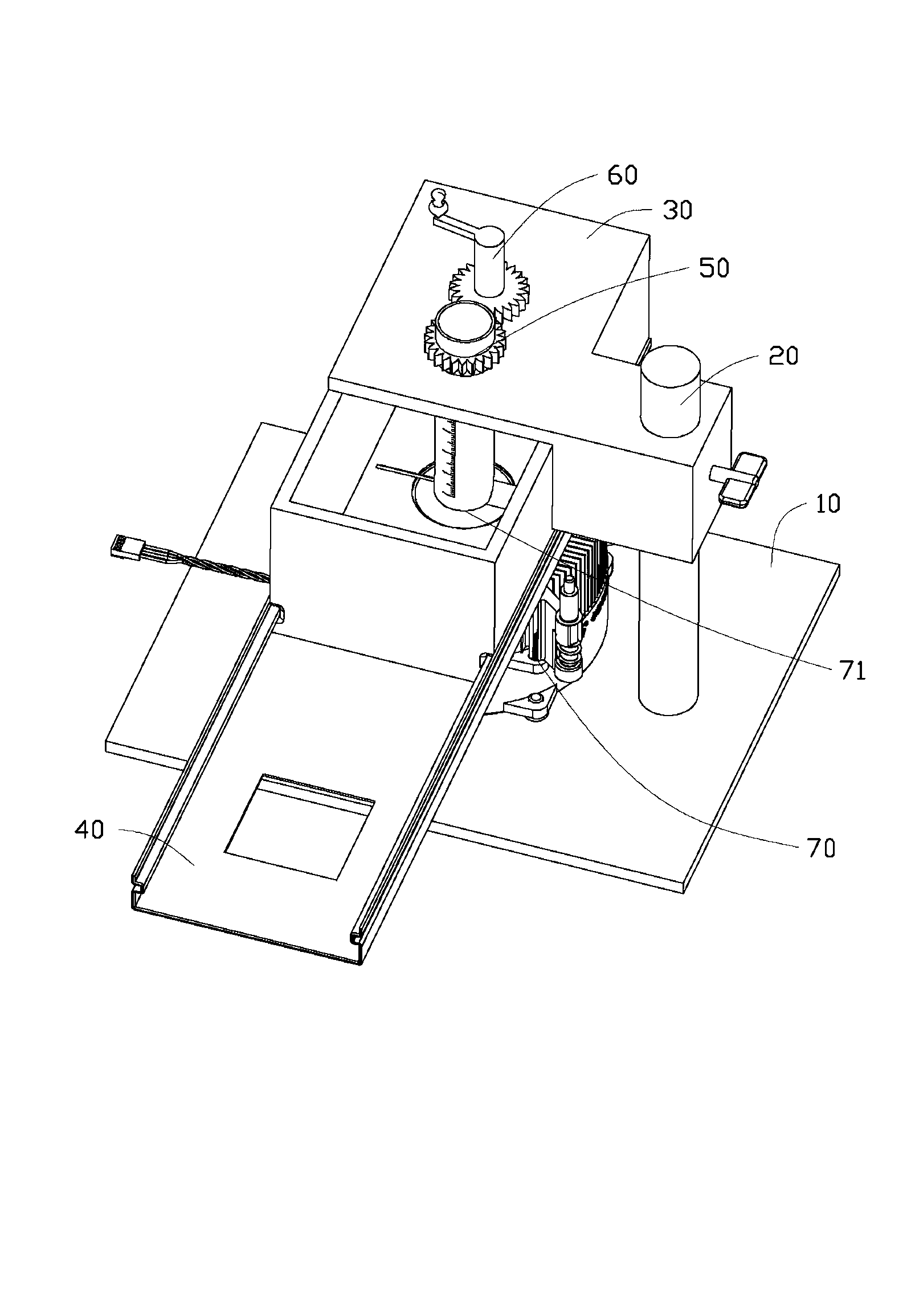

Convenient gluing device for making paper boxes

ActiveCN111804500AEasy and even glue applicationImprove smudge qualityLiquid surface applicatorsBox making operationsCrankEngineering

The invention relates to the technical field of paper boxes, and discloses a convenient gluing device for making paper boxes. The convenient gluing device comprises a main board, wherein a glue barrelis fixedly connected to the right end of the main board; a piston rod is slidably connected below the glue barrel; symmetrical baffle plates are fixedly connected to the left side of the main board;a rotating crank is rotationally connected between the baffle plates; a driving gear is fixedly connected to the upper end of the rotating crank; the lower portion of the rotating crank is fixedly sleeved with a cam; and a movable sleeve is rotationally connected to the middle of the rotating crank. According to the convenient gluing device for manufacturing the paper boxes, the rotating crank isstarted to rotate, then a gluing rubber is driven by a connecting rod to partially reciprocate for gluing, the driving gear is matched with the rotating crank to drive a transmission gear rod to rotate in the period, consequently, a transmission gear is further driven to rotate, and the gluing roller rotates by a driven gear, so that the paper boxes are conveniently and uniformly glued, and the gluing quality of a glue solution is improved.

Owner:临沂瑞鑫印刷包装有限公司

Electrical element manufacturing device and method for semiconductor device production

ActiveCN113078082AHigh viscosity phenomenonRealize dust-free operationSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusDevice materialEngineering

The invention discloses an electrical element manufacturing device and method for semiconductor device production, and belongs to the technical field of semiconductor manufacturing. The electrical element manufacturing device for semiconductor device production comprises: a box body and a processed product; a storage tank and a water box both located in the box body; a mechanical arm located at the top of the box body; and a smearing head connected to the output end of the mechanical arm, wherein the the processed product is smeared through the smearing head, conveying is conducted between the smearing head and the storage tank through a discharging pipe, the discharging pipe is subjected to heat preservation through hot water in the water box in the conveying process, and an adsorption body with static electricity is arranged at the top of the box body. Compared with an existing electrical element manufacturing device for semiconductor device production in the market, the electrical element manufacturing device for semiconductor device production can use water vapor generated by heat preservation of a photoresist to carry out dust fall after coating is completed.

Owner:江苏振宁半导体研究院有限公司

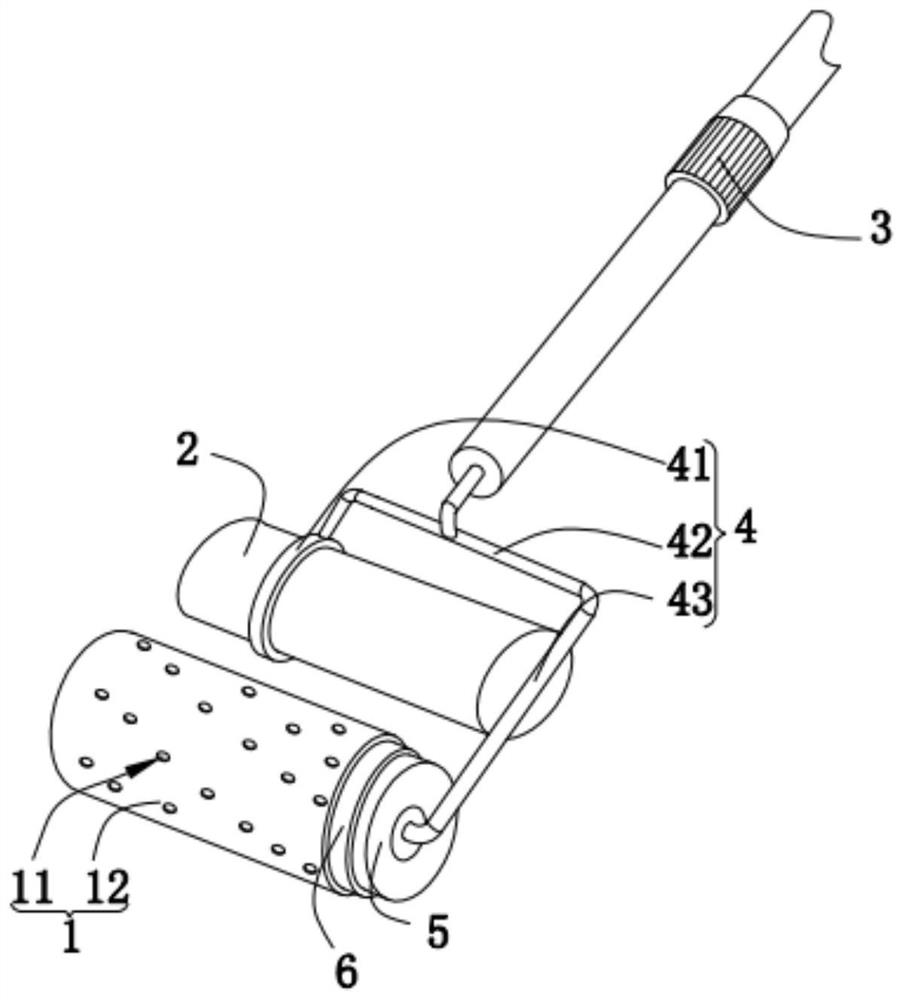

Automatic feeding type uniform smearing device

InactiveCN108393245AProportional speedProportional to feeding amountLiquid surface applicatorsCoatingsEngineeringPiston

The invention discloses an automatic feeding type uniform smearing device. The automatic feeding type uniform smearing device comprises a smearing roller, a transmission box and a material storage box. A material adding pipe is installed at the upper end of the material storage box. A transmission rotating shaft is installed in the transmission box. A first conical tooth is fixedly to the lower end of the transmission rotating shaft. A second conical tooth meshes with the right side of the first conical tooth. The right side of the second conical tooth is fixed on a U-shaped rotating shaft. The U-shaped rotating shaft is inserted into the material adding pipe. A push rod is fixed to the U-shaped rotating shaft through a sleeve, and the lower end of the push rod is fixed on a piston. The feeding cavity is formed in the smearing roller, and connecting pipes which are arranged by means of array are arranged on the periphery of the feeding cavity. The connecting pipes communicate with material retarding cavities. Material guiding layers are arranged on the smearing roller on the outer sides of the material retarding cavities. Discharging holes which are arranged by means of array are formed in the material guiding layers. The discharging holes communicate with the material retarding cavities. Sponge mats are arranged on the surface of the smearing roller on the outer side of the material guiding layers. According to the automatic feeding type uniform smearing device, the smearing is uniform, and the smearing quality is high.

Owner:武汉思异汇创科技有限公司

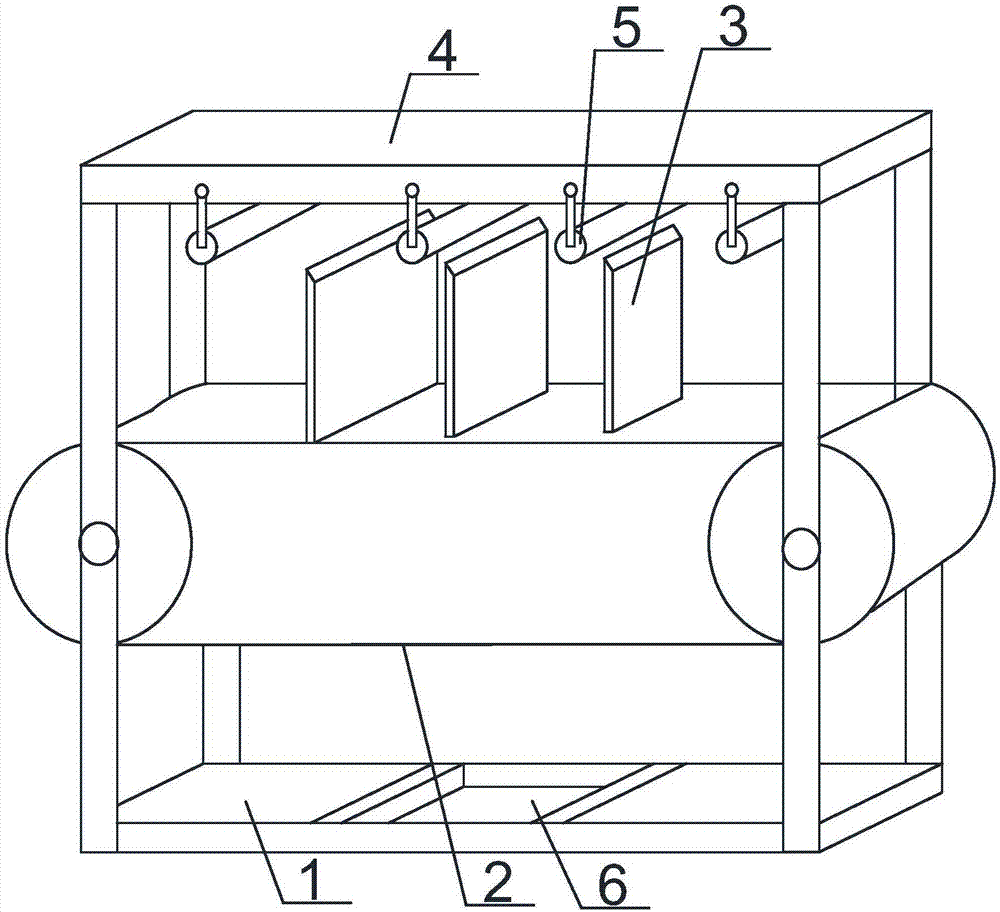

Device capable of improving anti-corrosion performance of surface of water treatment filter plate

InactiveCN107876323AImprove smudge qualityResolve overflowLiquid surface applicatorsCleaning using toolsBlade plateConveyor belt

The invention discloses a device capable of improving the anti-corrosion performance of the surface of water treatment filter plates. The device includes a horizontal plate used for storing the filterplates. The upper portion of the horizontal plate is connected with a belt conveyor belt with the conveyor surface parallel to the plate surface of the horizontal plate. The belt conveyor belt is provided with a plurality of scraper plates. The scraper plates are arranged on the belt conveyor belt in the conveying direction in parallel. The scraper plates are perpendicular to the belt conveyor belt. The transmission direction of the belt conveyor belt is used as standard, the plate surface areas of the scraper plates arranged on the belt conveyor belt from front to back are increased gradually. The contact side surfaces of the scraper plates and the filter plates are arranged as an inclined surface. The inclined surfaces are located in front of the scraper plates. According to the devicecapable of improving the anti-corrosion performance of the surface of the water treatment filter plates, the scraper plates of different areas are used, the problem of paint overflow is solved, and the coating quality of coating on the filter plates is improved.

Owner:四川宇科思通环保科技有限公司

Coating device for surface coating

ActiveCN109926263ALow technical requirementsImprove smudge qualityLiquid surface applicatorsCoatingsEngineeringMotor shaft

The invention discloses a coating device for a surface coating, and belongs to the field of coating devices of coatings. The coating device is characterized in that four corners of a table plate are fixedly connected with a supporting plate separately, and a first lead screw is rotatably connected between the two supporting plates at one side; a first guide rod is arranged between the two supporting plates at the other side; a second guide rod is separately arranged between the two supporting plates at the same side; the motor shaft of an electric motor is connected with one end of a rotary plate through a through hole in a first movable plate, and the other end of the rotary plate is embedded into a long guide hole of a second movable plate through a first guide pin roll; the two ends ofa fixed plate are fixedly connected with the lower end of a guide barrel separately; the upper end of the guide barrel passes through a guide through hole in the second movable plate; the lower end ofa pulling rod is inserted into a cavity of the guide barrel, and is perpendicularly connected to a positioning rod; the positioning rod passes through a rectangular slot hole, and abuts against the lower end of a limiting plate; and the guide barrel and the pulling rod are connected through a locking device. Compared with the prior art, the coating device has the characteristics of saving coatingand being relatively environmentally friendly.

Owner:安徽峻屹建筑工程有限公司

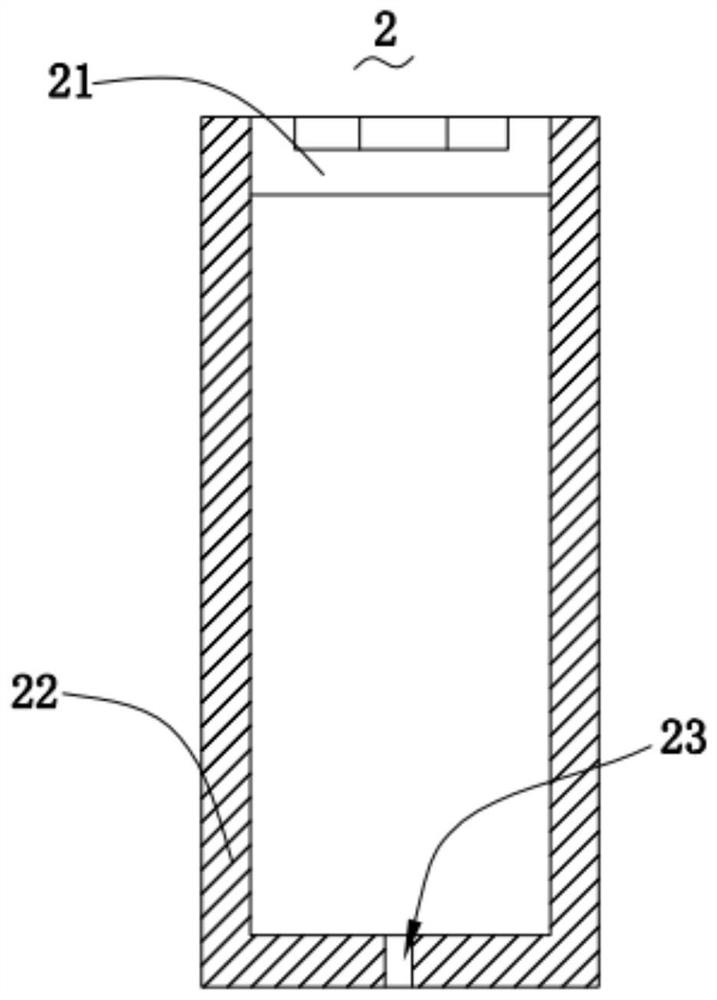

A tile grouting device

ActiveCN107327125BImprove application efficiencyImprove smudge qualityBuilding constructionsComposite materialCeramic tiles

The invention relates to the technical field of ceramic tile plastering, in particular to a plastering device for ceramic tiles. A ceramic tile placing plate for placing the ceramic tile is arranged on a supporting table, and a square container for containing plaster is arranged on ceramic tile; the square container is provided with an upper end opening and a lower end opening, and a baffle is arranged in the square container in a sliding manner; and the baffle can adjust a space for containing the plaster in the square container according to the width of the ceramic tile. Therefore, according to the plastering device for the ceramic tiles, the ceramic tile can be uniformly plastered by moving the square container, and the operation is simple and convenient, so that the plastering efficiency and the quality of ceramic plaster are effectively improved, and the working efficiency of a worker is improved.

Owner:MCC5 GROUP CORP SHANGHAI

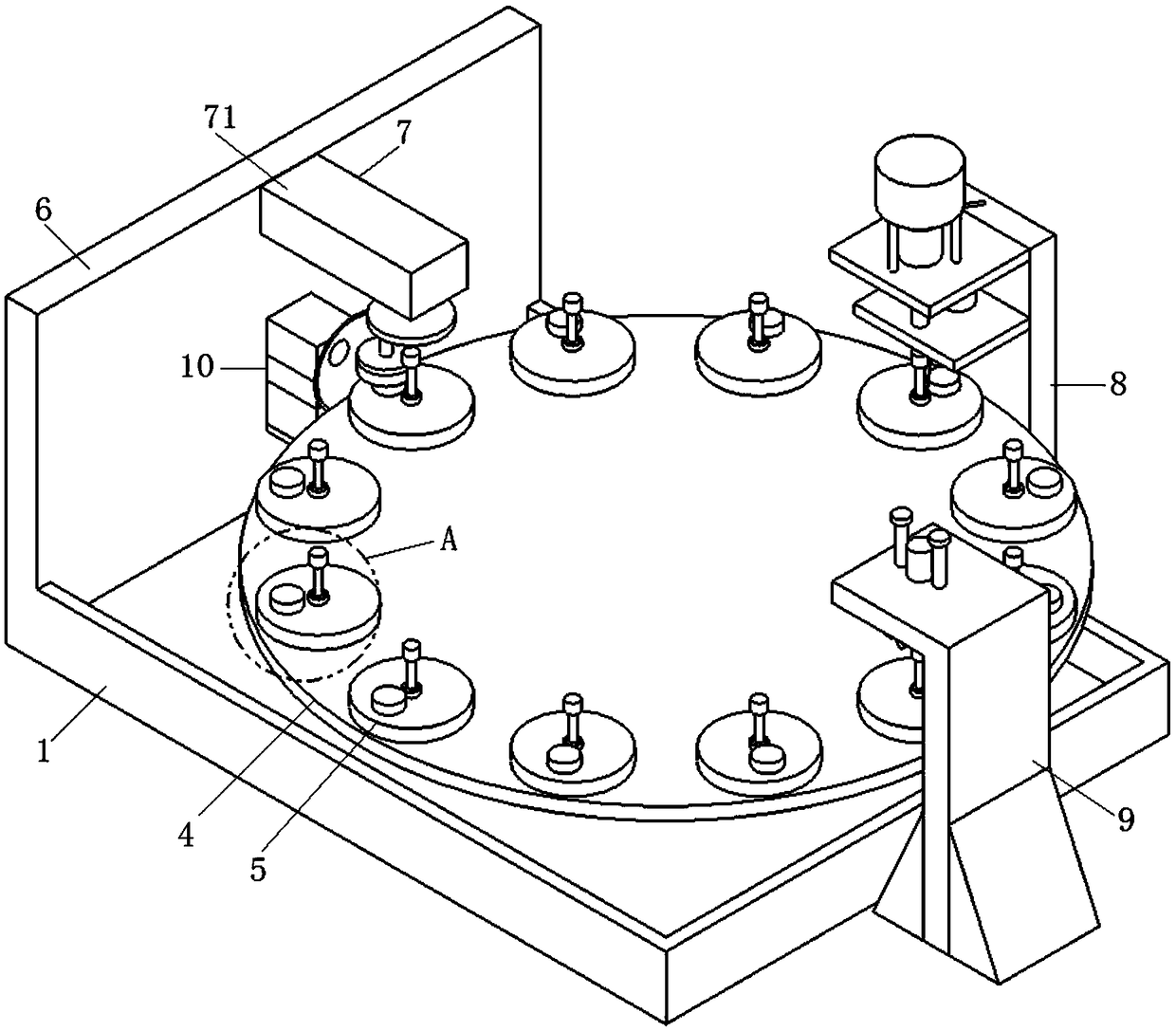

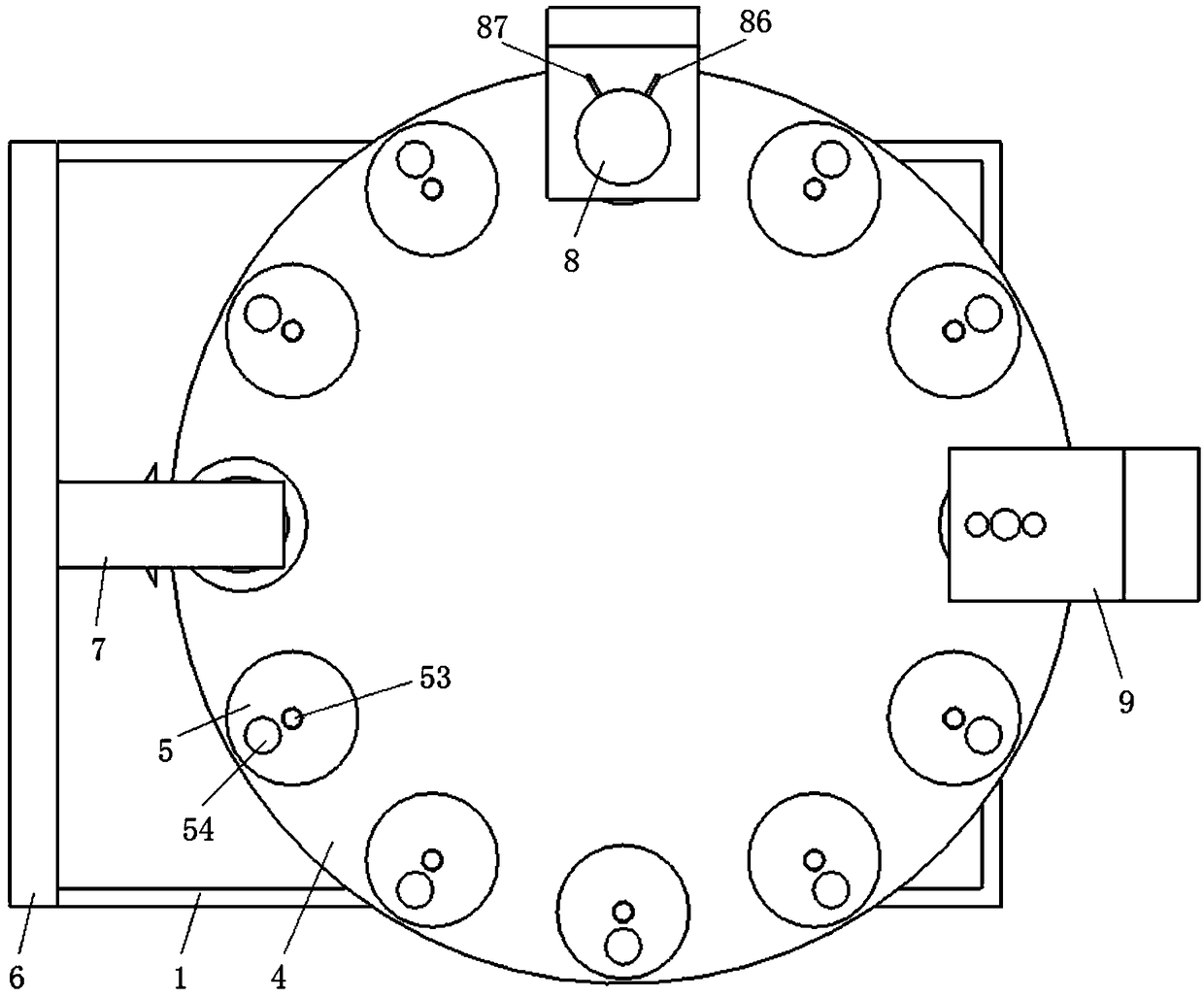

Welding equipment with smearing mechanism for exhaust pipes of upper shells of air-conditioning compressors

ActiveCN108856957AImprove cleanlinessRealize automatic stirringMetal working apparatusSoldering auxillary devicesElectricityNitrogen

The invention discloses welding equipment with a smearing mechanism for exhaust pipes of upper shells of air-conditioning compressors. The welding equipment comprise a bearing pond and controllers. Abase, a nitrogen supply device and a worktable are sequentially arranged in the bearing pond from bottom to top, a plurality of base plates are arranged on the worktable, clearing stations, smearing stations and welding stations are arranged on the bearing pond, a support plate is arranged at the end, which is close to the clearing stations, of the bearing pond, a clearing mechanism and a dust collection mechanism are arranged on the support plate, the smearing mechanism is arranged on the side, which is close to the smearing stations, of the bearing pond, a welding mechanism is arranged on the side, which is close to the welding stations, of the bearing pond, gas outlet assemblies are arranged on the base plates and are connected with the nitrogen supply device by nitrogen delivery pipes,nitrogen electromagnetic valves are arranged between the nitrogen supply device and the nitrogen delivery pipes, and stepper motors, the nitrogen electromagnetic valves, the nitrogen supply device, the clearing mechanism, the smearing mechanism and the welding mechanism are electrically connected with the controllers. The welding equipment has the advantages that that welding paste can be automatically smeared by the welding equipment, accordingly, the smearing efficiency can be improved, and the brightness of the exhaust pipes and the upper shells can be guaranteed.

Owner:芜湖美奥机械科技有限公司

Smearing device with three roller wheels

InactiveCN108580199AApply evenlyImprove smudge qualityLiquid surface applicatorsCoatingsPeristaltic pumpSoftware engineering

The invention discloses a smearing device with three roller wheels. The smearing device comprises a smearing roller and a storage box, the upper end of the storage box is provided with a feeding pipe,the left end of the storage box is fixedly provided with a connection pillar, the connection pillar is internally provided with a peristaltic pump, and the left end of the connection pillar is fixedly provided with an installation plate. The upper side of the left end of the installation plate is provided with a uniformly smearing roller, the lower end of the left side of the installation plate is provided with a dedusting roller, and the smearing roller is fixed to the installation plate through two symmetrical fixing arms. The smearing device with the three roller wheels is uniform in smearing and high in smearing quality.

Owner:武汉思异汇创科技有限公司

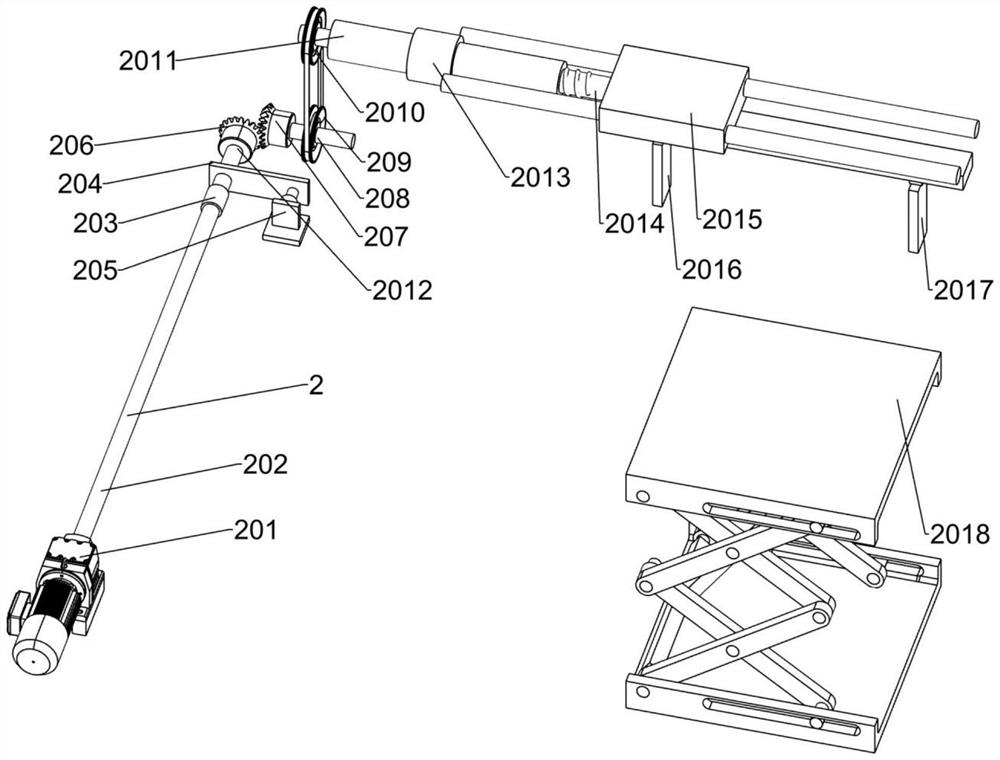

Wall building auxiliary device

ActiveCN111962890AReduce wasteImprove smudge qualityBuilding material handlingHollow coreStructural engineering

The invention relates to the field of buildings, in particular to a wall building auxiliary device. The technical problem of the invention is to provide the wall building auxiliary device. According to the technical scheme, the wall building auxiliary device comprises a lifting mechanism, a building block conveying mechanism, a mortar smearing mechanism, a building block wetting mechanism and a control screen. The building block conveying mechanism is arranged above the lifting mechanism; the mortar smearing mechanism is arranged above the lifting mechanism; the building block wetting mechanism is arranged above the lifting mechanism; the building block conveying mechanism is connected with the control screen; and the building block conveying mechanism is connected with the building blockwetting mechanism. According to the wall building auxiliary device, mortar smearing is automatically conducted on the hollow building blocks, workers are liberated from heavy physical labor, the laborintensity is reduced, the labor efficiency is improved, mortar waste is reduced, and the mortar smearing quality is improved.

Owner:重庆鹏威建筑工程有限公司

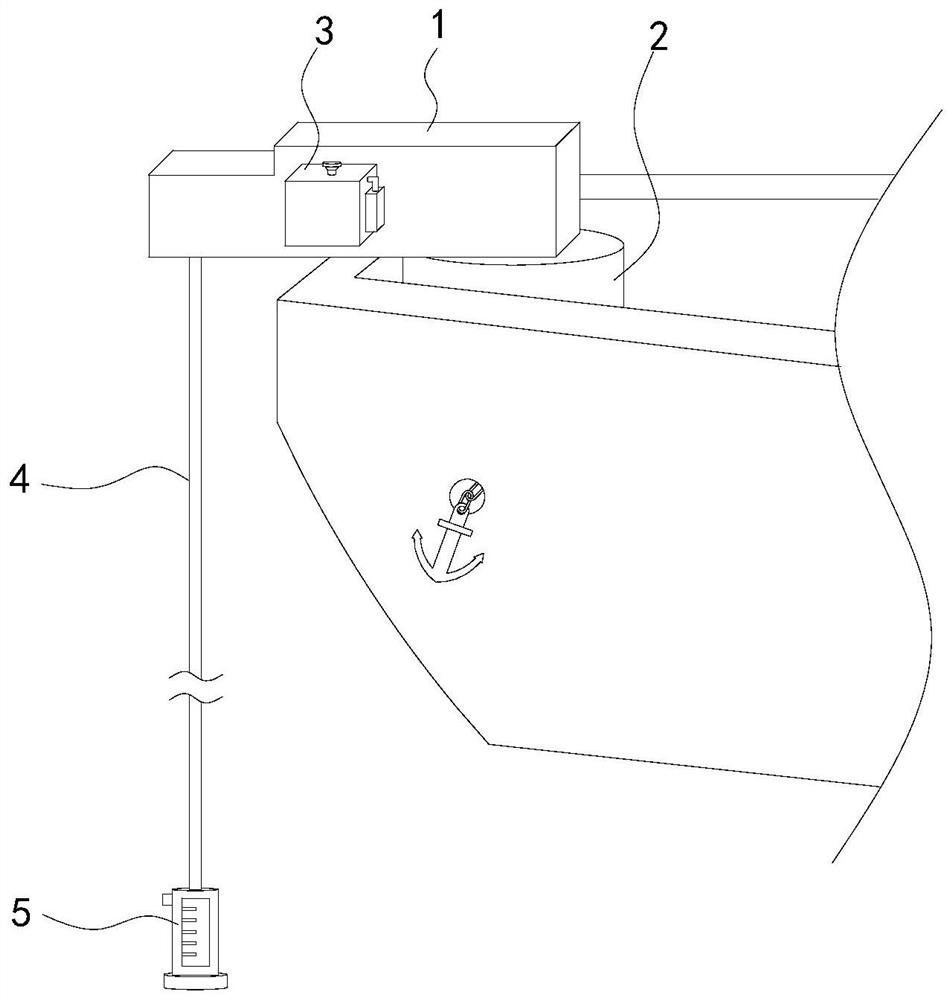

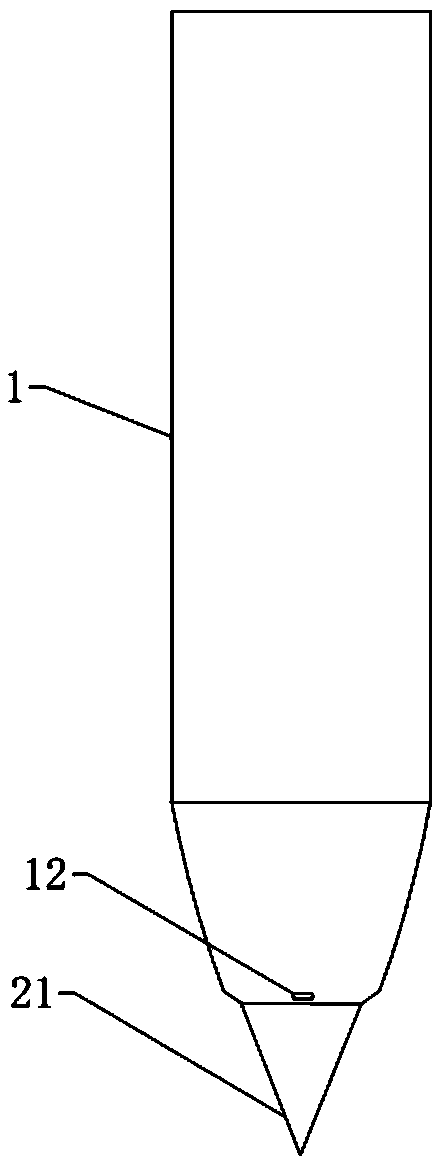

Marine water quality monitoring instrument capable of being prevented from being bitten by marine organisms and storage device thereof

InactiveCN112299138AExtended service lifeImprove smudge qualityFilament handlingRope making machinesMarine water qualityEngineering

The invention relates to the field of marine monitoring device protection equipment, in particular to a marine water quality monitoring instrument capable of being prevented from being bitten by marine organisms and a storage device thereof. The marine water quality monitoring instrument comprises a leading-out device, wherein a cable is movably mounted in the leading-out device, a sampling devicefixedly mounted at the lower end of the cable, and the storage device is fixedly mounted at the lower end of the right side of the leading-out device; and one end of the rope is connected into the storage device, a coating box is fixedly mounted on the outer side of the front face of the leading-out device, smearing rotating wheels are movably mounted in the leading-out device, the interior of the coating box communicates with a coating cavity, and the two coating rotating wheels are arranged up and down. After the lower ends of attaching plates enter the coating cavity, a liquid shark repellent mixed with water in the coating box can enter discharging channels of the attaching plates through the coating cavity under the action of an external pressurizing device and then makes contact with the outer side of the rope to achieve the effect of automatically smearing the shark repellent on the rope, and meanwhile the shark repellent on the outer side of the rope can be evenly scraped through the attaching plates by means of rotation of the smearing rotating wheels.

Owner:柳维朋

Mailbox device

InactiveCN108816625AEasy to apply and adjustSimple structureLiquid surface applicatorsCoatingsEngineeringPulley

The invention discloses a mailbox device. The mailbox device comprises a walking frame, a lifting power device and a smearing machine frame, wherein the lifting power device is arranged on the walkingframe, and the smearing machine frame is fixedly arranged on the lifting power device; is formed in the end surface of the left side of the smearing machine frame is internally provided with a firstsliding cavity; a first sliding base is arranged in the first sliding cavity in a sliding fit mode; a mailbox side smearing component is arranged in the first sliding base; the position, on the rightside of the first sliding cavity, in the smearing machine frame is provided with a transmission cavity; a first adapter shaft is arranged at the part between the transmission cavity and the first sliding cavity in a rotating fit mode; a first screw rod is fixedly arranged at the tail end of the left side of the first adapter shaft and is connected to the first sliding base in a threaded fit mode;a first cone pulley is fixedly arranged at the tail end of the right side of the first adapter shaft; the end surface of the top of the smearing machine frame is provided with a second sliding cavity; and a second sliding base is arranged in the second sliding cavity in a sliding fit mode.

Owner:永康市翌阳科技有限公司

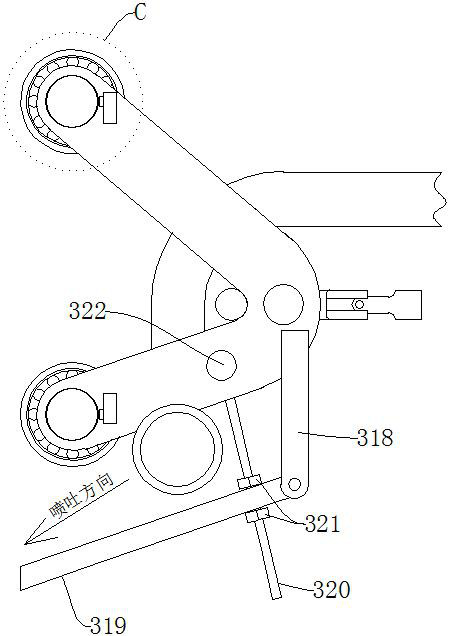

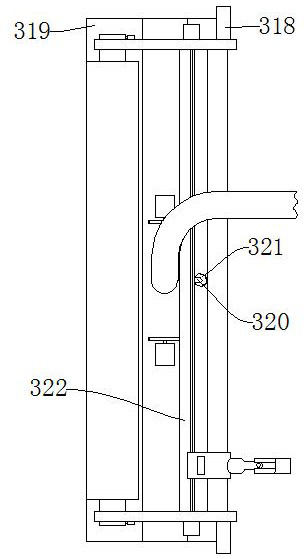

Ultrasonic flaw-detection coupling agent spray head

PendingCN107091883ASmear is effectiveApply evenly and quicklyMaterial analysis using sonic/ultrasonic/infrasonic wavesComposite materialUltrasound wave

The invention provides an ultrasonic flaw-detection coupling agent spray head. The spray head comprises a body and a mounting cavity, wherein the mounting cavity is formed in the body and is used for mounting an ultrasonic probe, a liquid inlet and liquid spray hole which are communicated with a coupling agent automatic liquid feeding device are formed in the body, a liquid spray channel communicated with the liquid inlet and the liquid outlet is formed in the body, the liquid inlet is formed in one side of the body, the liquid spray hole is formed in the top of the body and is aligned with the front end of the ultrasonic probe after the ultrasonic probe is mounted in place, and a locking component for fixing the ultrasonic probe into the mounting cavity is arranged on the other side of the body. Therefore, in a flaw detection process of a support pillar isolator or a ceramic sleeve, the problems that the sagging and loss of the coupling agent are caused due to time difference between the smearing of the coupling agent and the detection of the ultrasonic probe are avoided, and the support pillar isolator or the ceramic sleeve can be effectively, rapidly and uniformly smeared with the coupling agent, so that the accuracy during the detection of the ultrasonic probe is improved; and the use amount of the coupling agent in the detection process is reduced, so that the wasting of the coupling agent is reduced, and the detection cost is lowered.

Owner:STATE GRID ZHEJIANG TONGLU POWER SUPPLY +2

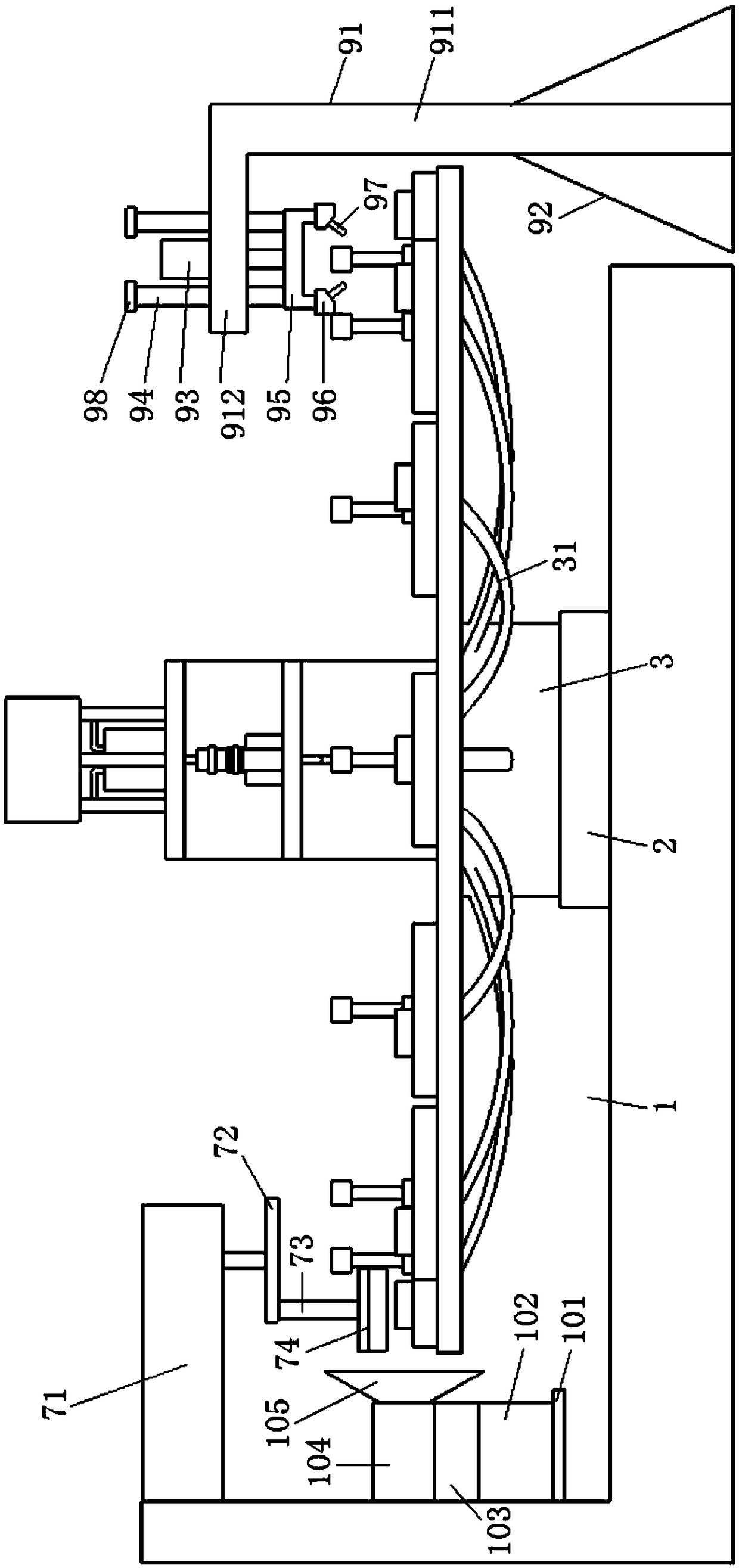

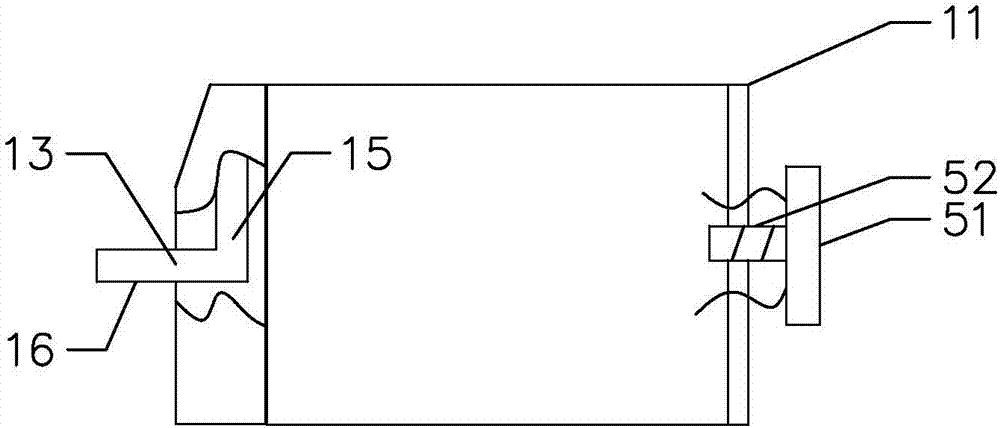

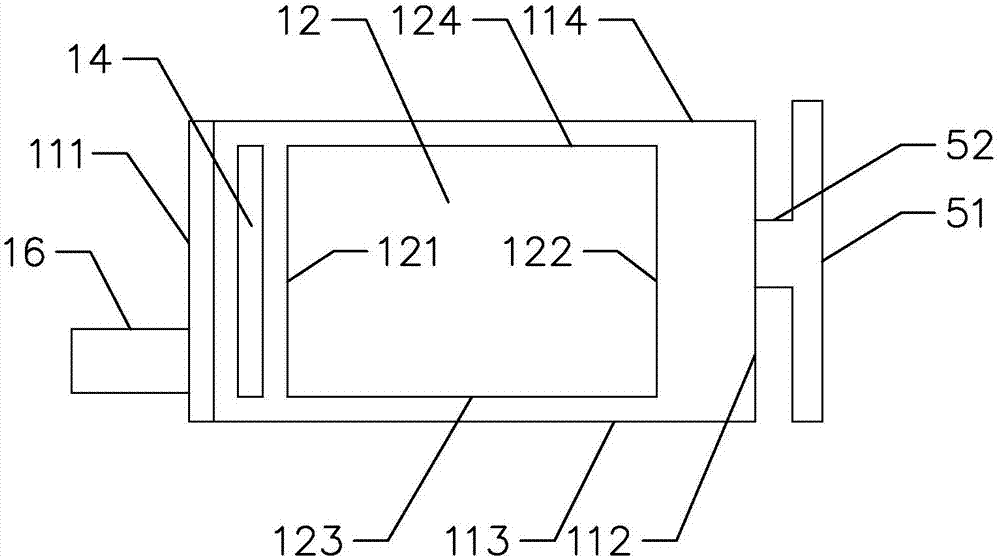

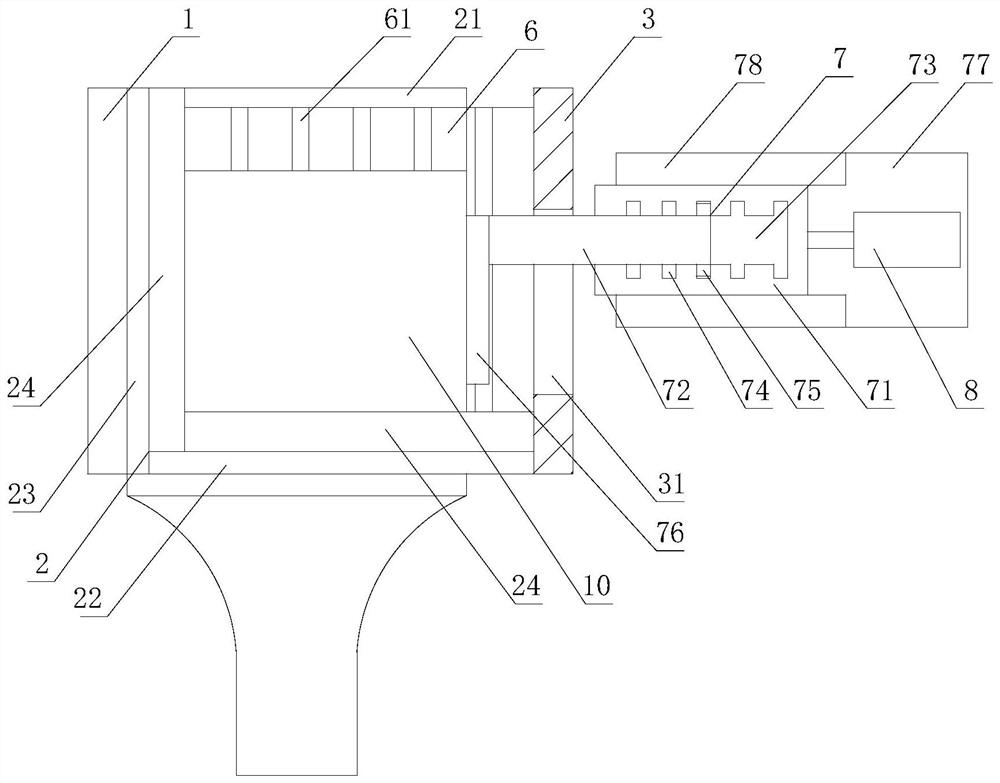

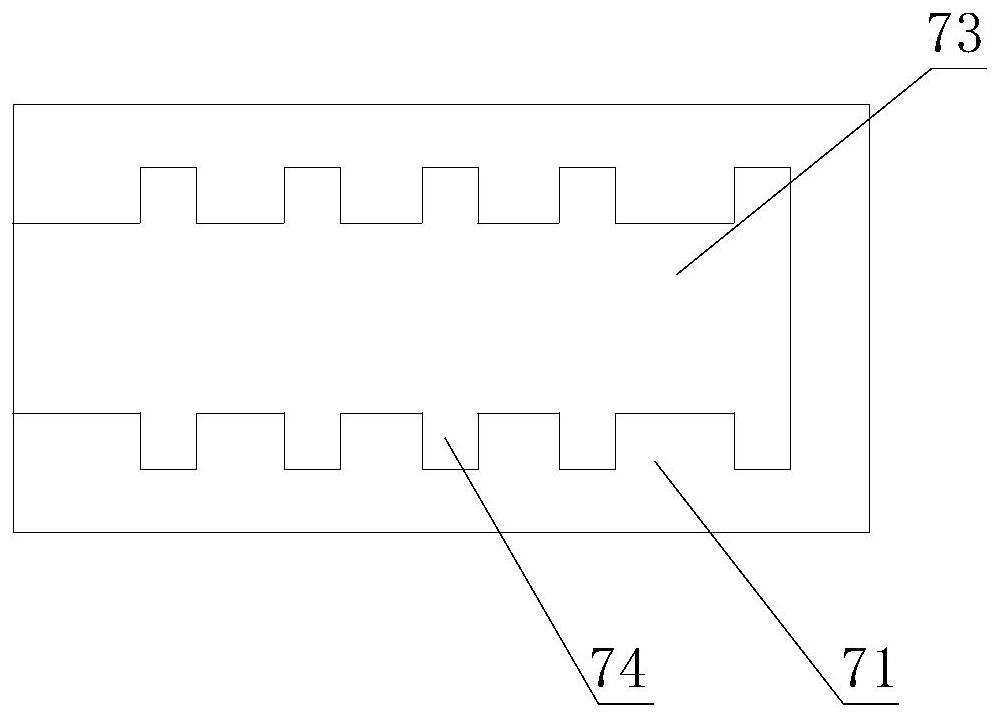

Thermal paste smearing apparatus

ActiveCN103170435AImprove smudge qualityImprove application efficiencyLiquid surface applicatorsSpraying apparatusEngineeringThermal contact

A thermal paste smearing apparatus is used for smearing a thermal paste on the thermal contact surface of a radiator, and comprises a platform arranged on the radiator, a support column arranged on the platform, a support fixed on the support column, a baseboard arranged at the bottom of the support, a top board arranged at the top of the support, and a hollow thermal paste conduit having an upper opening and a lower opening, the baseboard is provided with a smearing hole, the top board is provided with a through hole, the thermal paste conduit penetrates through the through hole, the lower opening of thermal paste conduit aligns and is close to the smearing hole, and the lower opening of the thermal paste conduit is provided with smearing sheets. When the thermal paste is smeared, the radiator is disposed on the platform, the thermal contact surface of the radiator upward abuts against the smearing hole, the thermal paste is filled from the upper opening of the thermal paste conduit, the thermal paste conduit rotates around the central axis of the thermal paste conduit, and the smearing sheets rotate with the thermal paste conduit to uniformly smear the thermal paste on the thermal contact surface of the radiator.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A wall coating device and method of use for recoverable blanking in building construction

ActiveCN111576804BEnables application conversionAdd practical functionsBuilding constructionsHydraulic cylinderArchitectural engineering

The invention discloses a wall-painting device used in the technical field of building construction, which is used for retractable blanking in building construction. It includes a base, the left and right sides of the top of the base are fixedly equipped with electro-hydraulic cylinders, and the top of the movable seat is equipped with a support frame. mechanism, the bottom of the support frame mechanism is provided with a blanking collection mechanism corresponding to the position of the wall painting mechanism, the top of the movable seat is provided with a disassembly drive mechanism that cooperates with the support frame mechanism, and the top of the base is located on two sets of push rods The position between is provided with the feeding mechanism that cooperates with the wall coating mechanism. When it is necessary to paint the wall on the top wall in the present invention, the hollow roller can be in contact with the top wall. When it is necessary to paint the vertical wall When the hollow roller is in contact with the vertical wall, it is enough to realize the conversion of the painting operation between the vertical wall and the top wall, improve the practicability and functionality of the device, and improve the efficiency and quality of use.

Owner:湖南善德红建设工程有限公司

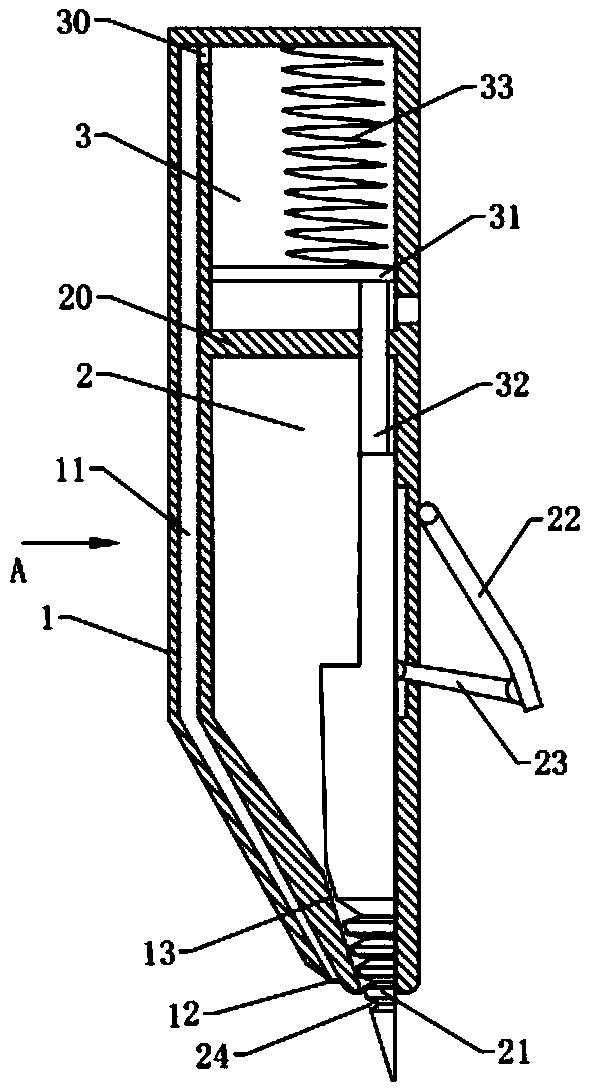

Photosensitive adhesive detecting and repairing device

InactiveCN109656100AImprove revision efficiencyImprove smudge qualityPhotomechanical apparatusPuncturingAdhesive

The invention relates to the technical field of plate making, in particular to a photosensitive adhesive detecting and repairing device, which comprises an outer casing, a repairing mechanism and a cleaning mechanism. The outer casing is provided with an air chamber and a liquid storage chamber from top to bottom, the lower end of the liquid storage chamber is opened, and the repairing mechanism comprises a dialing tip which is in sliding connection with the liquid storage chamber and the opening. The repairing mechanism also comprises a pushing portion which drives the dialing tip to upwardsmove to enter the liquid storage chamber through pressing. The cleaning mechanism comprises a piston slidingly connected with the air chamber, the piston is fixedly connected with a piston rod, and the piston rod penetrates into the liquid storage chamber and is fixed at the upper end of the tip end. The air chamber communicates with an air passage arranged inside the outer casing, and the position, close to the opening, of the lower end of the air passage is provided with a gas port. The dialing tip is used for trimming a screen, the dialing tip can be retracted into the liquid storage chamber, and the photosensitive adhesive flows out from the opening, so that the repaired portion of the screen can be coated with the photosensitive adhesive for repairing. The device has multiple functions of puncturing, coating and repairing and impurity removal, the problem of repeatedly switching tools during the manual retouching is solved, and the efficiency and quality of the retouching are improved.

Owner:汉诺(宁波)供应链管理有限公司

Protective layer applicator for steel structures

ActiveCN109838071BOutflow smoothlyAvoid wastingBuilding constructionsMechanical engineeringStorage structure

The invention provides a protective layer smearing device for a steel structure. The protective layer smearing device for the steel structure comprises a supporting structure, a fixing structure, a storage structure, a driving structure, an adjusting structure, a limiting structure and a first smearing structure; the adjusting structure comprises a plurality of third flow-guiding holes and an adjusting cylinder, the adjusting cylinder communicates with the storage structure through the driving structure, and the third flow-guiding holes are formed in the side wall of the adjusting cylinder; the limiting structure comprises a plurality of fourth flow-guiding holes and a sleeve, and the third flow-guiding holes in the adjusting cylinder are in one-to-one correspondence with the fourth flow-guiding holes in the sleeve; and the first smearing structure comprises a smearing roller and first smearing holes, and the fourth flow-guiding holes in the sleeve are in one-to-one correspondence withthe first smearing holes in the smearing roller. The protective layer smearing device for the steel structure is good in smearing effect and high in protective liquid utilization efficiency.

Owner:中博建设工程集团有限公司

A high-efficiency smear machine for the processing of lead-acid battery plates

ActiveCN110787953BImprove smudge qualityGuaranteed elastic contactLiquid surface applicatorsElectrode carriers/collectorsEngineeringMaterial storage

The invention discloses a high-efficiency smear machine for cutting and processing lead-acid battery plates, which comprises a working case, and the side walls at both ends of the working case are respectively provided with a material inlet and a material outlet. The lower end of the outer side of the discharge port is respectively provided with a roll loading / unloading linkage mechanism, and the two mechanisms are provided with a plate strip in a stretched state. Stirring barrel for storing materials, the other end is equipped with a heating device box, the two sides of the heating device box are respectively equipped with fan units, and the two ends of the air pipes on the two fan units are connected to both sides of the heating device box and The shells on both sides of the working case extend to the inside of the working case and are connected with an air outlet cover, and a coating mechanism box is arranged directly below the vertically corresponding to the storage mixing barrel inside the working box, and the coating mechanism box is provided with two Perforated rollers. The invention not only effectively improves the smearing quality of the cell board cutouts, but also significantly improves the production efficiency.

Owner:ANHUI YONGHENG STORAGE BATTERY

A clamping mechanism for applying conductive paste to wire clips

ActiveCN113231270BGuaranteed uniformityImprove the installation processLiquid surface applicatorsCoatingsConductive pasteEngineering

The invention relates to a clamping mechanism for applying conductive paste to a wire clip, comprising a left baffle, an upper baffle and a right baffle, and a height adjustment mechanism including a thrust cylinder and a lower baffle, a left baffle or / and a right baffle There is a width adjustment mechanism on the upper side, a clamping cylinder is connected to the width adjustment mechanism, and a smearing port is arranged on the upper baffle; The vertical direction of the wire clip is always subject to the force of the thrust cylinder, so the wire clip is not interfered by the smearing pressure when smearing, so that the surface of the wire clip is always in a horizontal state, thus effectively ensuring the uniform thickness of the conductive paste. Secondly, the width of the cavity is adjusted by the width adjustment mechanism, so it is only necessary to adjust the width of the width adjustment mechanism during installation to meet the needs of different types of wire clips, which improves the installation process of the wire clips.

Owner:JINHUA POWER TRANSMISSION & DISTRIBUTION ENG +1

A small external patch making device

InactiveCN109758367BImprove smudge qualityRealize integrationPharmaceutical product form changeElectric machineryStructural engineering

The invention discloses a small external patch production device, which belongs to the field of pharmaceutical equipment, and is characterized in that: the four corners of the bottom plate are respectively fixedly connected with one side of the support plate, and the two side support plates on one side of the bottom plate are provided with The first lead screw and the second lead screw, the first guide rod and the fifth guide rod are arranged between the two side support plates on the other side of the bottom plate, and the second guide rods are respectively arranged between the two side support plates on both sides of the bottom plate ; One end of the motor is fixedly connected to the first support, the motor shaft of the motor passes through the through hole on the first support and is connected to one end of the first telescopic device, and the other end of the first telescopic device is connected to the first guide pin; The first guide pin is embedded in the rectangular guide hole of the second support. Compared with the prior art, it has the characteristics of novel structure.

Owner:青岛市黄岛区中心医院

A method for making an exterior wall imitating the texture of rammed earth and a device for making a surface with rammed earth paint

ActiveCN112761275BImprove smudge qualityEffective isolationWallsBuilding material handlingMining engineeringStructural engineering

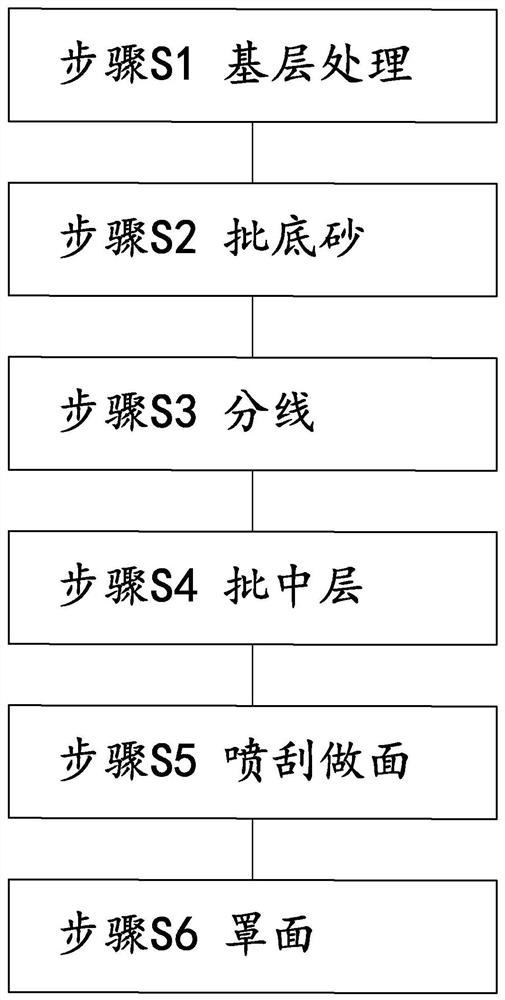

The invention discloses a method for making an exterior wall imitating the texture of rammed earth and a device for making a surface with rammed earth paint, comprising the following steps: treating the base layer: applying a special putty for the exterior wall with a spatula and a finishing knife, and using a roller on the surface of the putty layer Anti-alkali primer for exterior wall by rolling brush; Batch base sand: Use spatula and batch knife to scrape rammed earth special base sand to increase the bite and color conversion of rammed earth paint; Separation line: draw on the base sand to divide the paint The smear dividing line of the color block; batch middle layer: according to the smear dividing line, scrape the coarse sand and rammed earth paint on the base sand between the two smear dividing lines to form the middle layer; spray and scrape the surface: spray and scrape the coarse sand rammed earth paint Sand rammed earth paint, the fine sand rammed earth paint is formed gradually, and the area between the adjacent smeared dividing lines decreases gradually from one smeared dividing line to the other smeared dividing line, and in The fine-sand rammed-earth coating described in the last section is in the shape of an intermittent pattern; finish: use a spray gun to spray a special finish paint.

Owner:浙江异涂新材料有限公司

Tooling for Greasing Screw Assemblies

ActiveCN106402627BReasonable structural designSimple and fast operationEngine lubricationEngineeringMechanical engineering

Owner:WUHU QUAN CHENG INTELLIGENT TECH

A leather surface maintenance oil application equipment for leather bag production

ActiveCN108607767BApply evenlyQuality improvementLiquid surface applicatorsCoatingsProcess engineeringEnvironmental geology

The invention relates to maintenance oil coating equipment, in particular to leather surface maintenance oil coating equipment for leather bag production. The leather surface maintenance oil coating equipment for leather bag production is high in working efficiency, uniform in coating and convenient to operate. The leather surface maintenance oil coating equipment for leather bag production comprises a support table, a support plate, a support rod, a liquid storage box, a slide rail, a slide block, a fixed block, a first spring, a connecting rod, a T-shaped push rod, a brush, a liquid outlet pipe, a valve and the like; the top of the support table is connected with the support plate; the upper middle part of the support plate is connected with the support rod; the top of the support rod isconnected with the liquid storage box; the lower part of the left side surface of the liquid storage box is connected with the slide rail; and the slide rail is provided with the slide block. The brush moves left and right to brush leather surfaces, so that maintenance oil on the leather surfaces are uniformly coated; and the maintenance oil is stirred through stirring blades, so that the coatingquality of the maintenance oil can be improved, and the effects of high working efficiency, uniform coating and convenience to operate are achieved.

Owner:山东远腾环保设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com