Ultrasonic flaw-detection coupling agent spray head

A technology of ultrasonic and couplant, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves. It can solve problems such as loss of couplant, difficulty in detection work, easy smearing and unevenness, and reduce the use of Quantity, reducing the possibility of defects being missed, easy to fix and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

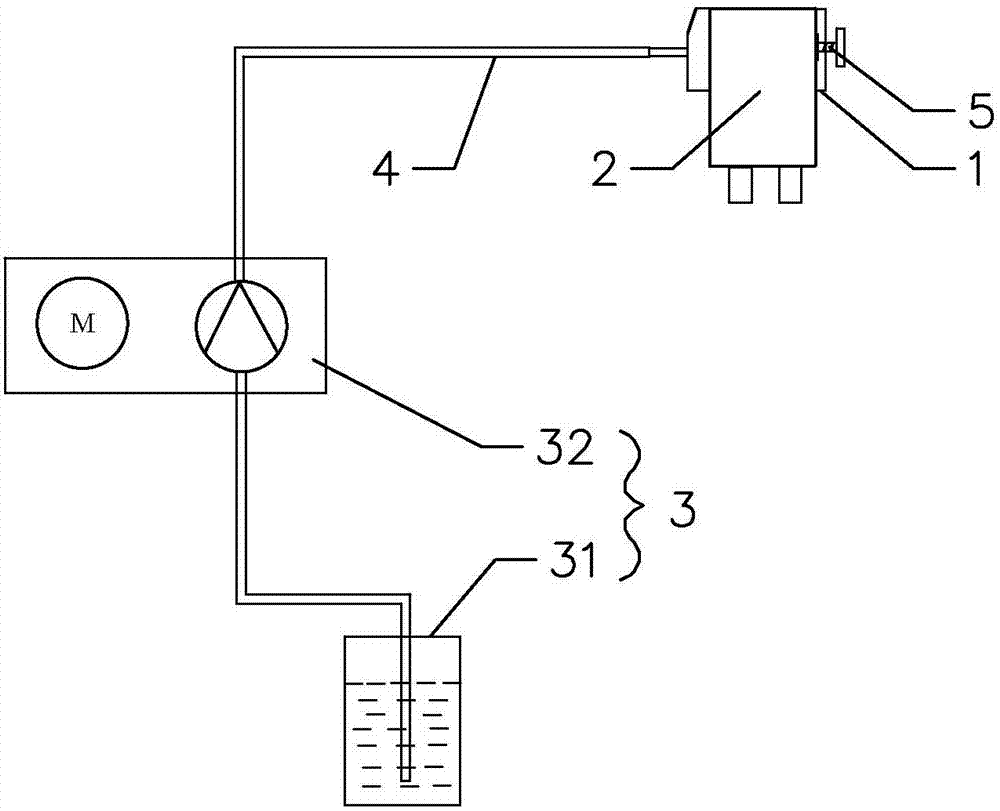

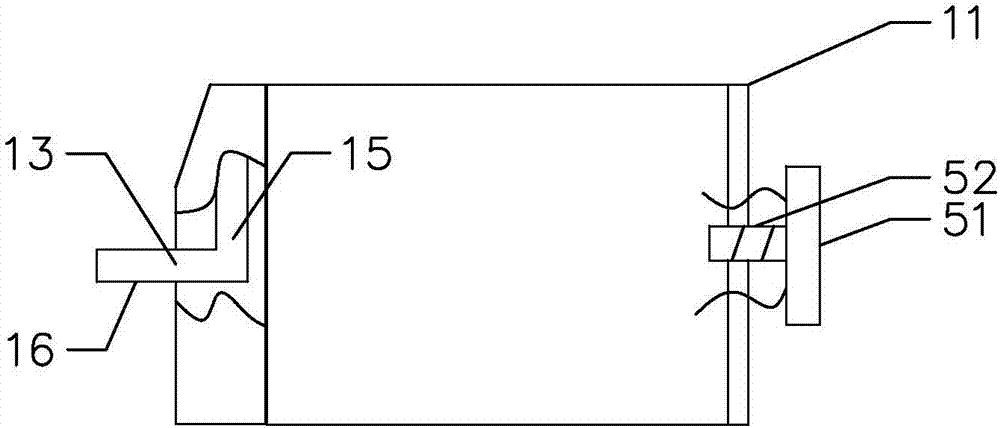

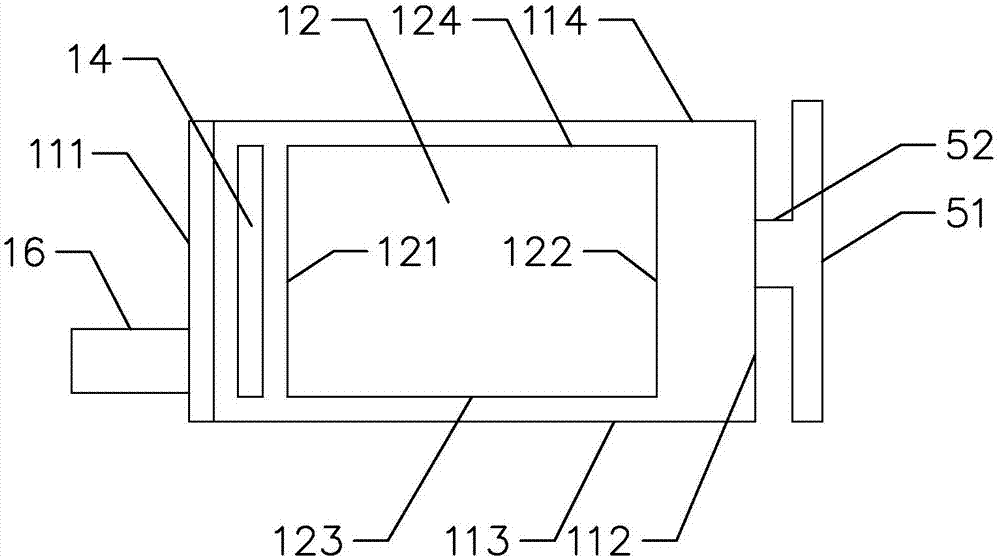

[0033] Such as Figures 1 to 4 As shown, the present invention provides an ultrasonic flaw detection couplant nozzle 1, including a body 11, an installation cavity 12 arranged on the body 11 and used for installing an ultrasonic probe 2, specifically, refer to image 3 The horizontal projection of the main body 11 is rectangular and includes the left side wall 111, the right side wall 112, the front side wall 113 and the rear side wall 114. The main body 11 is a metal body and an insulating body, specifically an aluminum body, which can ensure The strength of the nozzle improves the durability of the nozzle, and ensures that the nozzle will not get an electric shock during detection, improving the safety of use. The installation cavity 12 includes a left inner wall 121, a right inner wall 122, a front inner wall 123, and a rear inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com