Wall building auxiliary device

An auxiliary device and wall-building technology, which is applied in construction, building structure, and building material processing, can solve the problems of high labor intensity, waste, and mortar falling into block holes, etc., so as to improve labor efficiency and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

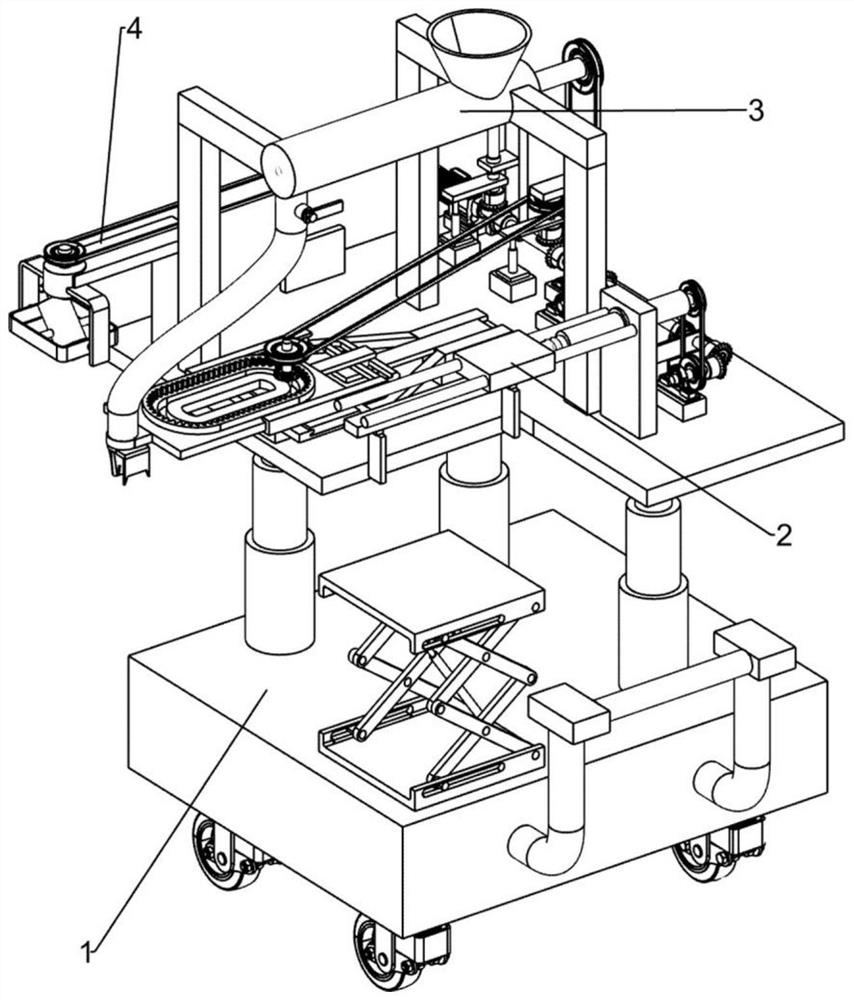

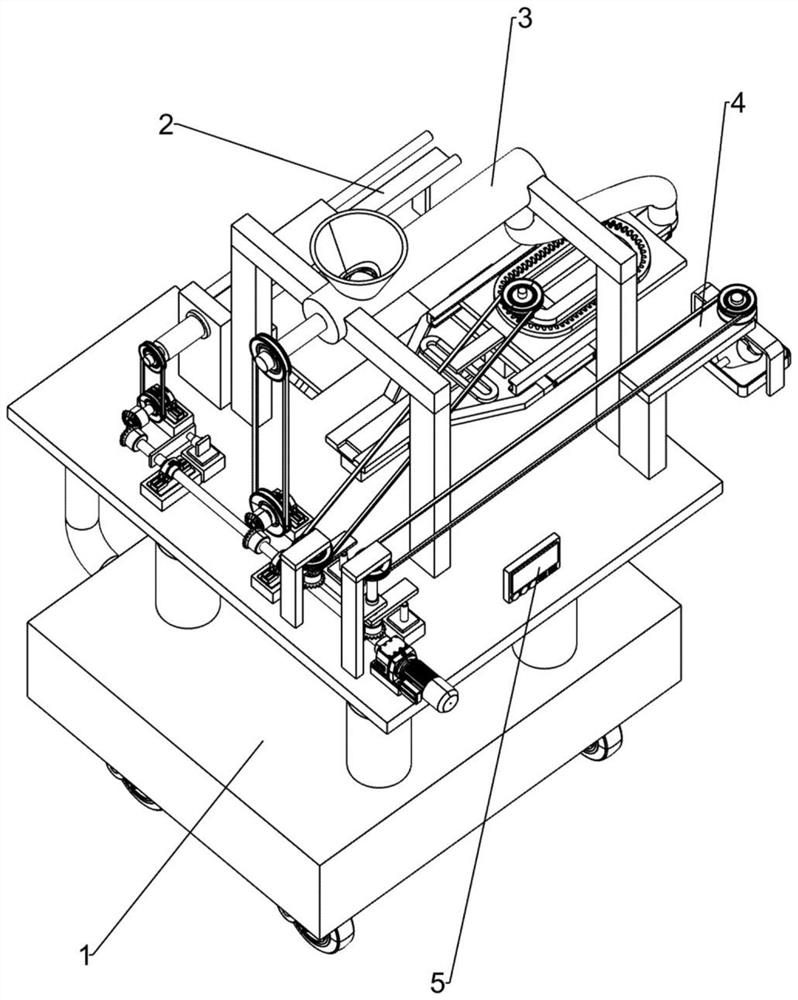

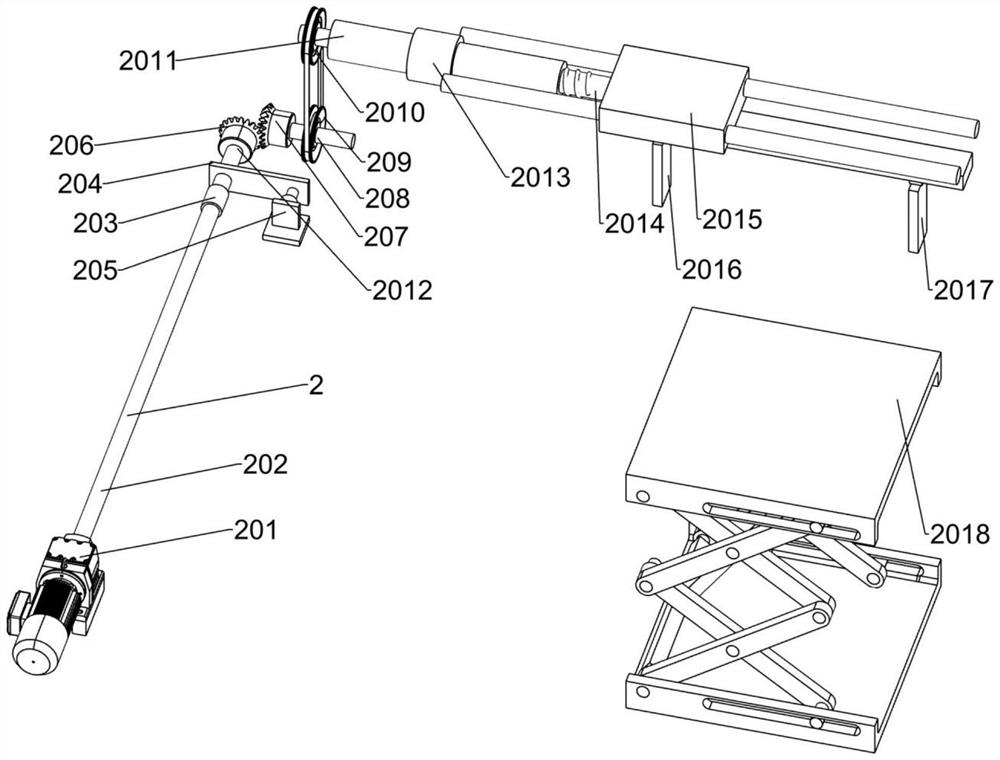

[0026] A wall-laying aid, such as Figure 1-7 As shown, it includes a lifting mechanism 1, a block transportation mechanism 2, a mortar application mechanism 3, a block wetting mechanism 4 and a control panel 5; a block transportation mechanism 2 is arranged above the lifting mechanism 1; a mortar application mechanism is arranged above the lifting mechanism 1 Mechanism 3; a block wetting mechanism 4 is arranged above the lifting mechanism 1; a block wetting mechanism 4 is arranged above the lifting mechanism 1; the block transportation mechanism 2 is connected with the control panel 5; the block transportation mechanism 2 is connected with the block wetting mechanism 4 connected; the mortar application mechanism 3 is connected with the block wetting mechanism 4.

[0027] Working principle: when in use, first place the auxiliary device for building the wall to the position to be used, then connect the external power supply, and start it through the control panel 5. First, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com