Tooling for Greasing Screw Assemblies

A screw and component technology, applied in the field of greased tooling for screw components, can solve the problems of high labor intensity, low work efficiency, uneven coating, etc., and achieve the effects of high work efficiency, easy operation and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

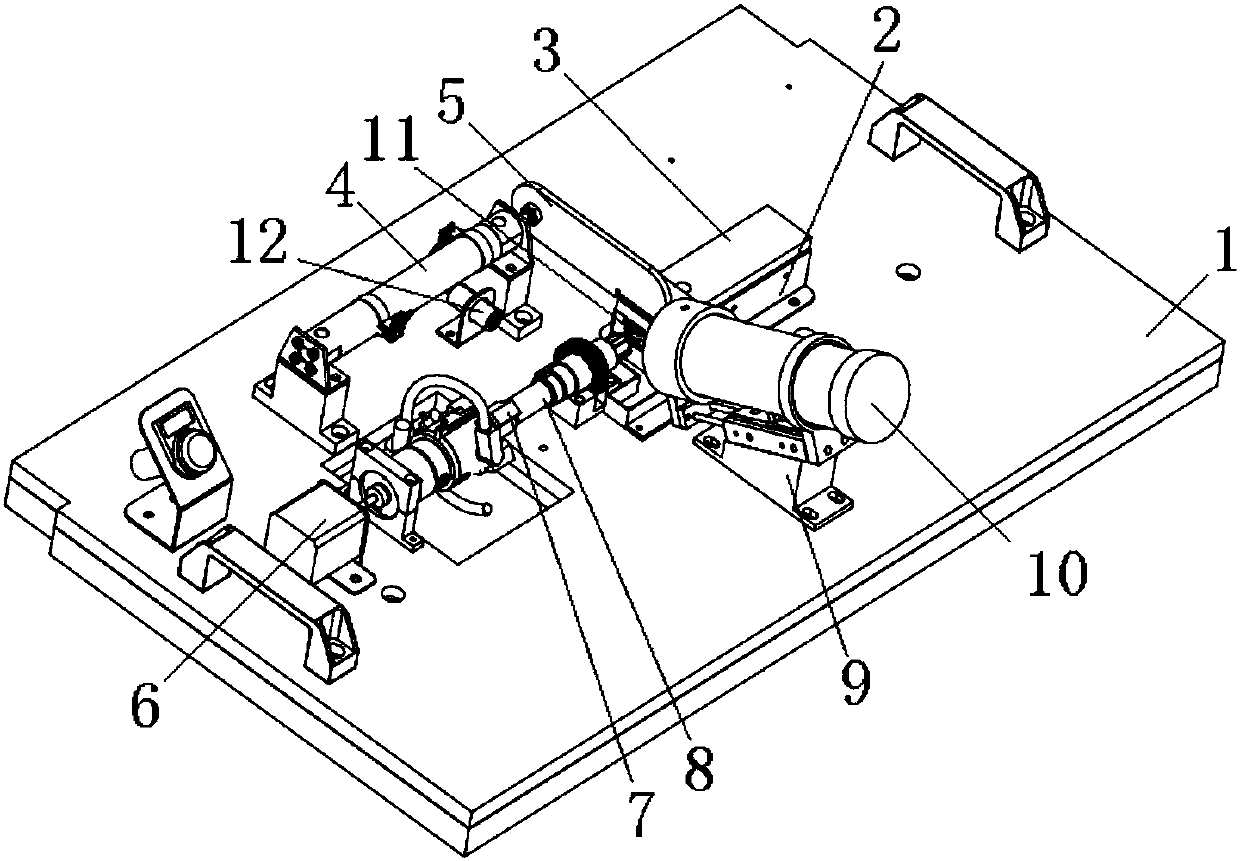

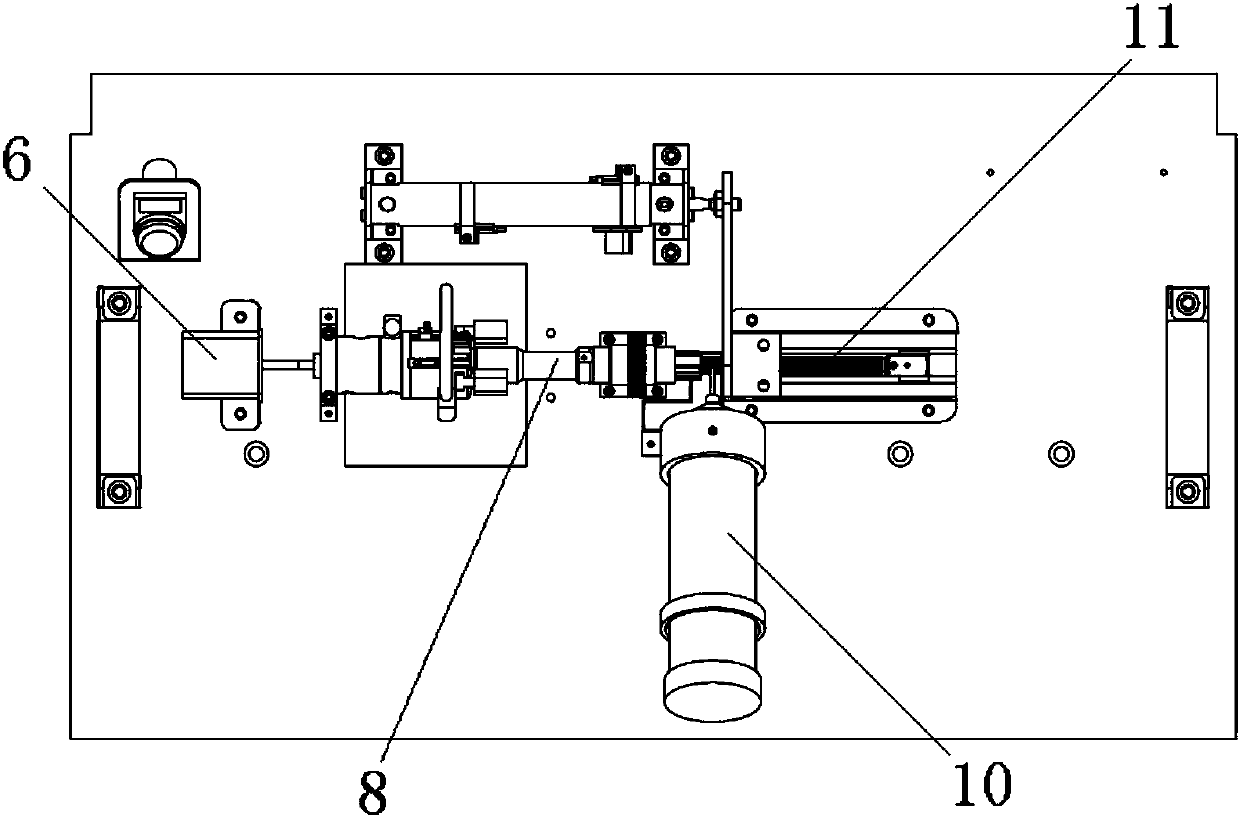

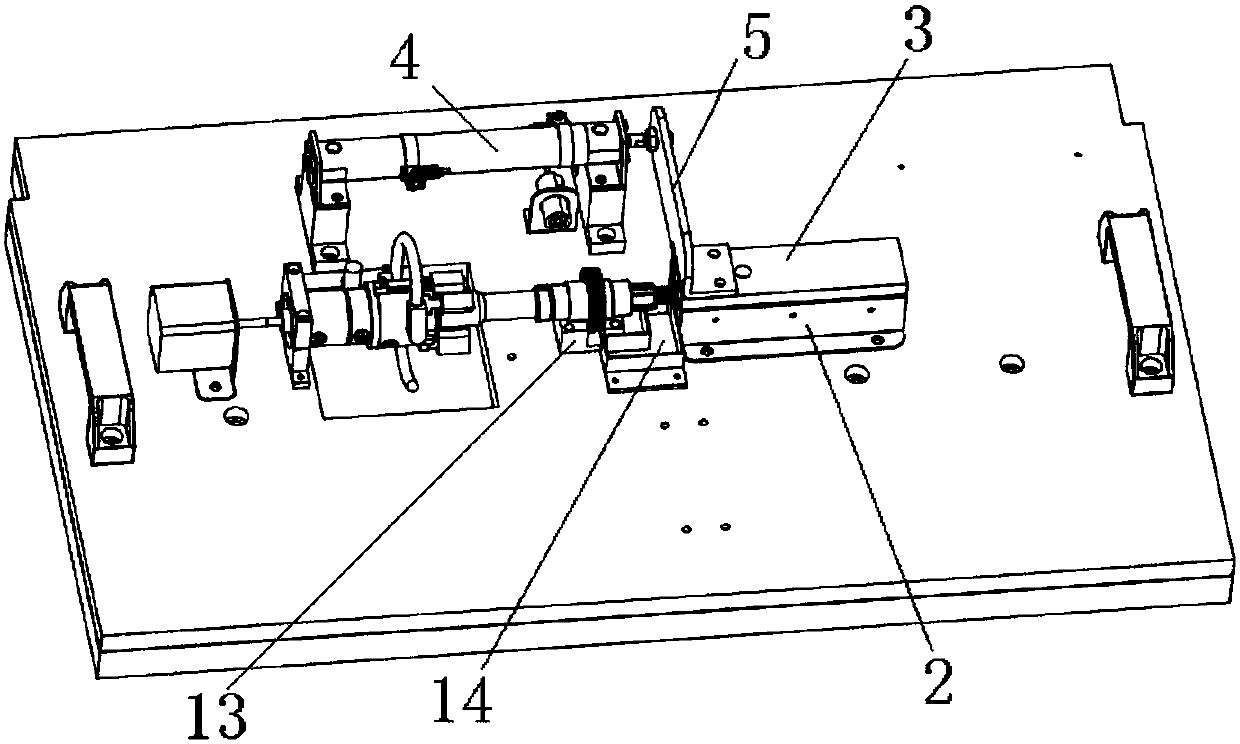

[0025] With reference to the accompanying drawings, the specific implementation of the present invention will be further described in detail through the description of the embodiments.

[0026] Such as Figure 1 to Figure 4 As shown, the tool for grease application of the screw assembly includes a stand, a working platform 1, a motor 6, a dispensing syringe 10, an air claw 7 for gripping the end of the screw sleeve, and a support for limiting the rotation of the screw The screw support 2 of, among which, the working platform 1 is set on the table top of the table, the table frame is a frame structure, the structure is strong, the top of the table is equipped with an illuminating lamp; there is a rubber pad between the table and the working platform Glue protects the mesa and reduces the plane accuracy of the mesa, which facilitates processing and reduces costs.

[0027] The working platform 1 is fixed on the table top of the platform by bolts, and handles are provided at both ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com