Electrical element manufacturing device and method for semiconductor device production

A technology for electrical components and manufacturing devices, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as thick photoresist and high viscosity of photoresist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

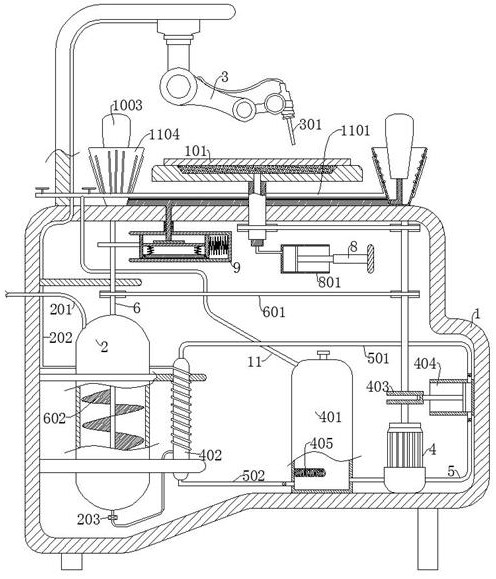

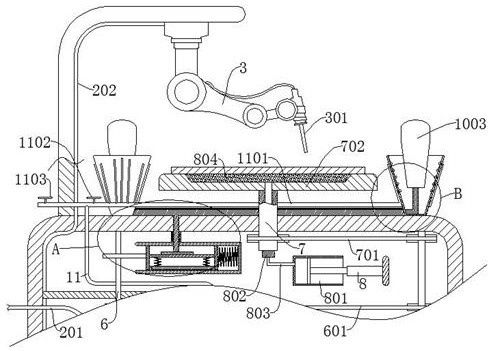

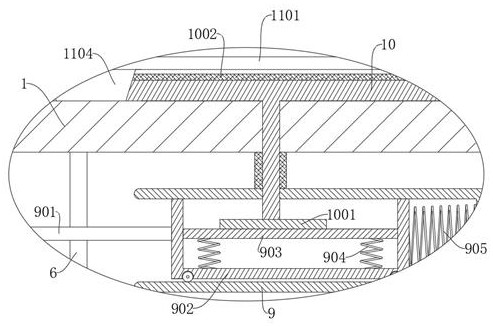

[0030] refer to Figure 1-6 , an electrical component manufacturing device for semiconductor device production, including a box body 1 and a processed product 101, and also includes: a storage tank 2 and a water tank 401, both located in the box body 1; a mechanical arm 3, located at the top of the box body 1; a coating head 301 , connected to the output end of the mechanical arm 3, the processed product 101 is smeared by the smear head 301, and the smear head 301 and the storage tank 2 are transported through the discharge pipe 202; Hot water for heat preservation; the top of the box body 1 is provided with an electrostatic adsorption body 1003, and the bottom of the adsorption body 1003 is covered with a dust receiving cylinder 1104; the nozzle 1105 is connected to the inner wall of the dust receiving cylinder 1104, and the nozzle 1105 is connected to the top of the water tank 401. The water vapor in the water tank 401 is used for dust reduction; wherein, the processed produ...

Embodiment 2

[0033] refer to Figure 1-6 , on the basis of Example 1, further,

[0034]A motor 4, a heat conduction tank 402 and a first piston assembly 404 are also provided in the box body 1. The output end of the motor 4 is connected to a crankshaft 403, and the crankshaft 403 is rotationally connected to the first piston assembly 404. Between the water tank 401 and the first piston assembly 404 The first piston assembly 404 is connected to the top of the heat conducting tank 402 through the second pipeline 501, the bottom of the heat conducting tank 402 is connected to the water tank 401 through the third pipeline 502, and the first pipeline 5 1. Both the second pipeline 501 and the third pipeline 502 are provided with check valves, the heat conduction tank 402 is made of heat conduction material, the discharge pipe 202 is wound on the surface of the heat conduction tank 402, and the water tank 401 is provided with a heating wire 405.

[0035] This embodiment discloses the specific pr...

Embodiment 3

[0038] refer to Figure 1-6 , on the basis of Example 2, further,

[0039] The top of the box body 1 is rotatably connected with a rotating rod 7, and the top of the rotating rod 7 is fixedly connected with a workbench 702. The workbench 702 is provided with a suction cup 804, and the processed product 101 is placed on the suction cup 804. The rotating rod 7 and the output end of the motor 4 pass through The second belt 701 is connected.

[0040] The casing 1 is provided with a cylinder 8 and a second piston assembly 801, the output end of the cylinder 8 is connected with the second piston assembly 801, the second piston assembly 801 is connected with the suction cup 804 through the sixth pipeline 803, and the sixth pipeline 803 is provided with a swivel joint 802, and the swivel joint 802 is connected to the bottom of the swivel rod 7.

[0041] This embodiment discloses the fixing method of the processed product 101. The processed product 101 is placed on the suction cup 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com