Clinker Container Loading System

A container and clinker technology, applied in loading/unloading, transportation and packaging, stacking of objects, etc., can solve the problems of dust pollution, equipment accumulation of dust, dust flying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A number of embodiments of the present invention will be disclosed in the following figures. For the sake of clarity, many practical details will be described together in the following description. It should be understood, however, that these practical details should not be used to limit the invention. That is, in some embodiments of the invention, these practical details are not necessary. In addition, for the sake of simplifying the drawings, some well-known structures and components are shown in a simple schematic manner in the drawings.

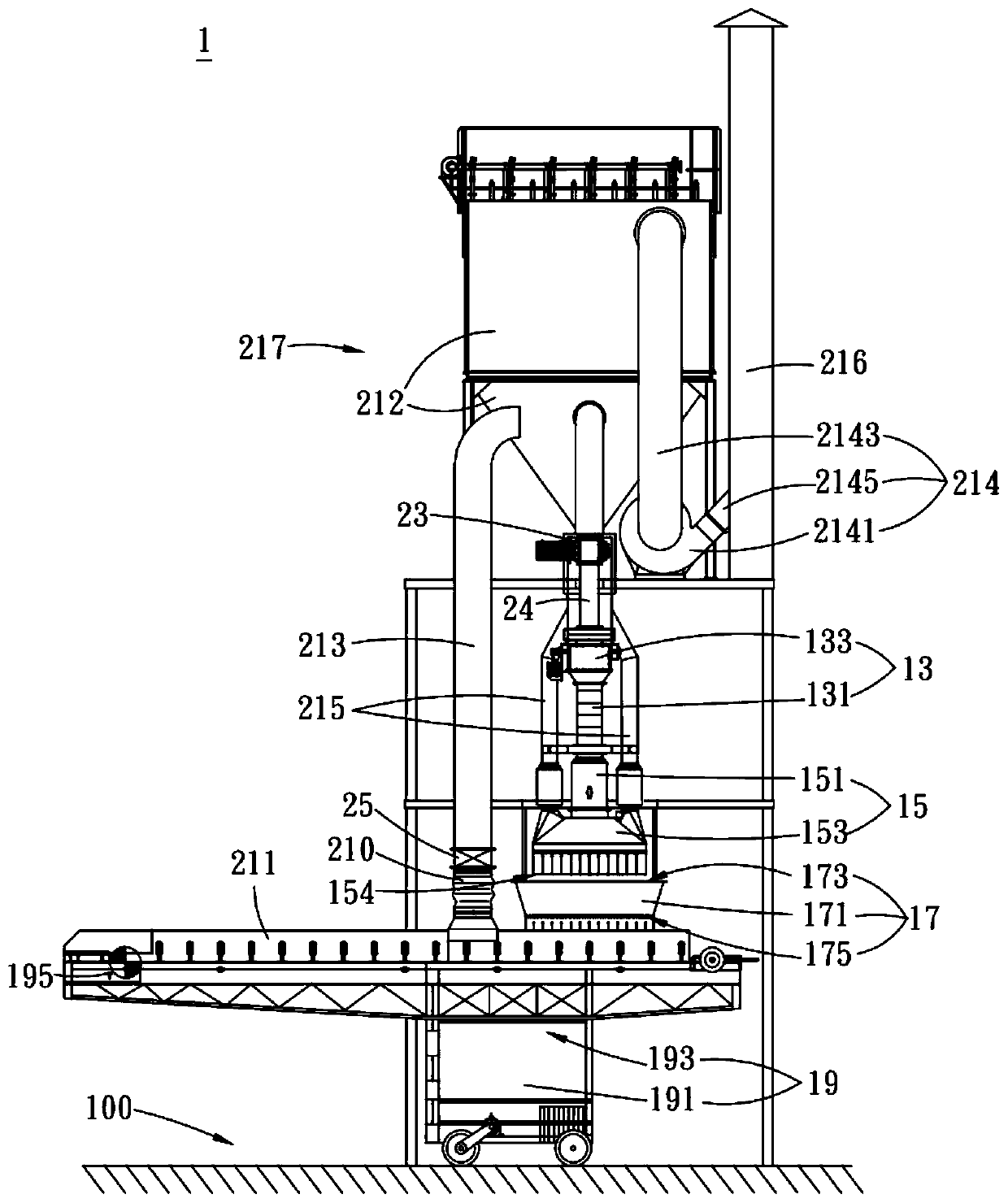

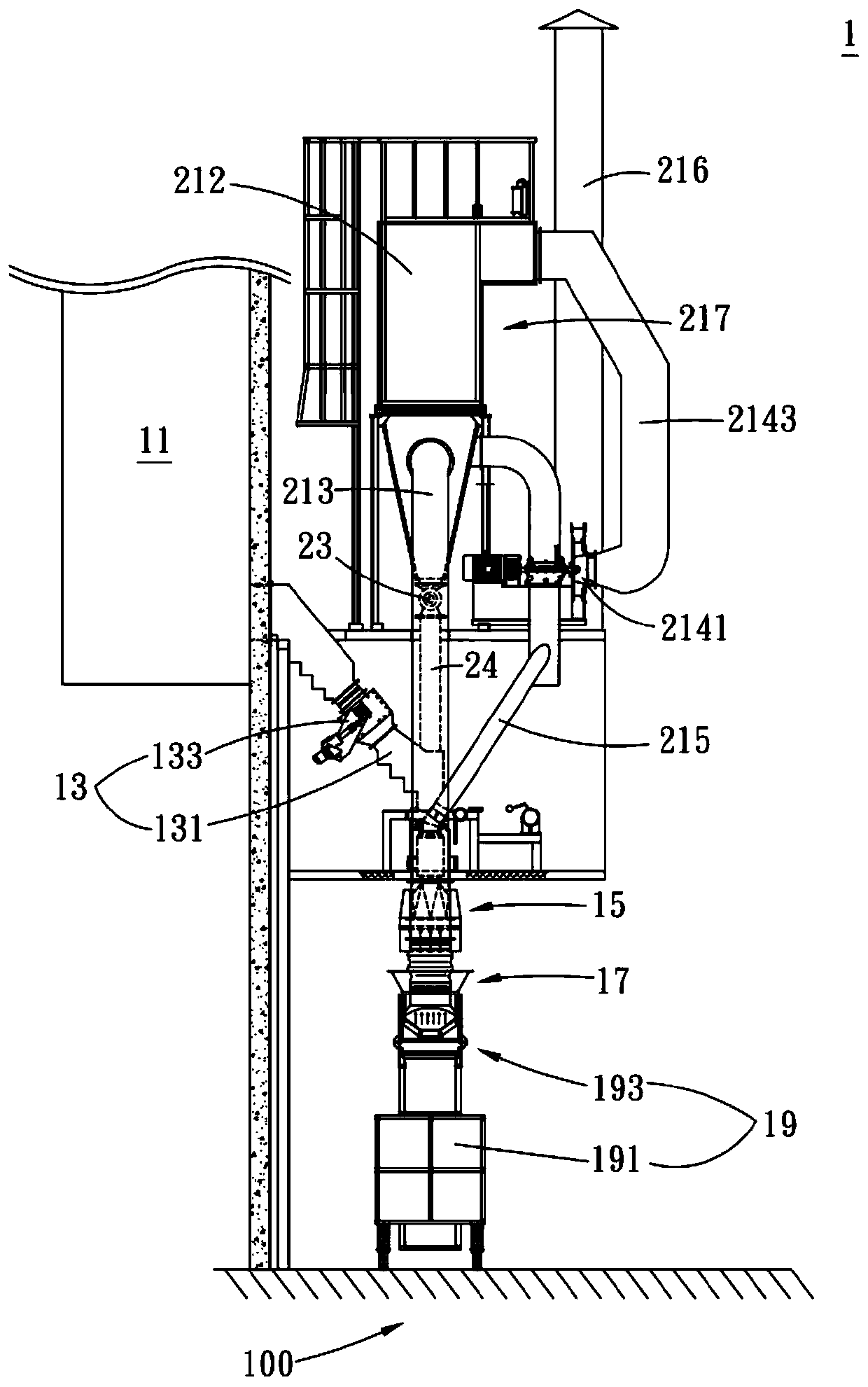

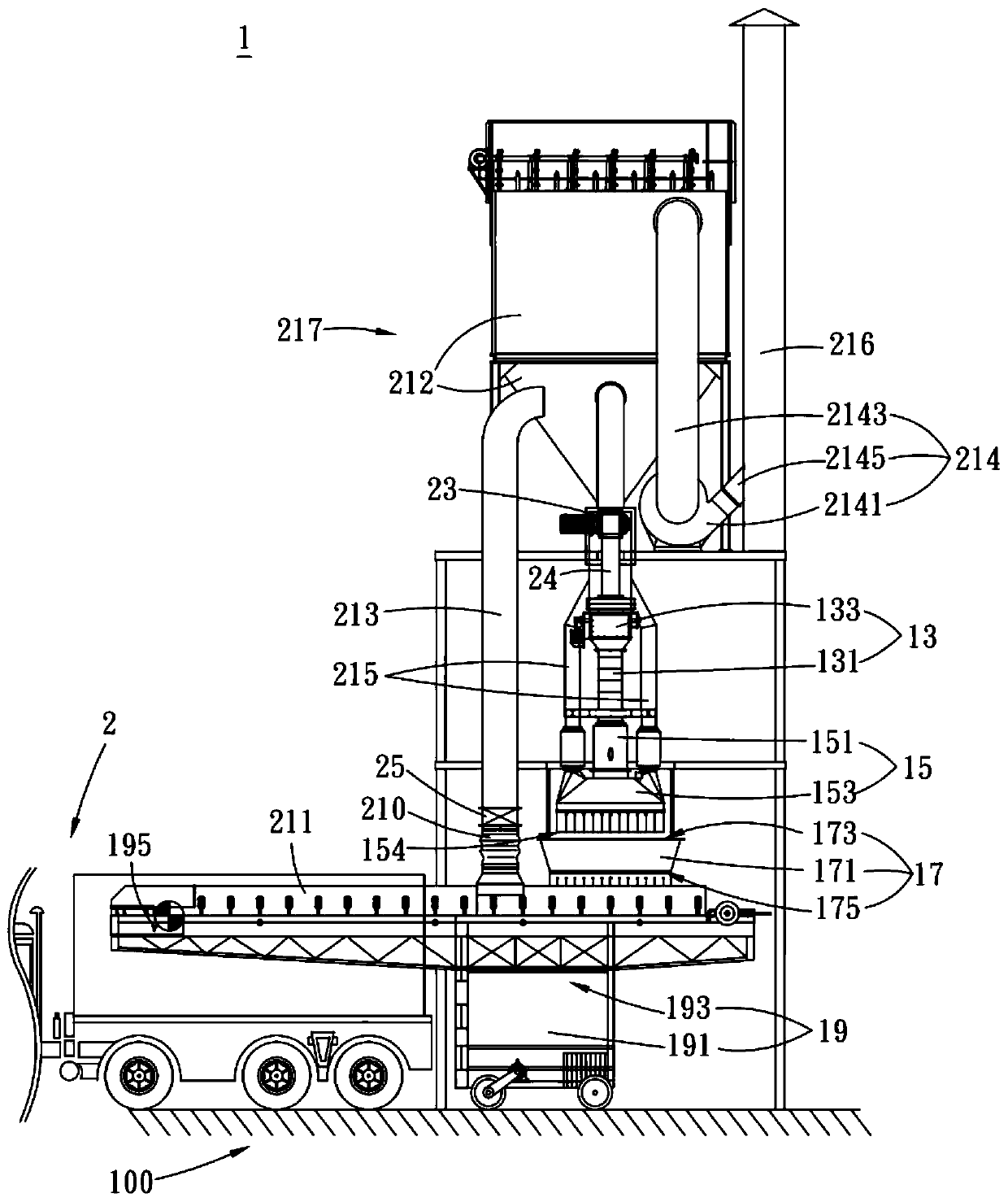

[0020] see figure 1 and figure 2 , which is a schematic diagram and a side view of the clinker container loading system of the present invention. As shown in the figure, this embodiment provides a clinker container loading system 1, which is used for the clinker loading operation, and can reduce the generation of dust during the clinker loading operation, making the working environment less Will be affected by dust. The clink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com