Photosensitive adhesive detecting and repairing device

A technology of photosensitive glue and casing, which is applied in the direction of optics, optomechanical equipment, instruments, etc., and can solve problems such as too thick coating, poor control of photosensitive glue, and low quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The embodiment is basically as follows:

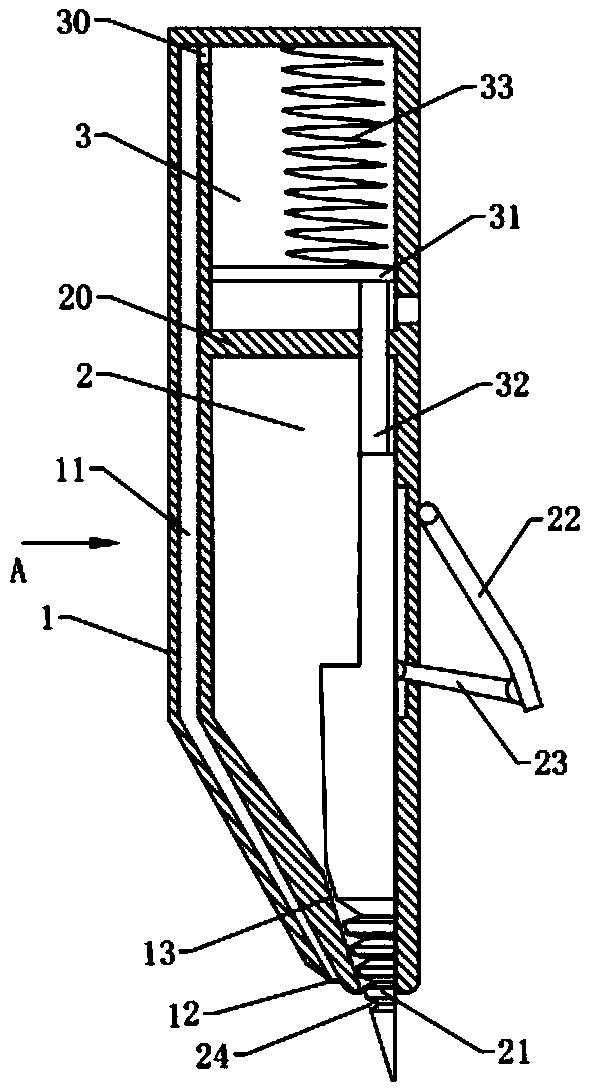

[0028] Sensitive adhesive testing and repairing devices, such as figure 1 and figure 2 As shown, it includes a casing 1, a repair mechanism and a cleaning mechanism. The casing 1 is cylindrical, and there are two upper and lower chambers separated by a partition 20 in the casing 1. The upper and lower chambers are respectively air chambers. 3 and reservoir chamber 2. The lower end of the liquid storage chamber 2 is provided with an opening, and the side wall of the lower part of the housing 1 is inclined to transition to the opening to form a funnel shape.

[0029] The repair mechanism is used to repair the photosensitive glue and the mesh, mainly including the tip 21 and the pressing part, the right side of the tip 21 is provided with a chute, the liquid storage chamber 2 is fixed with a slide rail, and the tip 21 passes through the chute 1. The slide rail is slidingly connected with the inner wall of the liquid storage cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com