Device capable of improving anti-corrosion performance of surface of water treatment filter plate

A filter plate and water treatment technology, which is applied in the field of equipment to improve the anti-corrosion performance of the water treatment filter plate surface, can solve the problems affecting the coating quality and scraping efficiency of the filter plate, low scraping efficiency and poor quality of the filter plate coating, and achieve Improve the quality of smearing, improve the quality of scraping, and improve the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

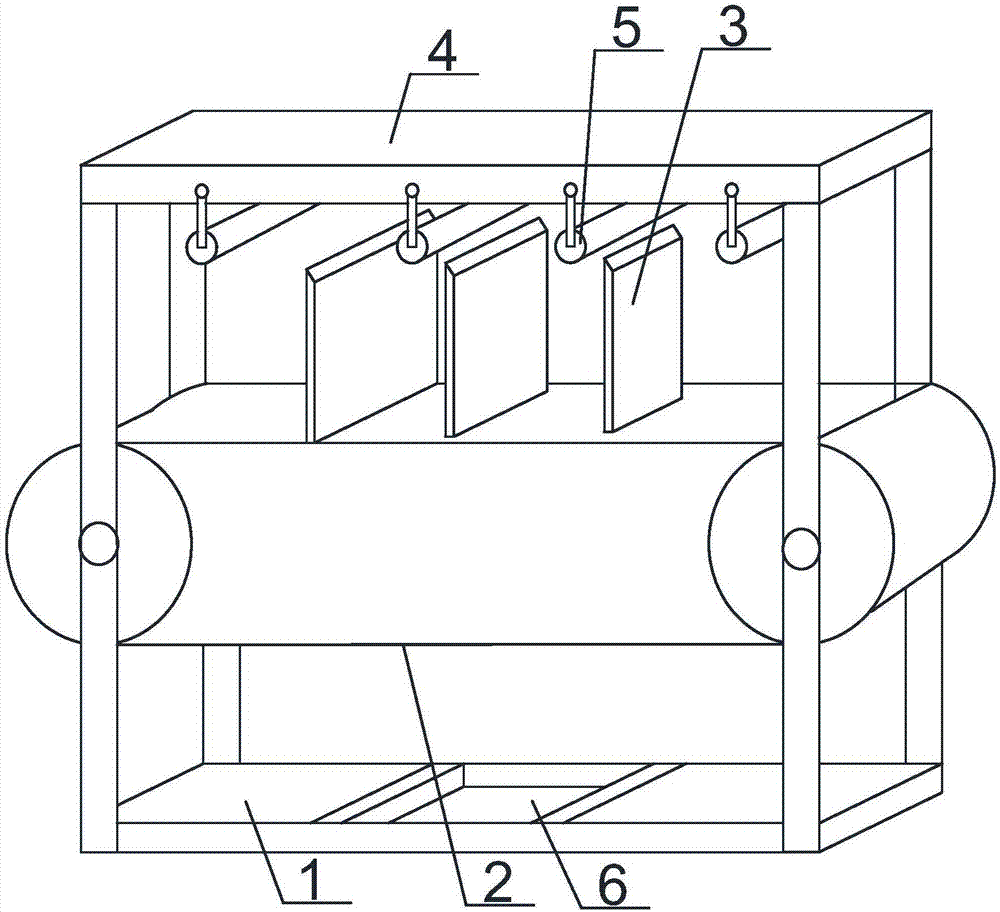

[0022] Such as figure 1 As shown, the present invention can improve the equipment of water treatment filter plate surface anticorrosion performance, comprise the horizontal plate 1 that places filter plate, the belt conveyor belt 2 that transmission surface is parallel with horizontal plate 1 plate surface is connected above the horizontal plate 1, the belt conveyor belt 2 is provided with a plurality of scrapers 3, all scrapers 3 are arranged in parallel in the transmission direction of the belt conveyor 2, the scrapers 3 are perpendicular to the belt conveyor 2, and the transmission direction of the belt conveyor 2 is used as a reference, the belt conveyor The surface area of the scrapers 3 arranged from front to back on the top 2 gradually increases, and the side of the scrapers 3 in contact with the filter plate is set as an inclined surface, and the inclined surface is located in front of the scrapers 3 .

[0023] In the prior art, a scraper is generally used to scrape ...

Embodiment 2

[0025] Based on Embodiment 1, the top of the belt conveyor 2 is provided with a fixed plate 4 parallel to the horizontal plate 1, and the bottom of the fixed plate 4 is provided with a plurality of cylinders 5 arranged in parallel along the direction of the belt conveyor 2, and all cylinders 5 are placed horizontally , the central axis of the drum 5 is perpendicular to the center line of the conveying direction of the belt conveyor 2, the outer of the drum 5 is wrapped with cotton cloth for scrubbing the paint on the inclined surface of the scraper 3, and the two ends of the drum 5 and the fixed plate 4 rotate through the shaft Connected, the roller 5 swings forward and backward along the rotating shaft in the conveying direction of the belt conveyor 2 . The cotton cloth is coarse cotton cloth.

[0026] Driven by the conveyor belt, the scraper moves in a circular motion. After the scraper that has scraped the paint moves to the upper conveying surface, it will pass through a r...

Embodiment 3

[0028] Based on the above embodiment, the horizontal plate 1 is provided with a plurality of grooves 6 for placing filter plates, and all the grooves 6 are arranged in sequence along the conveying direction of the belt conveyor 2 . A hard sponge pad is installed on the horizontal plate 1 between the adjacent grooves 6, and the hard sponge pad and the horizontal plate 1 are fixed by a spring connection. The grooves are used to hold the filter plate in place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com