A method for making an exterior wall imitating the texture of rammed earth and a device for making a surface with rammed earth paint

A paint and rammed earth technology, which is applied in the field of rammed earth paint surface device, can solve the problems of inability to achieve ornamental effect, long construction period of building exterior wall coating, and many manpower, so as to improve the texture of imitation rammed earth, improve the quality of painting, and improve the authenticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

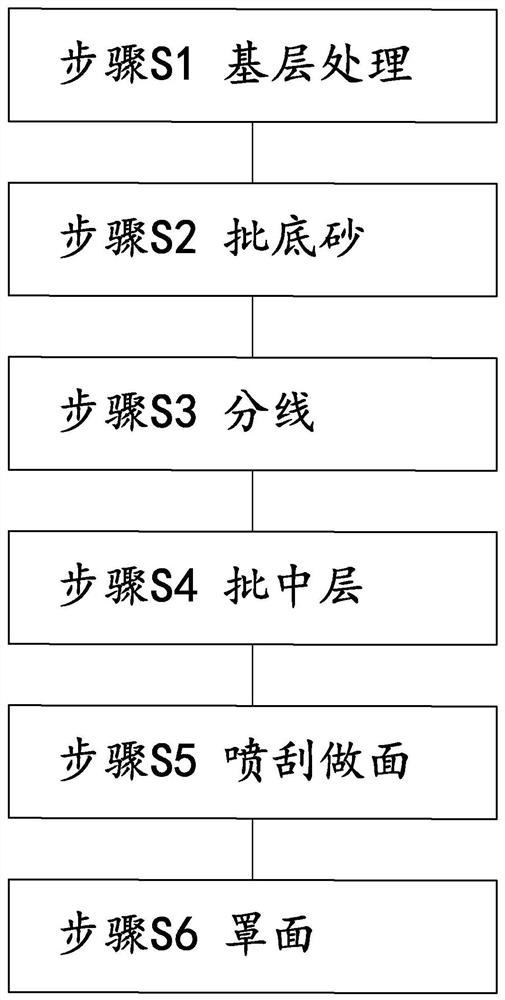

[0024] A method for making an exterior wall imitating the texture of rammed earth, comprising the following steps: Step S1, base treatment: apply special putty for exterior walls with a spatula and a polishing trowel, so that a putty layer is formed on the surface of the exterior wall. The putty layer fills the depressions on the surface of the outer wall to improve the smoothness of the surface. In addition, the putty layer also has the effect of preventing surface cracks, preventing the outer wall from shelling, falling off or water seepage on the wall due to cracks. In this embodiment, the putty layer includes a primary bottom layer and a secondary surface layer. The secondary surface layer can further repair the problems of the primary bottom layer and improve the overall application quality of the putty layer. After the scraping of the secondary surface layer is completed, it needs to be inspected and repaired to ensure the cleanliness of the secondary surface, and after i...

Embodiment 2

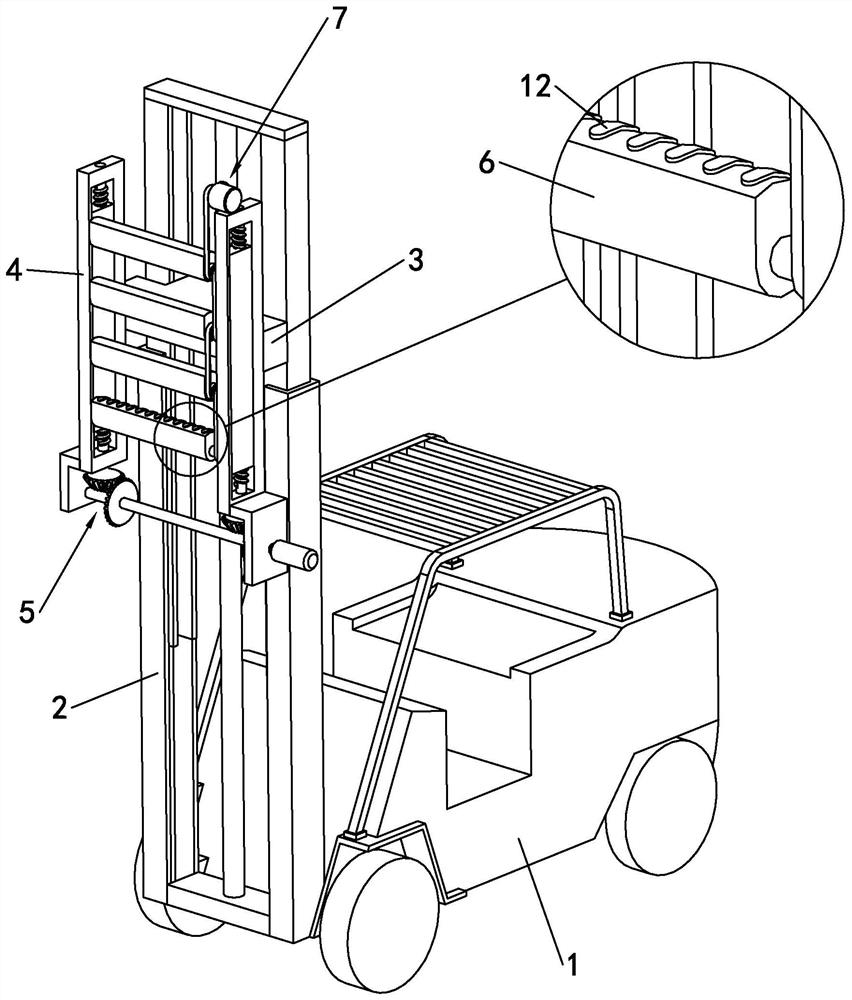

[0031]A surface-making device with rammed earth paint, which is used to process the process of step S5, including a moving car body 1, which can quickly move the device to a position where the surface needs to be made with rammed earth paint, so as to improve the working efficiency of the device efficiency. The front end of the mobile car body 1 is provided with a lifting platform 2, and a vertically arranged rotating platform 3 is installed on the lifting platform 2. In this embodiment, the rotating platform 3 is a hollow rotating platform 3, which has high working efficiency, high precision and high rigidity. advantage. A mounting frame 4 is provided on the rotating platform 3 , and the shape of the mounting frame 4 in this embodiment is rectangular, and screw drive assemblies 5 are provided on both sides of the mounting frame 4 . In this embodiment, the screw drive assembly 5 includes a screw with two ends rotatably connected to the mounting bracket 4 and a servo motor to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com