Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Improve material efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

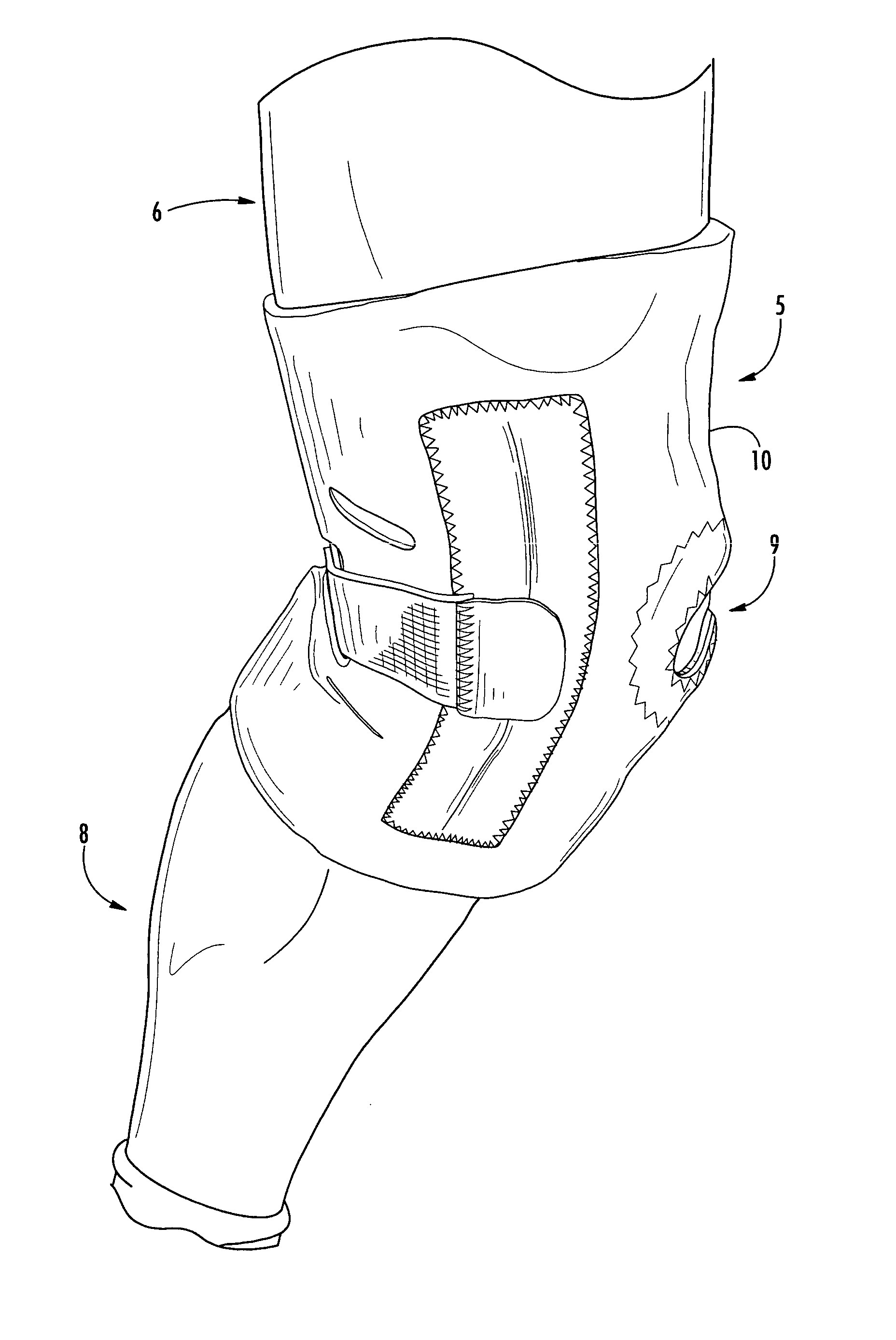

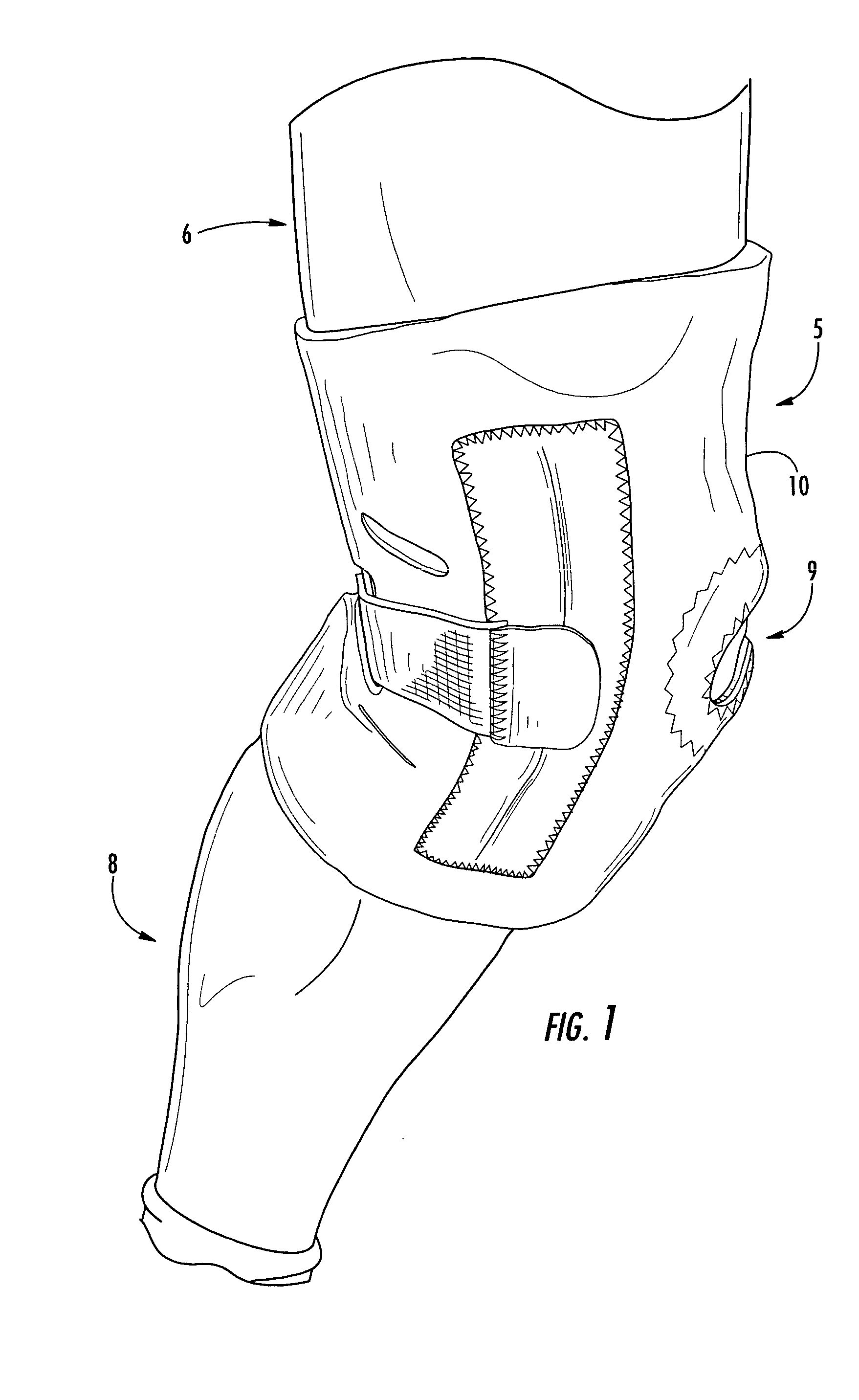

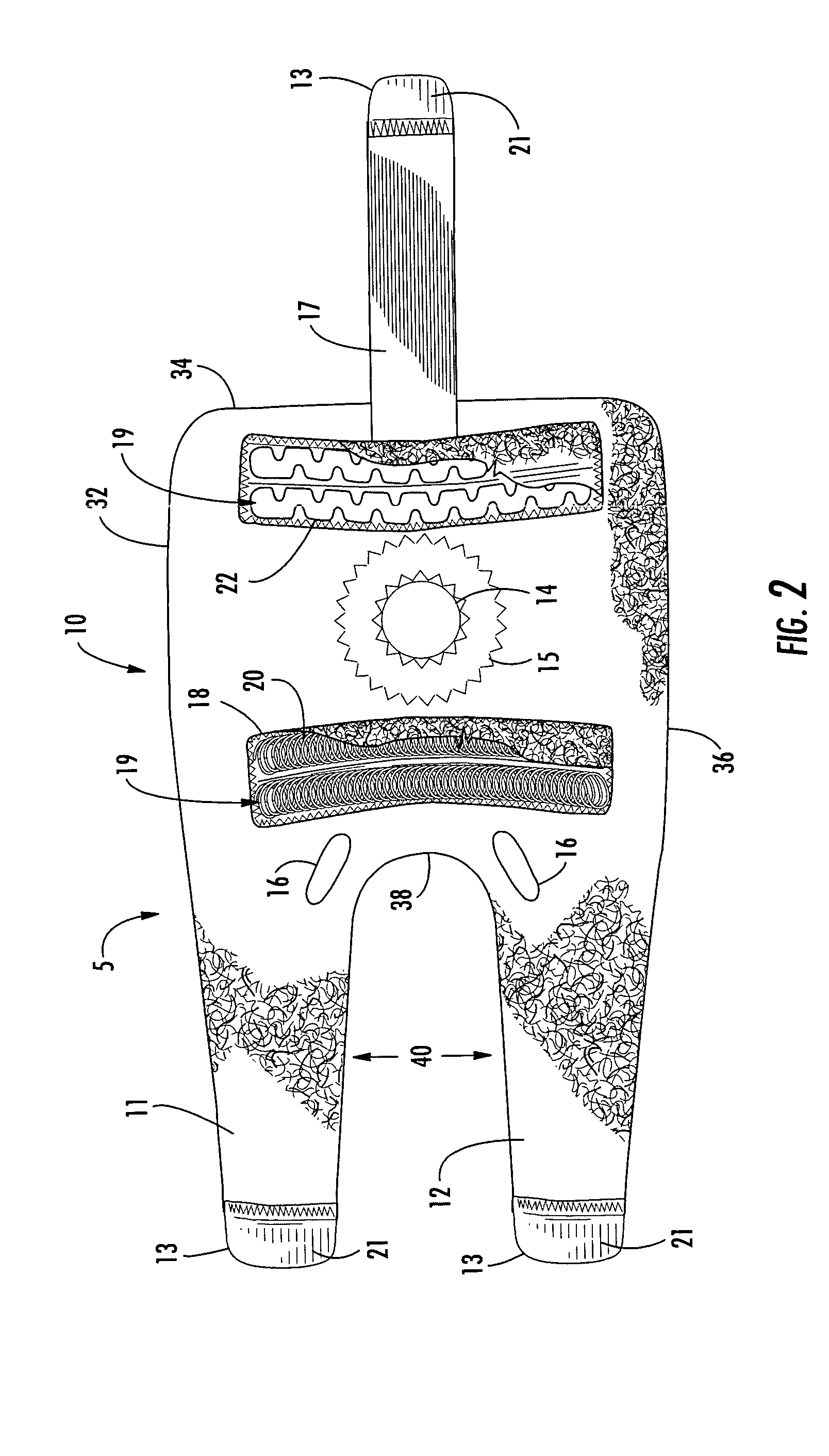

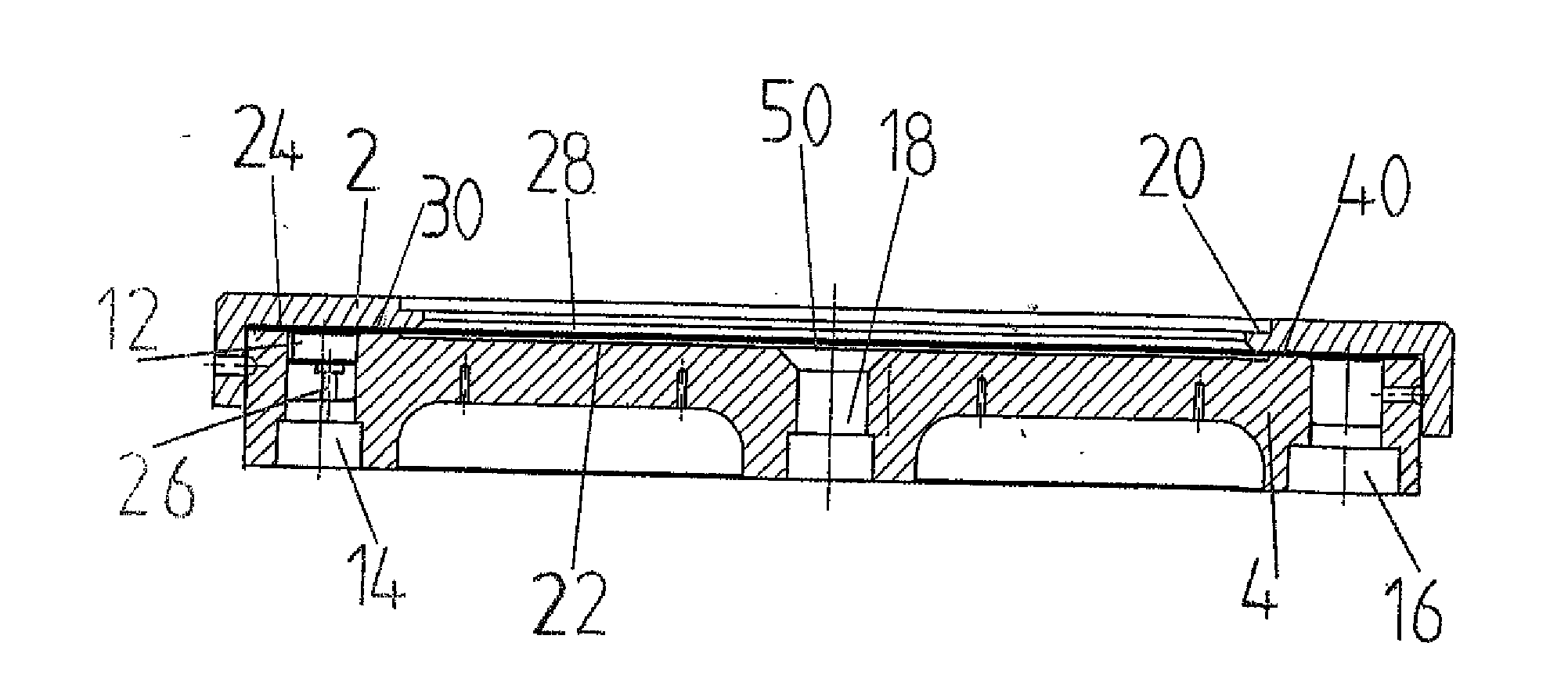

Adjustable knee stabilizer

InactiveUS20050038367A1Efficient use ofImprove material efficiencyNon-surgical orthopedic devicesEngineeringNormal flexion

Owner:BEIERSDORF INC

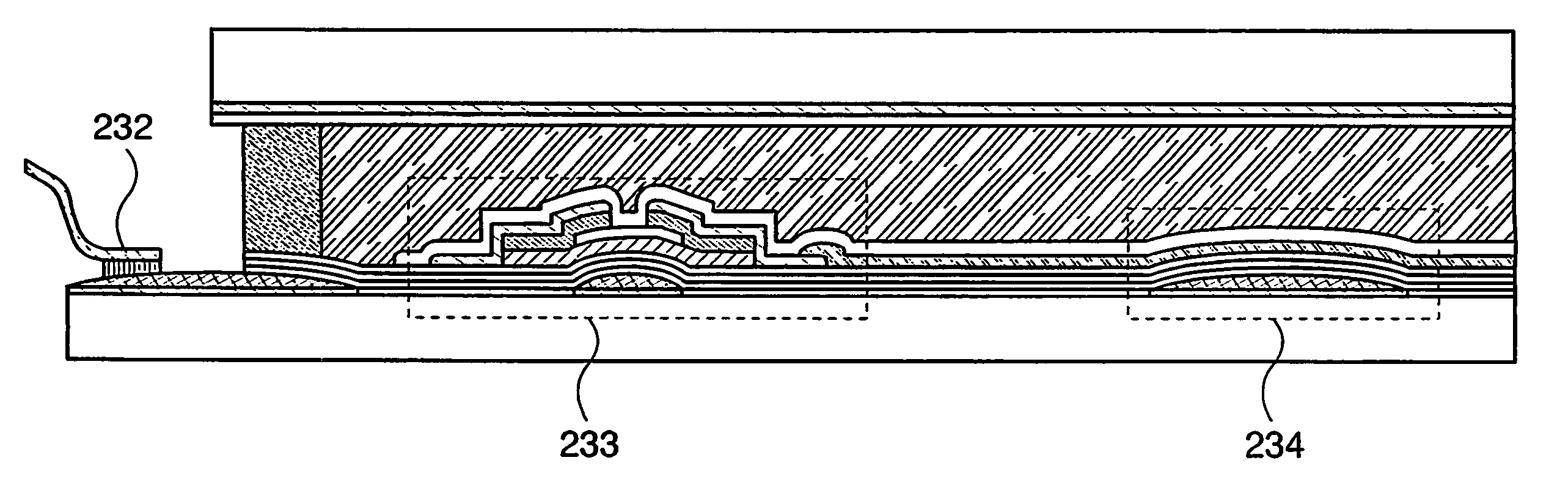

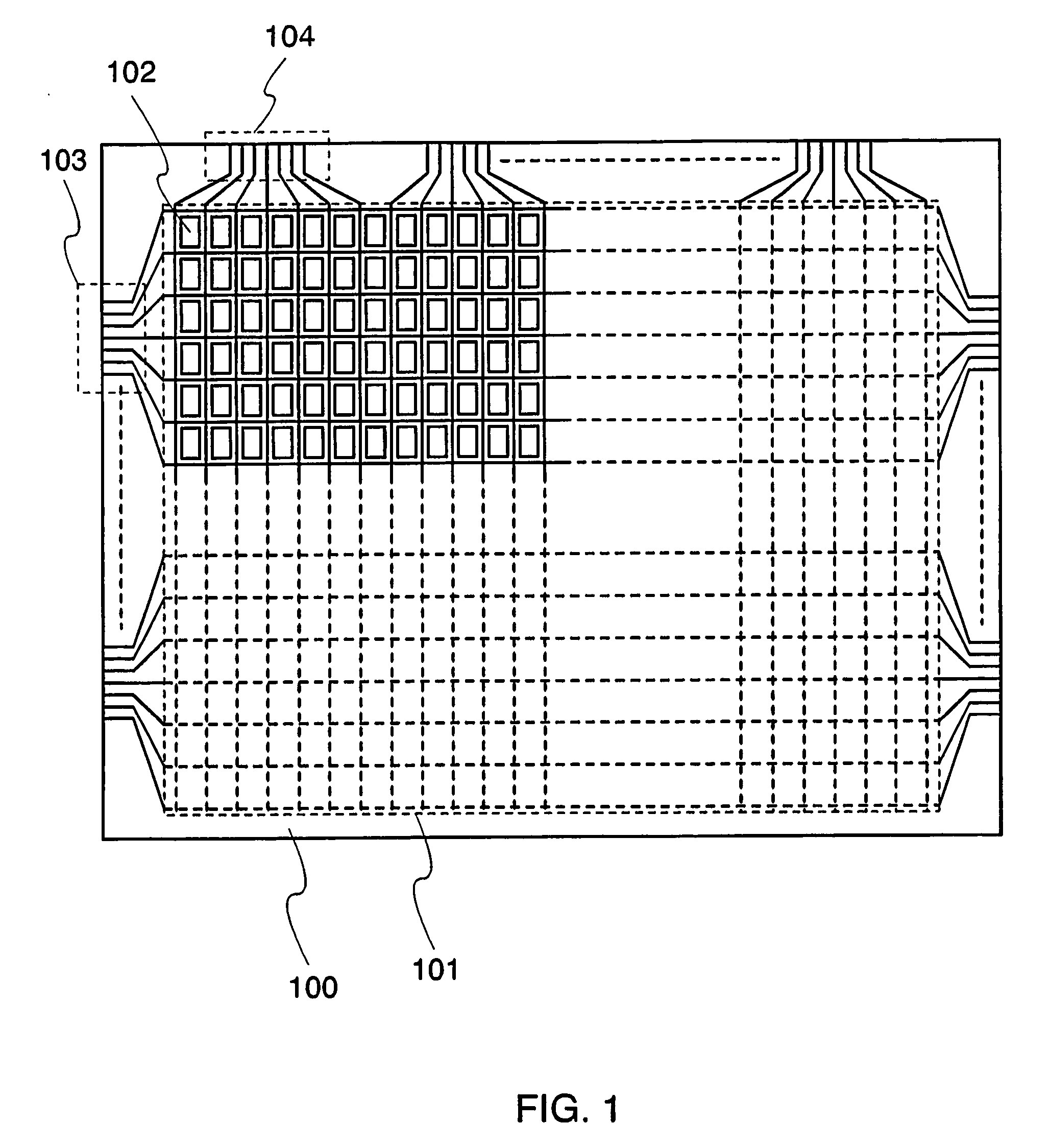

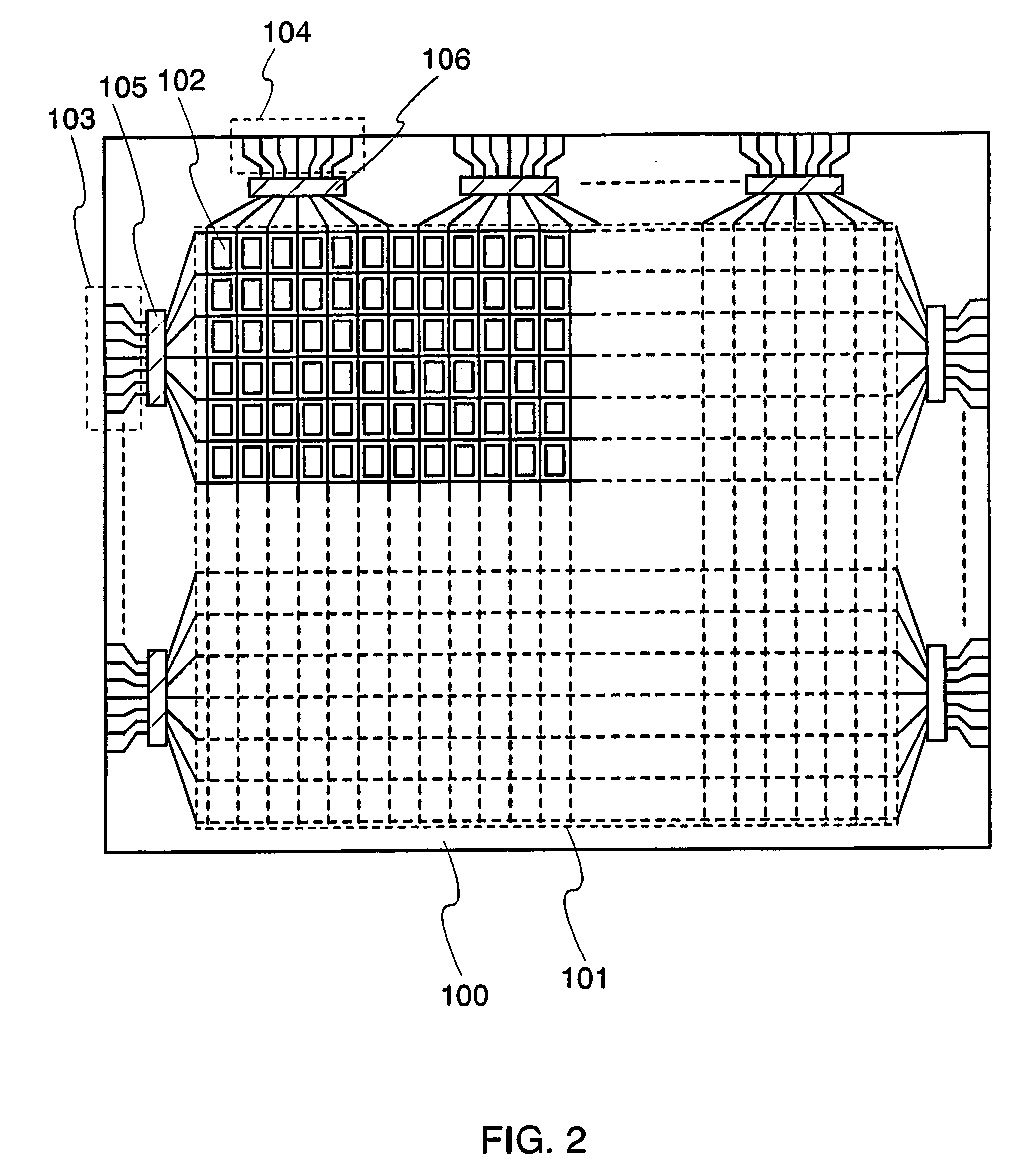

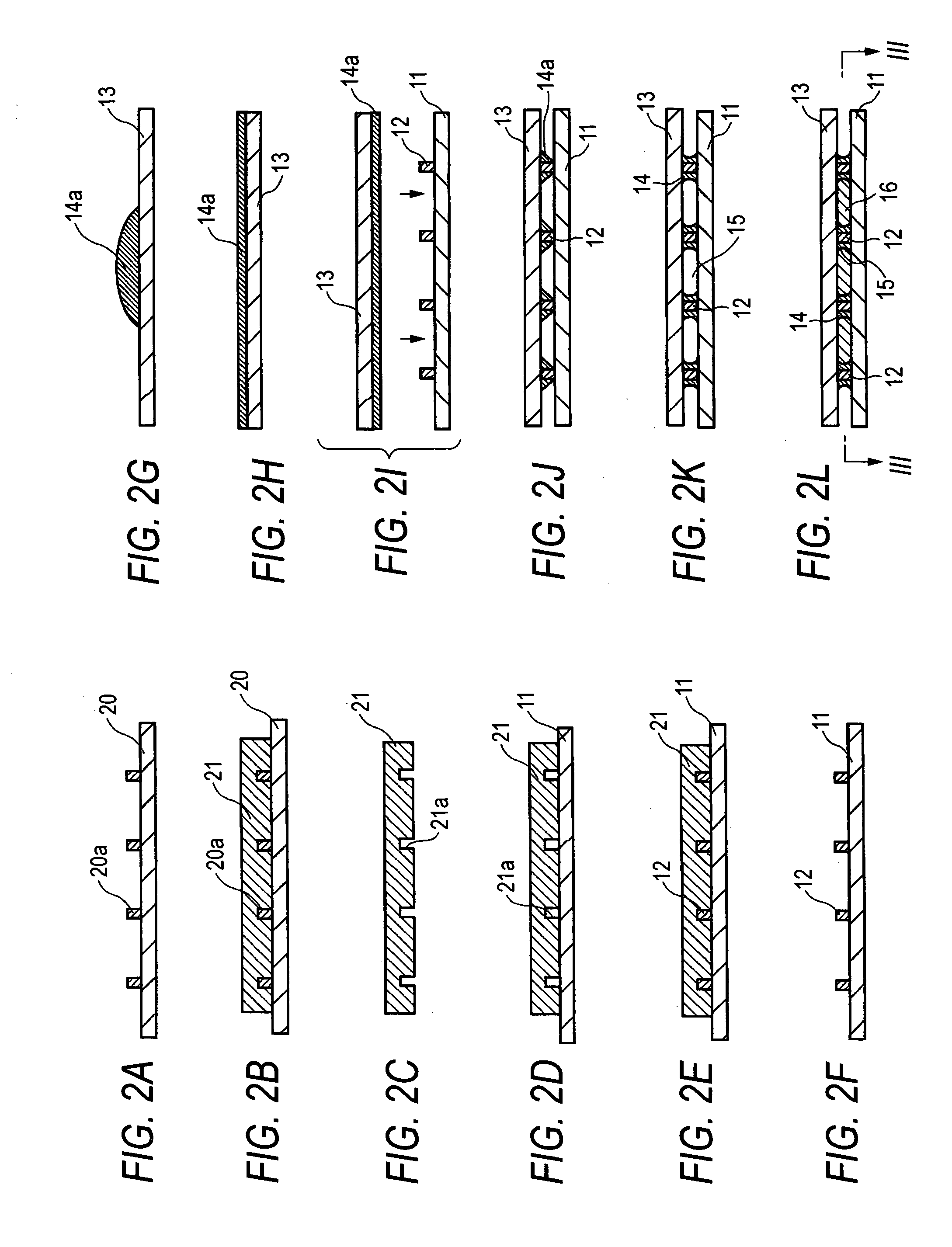

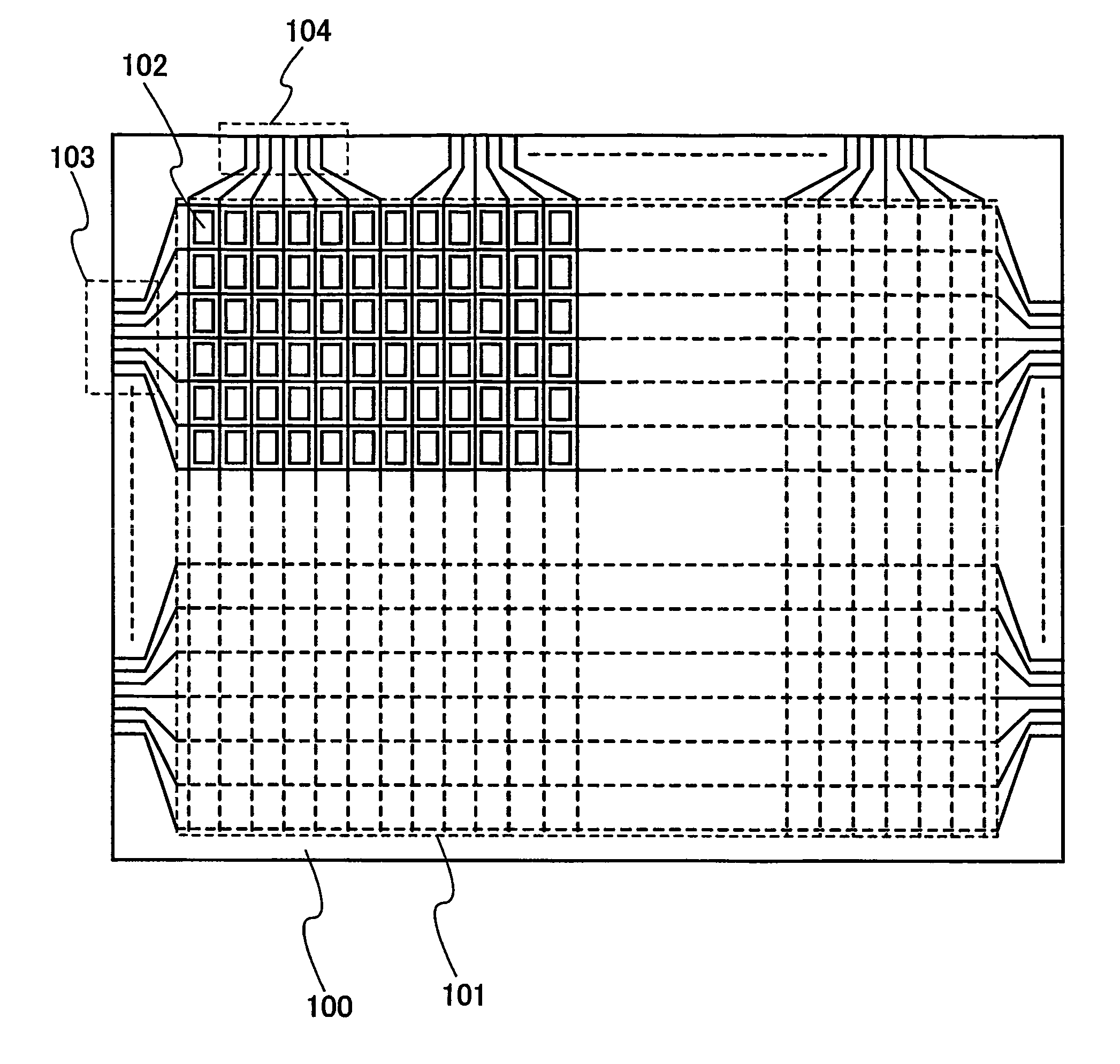

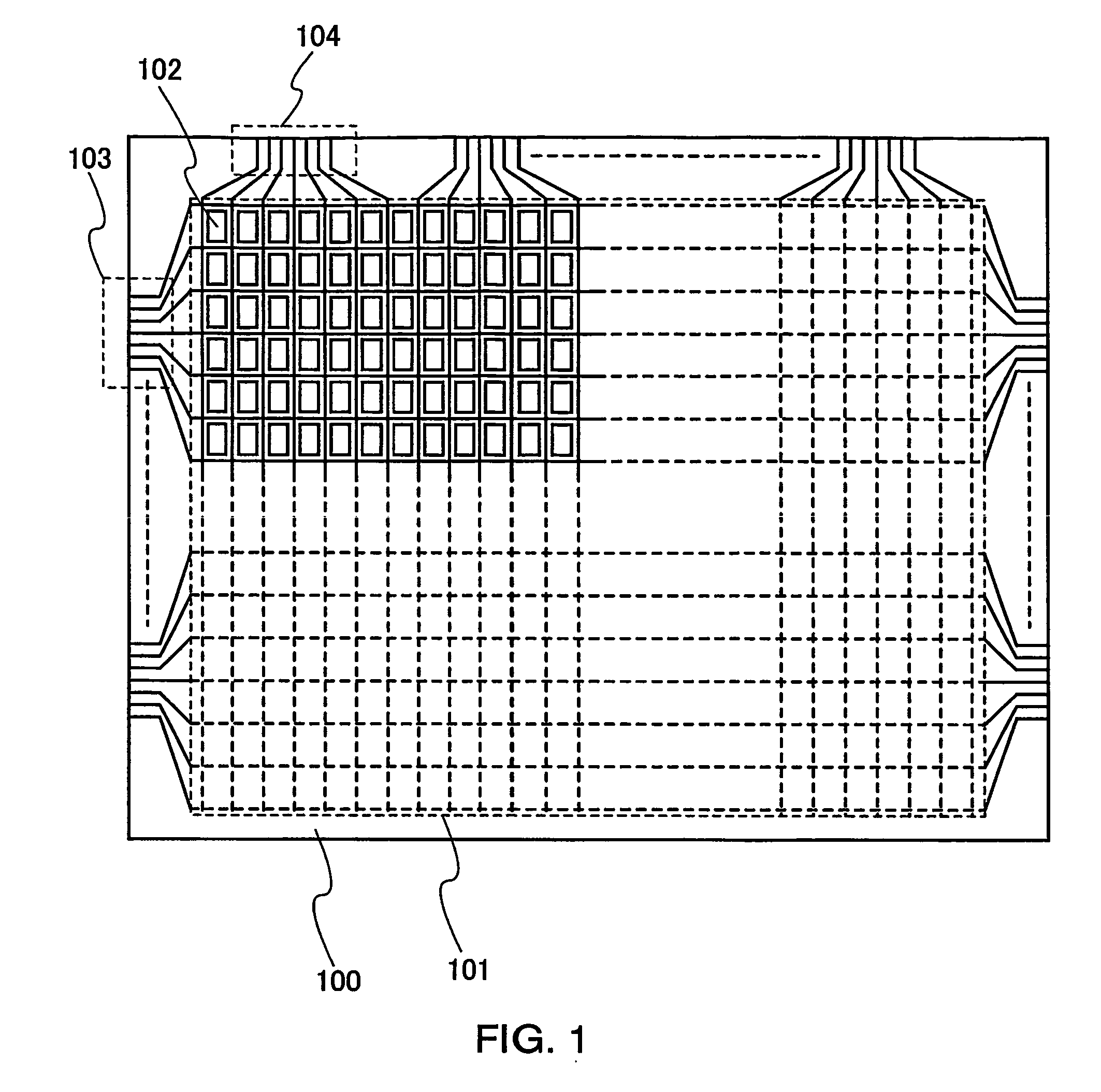

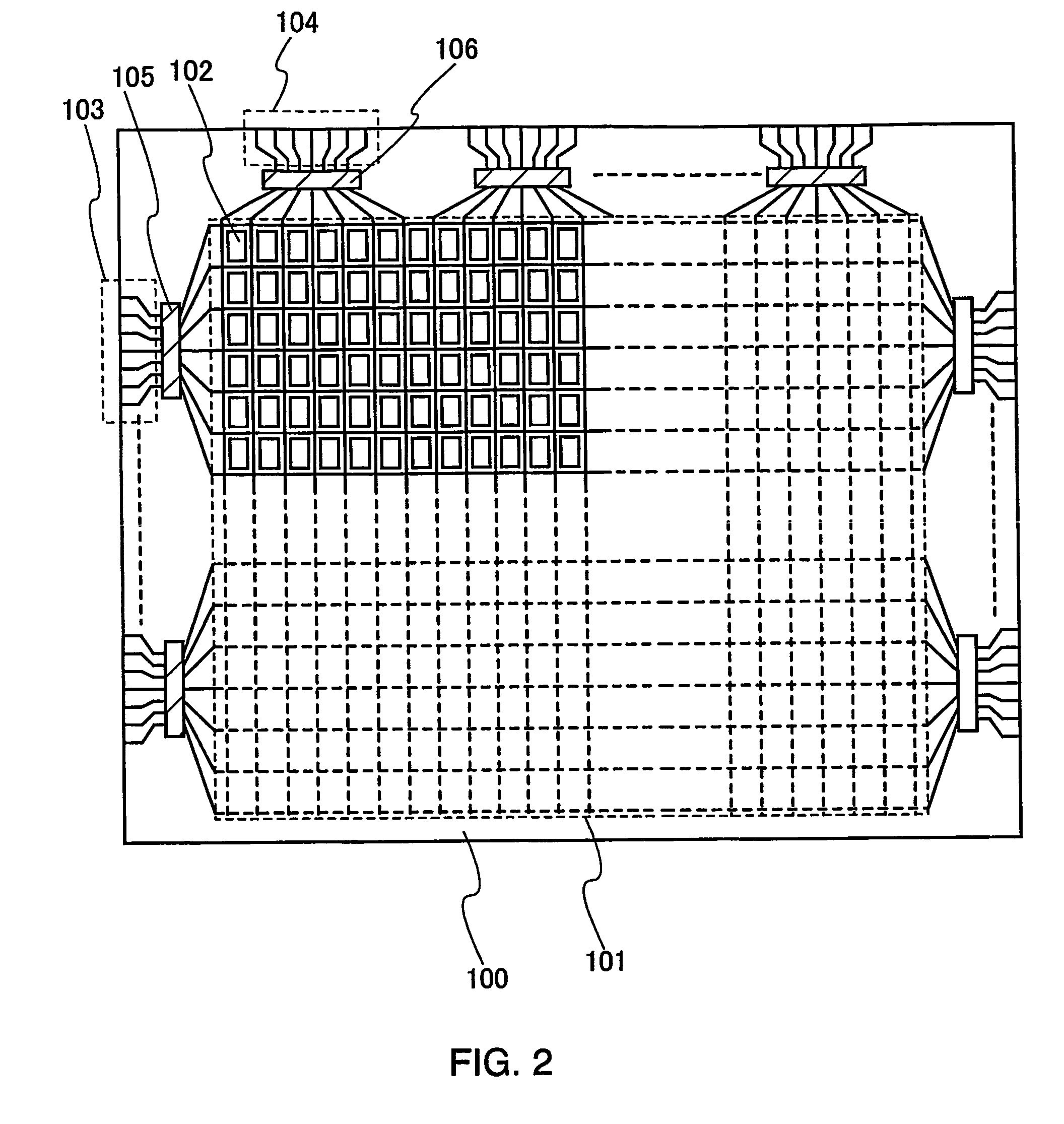

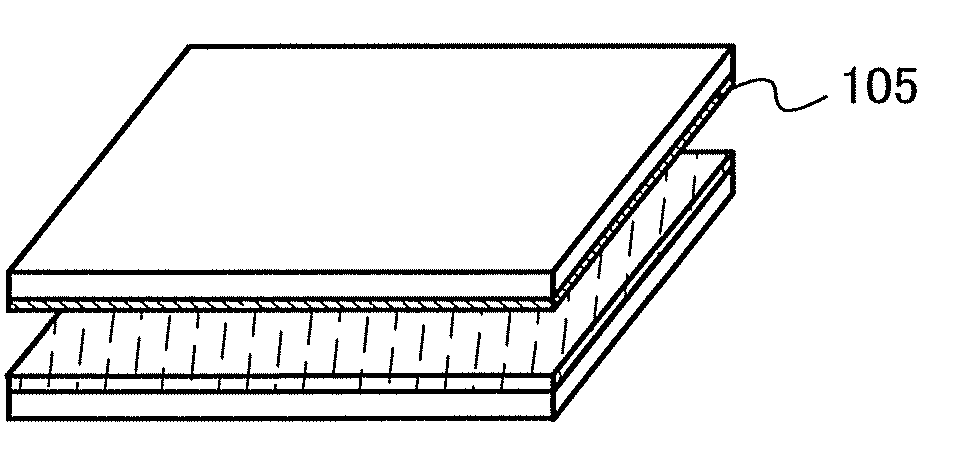

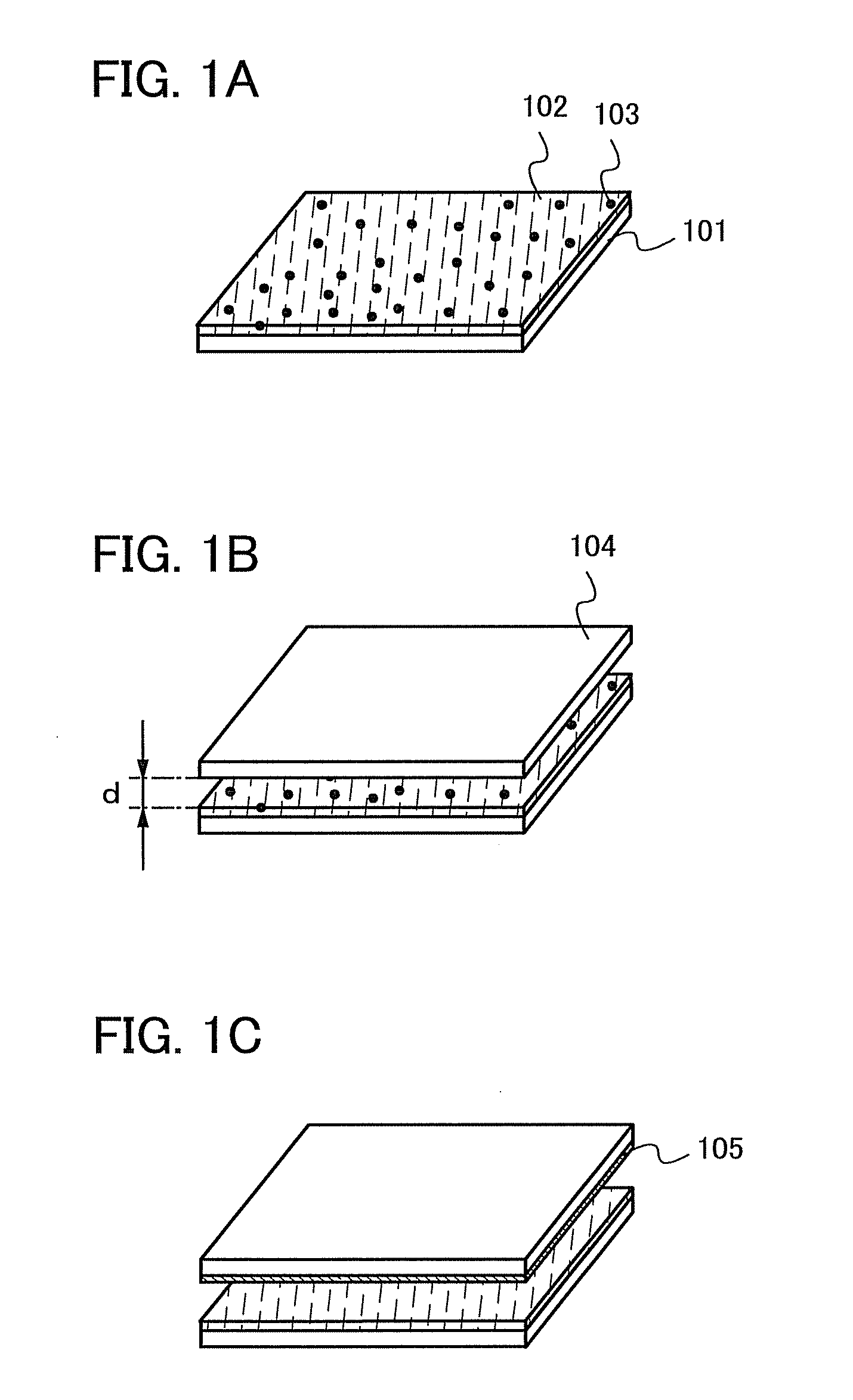

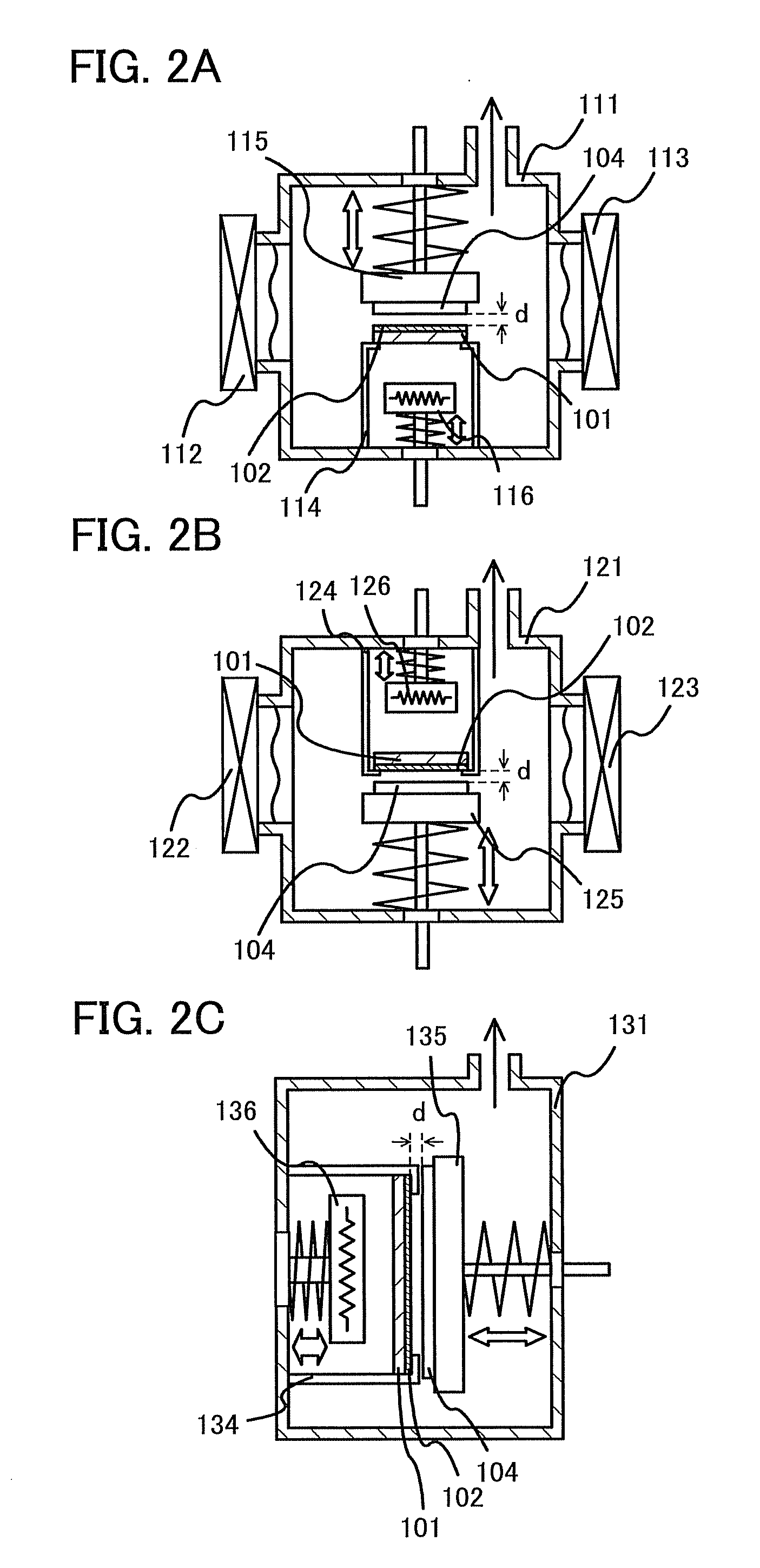

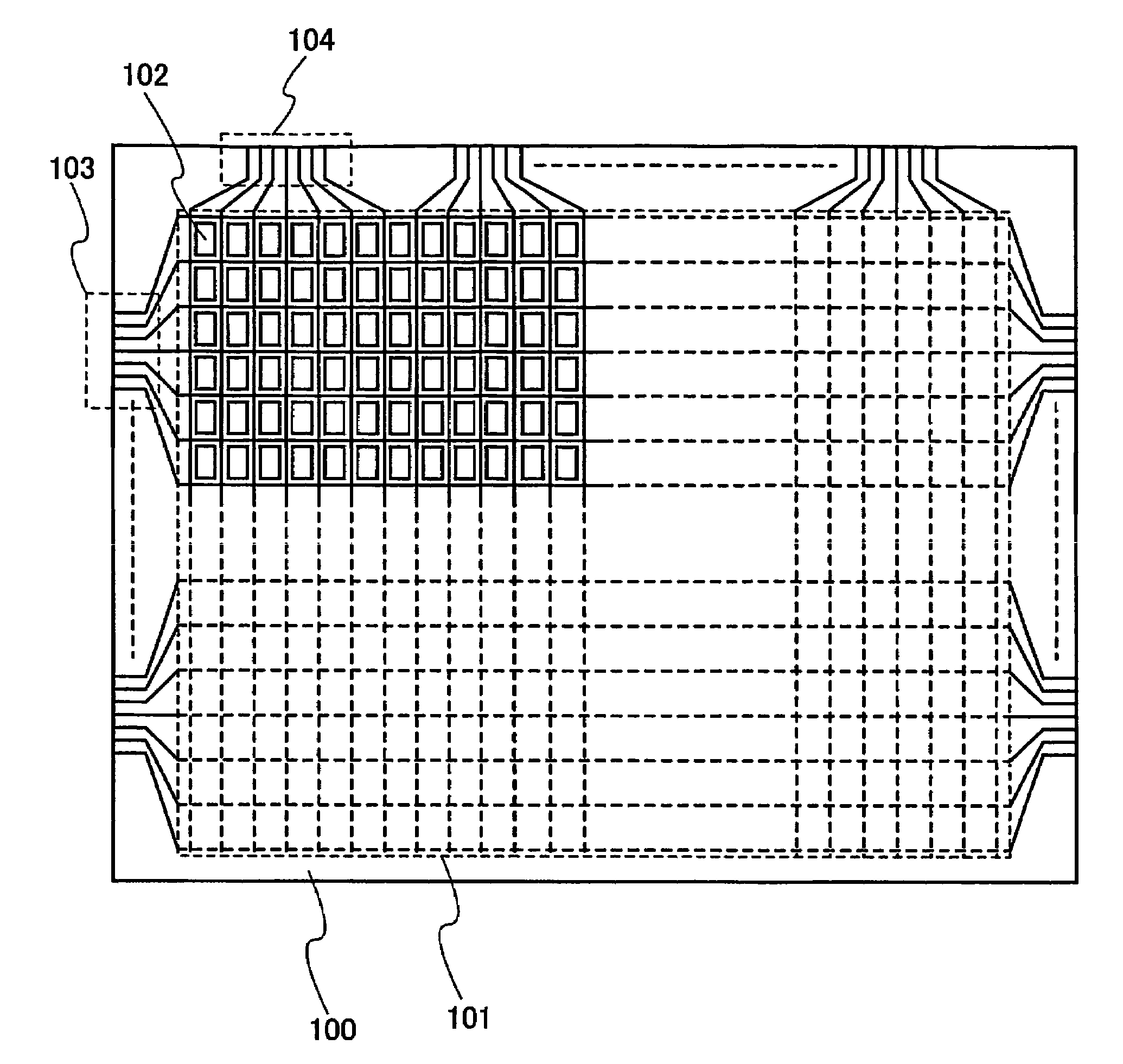

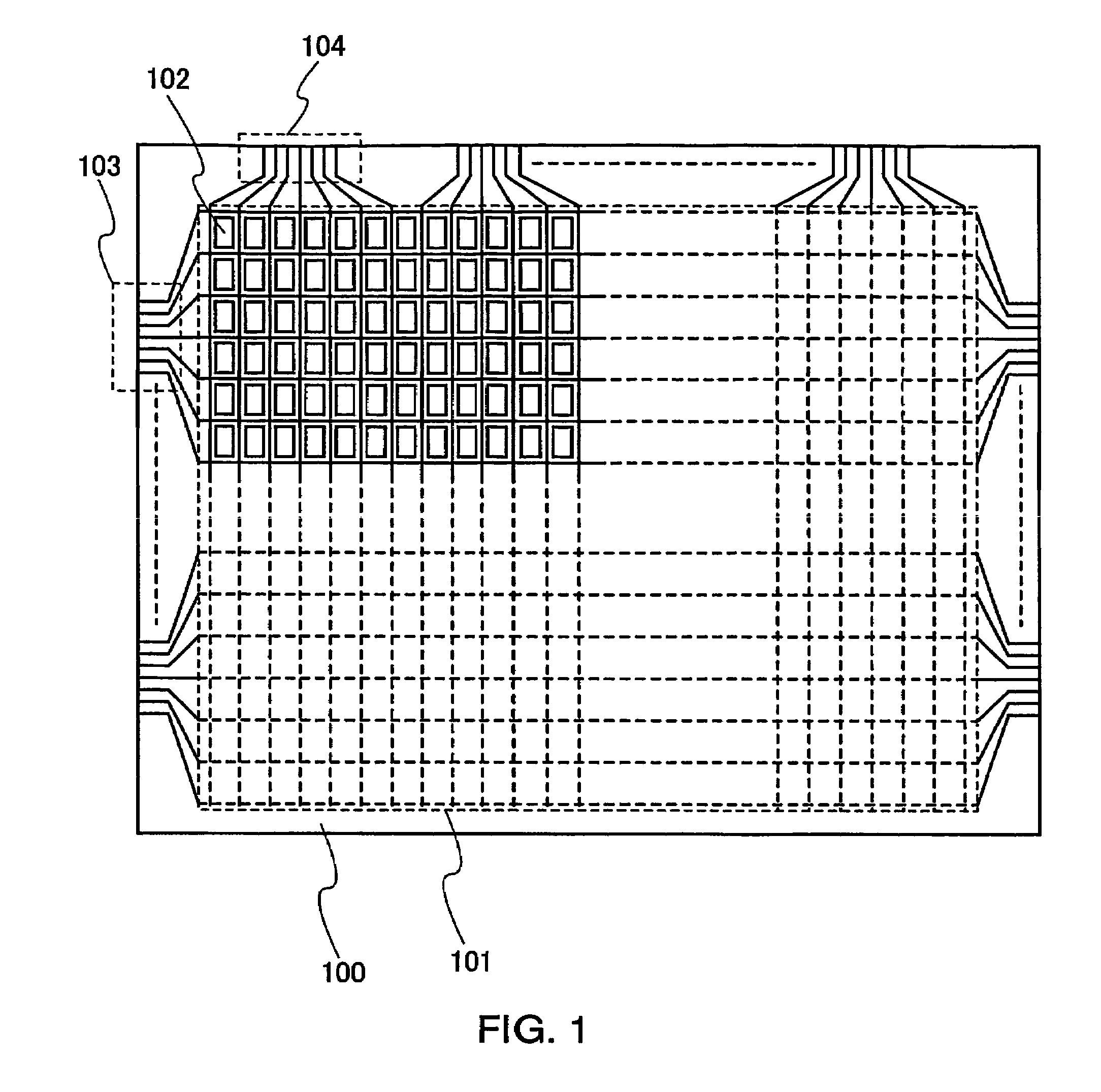

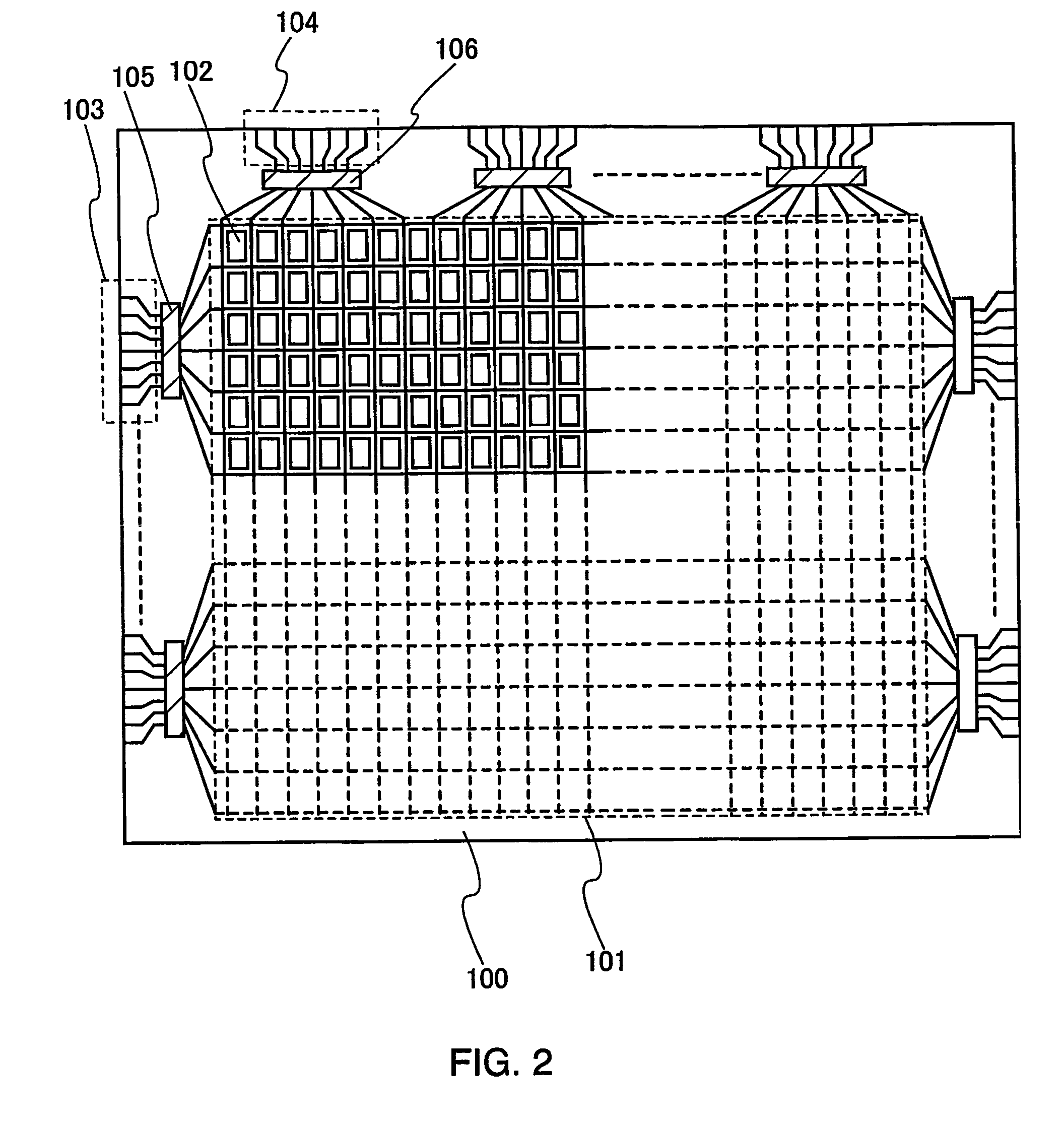

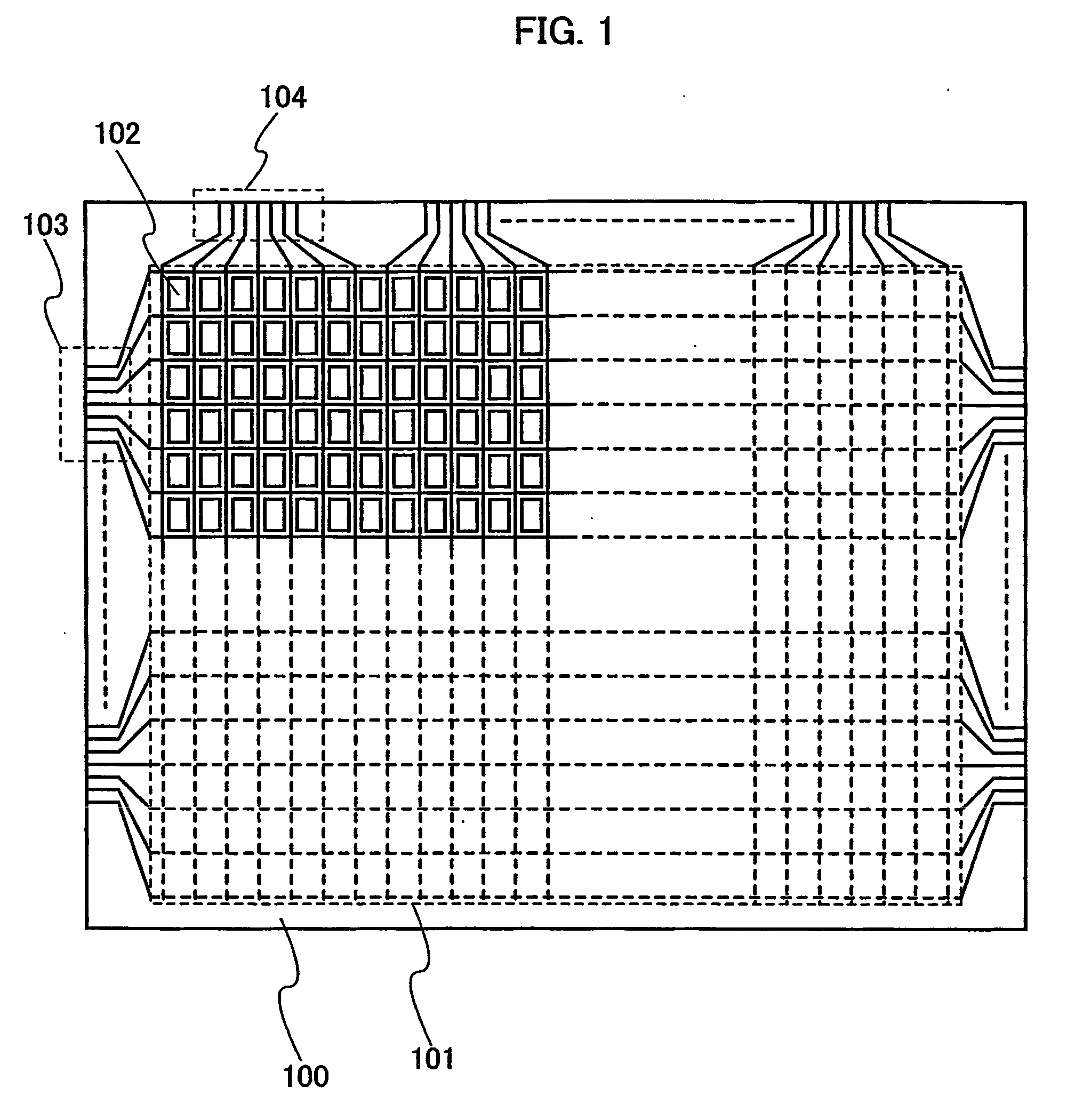

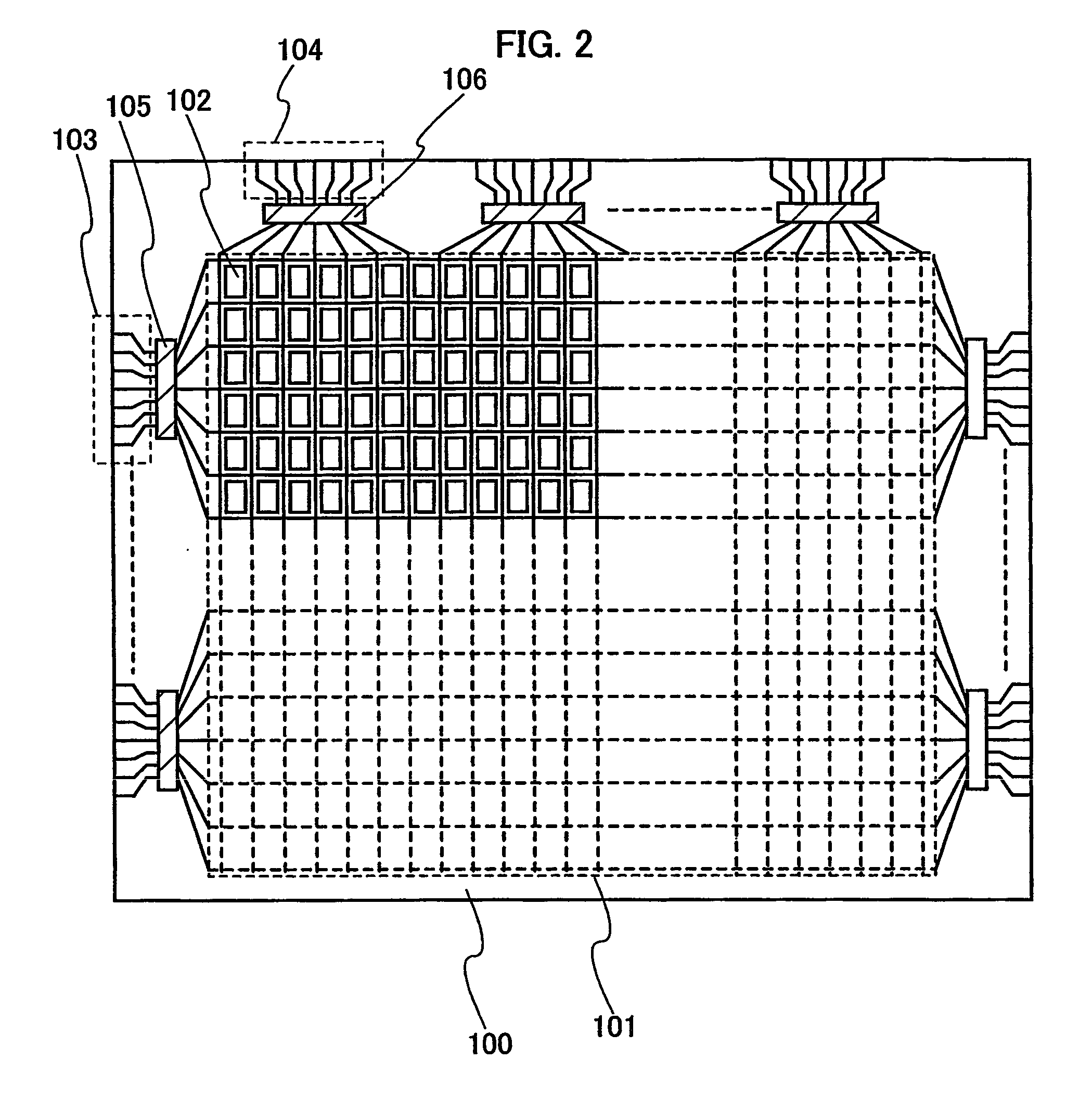

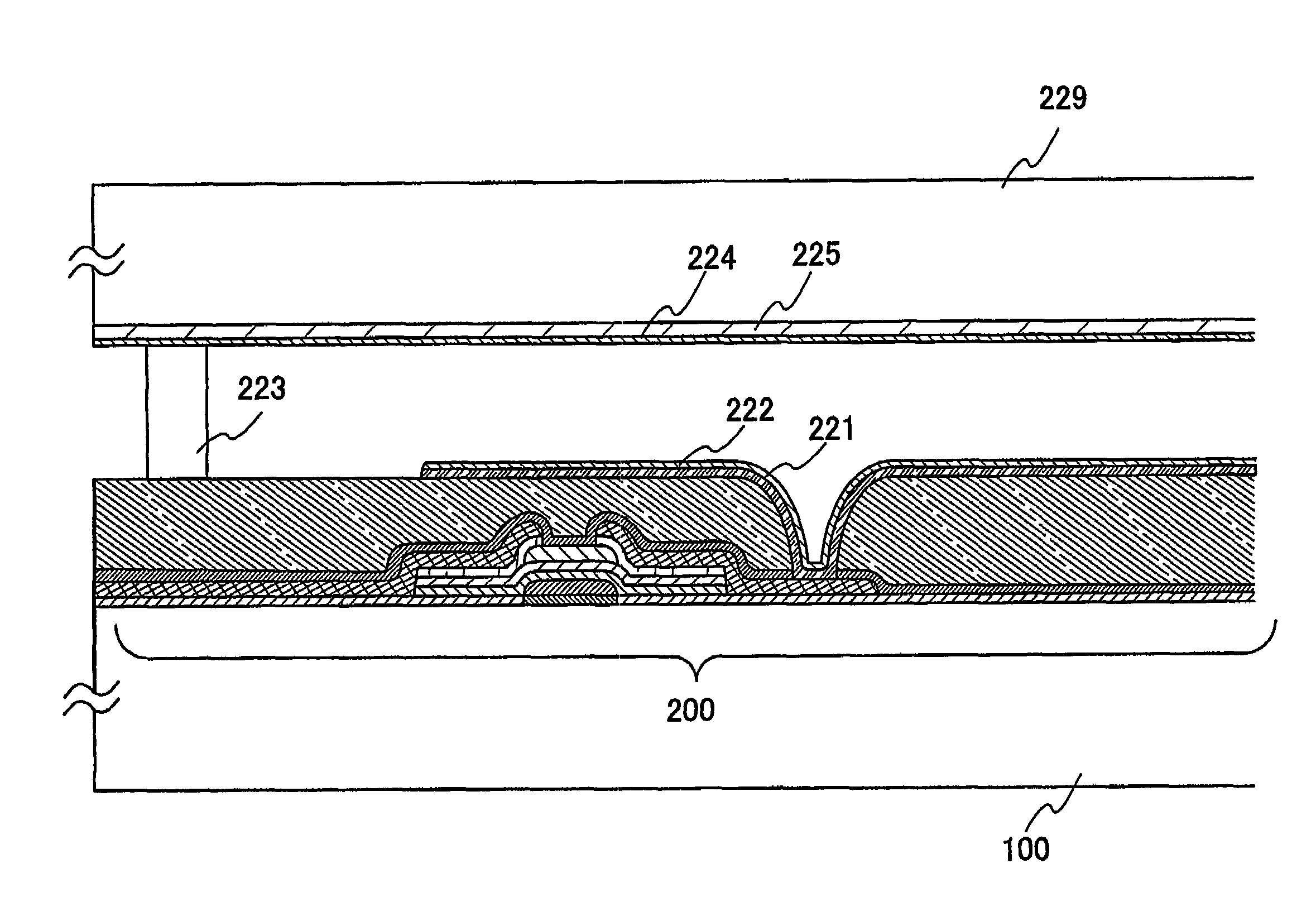

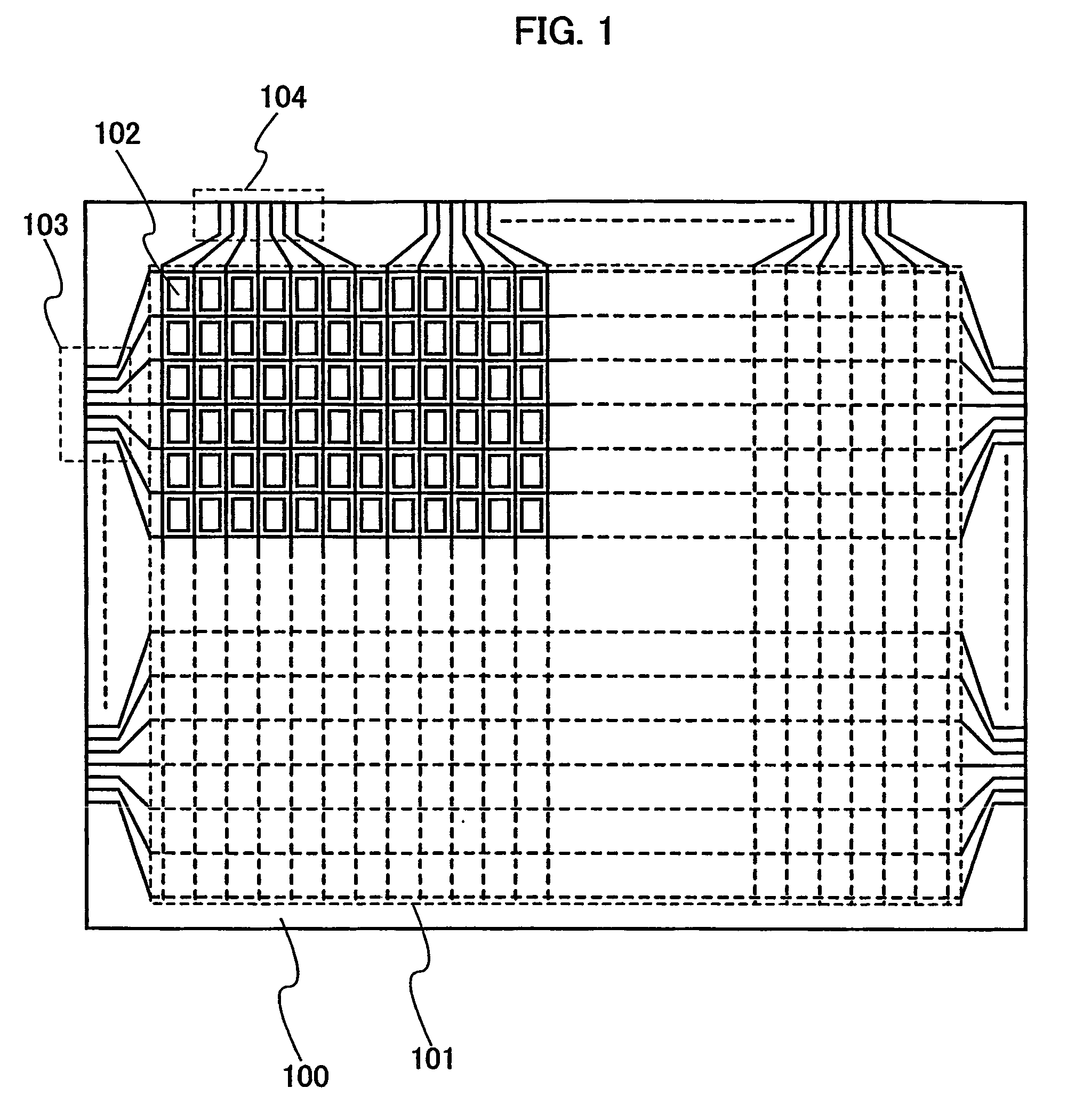

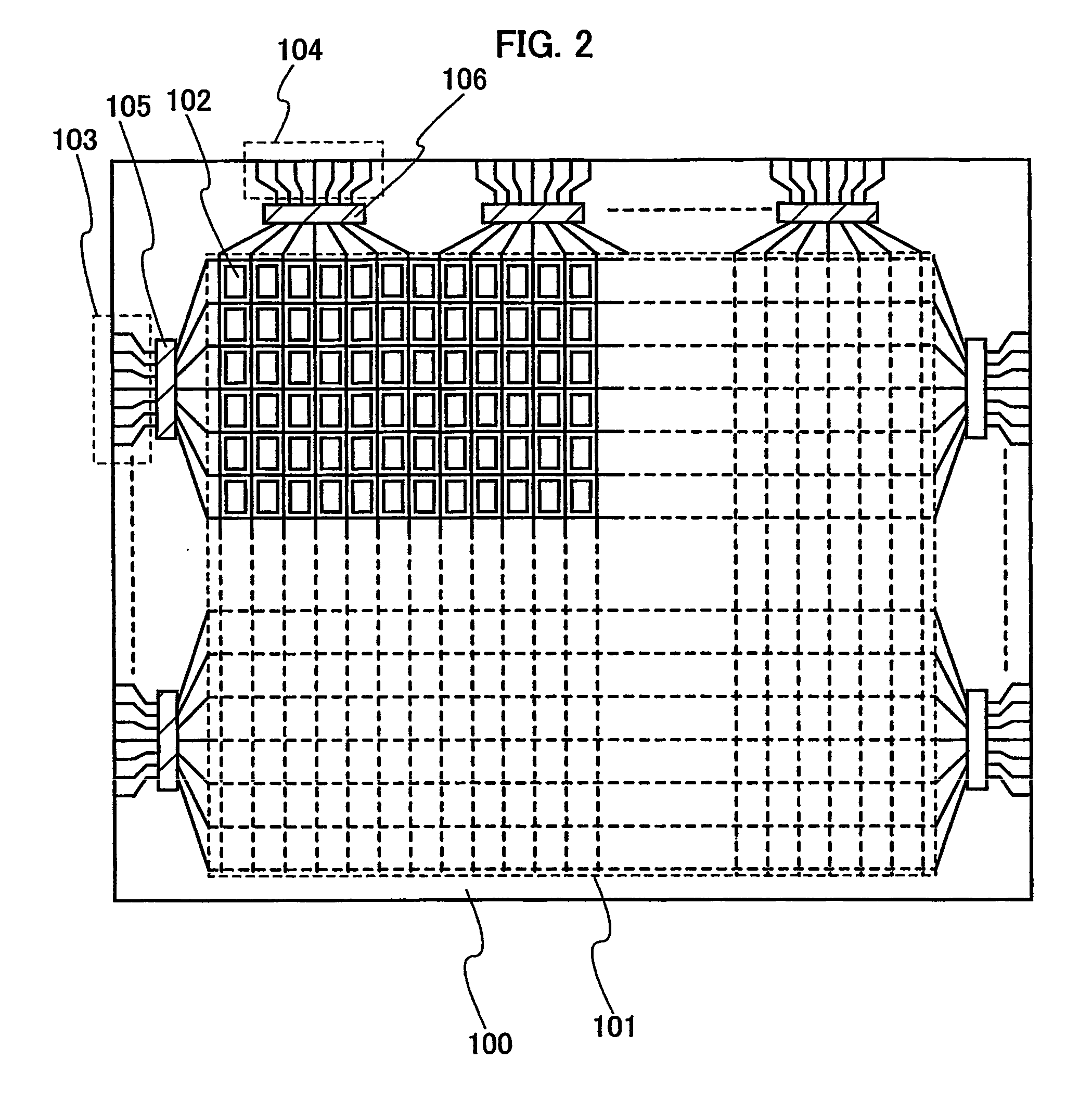

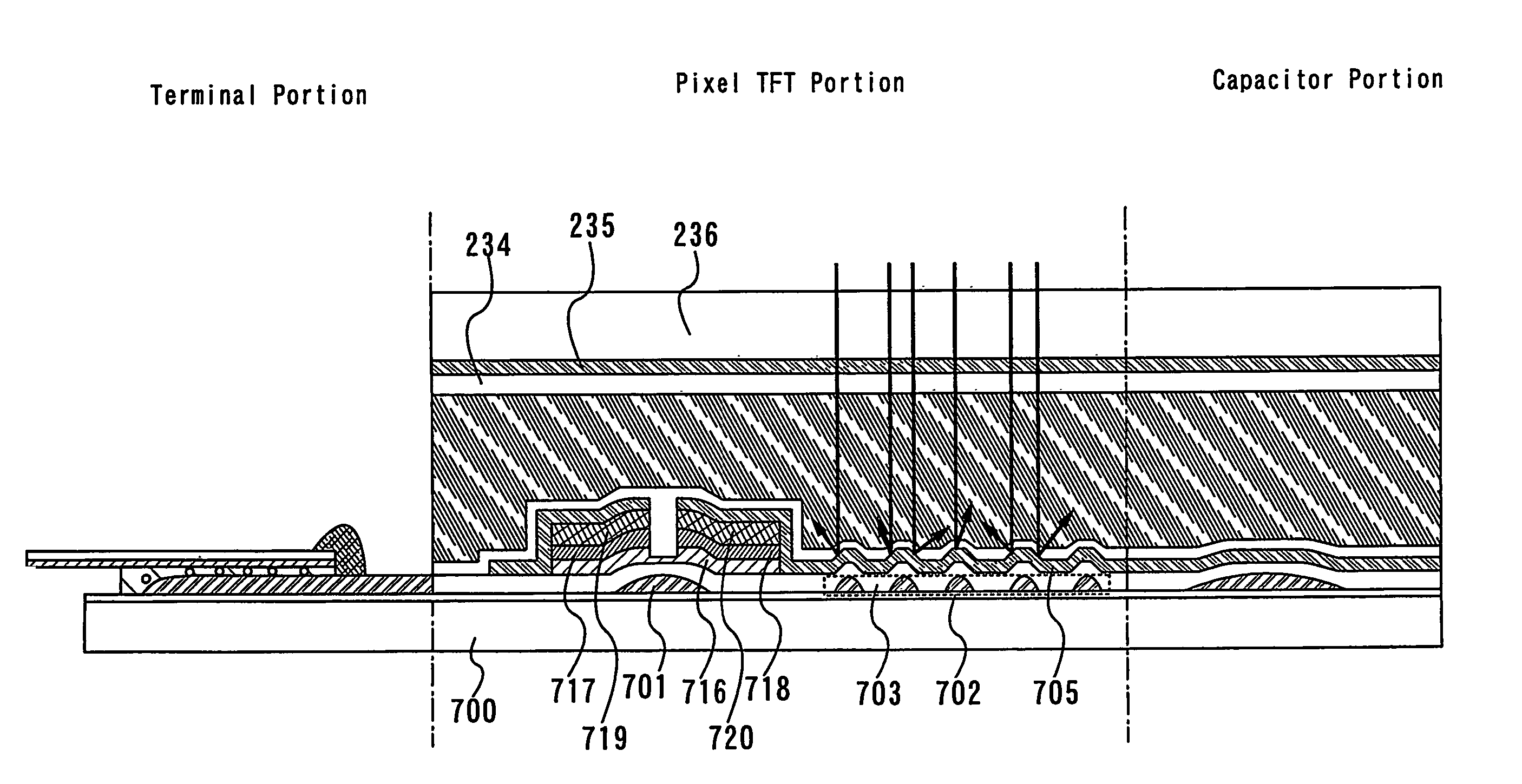

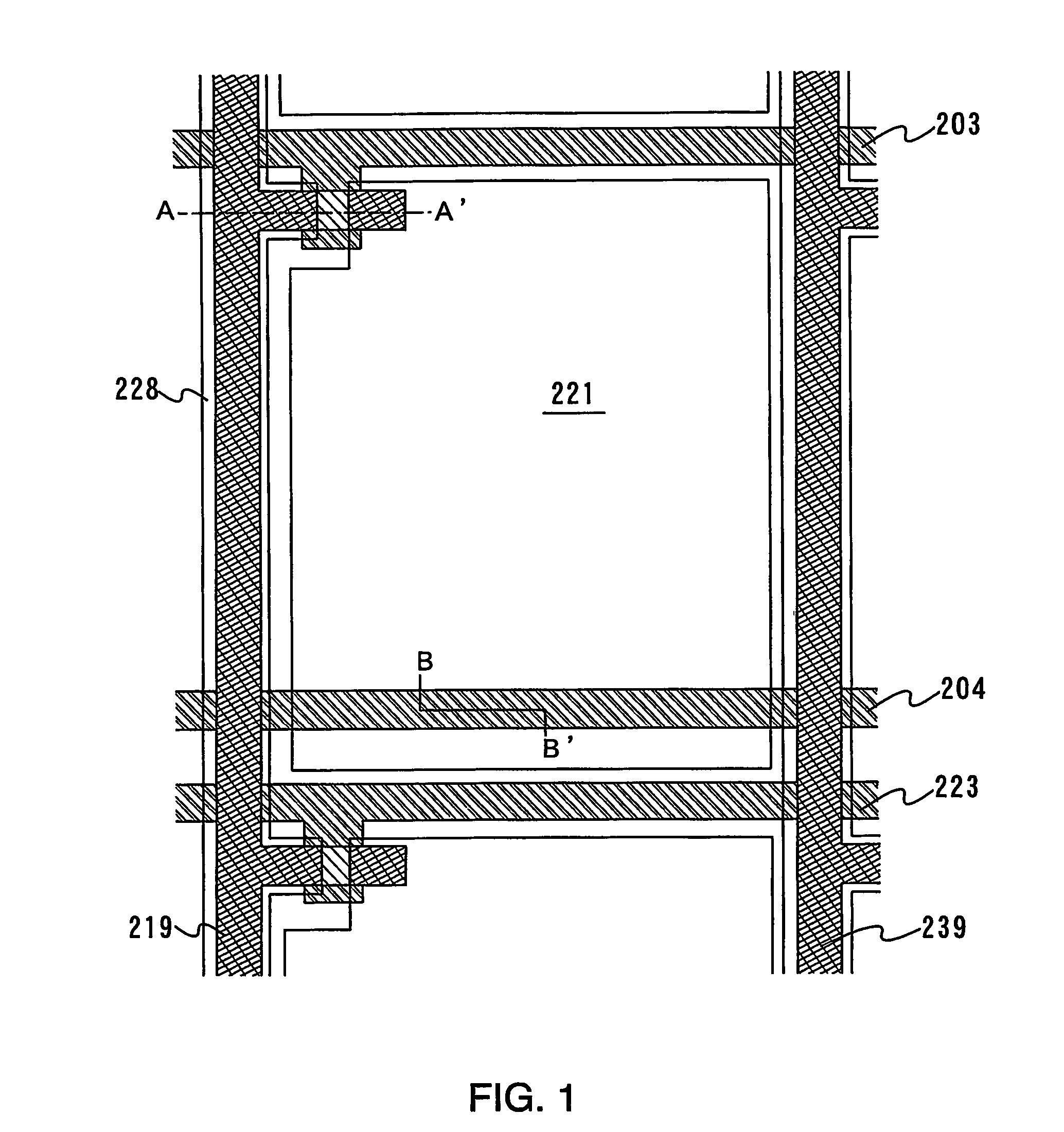

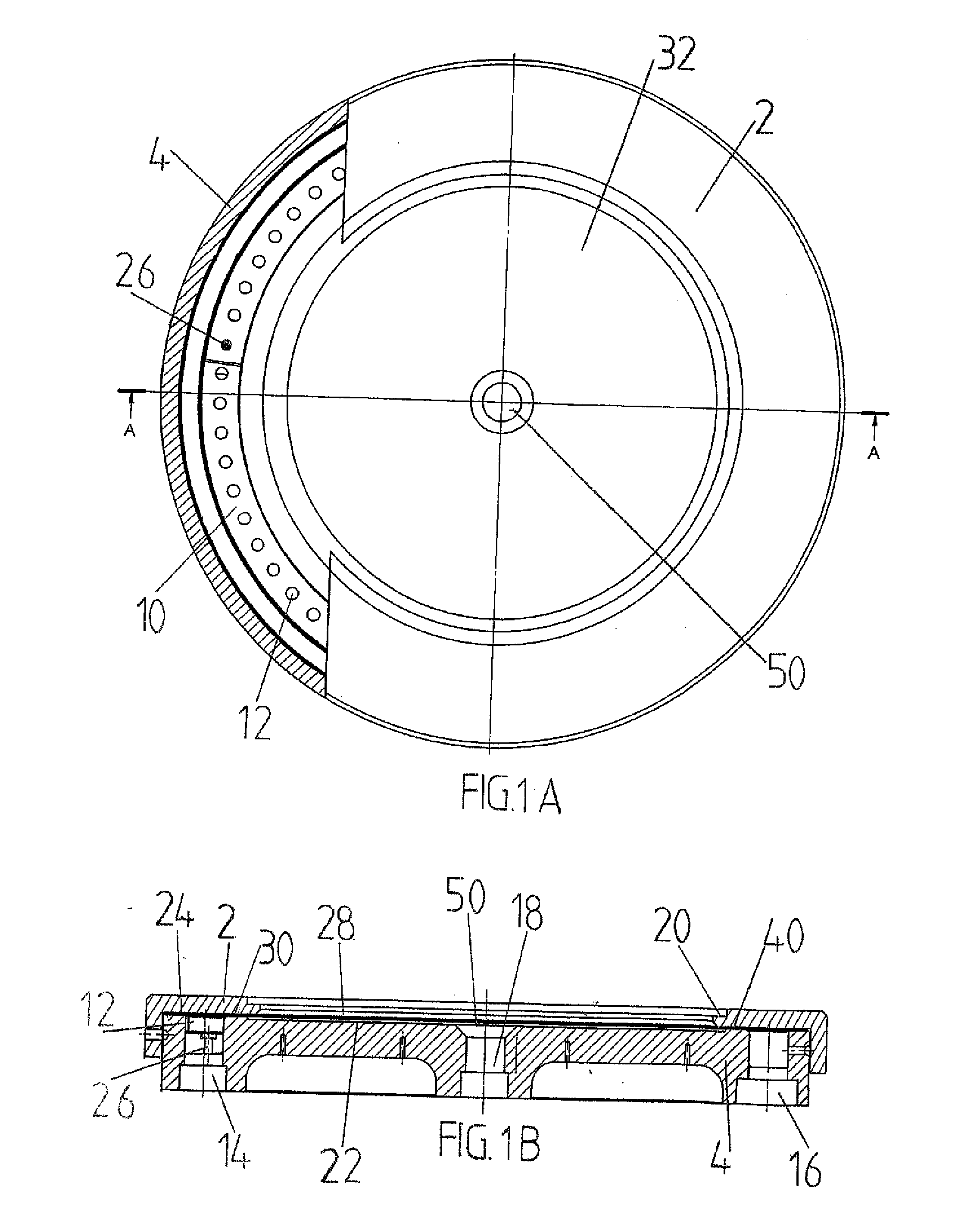

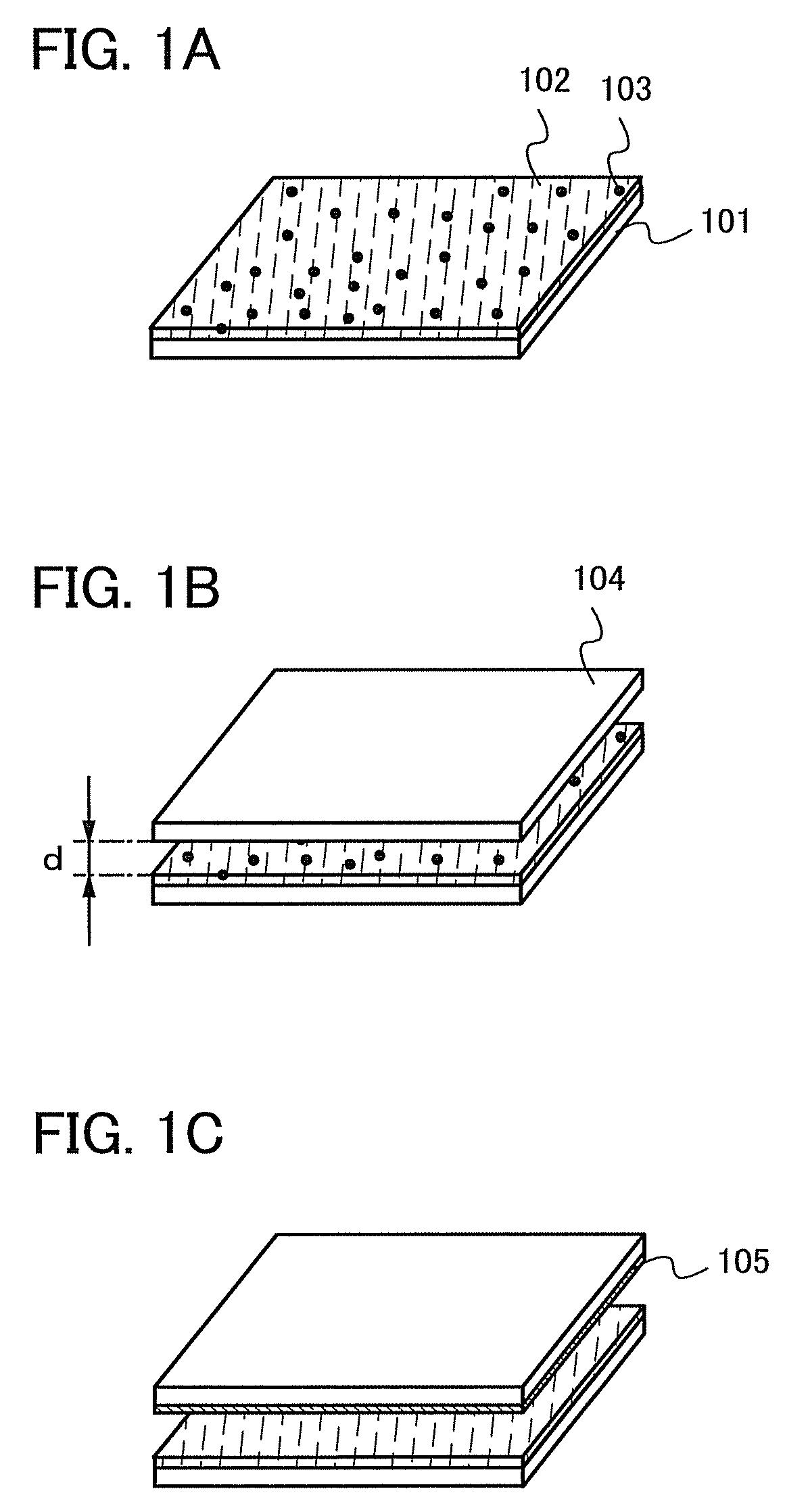

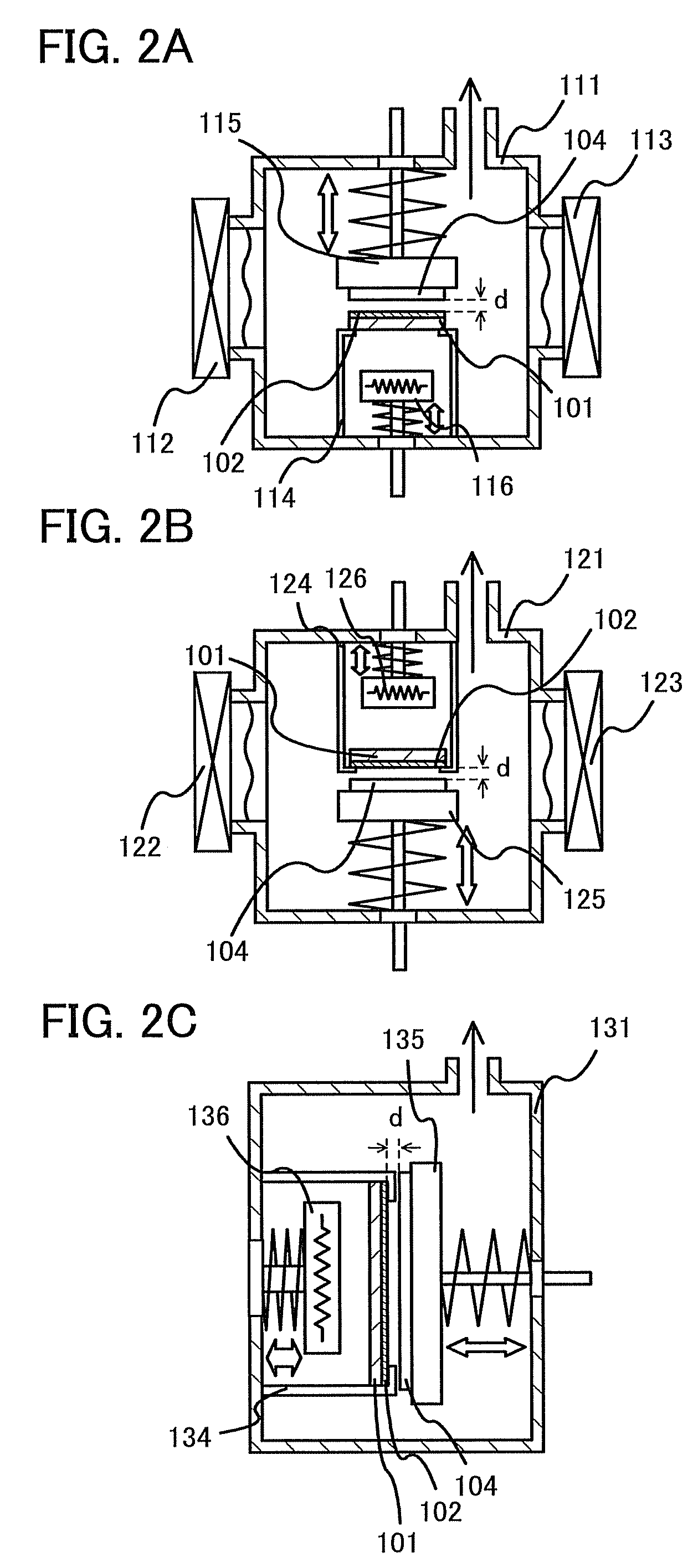

Liquid crystal display device and method for manufacturing the same, and liquid crystal television receiver

InactiveUS20070051952A1Improve material efficiencySimplify manufacturing stepsProjectorsSolid-state devicesTelevision receiversEngineering

At least one or more of a conductive layer which forms a wiring or an electrode and a pattern necessary for manufacturing a display panel such as a mask for forming a predetermined pattern is formed by a method capable of selectively forming a pattern to manufacture a liquid crystal display device. A droplet discharge method capable of forming a predetermined pattern by selectively discharging a droplet of a composition in accordance with a particular object is used as a method capable of selectively forming a pattern in forming a conductive layer, an insulating layer, or the like.

Owner:SEMICON ENERGY LAB CO LTD

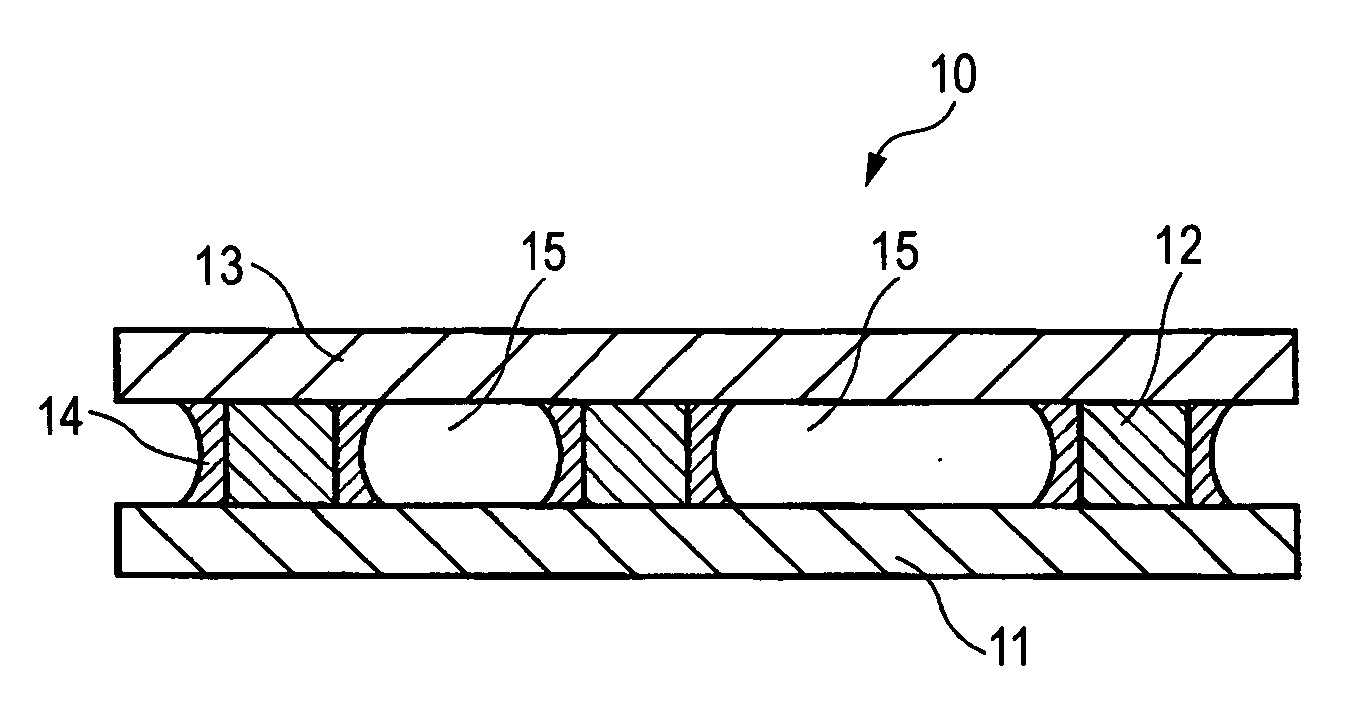

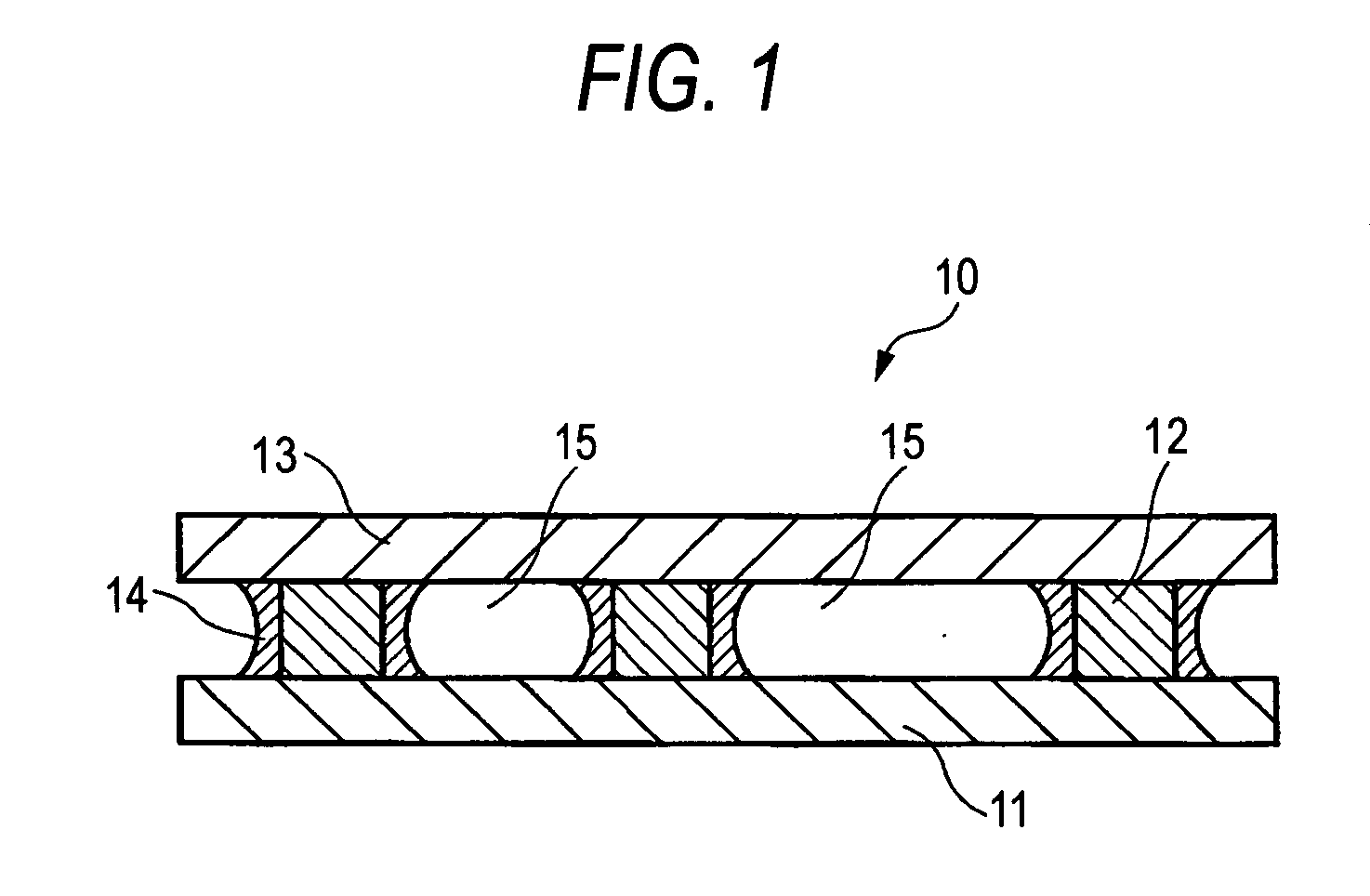

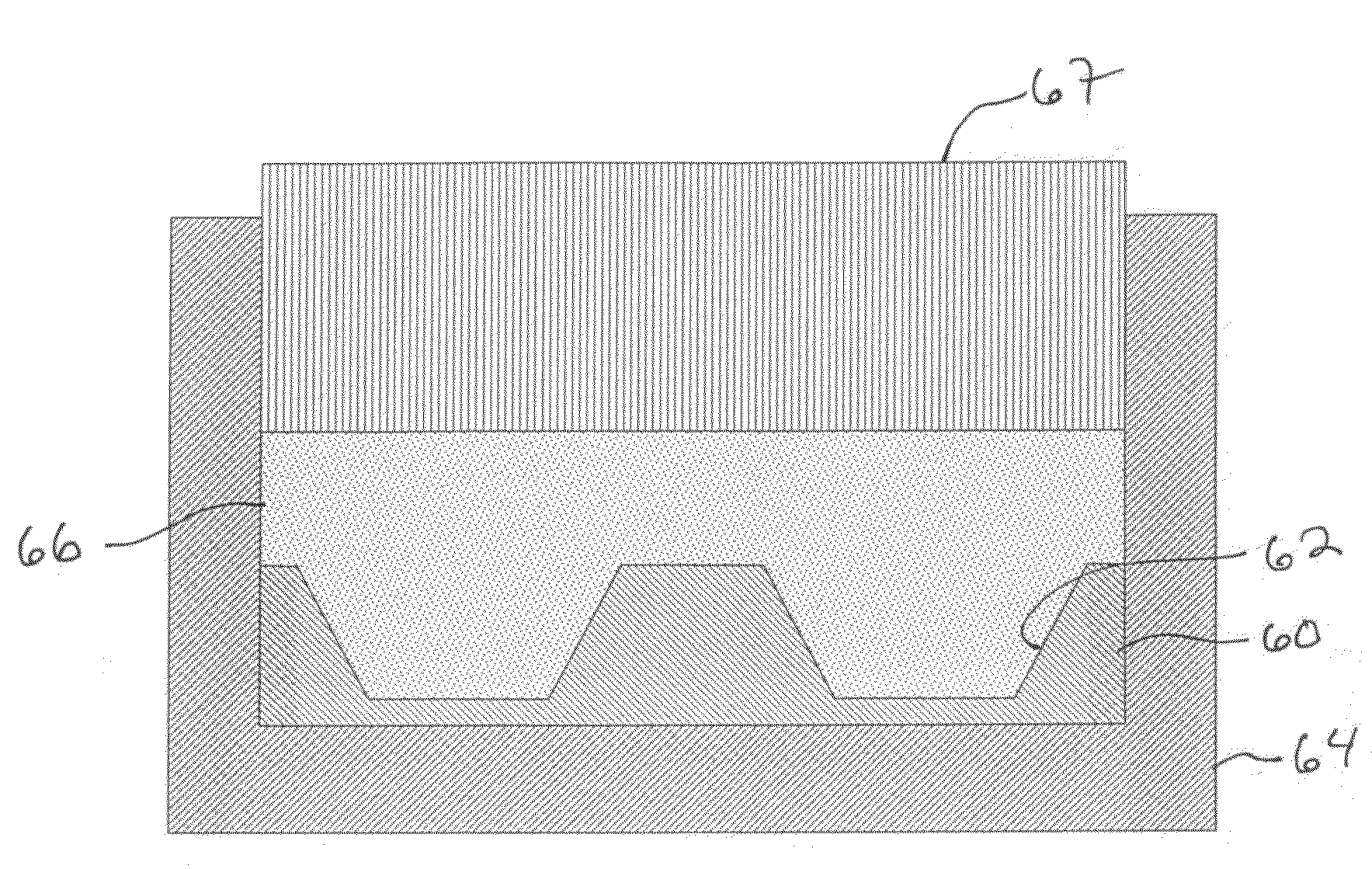

Optical waveguide, method of manufacturing the same and optical communication module

InactiveUS20070292091A1Low costImprove production efficiencyCoupling light guidesOptical waveguide light guideOptical communicationWaveguide

An optical waveguide includes: a lower substrate; a waveguide core that is formed on the lower substrate; a clad that is formed to surround a periphery of the waveguide core; and an upper substrate that is opposed to the lower substrate, wherein the waveguide cores, the lower substrate and the upper substrate surround a cavity extended along the waveguide core.

Owner:FUJIFILM BUSINESS INNOVATION CORP

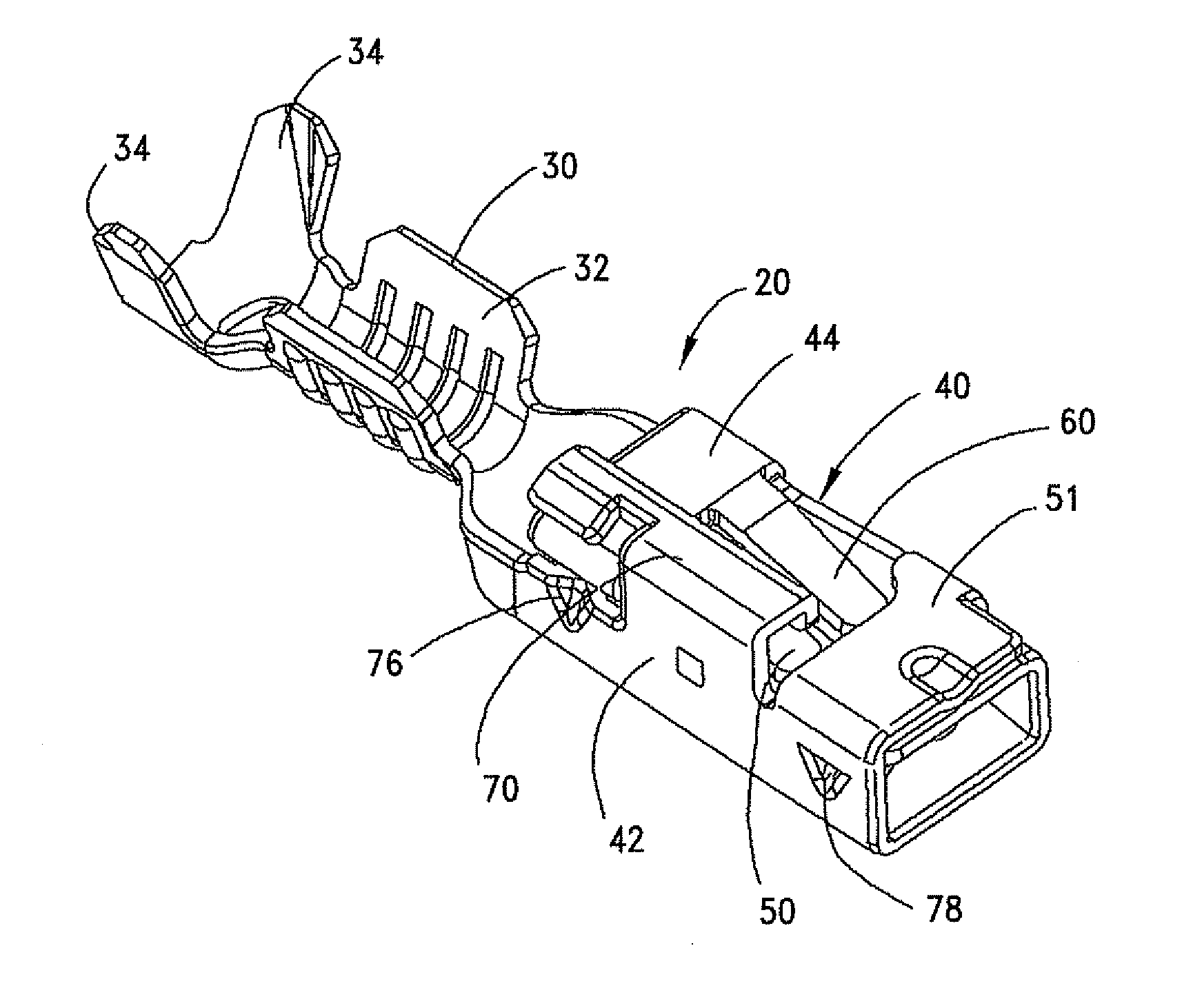

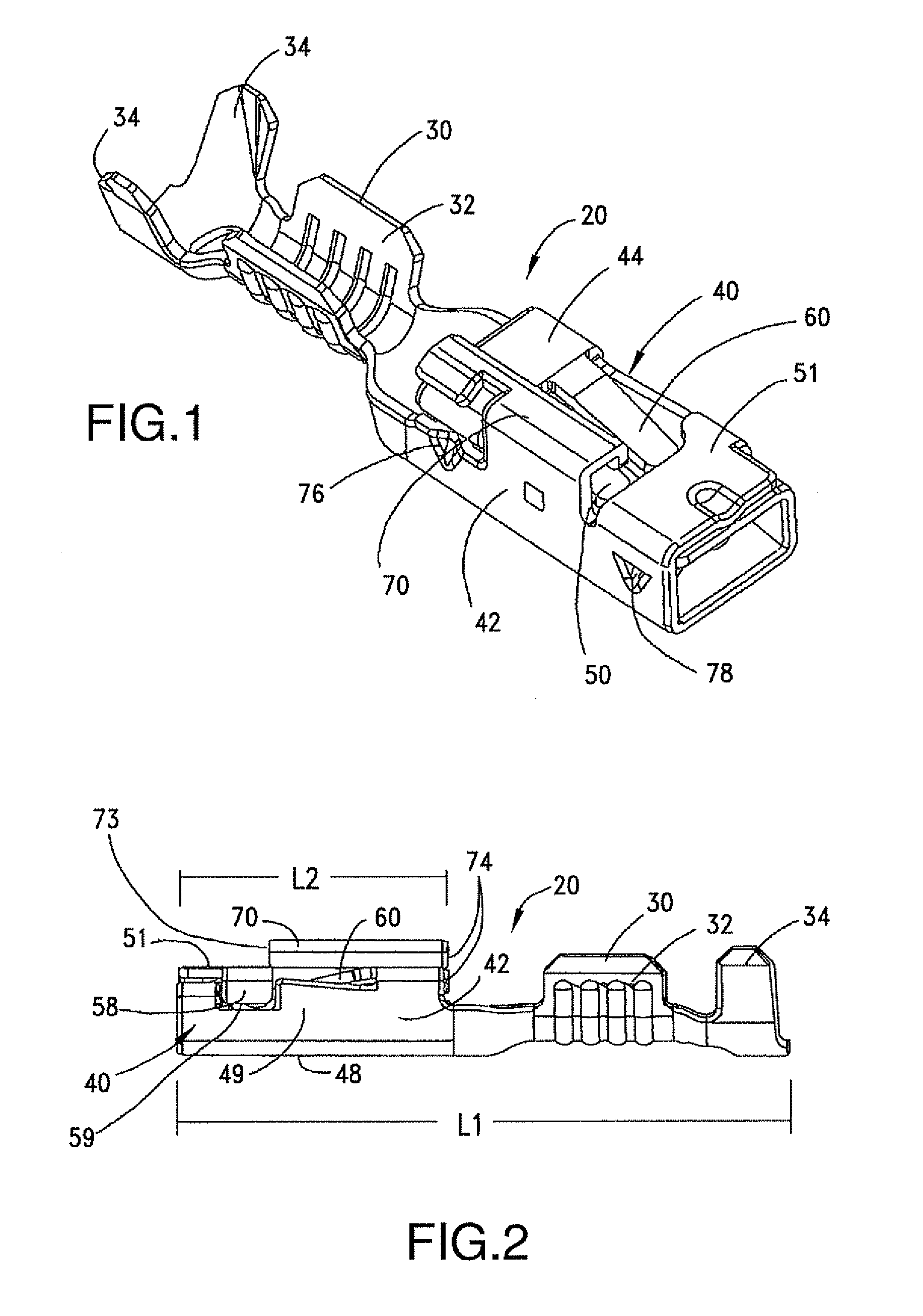

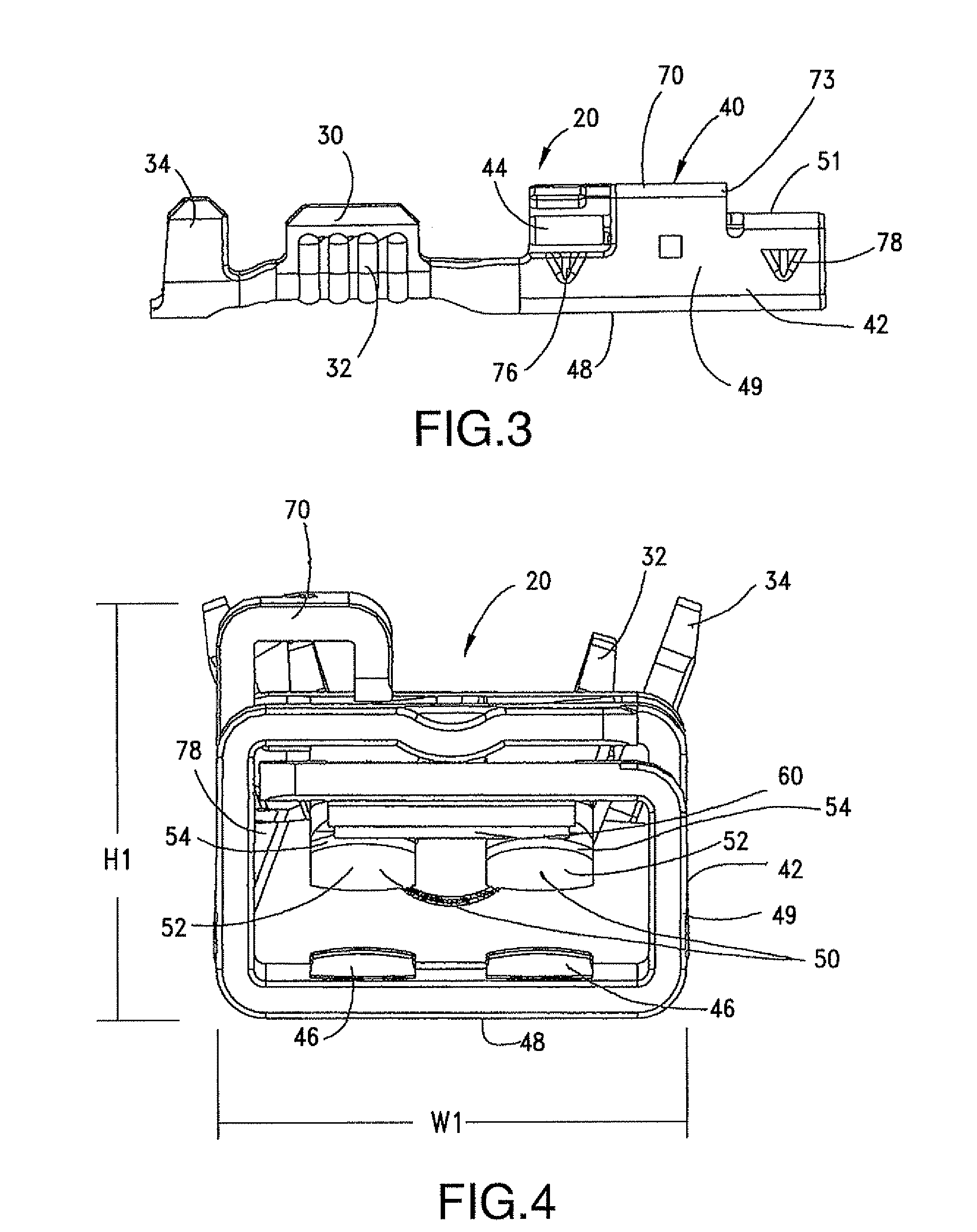

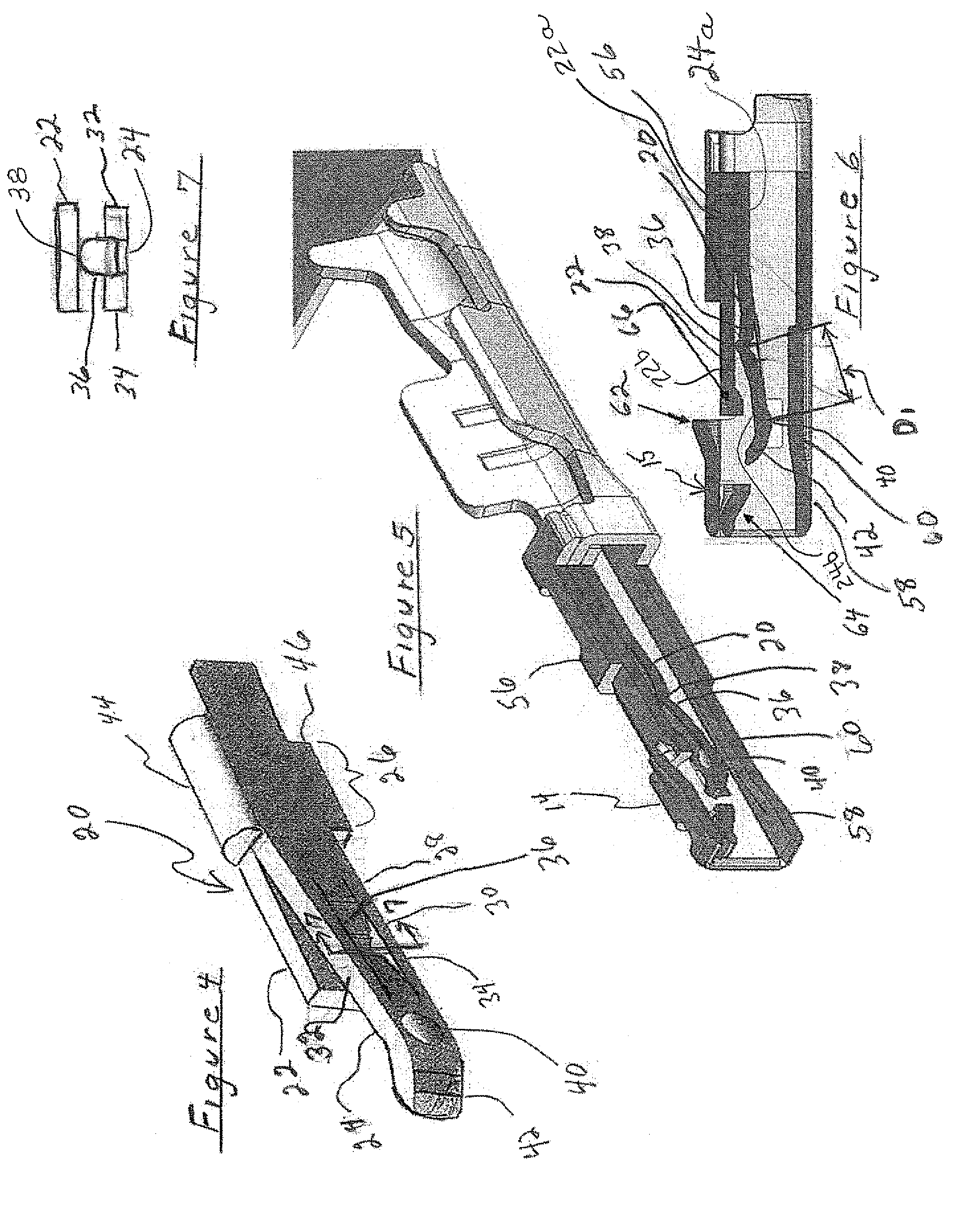

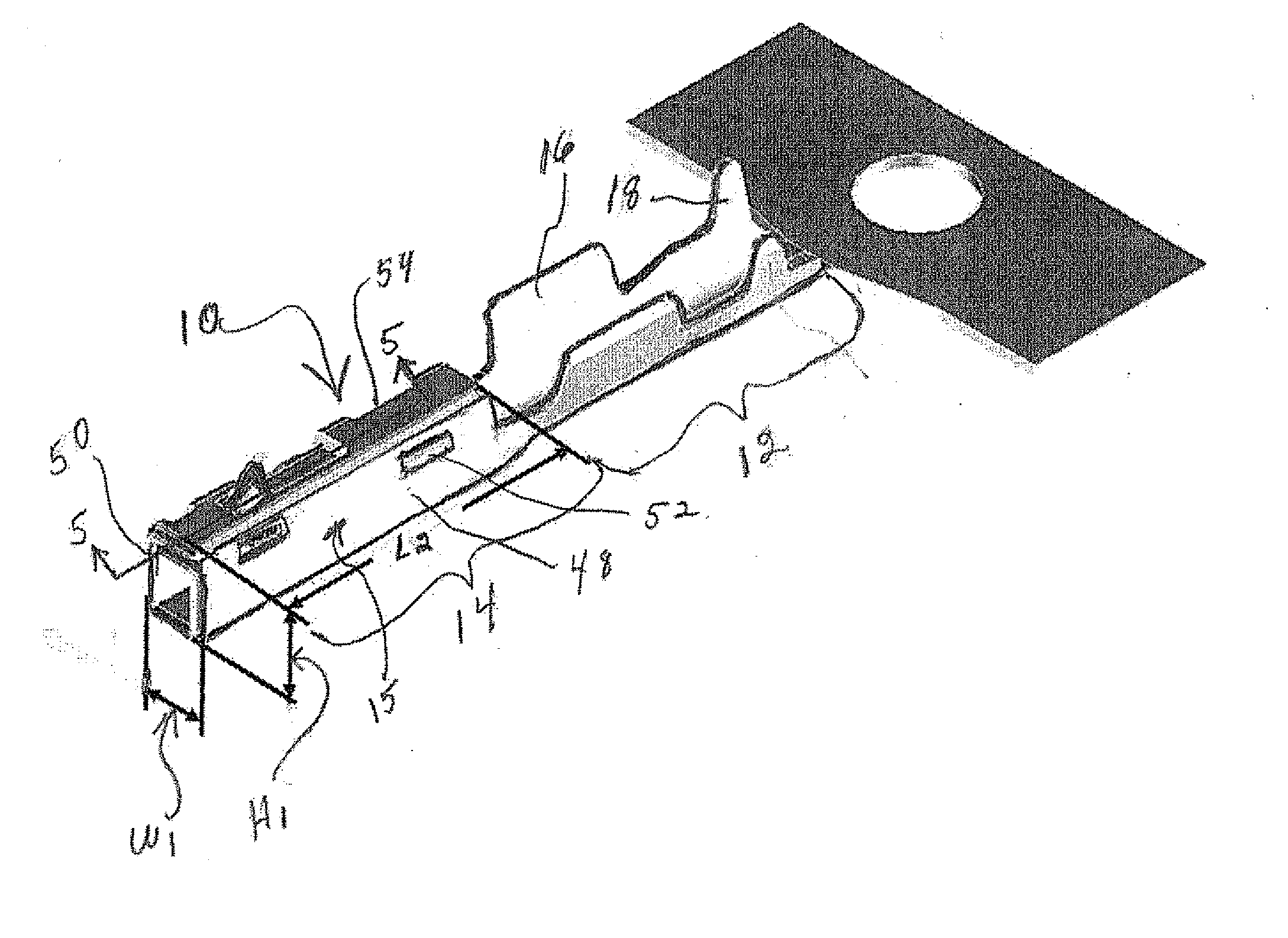

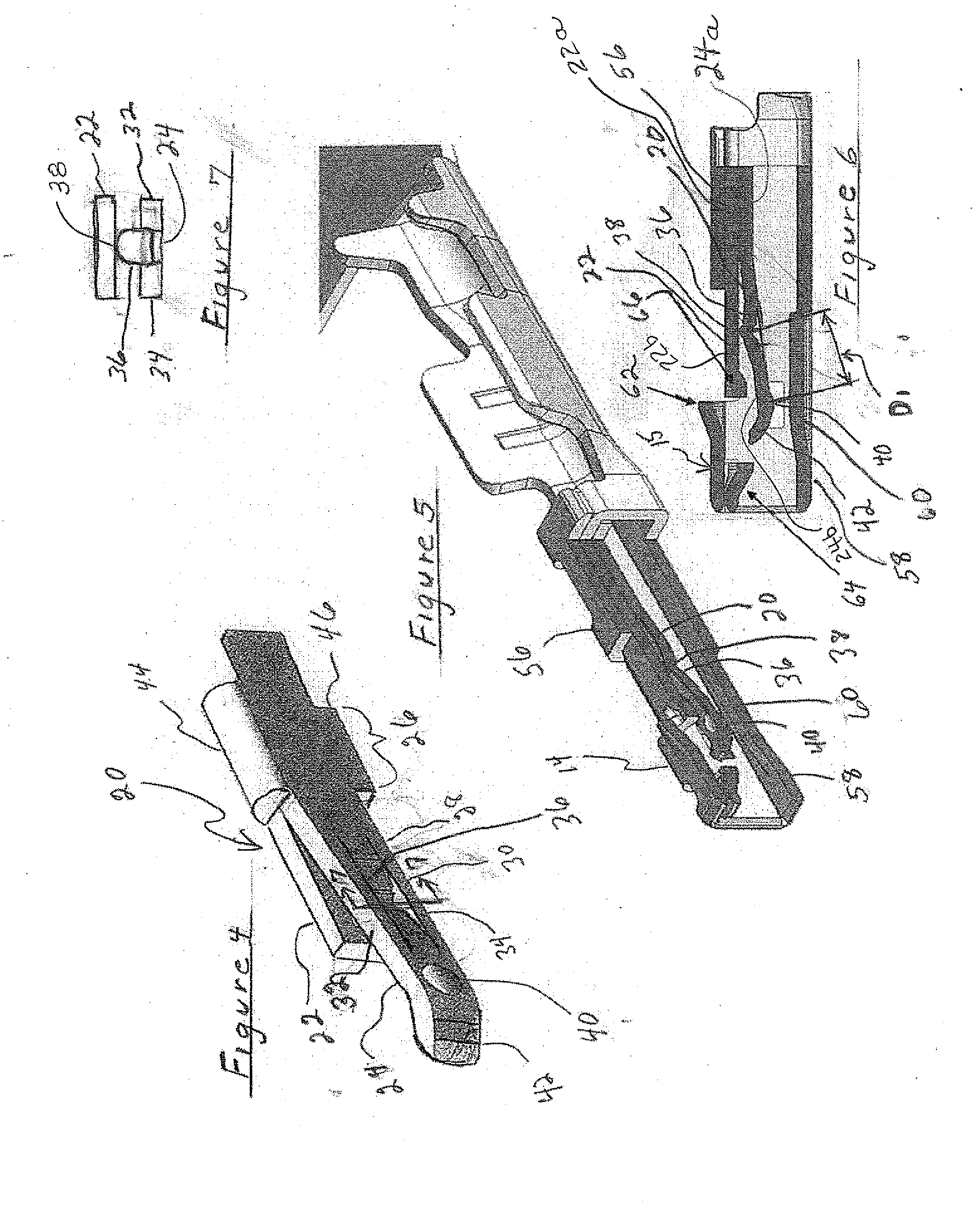

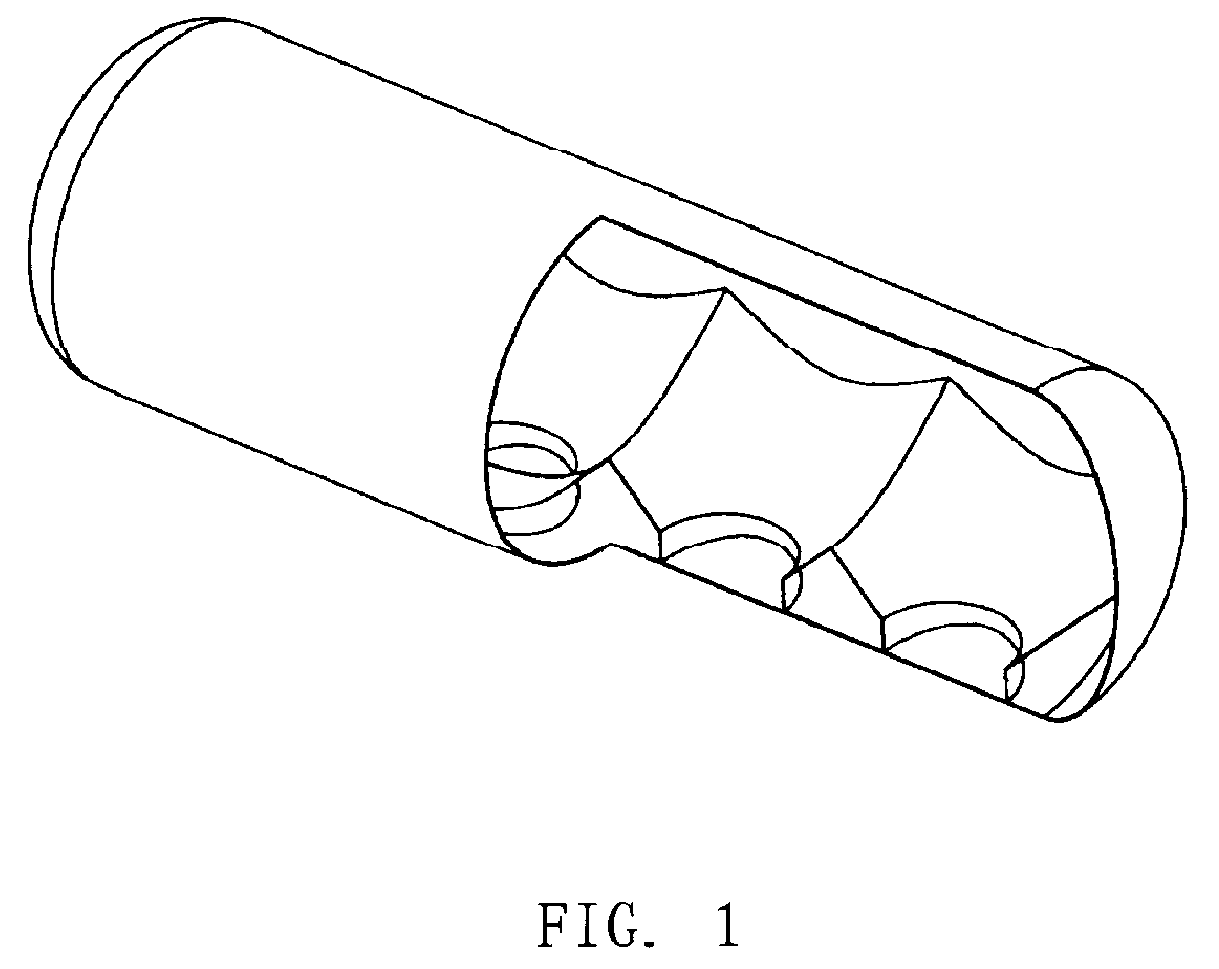

Miniature receptacle terminals

ActiveUS20120244756A1Minimize variationMinimizes contact force variationElectric discharge tubesCoupling contact membersPRIMARY CONTACTEngineering

This approach generally pertains to a miniature receptacle terminal with a connection section and a mating section. The mating section has a dual primary contact beam component that includes contact springs having resilient contact beams and a secondary beam. Each contact beam has a contact point opposing the opposing wall of the receptacle terminal, which can include a contact bump. A distributed and balanced contact force is exerted on a male terminal pin that is inserted between the primary contact beams and the contact bumps. Overstress protection of the contact spring is provided and the terminal is economical to produce.

Owner:MOLEX INC

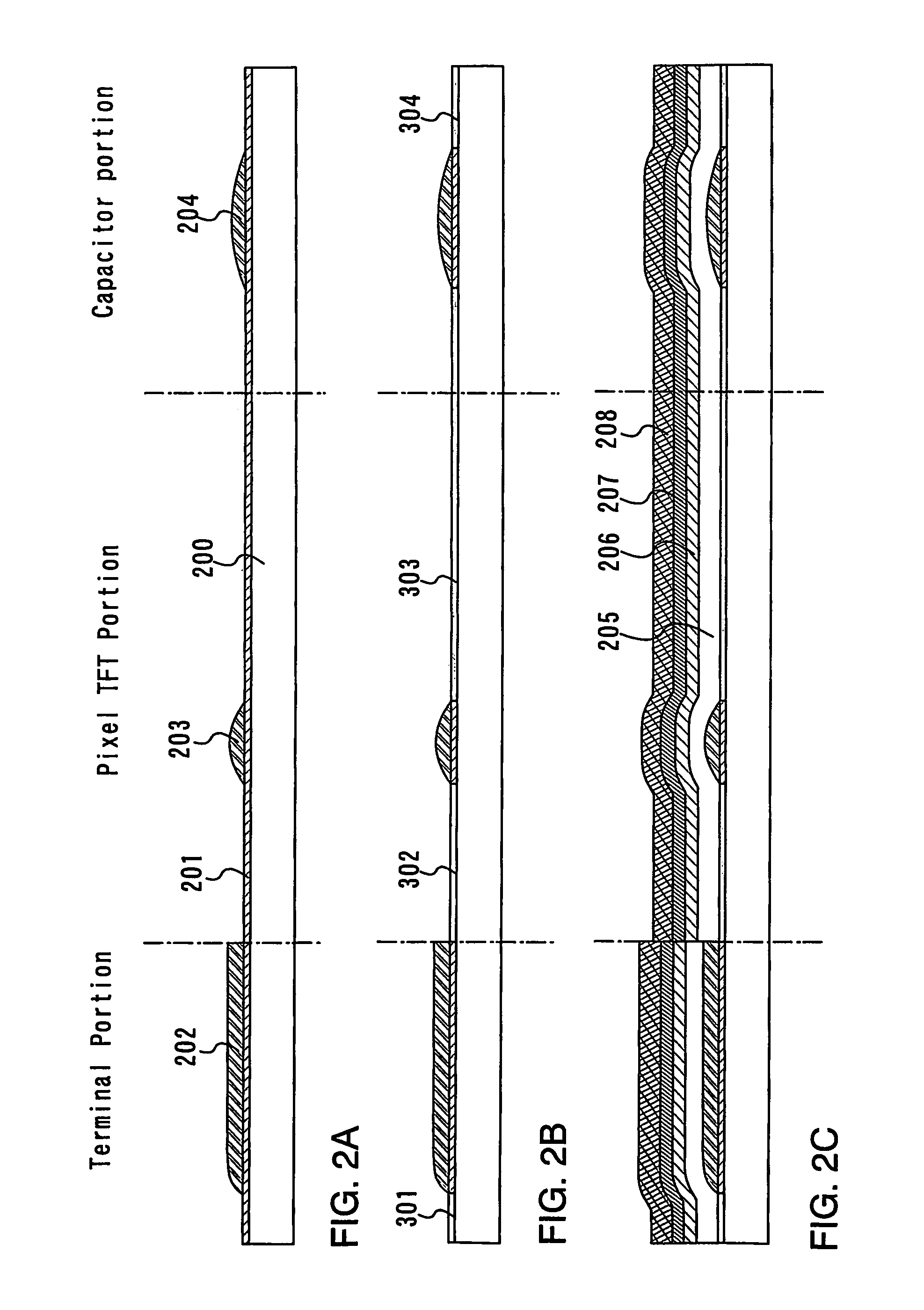

Method for manufacturing liquid crystal display device

InactiveUS20070082443A1Manufacture step be simplifyLow costTransistorSolid-state devicesLiquid-crystal displayEngineering

A conventionally followed technique of manufacturing a liquid crystal display device is a method for forming various types of coatings over an entire surface of a substrate and for removing the coatings with a small region left by etching, which requires wasting a material cost and treating a large quantity of waste. A liquid crystal display device is manufactured by forming at least one or more of patterns necessary for manufacturing a liquid crystal display device by a method capable of selectively forming a pattern. A droplet discharge method capable of forming a predetermined pattern by selectively discharging a droplet of a composition prepared for a specific purpose is employed as the method capable of selectively forming a pattern.

Owner:SEMICON ENERGY LAB CO LTD

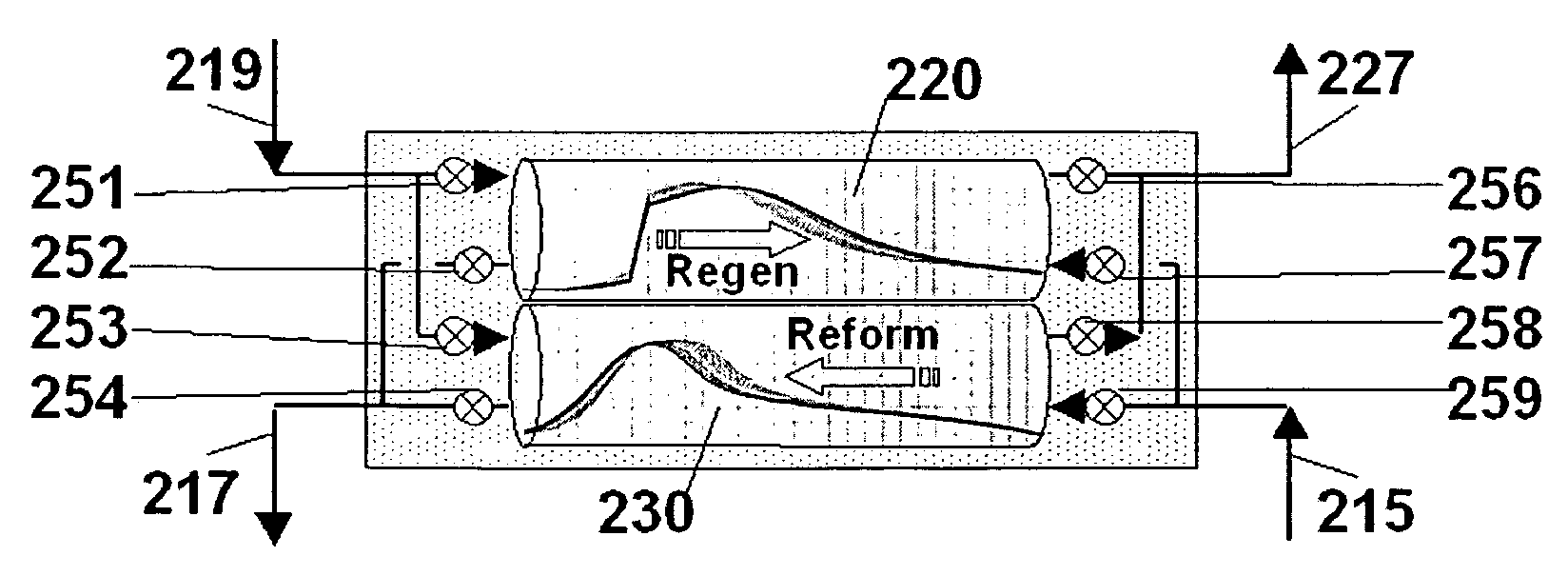

Proton conducting solid oxide fuel cell systems having temperature swing reforming

ActiveUS20060188760A1Excellent thermalImprove material efficiencyFuel cells groupingFuel cell auxillariesSyngasFuel cells

The present invention provides an improvement in the process of producing energy from fuel cells. A cyclic reforming process, referred to as temperature swing reforming, provides an efficient means for producing a hydrogen containing synthesis gas for use in proton conducting solid oxide fuel cell applications. In one embodiment, at least some synthesis gas which is first produced in the temperature swing reforming process is combusted with air to provide the heat for the regeneration step of the temperature swing reforming process. The syngas produced in TSR is particularly well suited for use in proton conducting solid oxide fuel cell applications.

Owner:EXXON RES & ENG CO

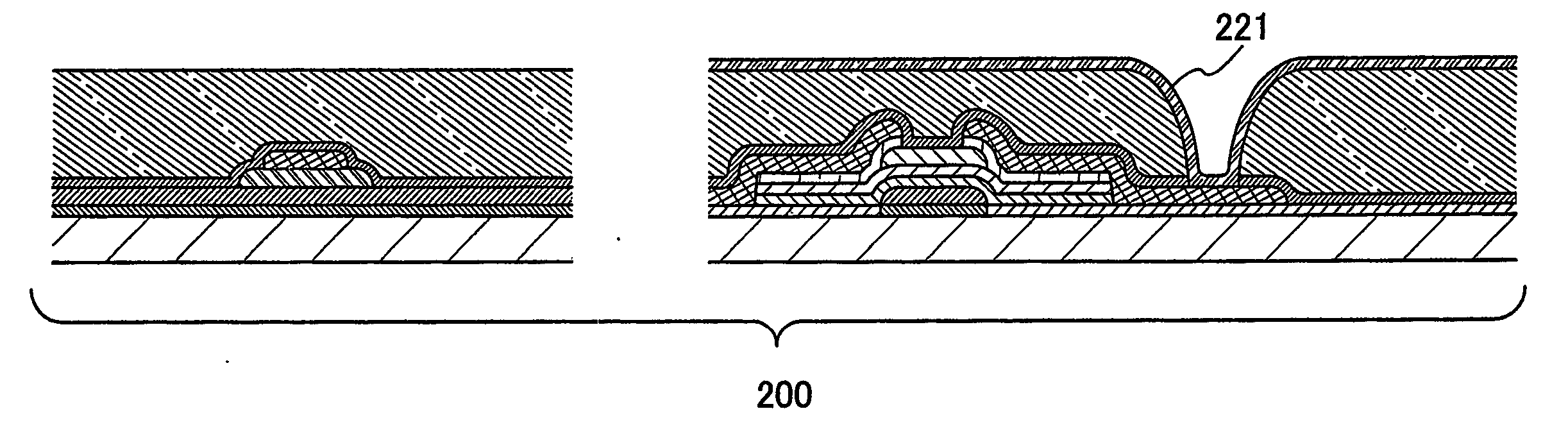

Film Formation Method and Method for Manufacturing Light-Emitting Device

InactiveUS20080268137A1Improve throughputFilm qualityElectroluminescent light sourcesSolid-state devicesProduction rateEvaporation

A binder material layer including an evaporation material is formed over a main surface of an evaporation source substrate, a substrate on which a film is formed is placed so that the binder material layer and a main surface thereof face each other, and heat treatment is performed on a rear surface of the evaporation source substrate so that the evaporation material in the binder material layer is heated to be subjected to sublimation or the like, whereby a layer of the evaporation material is formed on the substrate on which a film is formed. When a low molecular material is used for the evaporation material and a high molecular material is used for the binder material, the viscosity can be easily adjusted, and thus, film formation is possible with higher throughput than conventional film formation.

Owner:SEMICON ENERGY LAB CO LTD

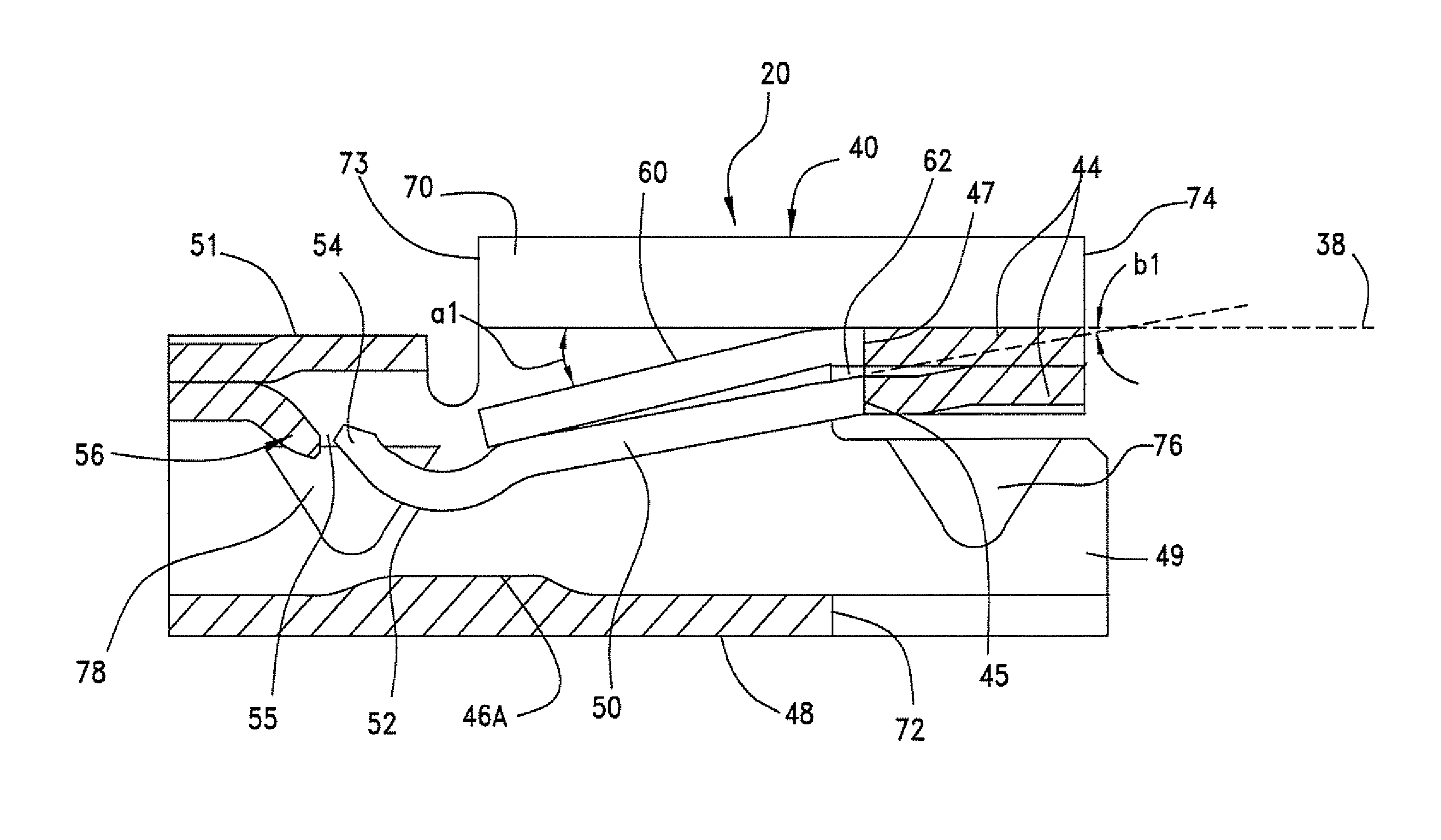

Miniature receptacle terminals

ActiveUS8662935B2Minimizes contact force variationEasy to controlElectric discharge tubesCoupling device detailsContact forceEngineering

This approach generally pertains to a miniature receptacle terminal with a connection section and a mating section. The mating section has a dual primary contact beam component that includes contact springs having resilient contact beams and a secondary beam. Each contact beam has a contact point opposing the opposing wall of the receptacle terminal, which can include a contact bump. A distributed and balanced contact force is exerted on a male terminal pin that is inserted between the primary contact beams and the contact bumps. Overstress protection of the contact spring is provided and the terminal is economical to produce.

Owner:MOLEX INC

Method for manufacturing liquid crystal display device

InactiveUS7439086B2Low costBig investmentTransistorSolid-state devicesLiquid-crystal displayEngineering

A conventionally followed technique of manufacturing a liquid crystal display device is a method for forming various types of coatings over an entire surface of a substrate and for removing the coatings with a small region left by etching, which requires wasting a material cost and treating a large quantity of waste. A liquid crystal display device is manufactured by forming at least one or more of patterns necessary for manufacturing a liquid crystal display device by a method capable of selectively forming a pattern. A droplet discharge method capable of forming a predetermined pattern by selectively discharging a droplet of a composition prepared for a specific purpose is employed as the method capable of selectively forming a pattern.

Owner:SEMICON ENERGY LAB CO LTD

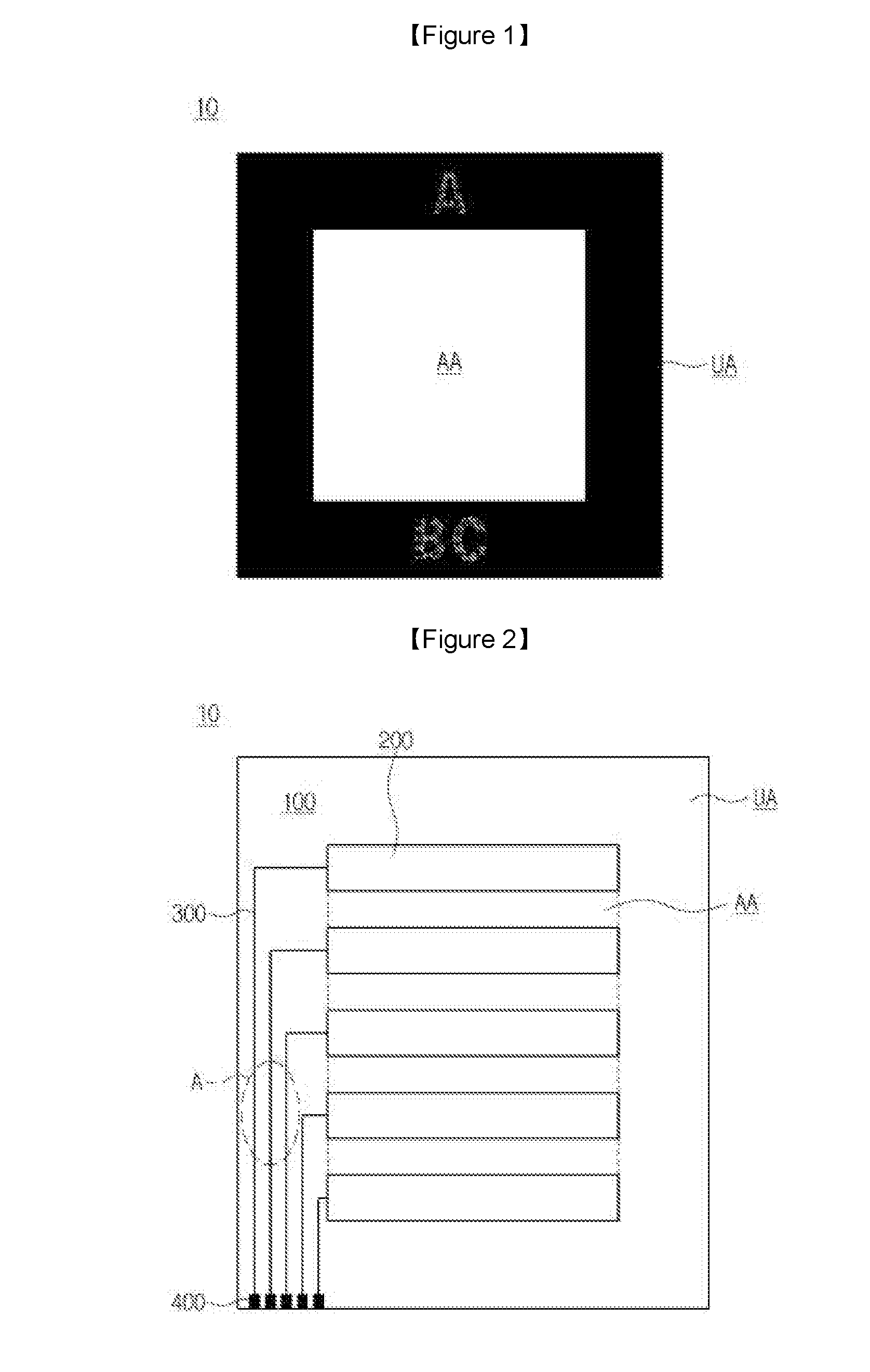

Display device and method for manufacturing the same

InactiveUS20070057258A1Improve material efficiencySimplify manufacturing stepsTransistorSolid-state devicesDisplay deviceEngineering

According to one aspect of the present invention, at least one or more of patterns required for manufacturing a display device, such as a conductive layer which forms a wiring or an electrode and a mask, is formed by a droplet discharging method. At that time, a portion of the gate insulating film where is not located under the semiconductor layer is removed during manufacturing steps of the present invention.

Owner:SEMICON ENERGY LAB CO LTD

Display device and method for manufacturing the same

InactiveUS7601994B2Simple manufacturing processImprove material efficiencyTransistorSemiconductor/solid-state device detailsDisplay deviceSemiconductor

According to one aspect of the present invention, at least one or more of patterns required for manufacturing a display device, such as a conductive layer which forms a wiring or an electrode and a mask, is formed by a droplet discharging method. At that time, a portion of the gate insulating film where is not located under the semiconductor layer is removed during manufacturing steps of the present invention.

Owner:SEMICON ENERGY LAB CO LTD

Liquid crystal display device and manufacturing method thereof

InactiveUS7499117B2Increase productionLow production costSolid-state devicesSemiconductor/solid-state device manufacturingResistLiquid-crystal display

By using one photo mask in the manufacturing steps of a liquid crystal display device, steps such as resist coating, prebaking, exposure, development, and postbaking, as well as the formation of a covering film, etching, resist peeling, rinsing, drying and the like before and after the aforementioned steps are required, which make the process complicated. To solve the problem, a channel-etch type bottom gate TFT (inverted staggered TFT) is employed to pattern source and drain regions and a pixel electrode with the same mask. Moreover, according to the invention, among the patterns required to form a liquid crystal display device such as a conductive layer for a wiring layer or an electrode, a mask for forming a predetermined pattern and the like, at least one or more of them is formed by a method by which a pattern can selectively be formed, thereby manufacturing a liquid crystal display device.

Owner:SEMICON ENERGY LAB CO LTD

Ald reactor

InactiveUS20090255470A1Eliminates back flow and dead-end pocketReduce areaFrom chemically reactive gasesChemical vapor deposition coatingGas exchangeReaction chamber

The invention relates to a reaction chamber of an ALD reactor which comprises a bottom wall, a top wall and side walls extending between the bottom wall and the top wall which define an inner portion (28) of the reaction chamber. The reactor further comprises one or more feed openings (30) for feeding gas into the reaction chamber and one or more discharge openings (40,50) for discharging gas fed into the reactor from the reaction chamber. The reaction chamber is characterized in that each side wall of the reaction chamber comprises one or more feed openings (30), in which case all side walls of the reaction chamber participate in gas exchange.

Owner:BENEQ OY

Non-cementitious dry finish compositions comprising a combination of film forming polymers

InactiveUS20130196070A1Good flexibilityAbility to be pigmentedPretreated surfacesCoatingsPolymerMaterials science

Owner:TREMCO CPG INC

Miniature receptacle terminals

ActiveUS8323061B2Increase contact forceEasy to controlCoupling contact membersElectric connection basesEngineeringMechanical engineering

This approach generally pertains to a miniature terminal receptacle (10) with a connection section (12) and a mating section (14). The mating section has a pseudo- two-beam component that includes a contact spring (20) having a stationary beam, a resilient contact beam (24) and a beam overlapping section (26). The resilient contact beam has a contact bump (40) and a stiffening section (30) with a pivotal point (38). The shape of the contact spring increases the contact engagement or holding force on a male pin during mating. Overstress protection of the contact spring is provided and the terminal is economical to produce.

Owner:MOLEX INC

Film formation method and method for manufacturing light-emitting device

InactiveUS8119204B2Improve throughputFilm qualityVacuum evaporation coatingSolid-state devicesProduction rateEvaporation

A binder material layer including an evaporation material is formed over a main surface of an evaporation source substrate, a substrate on which a film is formed is placed so that the binder material layer and a main surface thereof face each other, and heat treatment is performed on a rear surface of the evaporation source substrate so that the evaporation material in the binder material layer is heated to be subjected to sublimation or the like, whereby a layer of the evaporation material is formed on the substrate on which a film is formed. When a low molecular material is used for the evaporation material and a high molecular material is used for the binder material, the viscosity can be easily adjusted, and thus, film formation is possible with higher throughput than conventional film formation.

Owner:SEMICON ENERGY LAB CO LTD

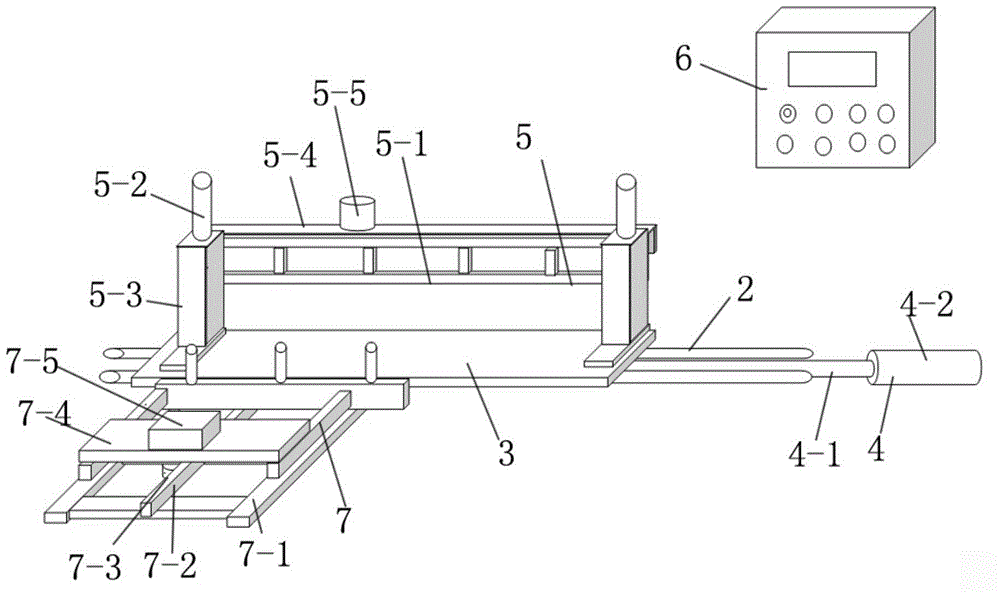

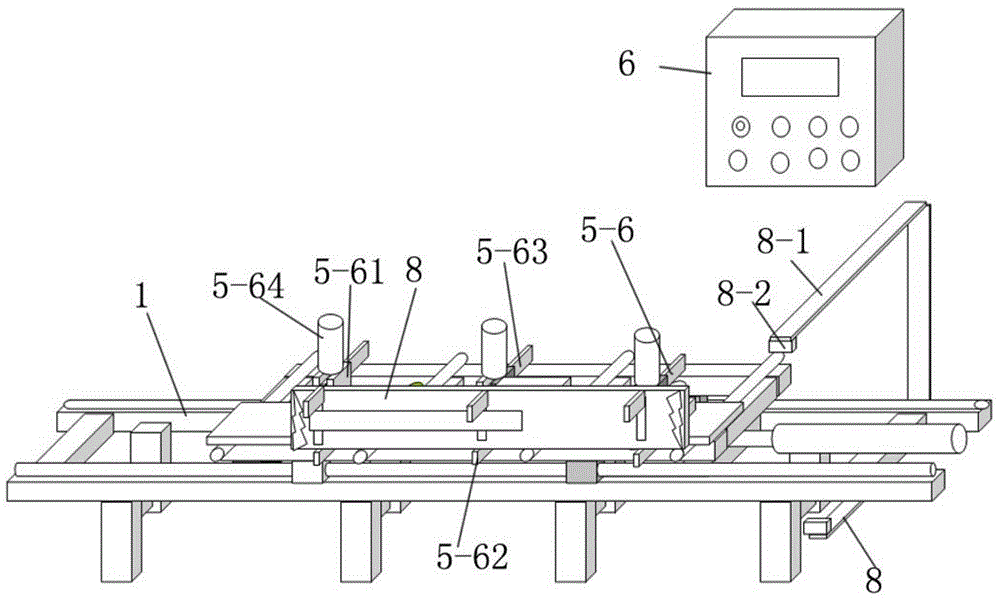

Automatic pushing platform for woodworking

InactiveCN104858941AImprove securityReduce the likelihood of work-related injuriesFeeding devicesGripping devicesEngineeringMaster controller

The invention discloses an automatic pushing platform for woodworking. The automatic pushing platform for woodworking is characterized by comprising a rack, first guide rails arranged on the rack, a pushing platform body matched with the first guide rails in a sliding mode, a power device which is connected with the pushing platform body and drives the pushing platform body to slide along the first guide rails, a wood positioning mechanism arranged on the pushing platform body, and a master controller which is connected with the power device and the wood positioning mechanism and used for controlling the power device and the wood positioning mechanism. The power device comprises a first pressure cylinder arranged on the rack, and a pressure rod of the first pressure cylinder is connected to one end of the pushing platform body. Manpower can be saved by half compared with the prior art; production efficiency is high; the possibility of occupational injuries is reduced, and safety performance is greatly improved.

Owner:FOSHAN CITY SANSHUI DISTRICT YOUSHENG WOOD IND CO LTD

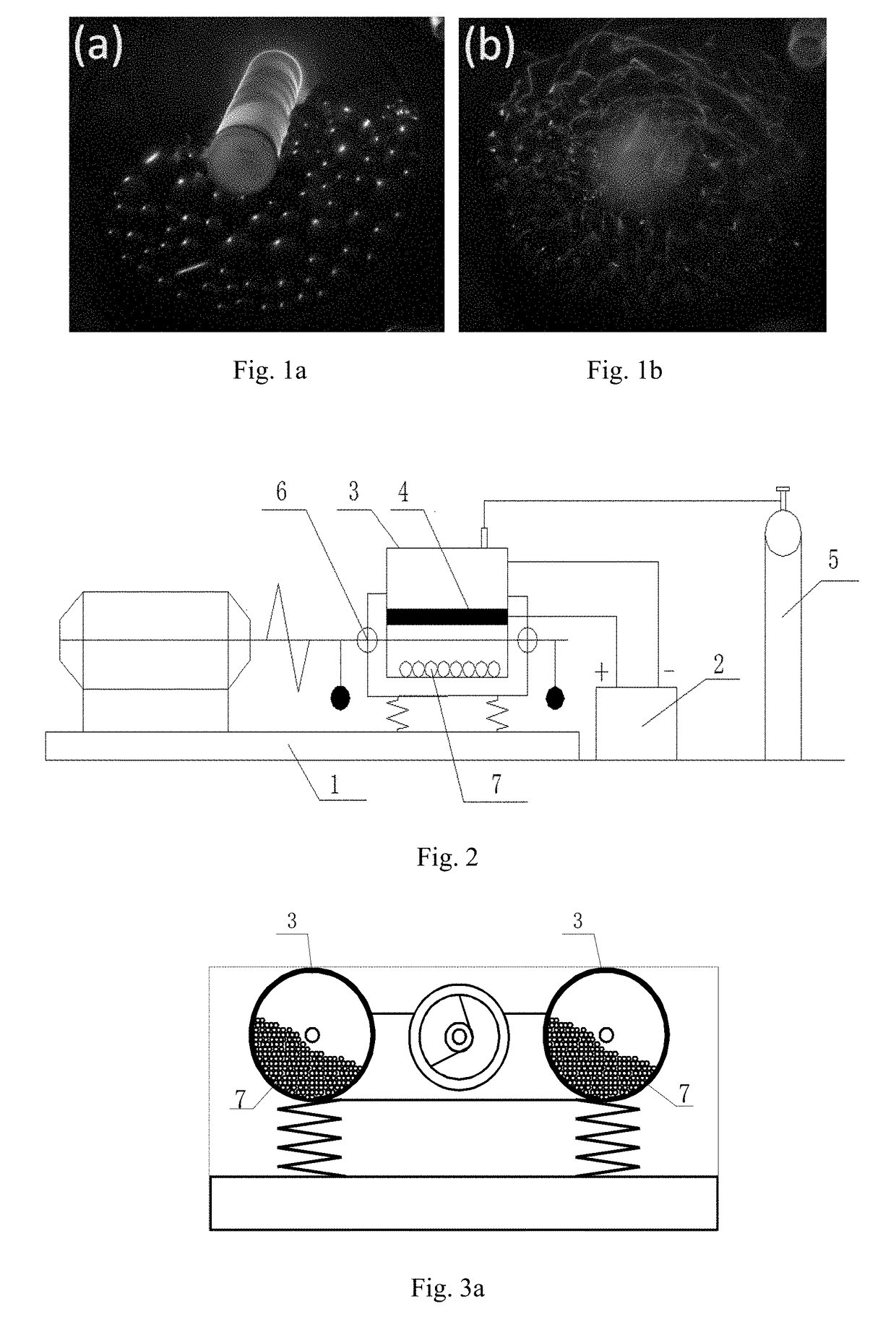

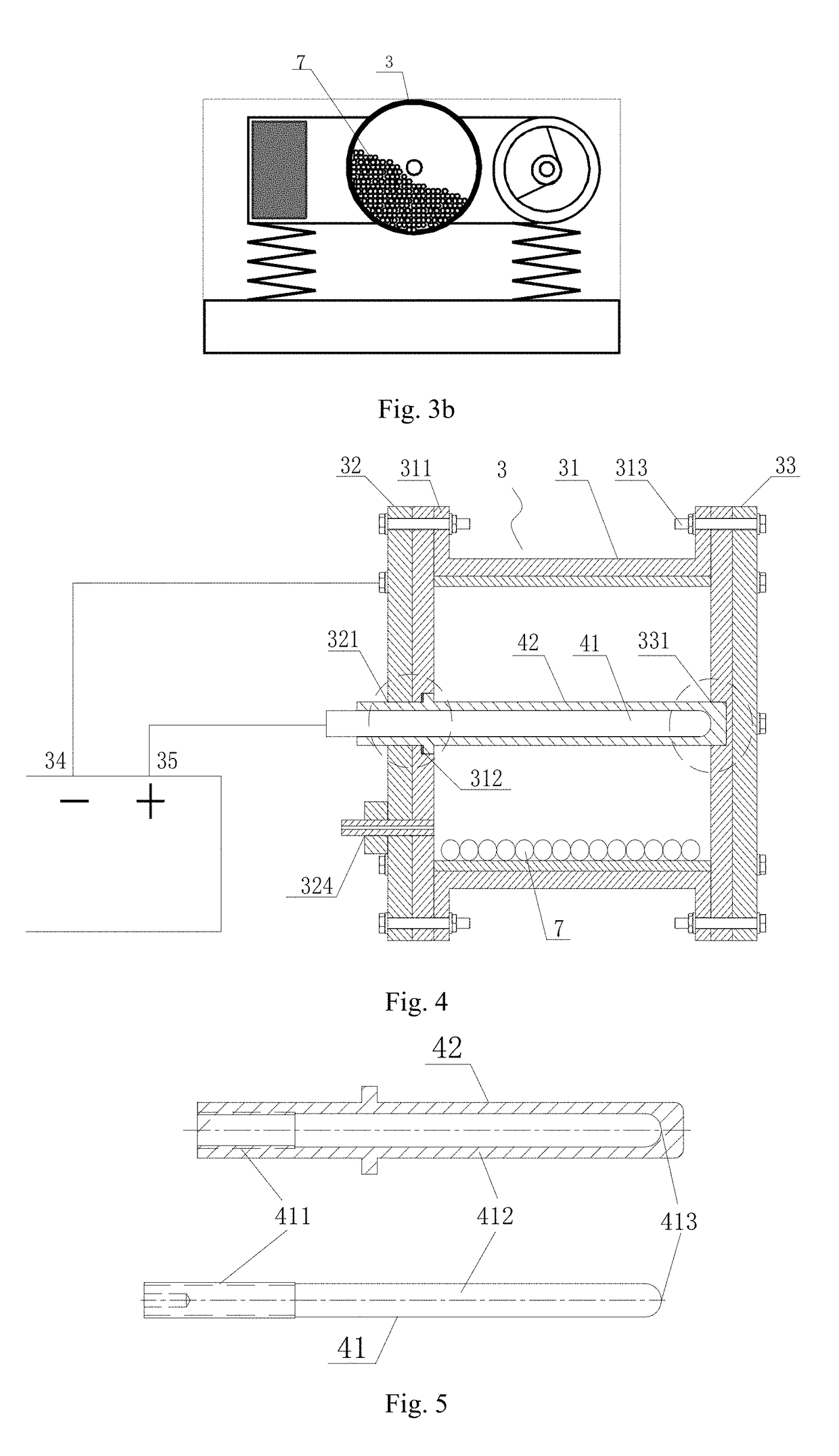

Application method and device for cold field plasma discharge assisted high energy ball milled powder

ActiveUS20170348699A1Strong destructive powerImprove processing efficiencyGrain treatmentsHigh energyHigh pressure

The present invention provides an application method for cold field plasma discharge assisted high energy ball milled powder and a plasma assisted high energy ball milling device using the method for cold field plasma high energy ball milled powder. The present invention generates plasma by using dielectric barrier discharge and introducing a dielectric barrier discharge electrode bar into a high-speed vibrating ball milling tank, which requires that, on one hand, a solid insulation medium on the outer layer of the electrode bar can simultaneously bear high-voltage discharge and mechanical shock failure of the grinding ball, and on the other hand, the high-speed vibrating ball milling device can uniformly process the powder. Based on the ordinary ball milling technology, the discharge space pressure is set to a non-thermal equilibrium discharge state with a pressure of about 102 to 106 Pa, discharge plasmas are introduced to input another kind of effective energy to the processed powder, so as to accelerate refinement of the powder to be processed and promote the alloying process under the combined action of the mechanical stress effect and the thermal effect of the external electric field, thereby greatly improving the processing efficiency and the effect of the ball mill.

Owner:SOUTH CHINA UNIV OF TECH

Miniature receptacle terminals

ActiveUS20120003881A1Protection from damageIncrease contact forceCoupling contact membersElectric connection basesEngineeringMechanical engineering

This approach generally pertains to a miniature terminal receptacle (10) with a connection section (12) and a mating section (14). The mating section has a pseudo- two-beam component that includes a contact spring (20) having a stationary beam, a resilient contact beam (24) and a beam overlapping section (26). The resilient contact beam has a contact bump (40) and a stiffening section (30) with a pivotal point (38). The shape of the contact spring increases the contact engagement or holding force on a male pin during mating. Overstress protection of the contact spring is provided and the terminal is economical to produce.

Owner:MOLEX INC

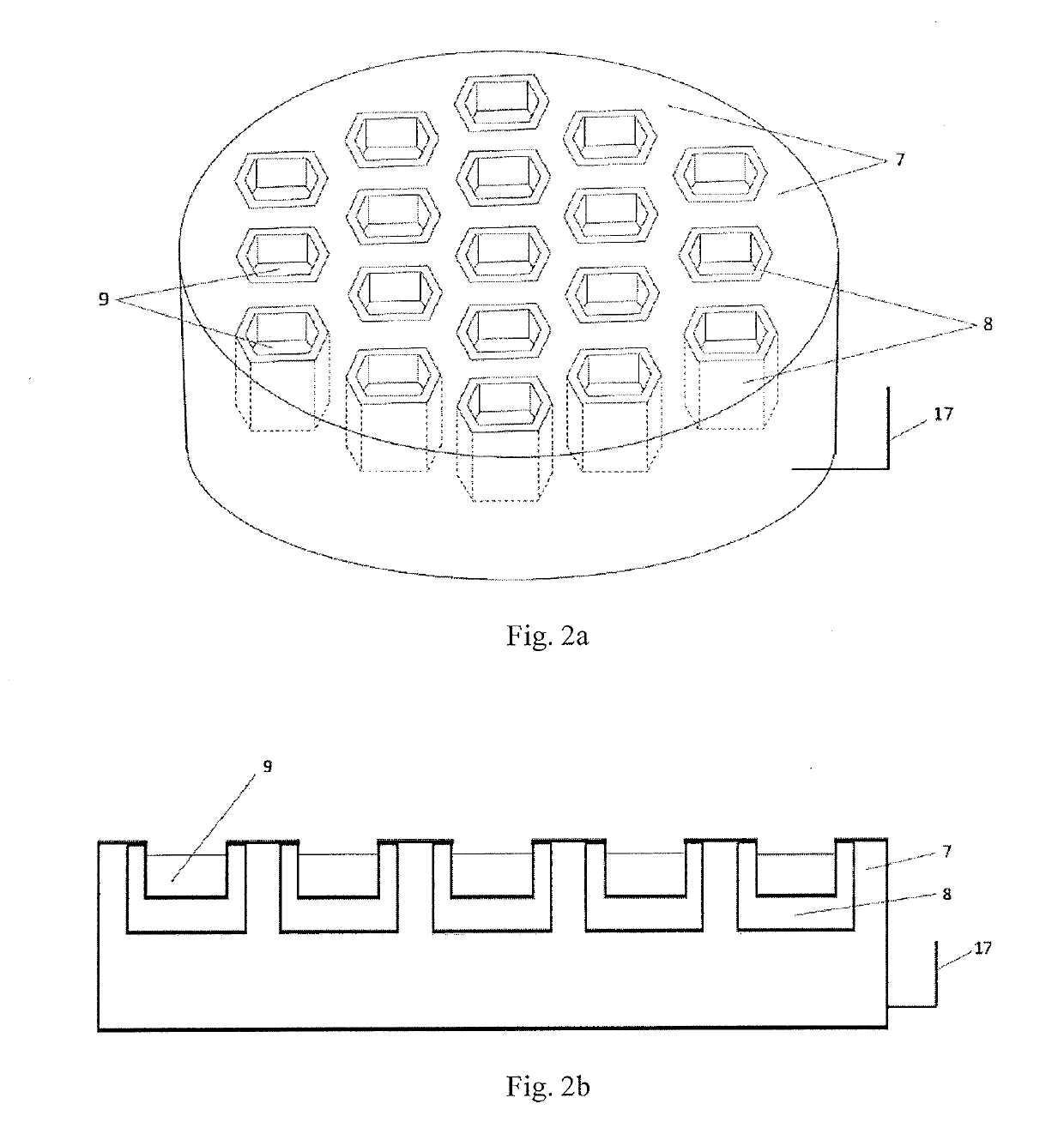

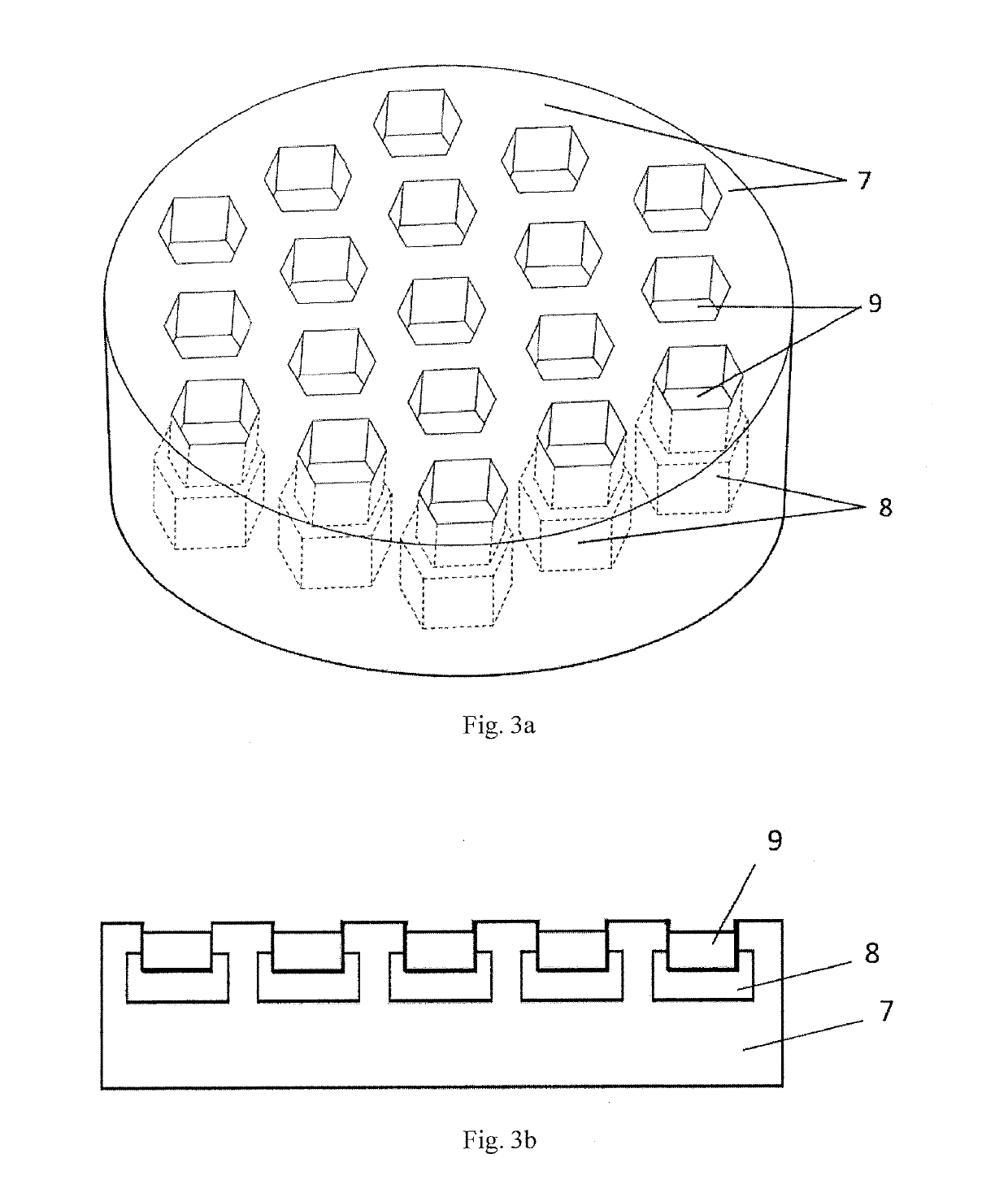

High throughput micro-synthesis method of multi-component materials

ActiveUS20190111481A1Improve heating efficiencyHigh heatTransportation and packagingMetal-working apparatusMaterial consumptionHeating efficiency

The present invention belongs to the technical field of high throughput preparation and hot working of materials, and in particular to a high throughput micro-synthesis method of multi-component materials based on the temperature gradient field controlled by microwave energy. This invention, characterized by flexible material selection, quick temperature rising and high-efficient heating, uses microwave heating both to achieve quick preparation of small block combinatorial materials under the same temperature field in one time and to realize micro-synthesis under the different temperature gradient fields in one time including high-throughput sintering-melting and heat treatment of materials. This invention successfully overcomes drawbacks of current material preparation, such as unitary combination of components, low-efficient external heating, unique control temperature, huge material consumption and high cost during material preparation and heat treatment.

Owner:CENT IRON & STEEL RES INST

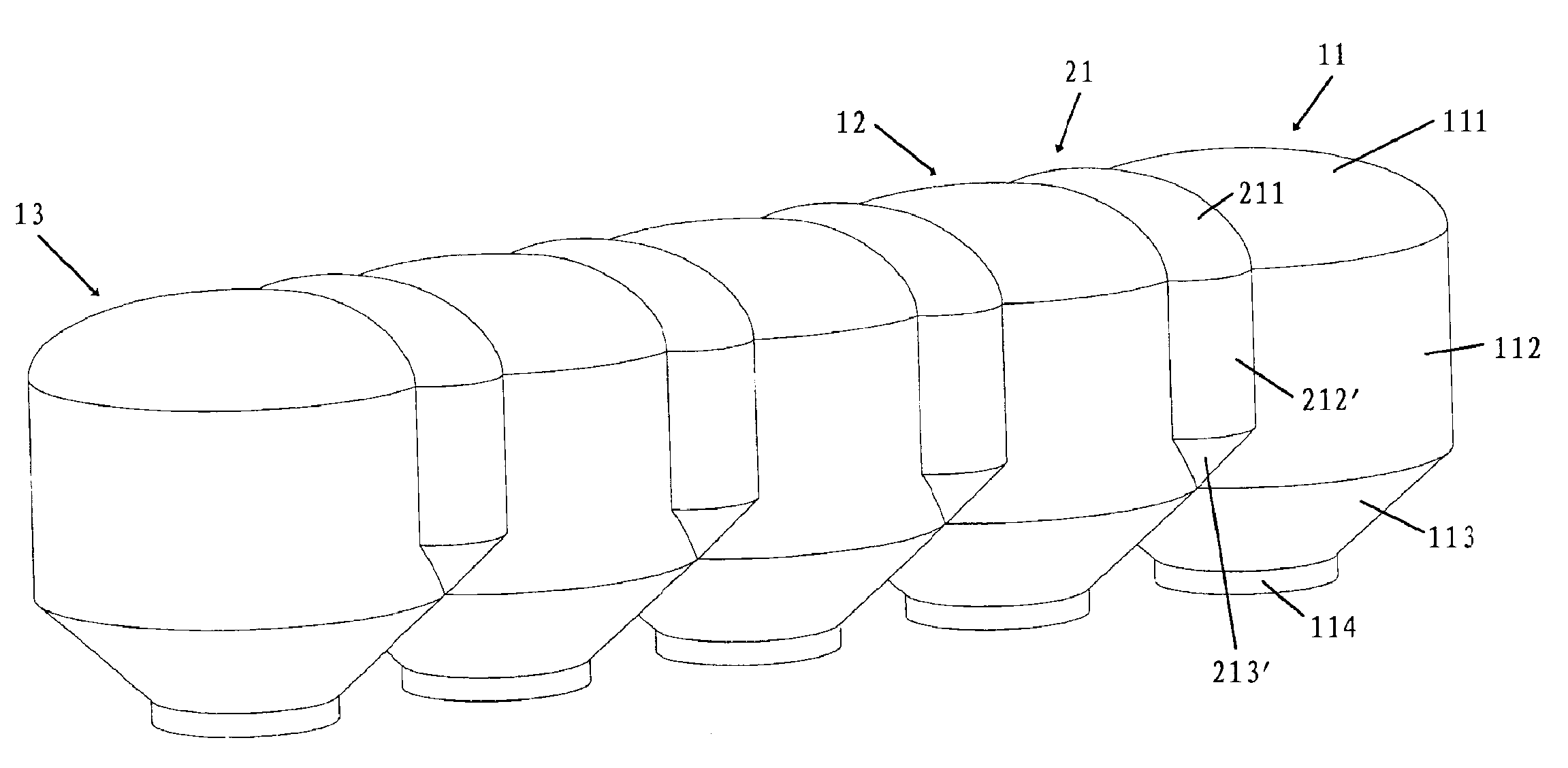

Composite bin for powder or particle material

InactiveUS8479938B2Improve material efficiencyImprove efficiencyLarge containersLiquid transferring devicesMechanical engineeringParticle material

A sealed composite bin for accommodating and delivering powder or particle material has multiple main bin units (11-13) arranged vertically and connected with each other, each including an arched main top part (111), a cylindrical main side wall (112) and a conical main bottom part (113). The radius of each main side wall is approximately the same, the in-line arrangement of the multiple main bin units (11-13) make the distance between the axes of the adjacent main bin units less than the sum of the radii of the two corresponding main side walls, and the multiple main bin units are communicated with each other. A supplementary bin unit (21) is provided between the adjacent main bin units, and the supplementary bin unit (21) includes a supplementary top part (211) connected to the top parts of the adjacent main bin units and cylindrical supplementary side walls (212,212′) connected to the side walls of the adjacent main bin units. The structure of the composite bin of the invention can obtain more inner volume by using the same amount of material for the exterior surface, and hence improves the using efficiency of the material.

Owner:PU XIAO +1

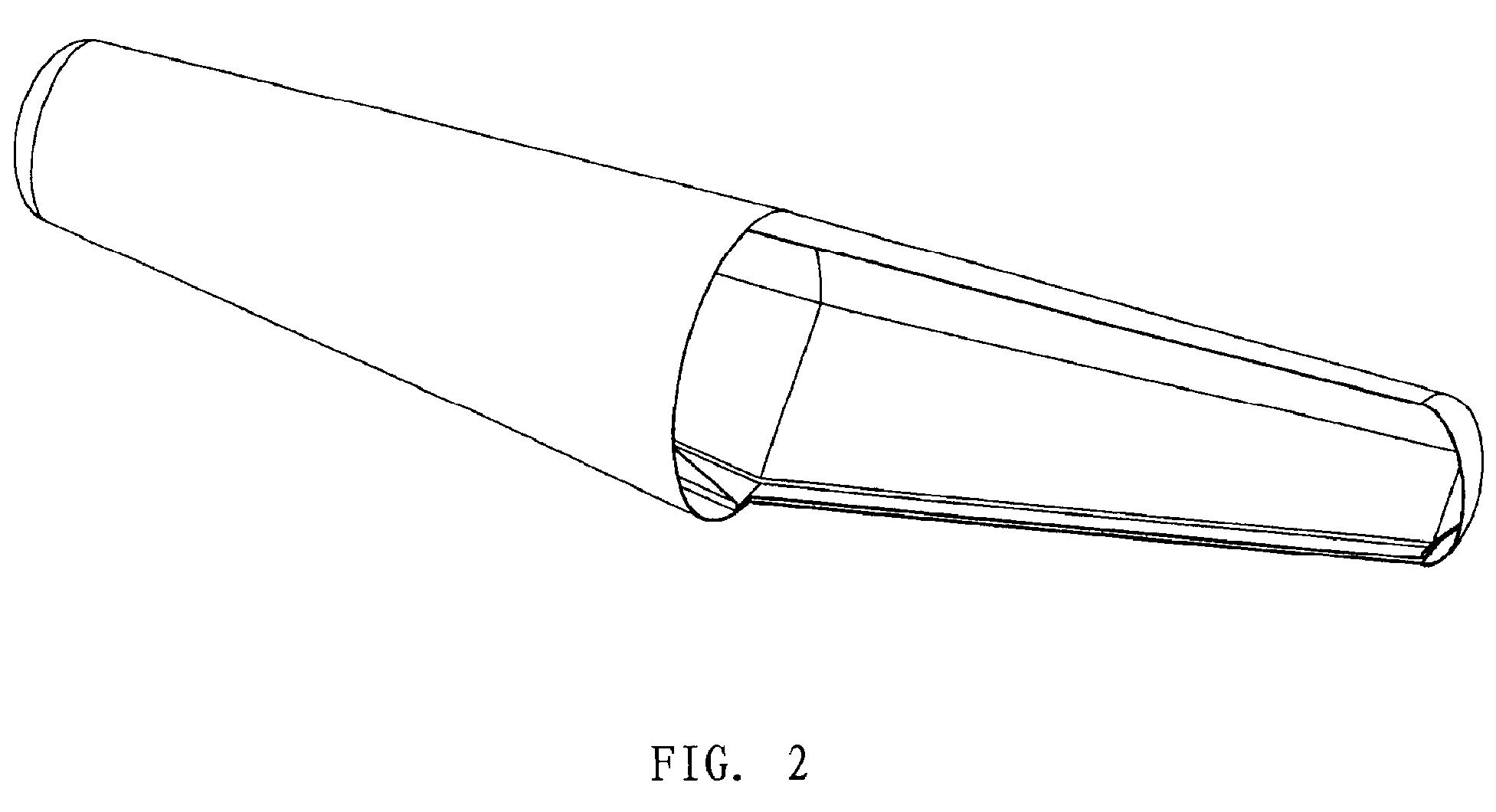

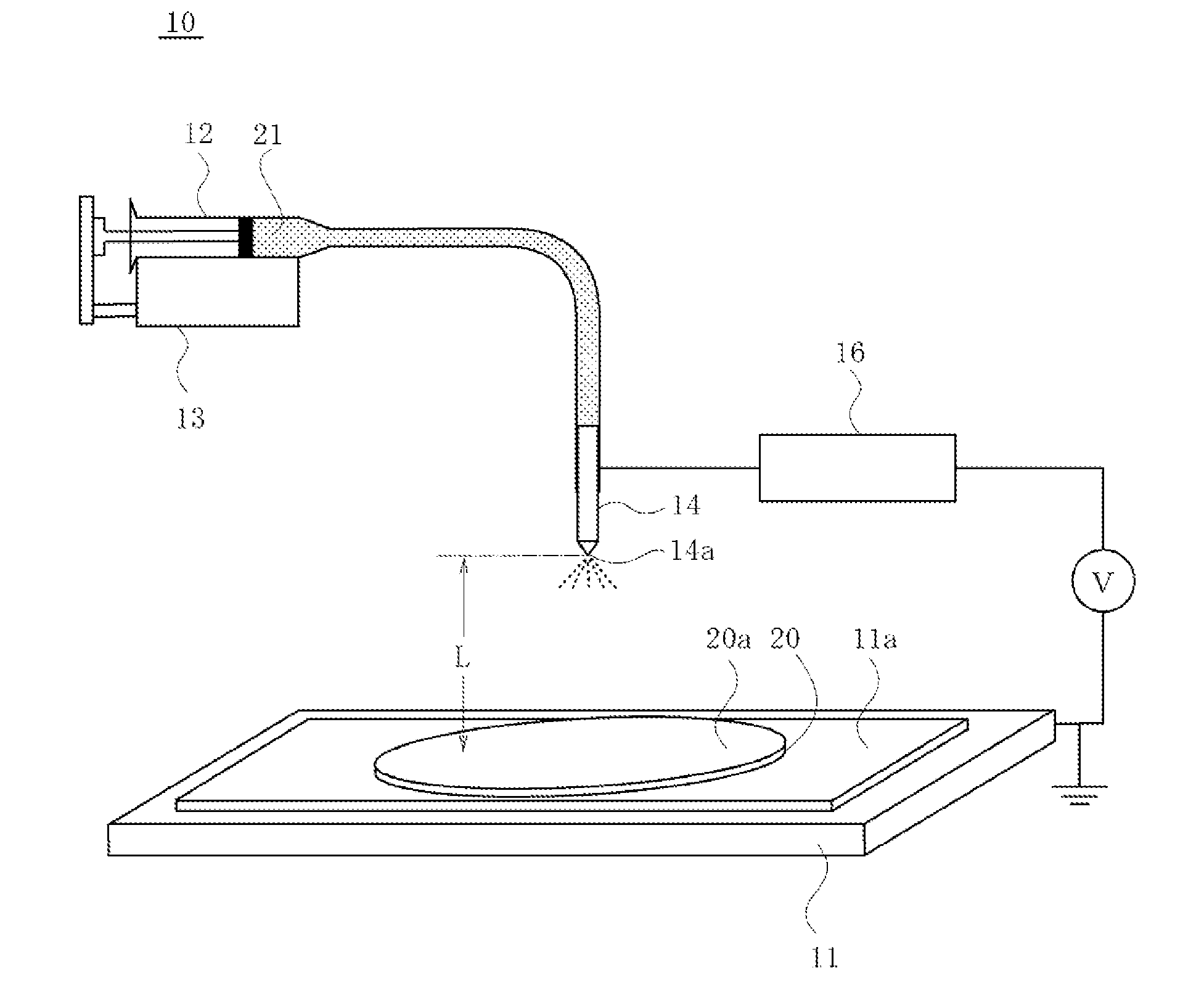

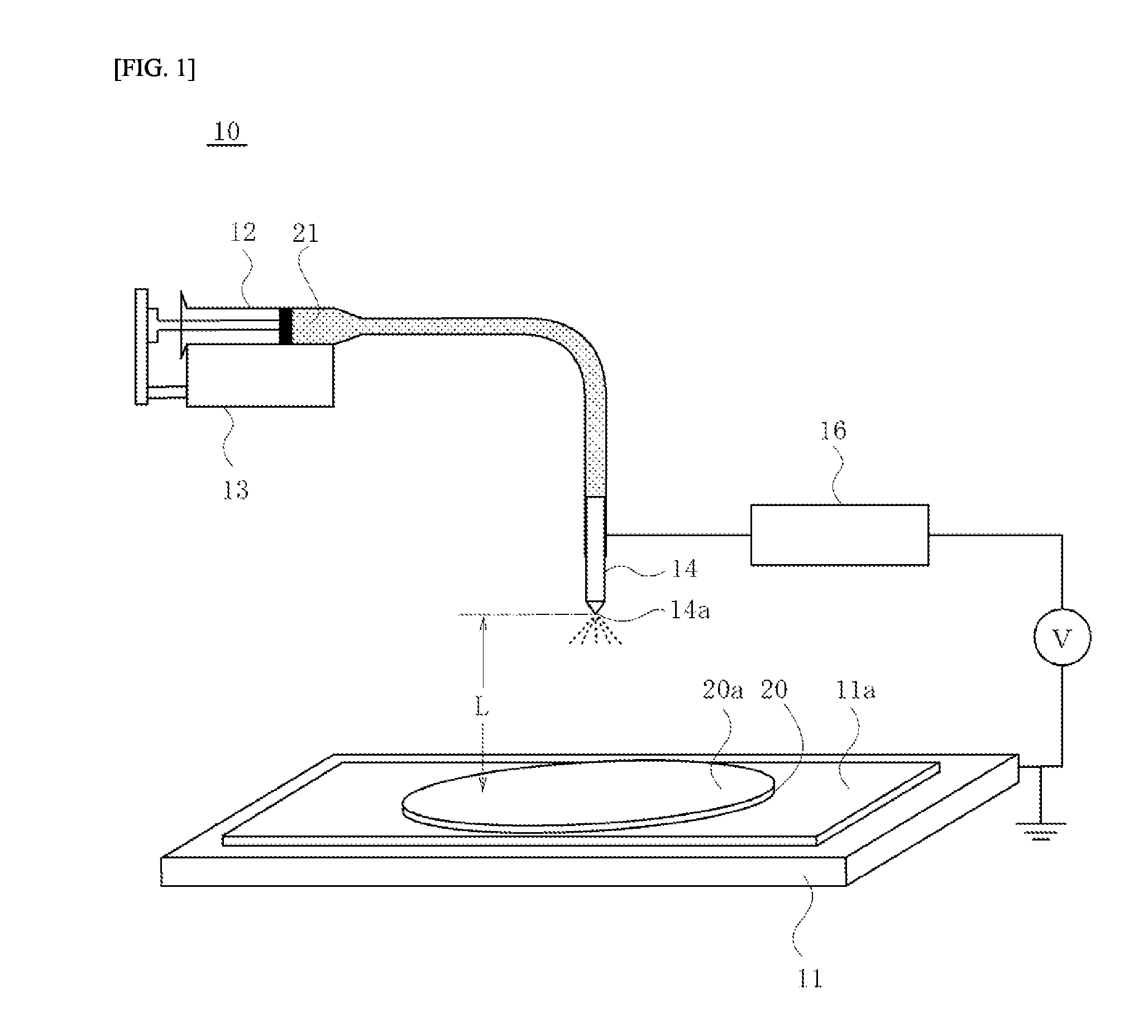

Method of manufacturing ferroelectric thin film

InactiveUS20130260051A1Excellent electrical propertiesEasy to useLiquid surface applicatorsElectric shock equipmentsFerroelectric thin filmsRefractive index

A method of manufacturing a ferroelectric thin film on a lower electrode by electrostatically spraying a ferroelectric thin film-forming sol-gel solution from a spout of a capillary toward the lower electrode of a substrate having the lower electrode so as to coat the sol-gel solution on the lower electrode and form a coated film, drying, calcining, and then firing the coated film so as to crystallize the coated film, in which a distance between the spout of the capillary and the lower electrode and an applied voltage during electrostatic spray are set so that a refractive index during drying and calcination of the coated film becomes 2 or more, and a film thickness sets in a range of 150 nm or less when the sol-gel solution is coated in a single spray process, calcined, and then fired so as to be crystallized.

Owner:MITSUBISHI MATERIALS CORP

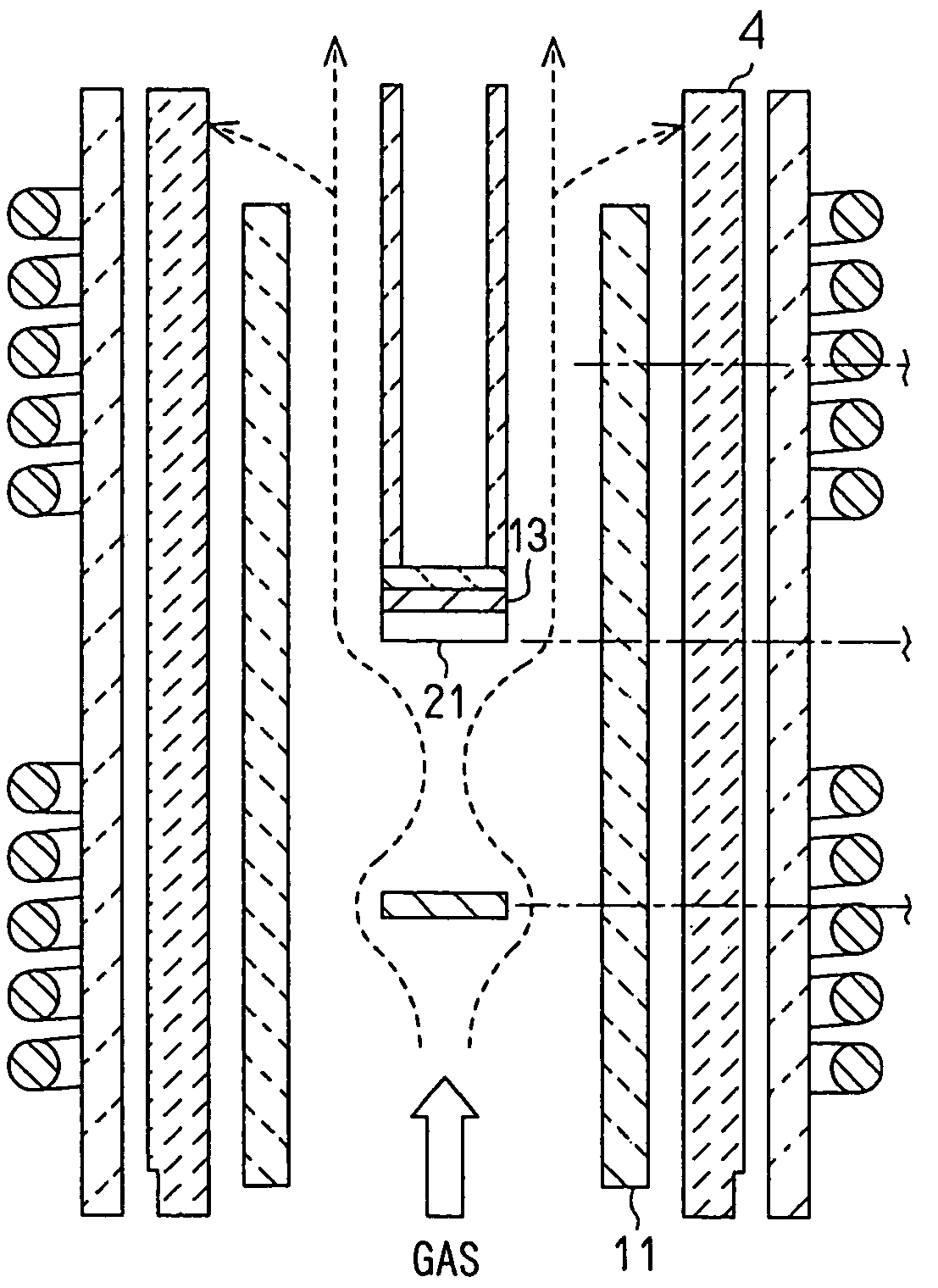

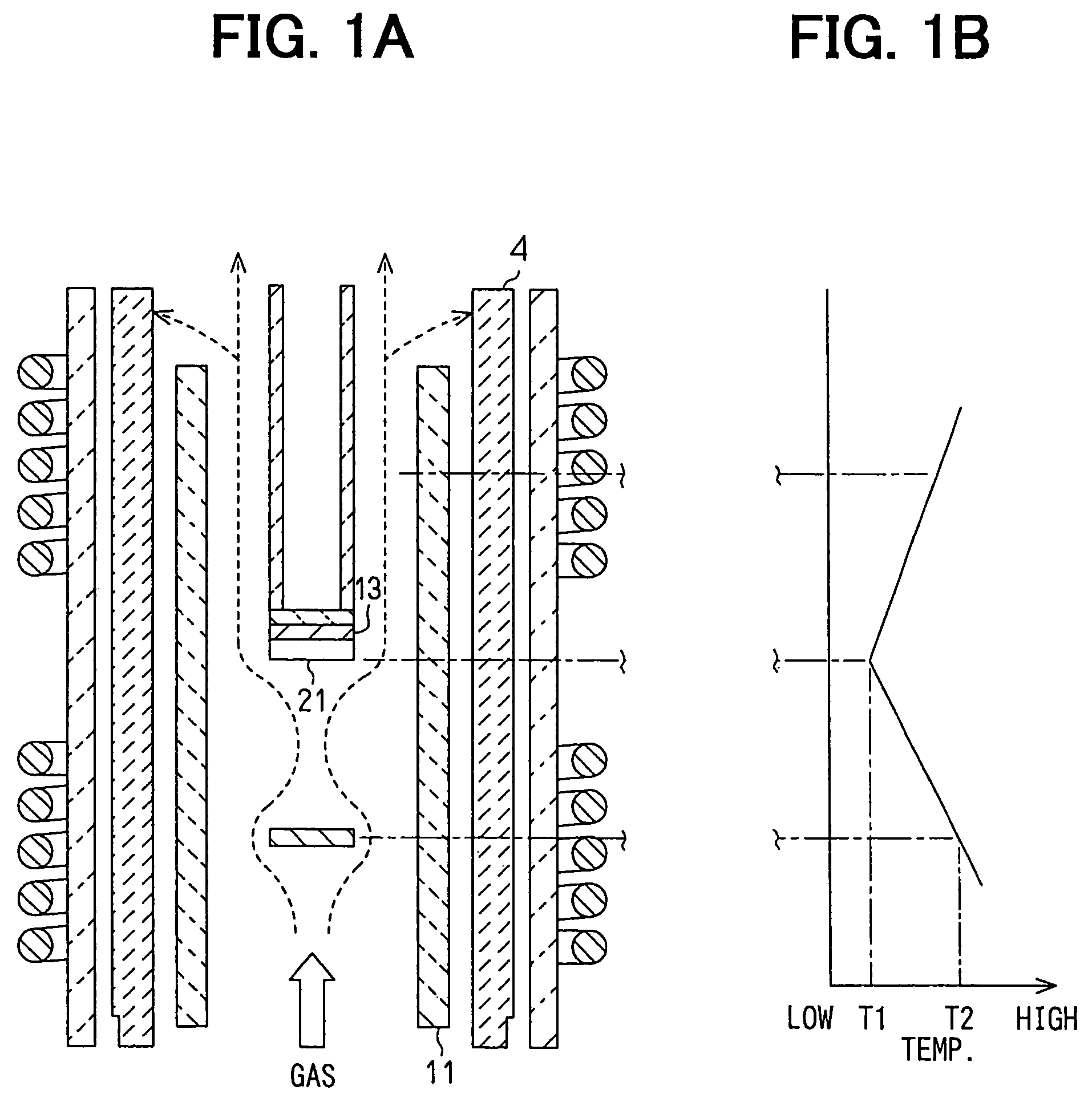

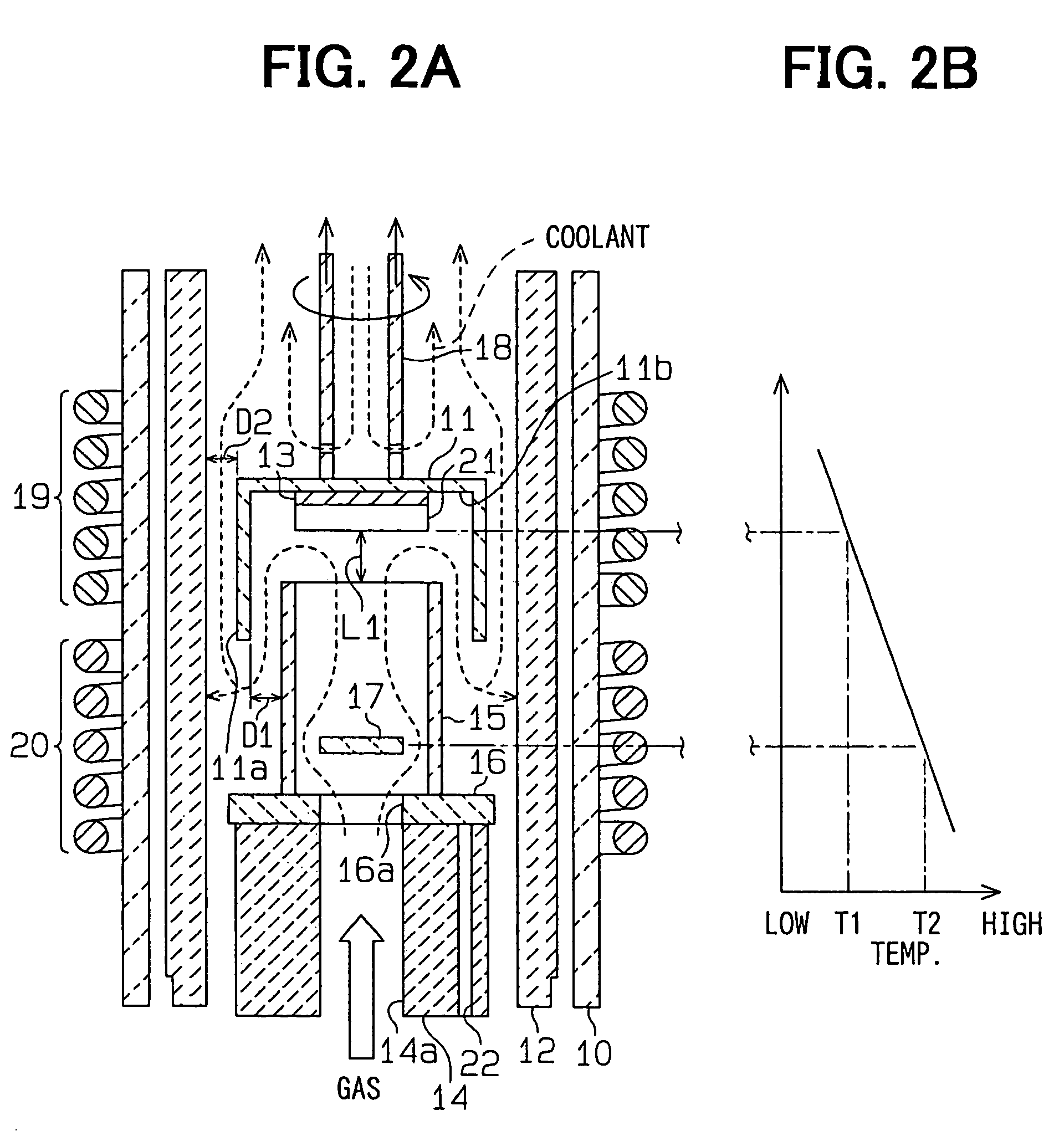

Equipment and method for manufacturing silicon carbide single crystal

ActiveUS7217323B2Growth of crystal growth highLarge temperature differenceAfter-treatment apparatusPolycrystalline material growthProduct gasCrystal growth

Owner:DENSO CORP

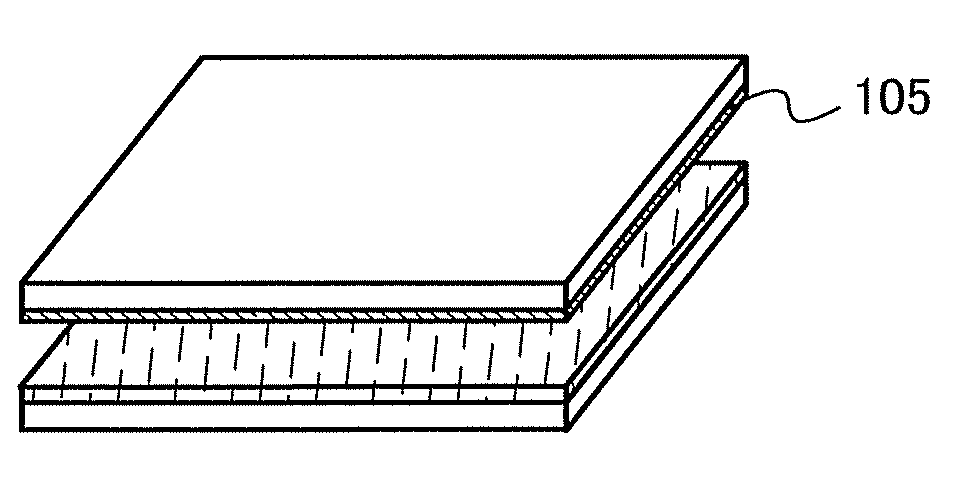

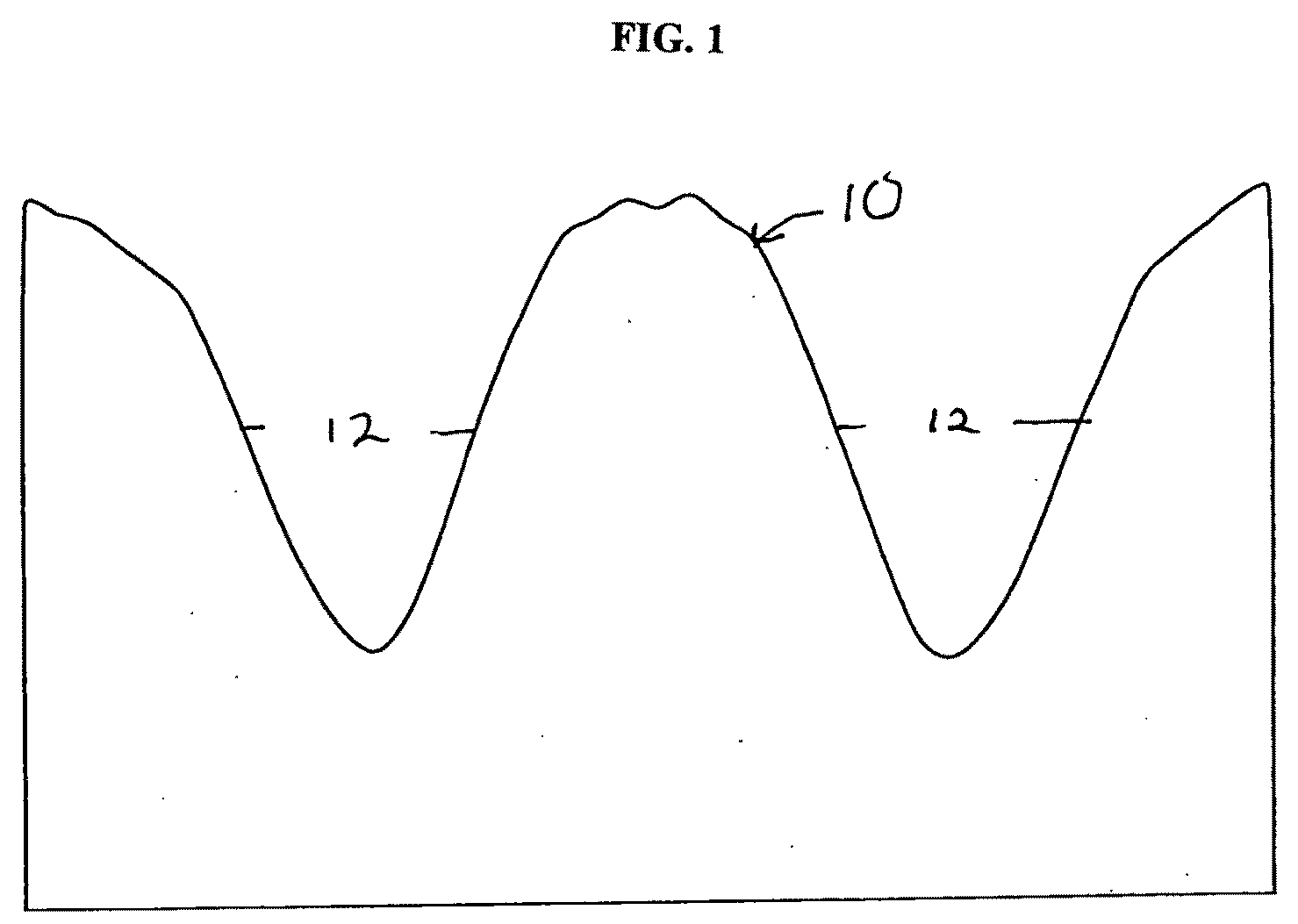

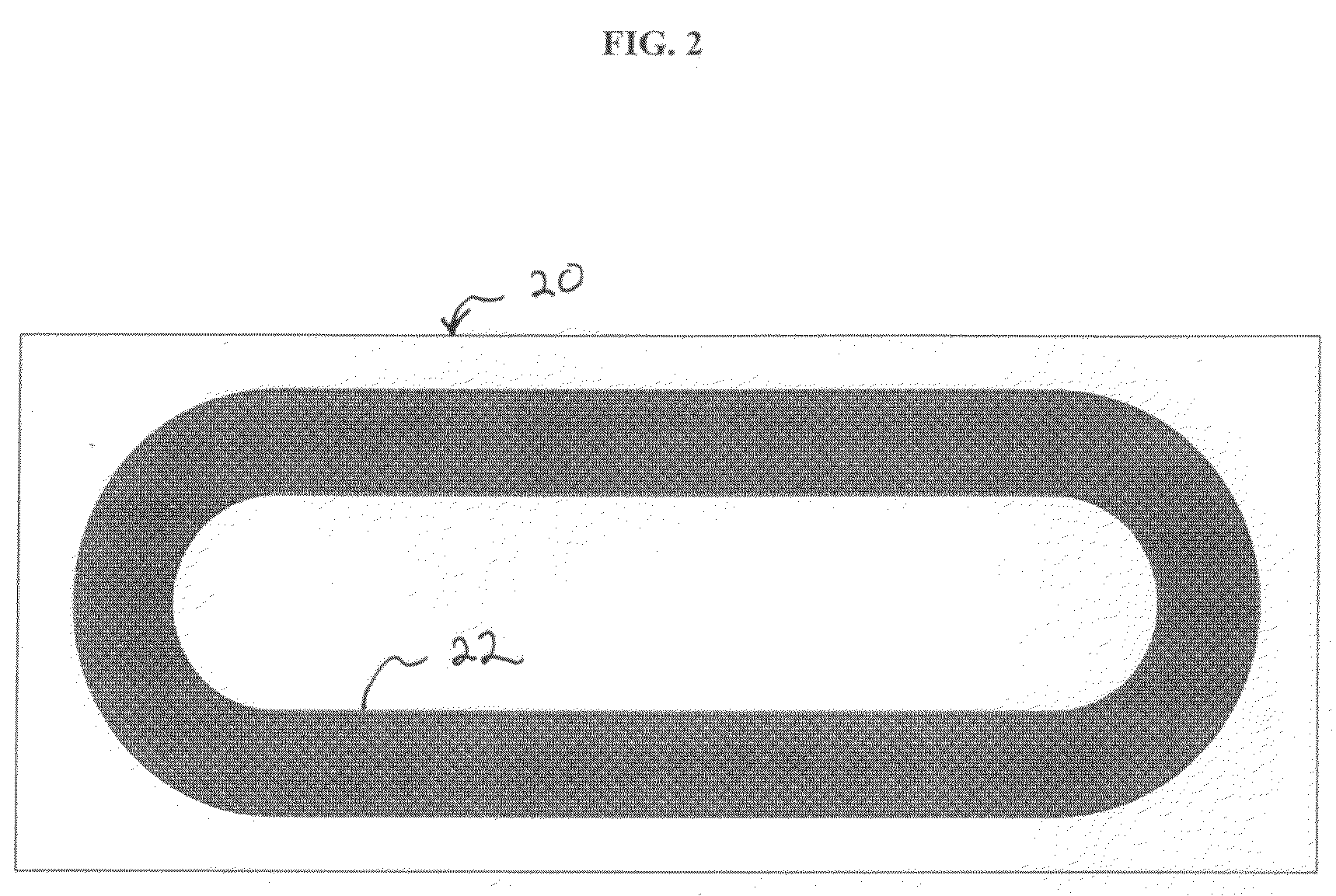

Method for making composite sputtering targets and the tartets made in accordance with the method

Composite sputtering targets are made by hot pressing metal or metal containing powders into a backing plate which can be comprised of a different material with a depression formed in a surface or can be a used sputtering target of the same or different material. The depression corresponds to the erosion pattern of a target having the same geometry. The depression can be formed for example, by machining. The backing plate is loaded into a graphite die and covered with the sputtering material to form an assembly. A ram is added and the assembly with the ram is loaded into a hot press which is taken to an appropriate pressure and temperature under vacuum to form a composite sputtering target having a sputtering zone of densified sputtering material.

Owner:SCI ENGINEERED MATERIALS INC

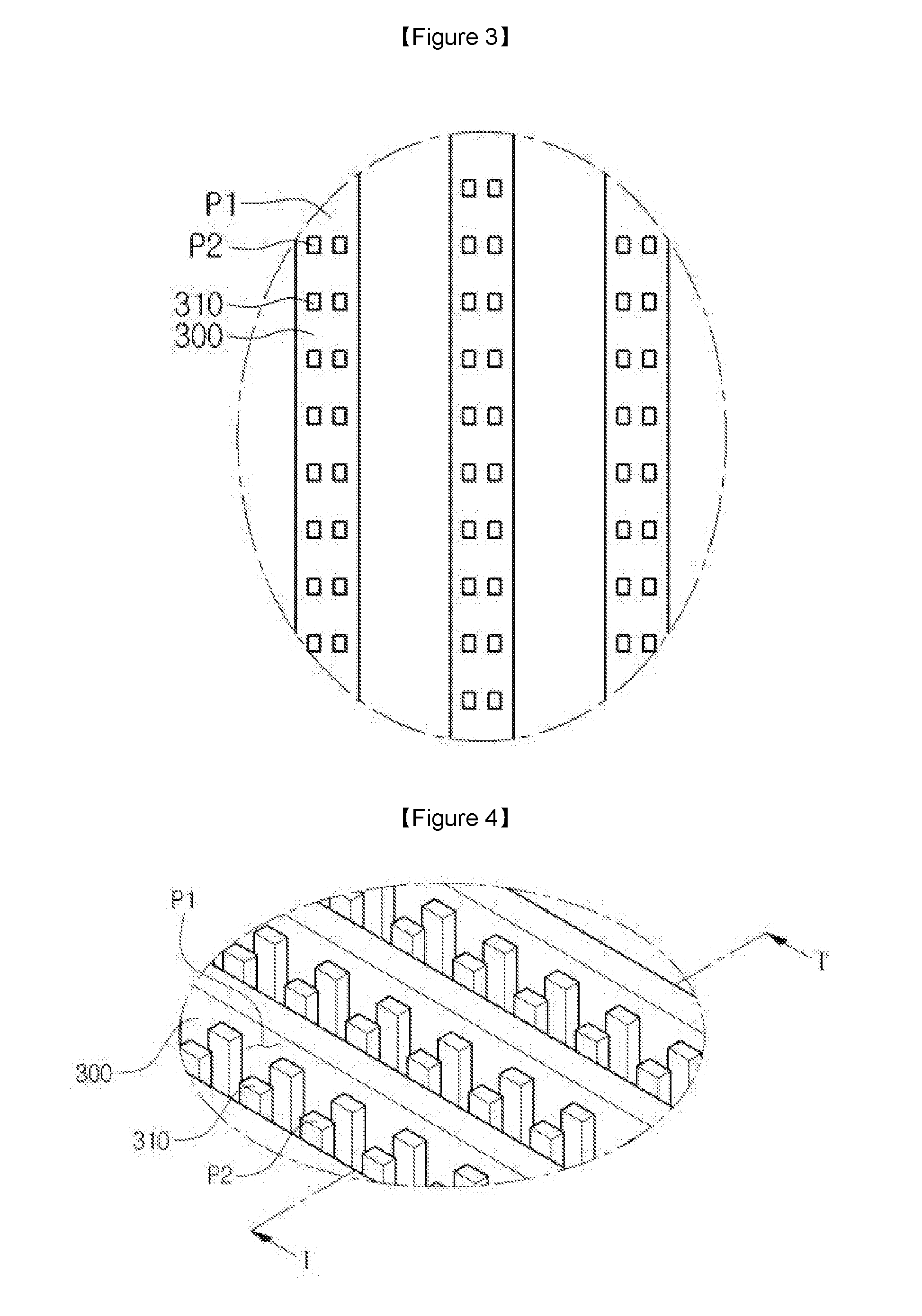

Touch window

ActiveUS20160170555A1High pattern accuracyImprove fill rateInput/output processes for data processingElectrical and Electronics engineeringElectrode

Disclosed is a touch window. The touch window includes a substrate, a sensing electrode on the substrate, and a wire to electrically connect the sensing electrode, and a dummy part is provided in the wire. The touch window includes a substrate, a sensing electrode on the substrate, and a wire to electrically connect the sensing electrode. The wire includes a first wire part and a second wire part adjacent to the first wire part, and the first wire part has a directionality different from a directionality of the second wire part.

Owner:LG INNOTEK CO LTD

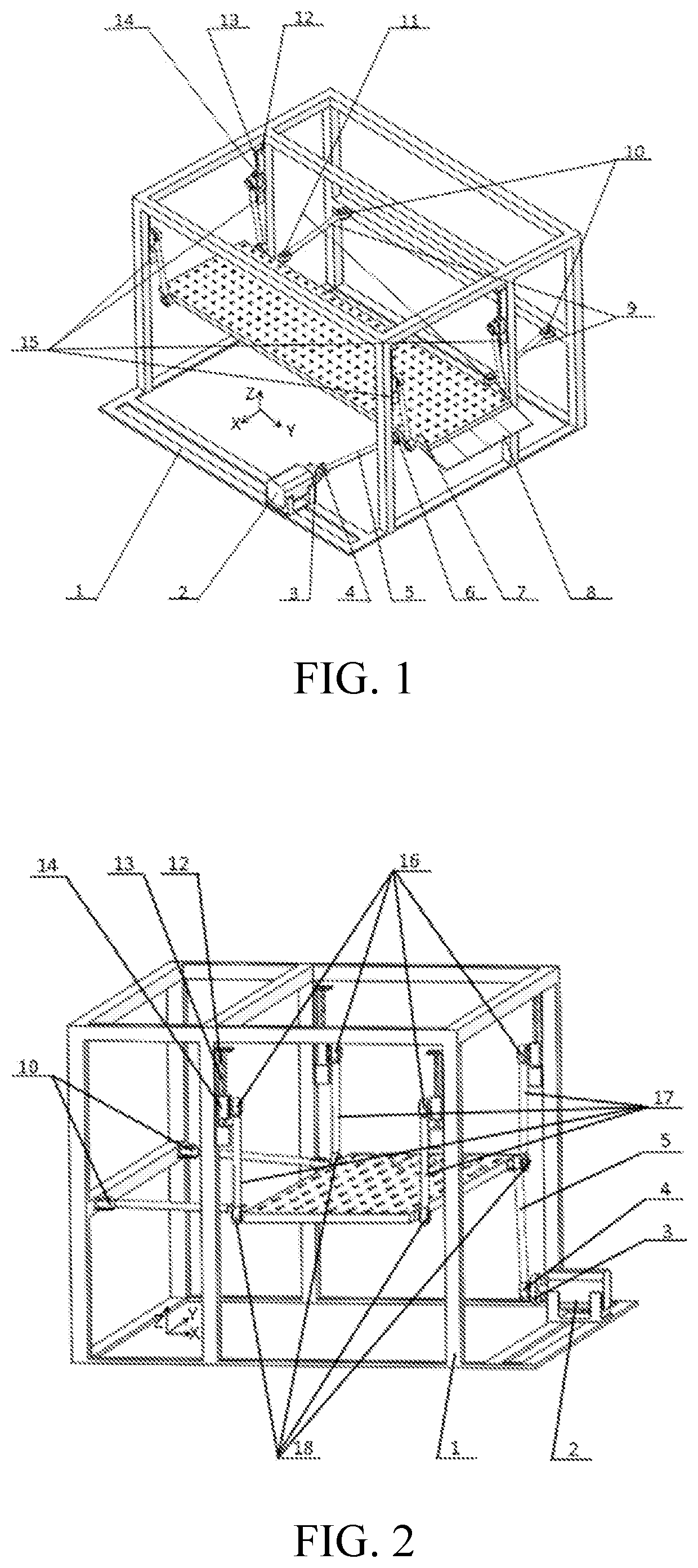

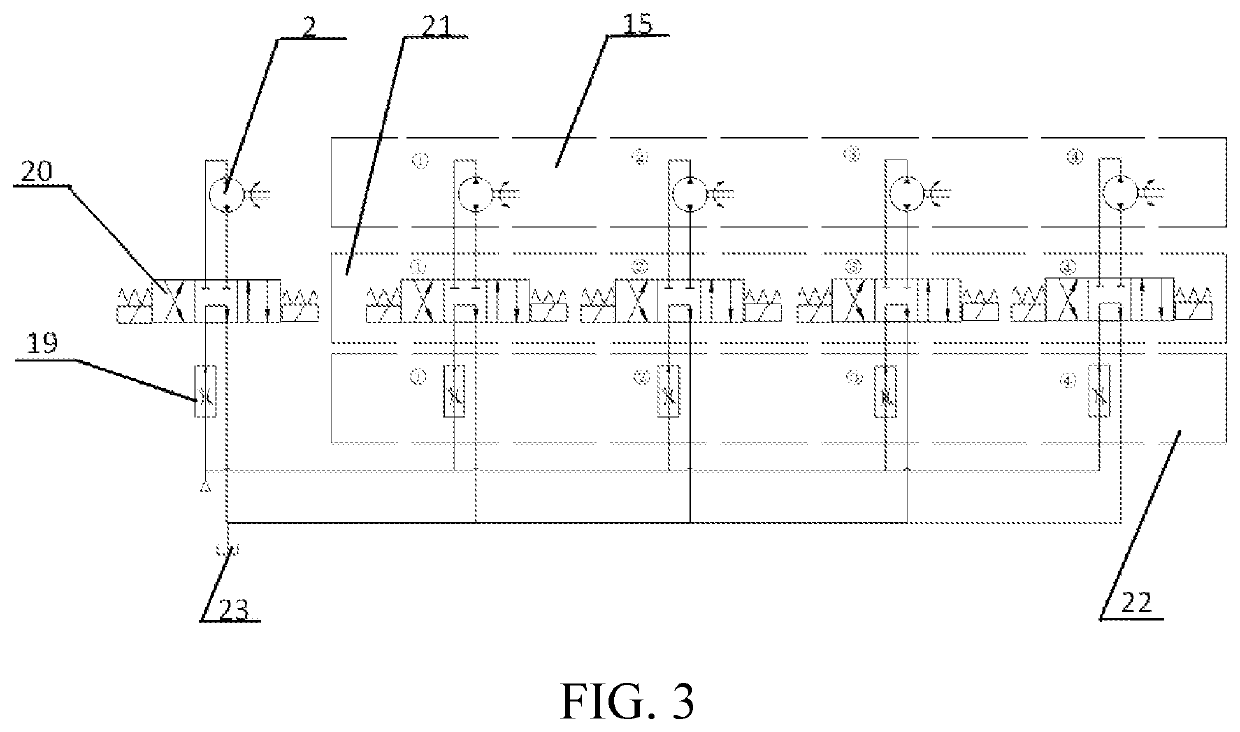

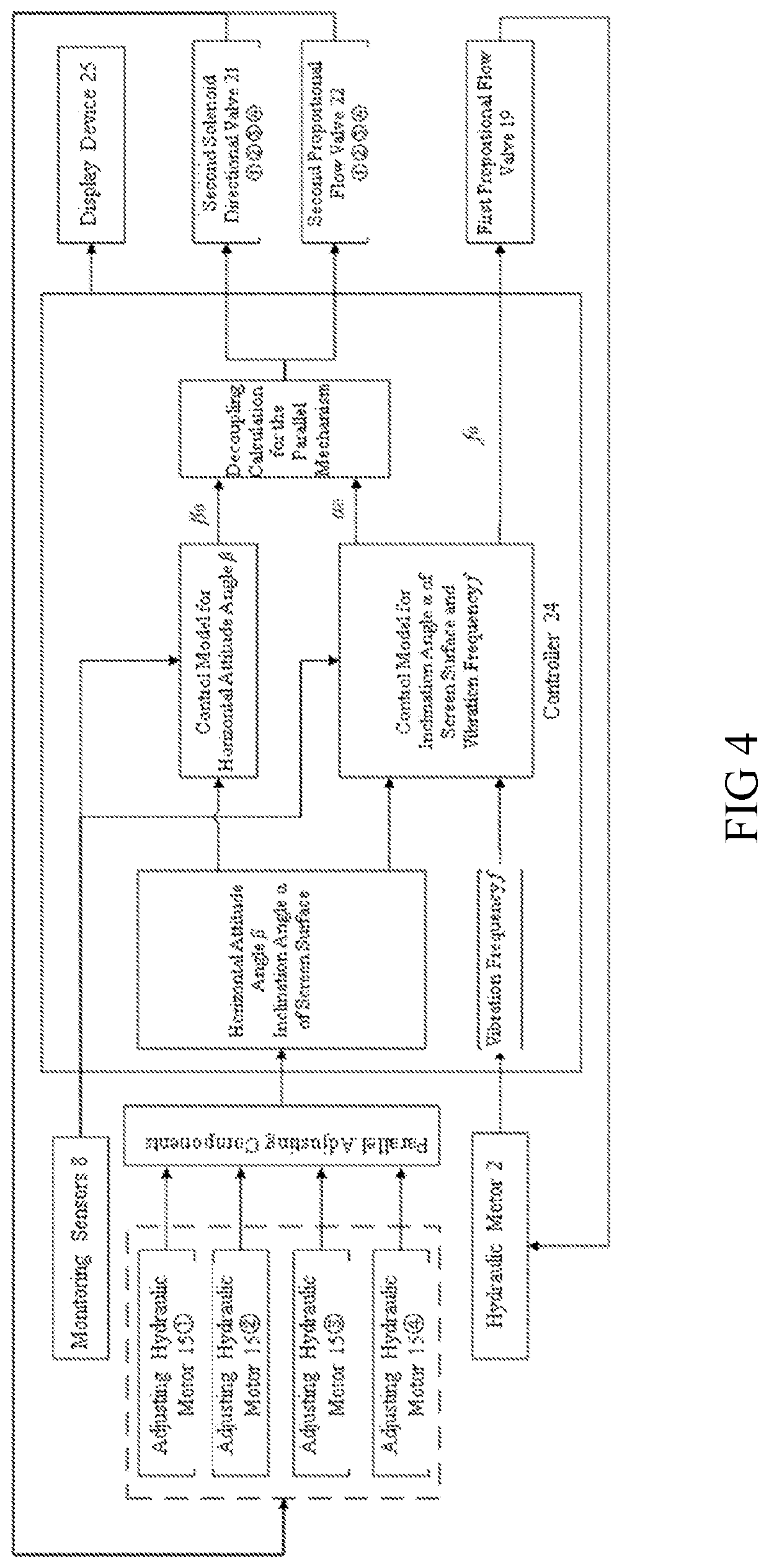

Three-Degree-of-Freedom Hybrid Vibratory Screening Mechanism, Control Method Thereof, and Harvester

ActiveUS20210402437A1Material efficiency be improveDecrease in rate of lossSievingScreeningReciprocating motionControl engineering

The present invention provides a three-degree-of-freedom hybrid vibratory screening mechanism, a control method thereof, and a harvester. The three-degree-of-freedom hybrid vibratory screening mechanism comprises a frame, a vibrating screen, a first driving mechanism, a second driving mechanism, sensors and a controller; parallel drive of hydraulic motors are used for achieving two-degree-of-freedom rotational adjustment of the horizontal attitude angle and inclination angle of the screen surface of the vibrating screen, and the first driving mechanism drives the vibrating screen to reciprocate in one degree of freedom, so as to realize three-degree-of-freedom vibration adjustment of the screen surface; a vibration parameter control model is established by means of theoretical analysis in combination with experiment. In the operating process, the sensors installed at the tail part of the vibrating screen monitor the loss rate and distribution of the grains in real time, and the horizontal attitude angle of the screen surface, inclination angle of the screen surface and vibration frequency are self-adaptively optimized and adjusted to promote uniform and discrete distribution of the material on the screen surface, so that the screening efficiency of the material under a condition of non-uniform material feeding is effectively improved and the loss rate of the grains is decreased.

Owner:JIANGSU UNIV

Method and Apparatus for Coating a Substrate and Printed Matter

InactiveUS20080044618A1Efficient and economical mannerImprove material efficiencySpecial visual effect coatingsLayered productsEngineeringSolid content

A method and an apparatus for coating a substrate (7), in which a coating agent (9) is applied onto the substrate (7) in order to form a printing surface, and in which the coating agent (9) is brought into contact with the substrate (7) with a solids content above 80%, and the coating agent (9) is fixed to the substrate (7), the coating being performed during a printing process in a printing machine (10), between the input of the substrate (10) and the output of the printed matter (1), before the actual information (2, 3, 4) is printed.

Owner:VALMET TECH INC

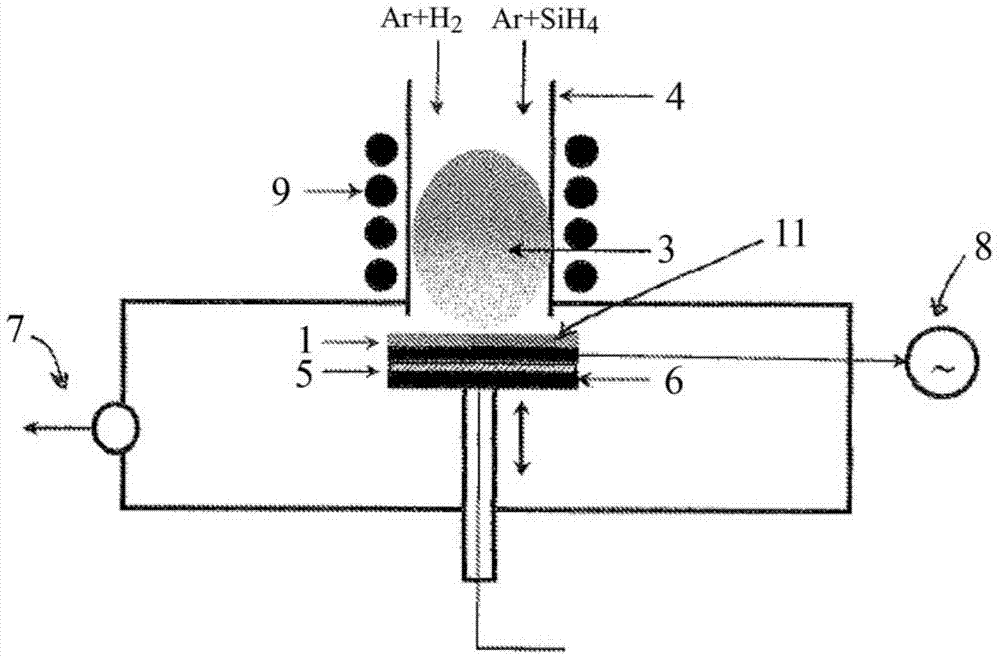

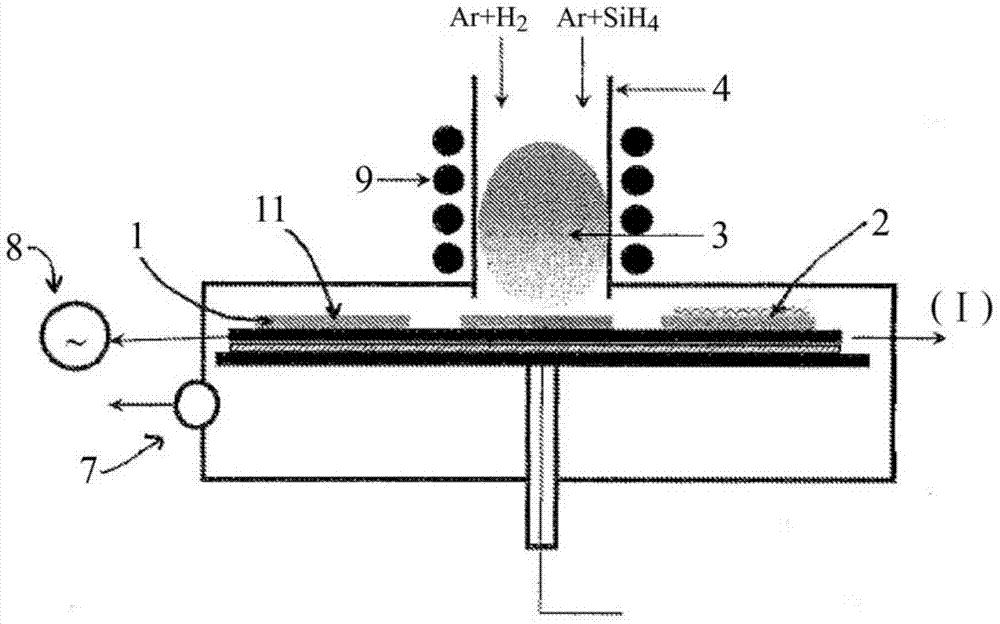

Method for forming epitaxial silicon layer

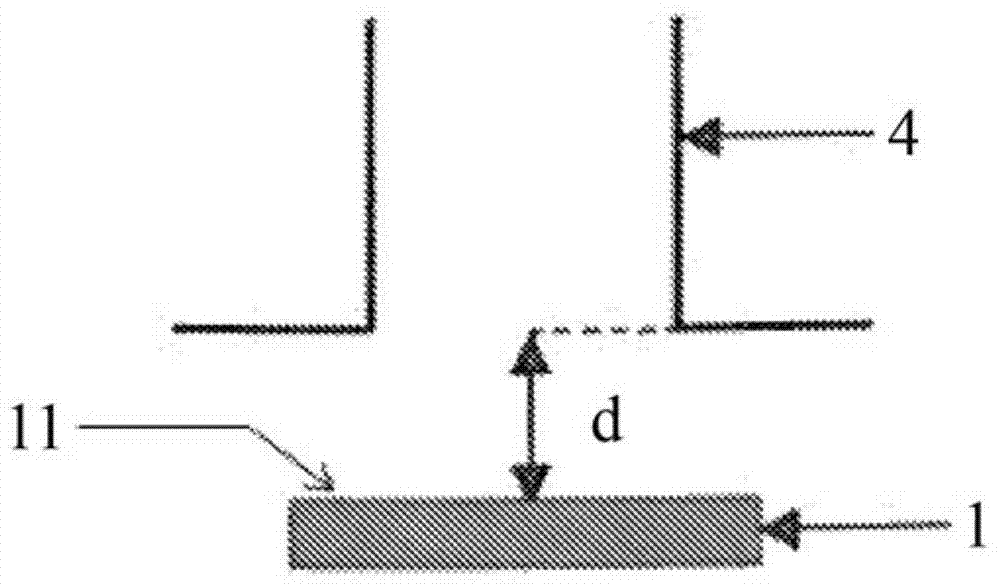

InactiveCN104781455AHigh Energy Conversion YieldIncrease growth ratePolycrystalline material growthFinal product manufactureInduction plasma technologyMetal impurities

The invention relates to a method for forming a crystallised silicon layer (2) having a crystallite size higher than or equal to 100 µm, by means of epitaxial growth in a vapour phase, on the surface of at least one silicon substrate (1), comprising at least the steps consisting in: (i) providing a silicon substrate (1) having a particle size higher than or equal to 100 µm and comprising a metal impurities content of between 0 ppb and 1 ppm by weight; and (ii) forming said silicon layer on the surface of said substrate heated to a temperature of between 1000 and 1300 °C, by decomposition of at least one silicon precursor by means of an inductive plasma torch (4), the surface (11) of said substrate for supporting the silicon layer (2) being positioned close to the outlet of the plasma torch in step (ii).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

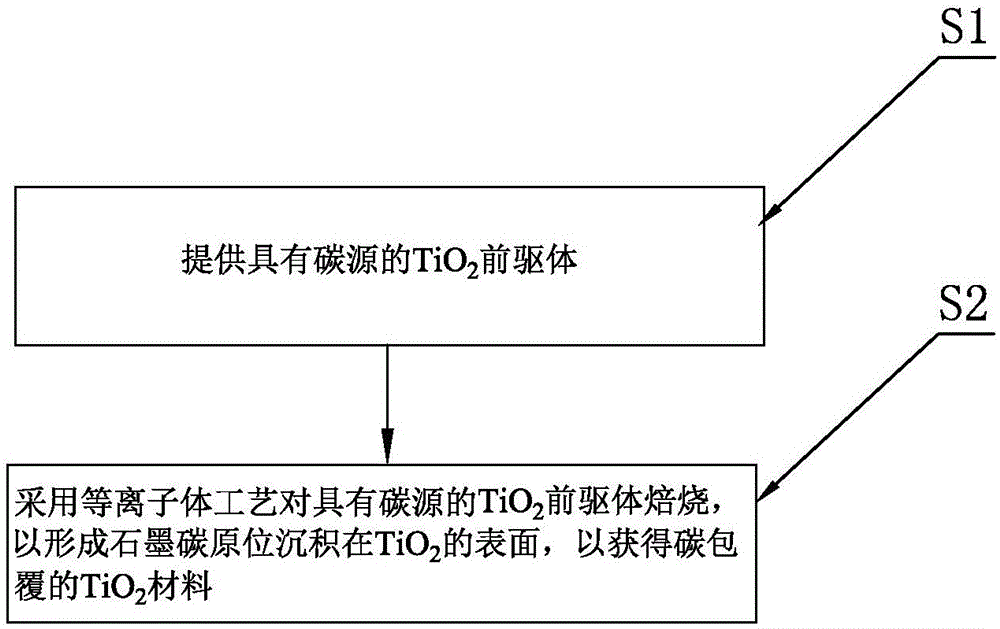

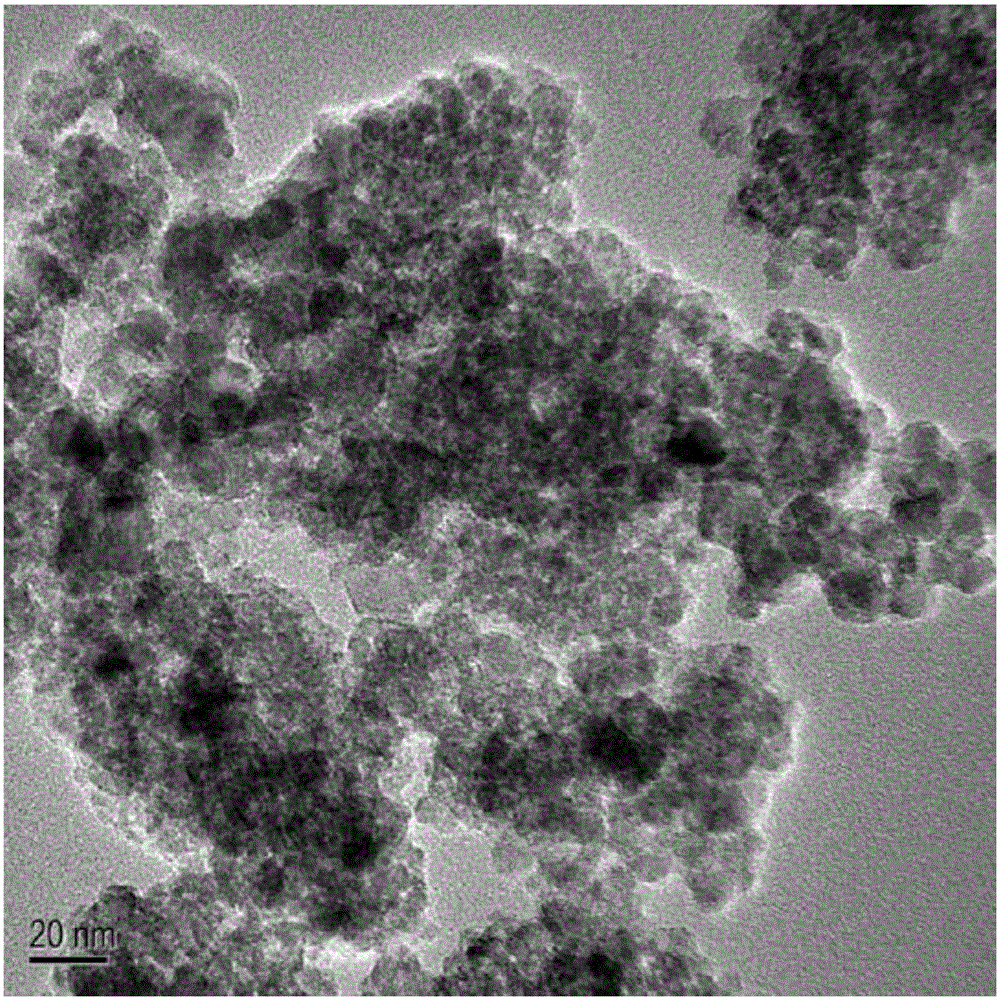

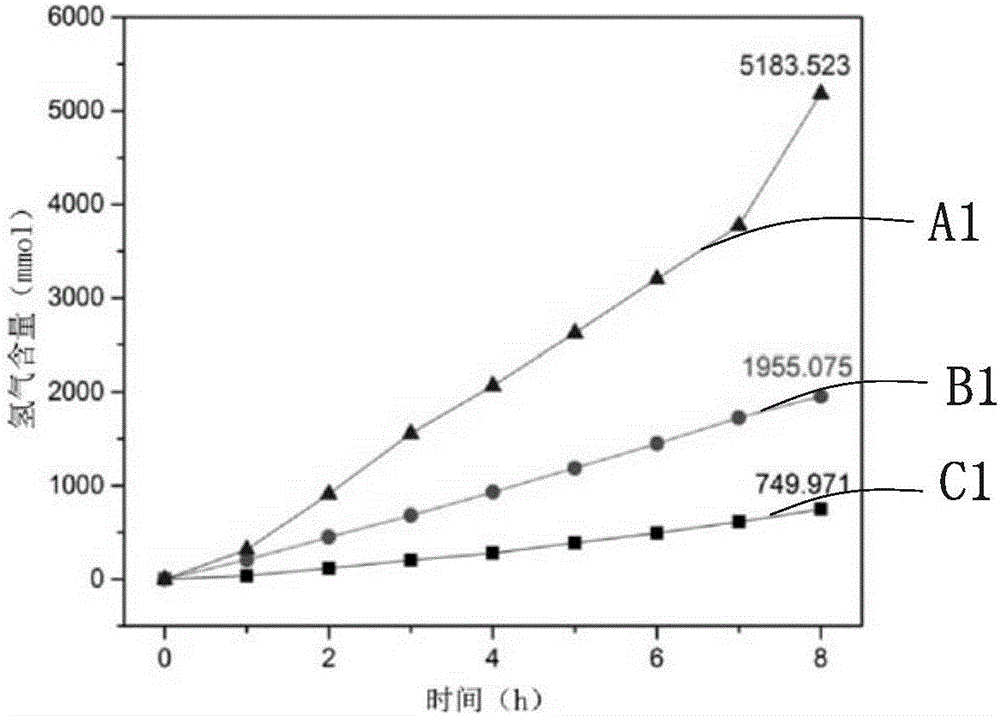

Carbon-coated TiO2 material and preparation method therefor

ActiveCN106563433AImprove efficiencyPromote absorptionPhysical/chemical process catalystsNanotechnologyCarbon coatingGraphite carbon

The invention relates to a carbon-coated TiO2 material and a preparation method therefor. The preparation method for the carbon-coated TiO2 material comprises the steps of providing a TiO2 precursor with a carbon source, roasting the TiO2 precursor with the carbon source by adopting a plasma process so as to deposit graphite carbon on the surface of TiO2 in situ and obtain the carbon-coated TiO2 material. The particle size of the carbon-coated TiO2 material is 8nm to 15nm, carbon coating the TiO2 is of a graphite carbon structure, and the mass of the carbon accounts for 20% to 75.5% the total mass of the carbon-coated TiO2 material. The preparation method for the carbon-coated TiO2 material is simple in process and short in preparation cycle, the efficiency of depositing the carbon on the surface of the TiO2 in situ can be increased, and the catalytic activity of the carbon-coated TiO2 material can be improved remarkably.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

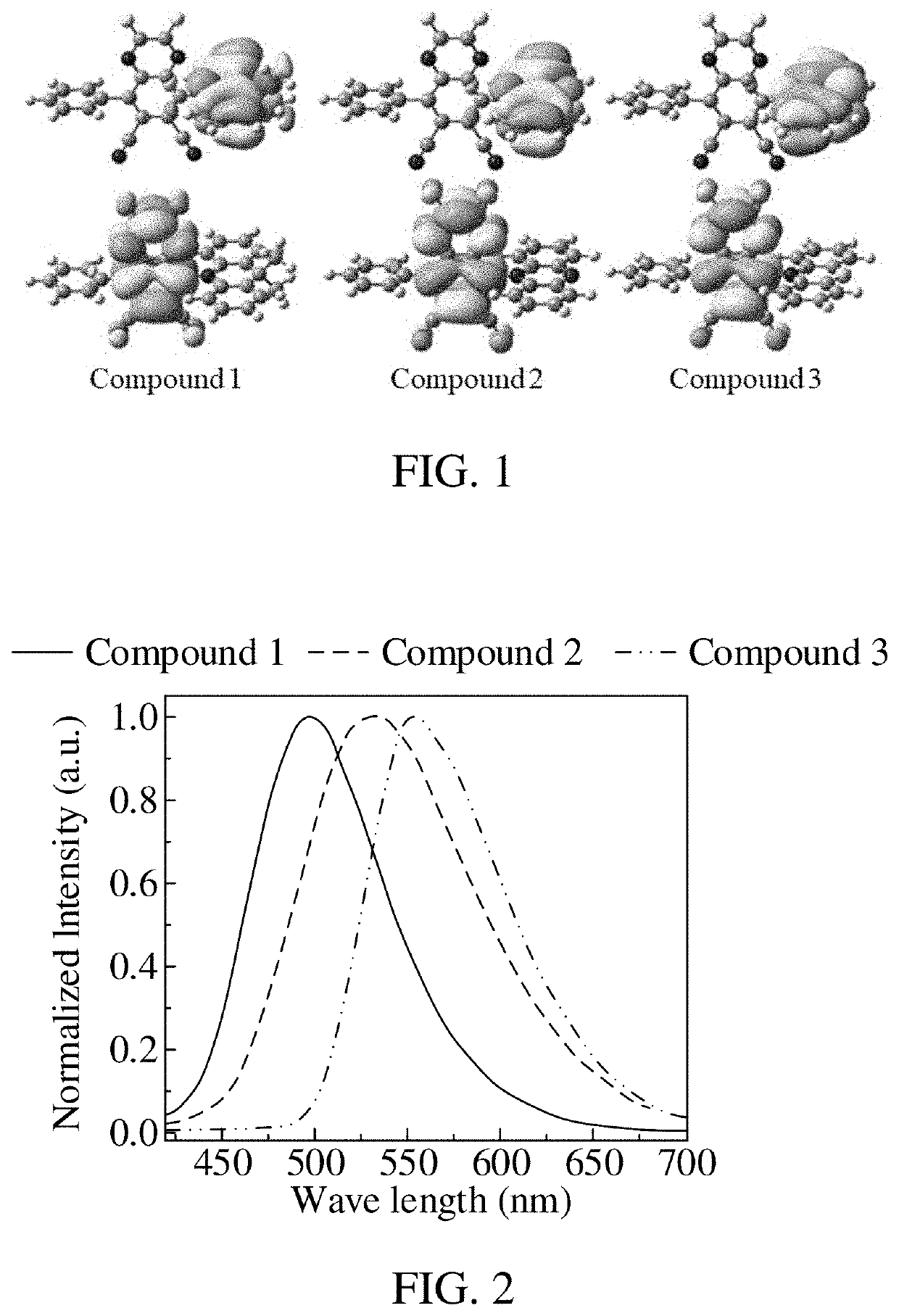

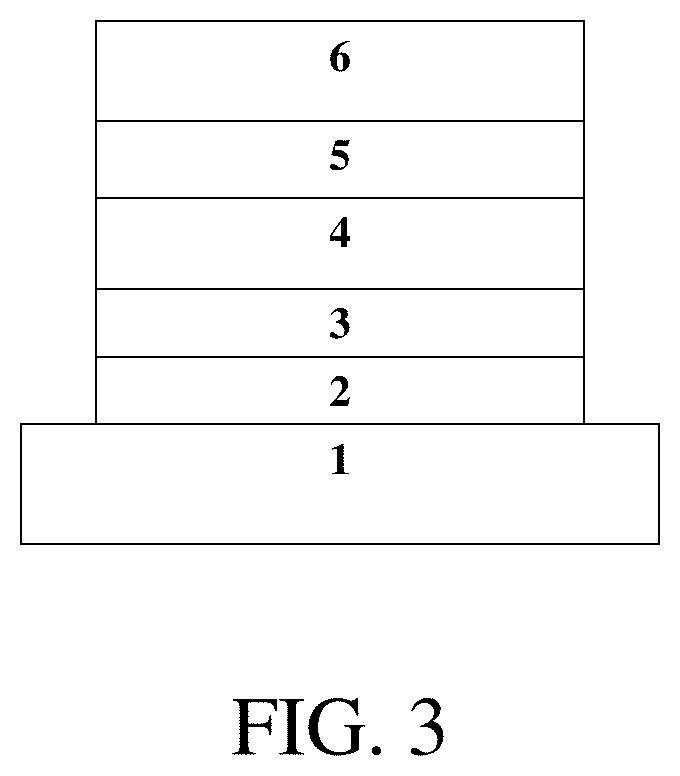

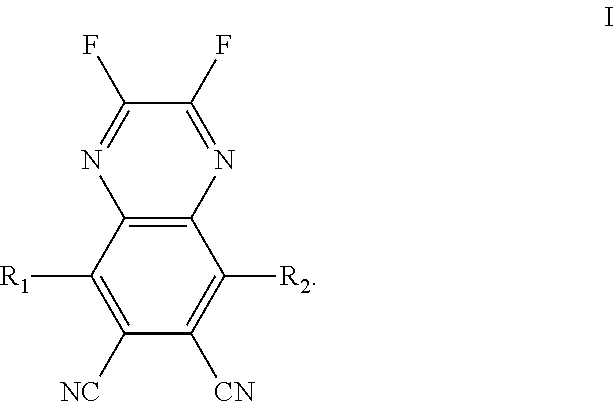

Efficient blue-green to orange-red thermally activated delayed fluorescence material, manufacture method, and application thereof

ActiveUS20210280797A1Improve luminous efficiencyImprove efficiencyOrganic chemistrySolid-state devicesNMR - Nuclear magnetic resonanceFluorescence

An efficient blue-green to orange-red thermally activated delayed fluorescence material, a manufacture method, and an application thereof are provided. This disclosure solves the technical problems in the art by cleverly synthesizing a series of thermally activated delayed fluorescence materials, which have lower singlet-triplet energy difference, high luminous efficiency, and fast reverse intersystem crossing constant, and simultaneously fine-tuning the structure to cover the spectrum from blue-green light to orange-red light. Further, their structures are confirmed by nuclear magnetic resonance and mass spectroscopy, and their photophysical properties are also determined. Therefore, these luminescent thermally activated delayed fluorescence (TADF) materials are applied to light-emitting layer for manufacturing a series of organic light-emitting diodes (OLEDs) having high performance, which have great application prospects and economic value.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com