Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Improve gas-liquid separation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

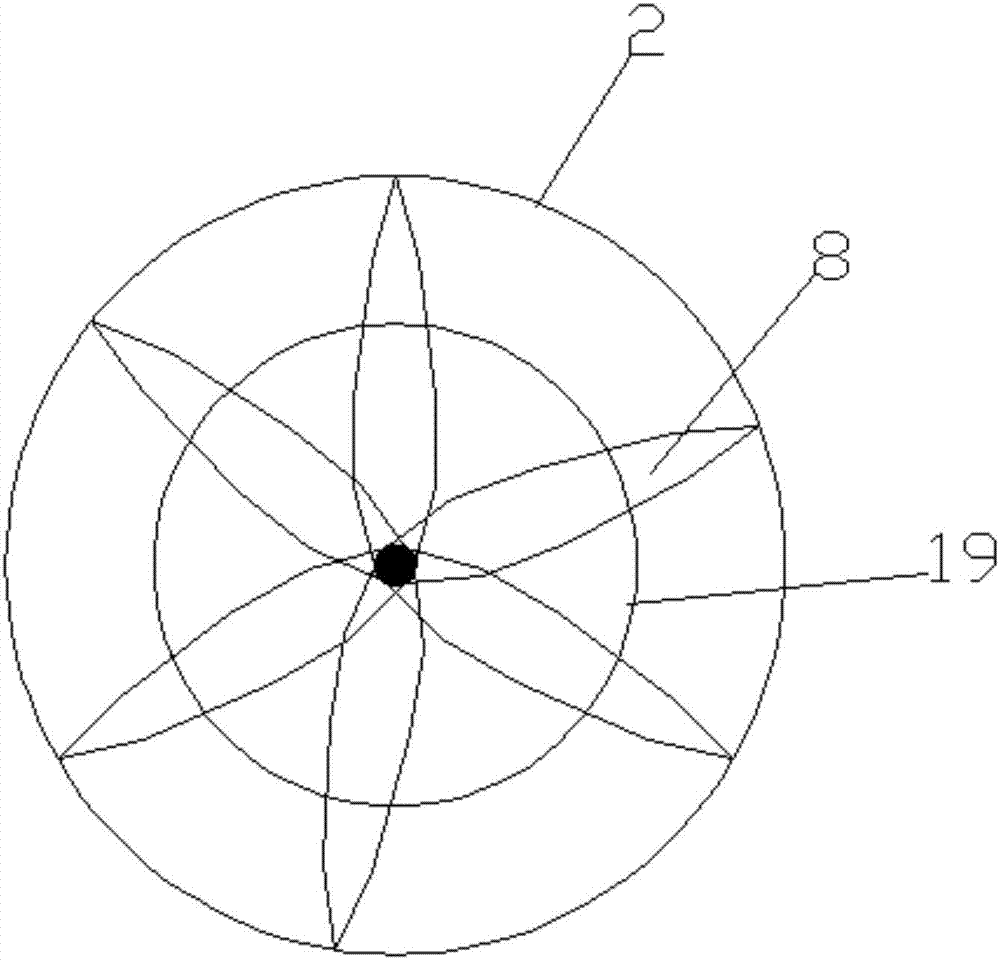

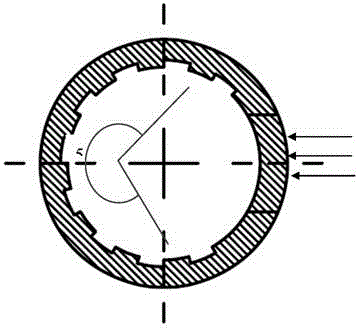

Active centrifugal gas-liquid separation device

InactiveCN102580408AImprove gas-liquid separation efficiencyLarge gas volumeDispersed particle separationDry gasNatural gas

The invention is applied in the industries of medicine, air compression, natural gas, synthetic ammonia, oil refining, coking and the like, and relates to a gas-liquid separation device. The device comprises a shell, an air inlet pipe and an exhaust pipe; a drum driven to rotate by a power device is arranged in the shell; the wall of the drum is provided with air holes; a partition plate is arranged in the drum to partition the drum into an air inlet end and an exhaust end which are respectively communicated with the air inlet pipe and the exhaust pipe; the air inlet pipe is communicated with the exhaust pipe through the air inlet end of the drum, the air holes in the wall of the drum, an air passage and the exhaust end of the drum; and the shell is provided with a drain pipe. Through the device, the separation efficiency of liquid particles with the diameters of over 0.1 micron reaches over 99.5 percent; and the device is large in treated gas quantity and suitable for wet gas with high liquid content, does not require circulation of a large quantity of washing absorption liquid, does not require a high-voltage electrostatic system, has good adaptability to the physical properties of the liquid, has certain capability of separating dry gas components with different densities, and is small in volume, light in weight, small in occupied space and low in manufacturing cost.

Owner:杨东进

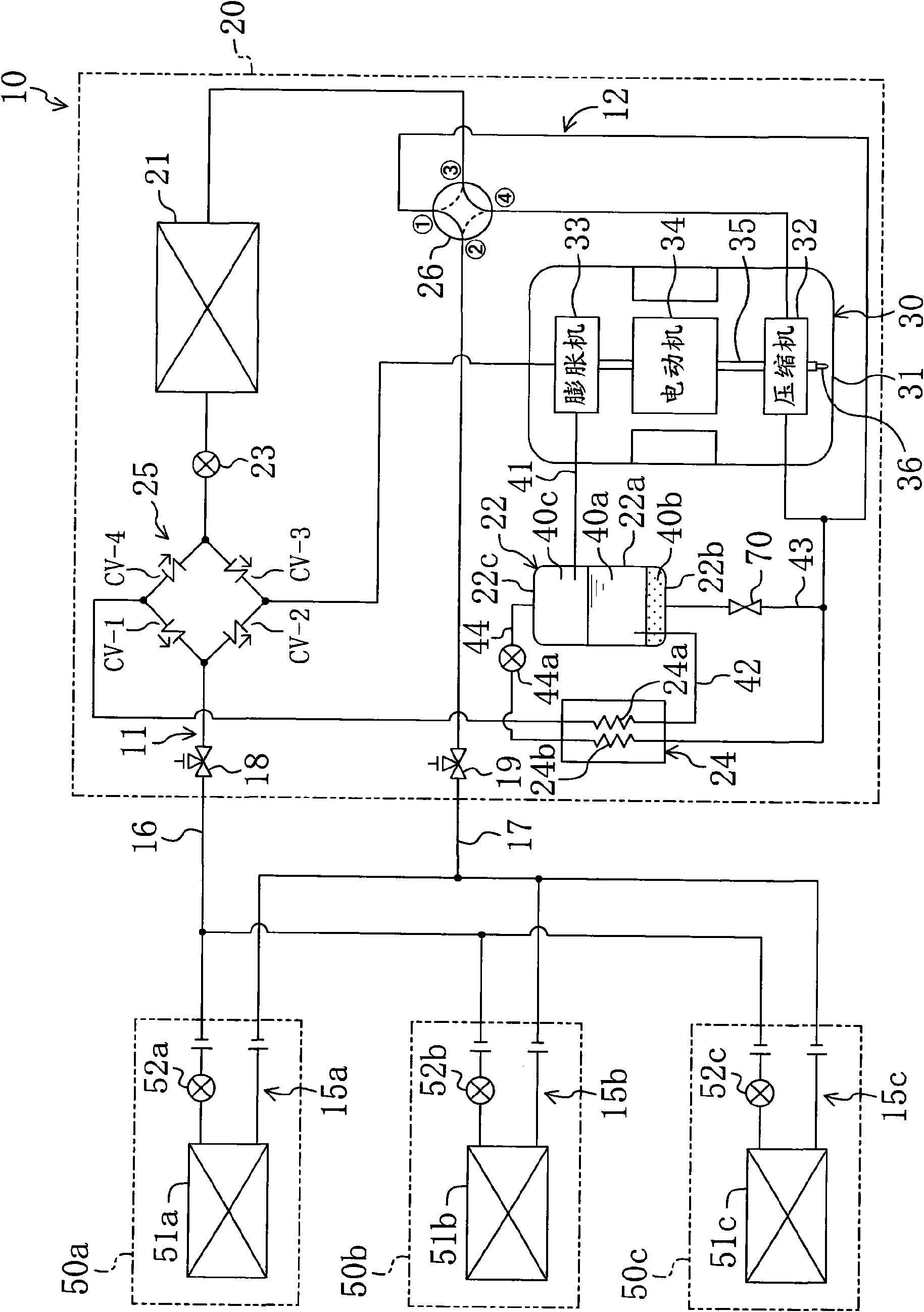

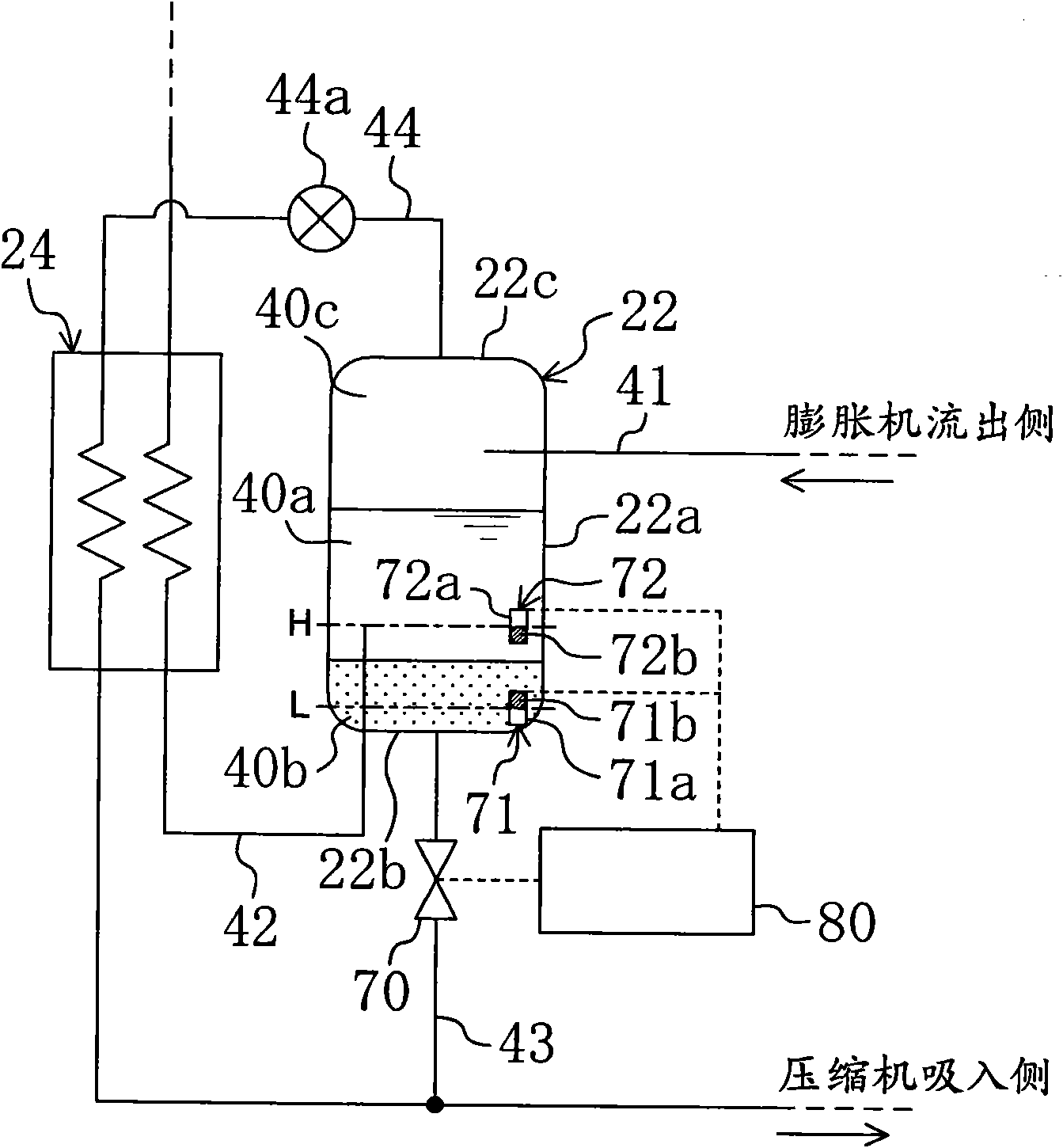

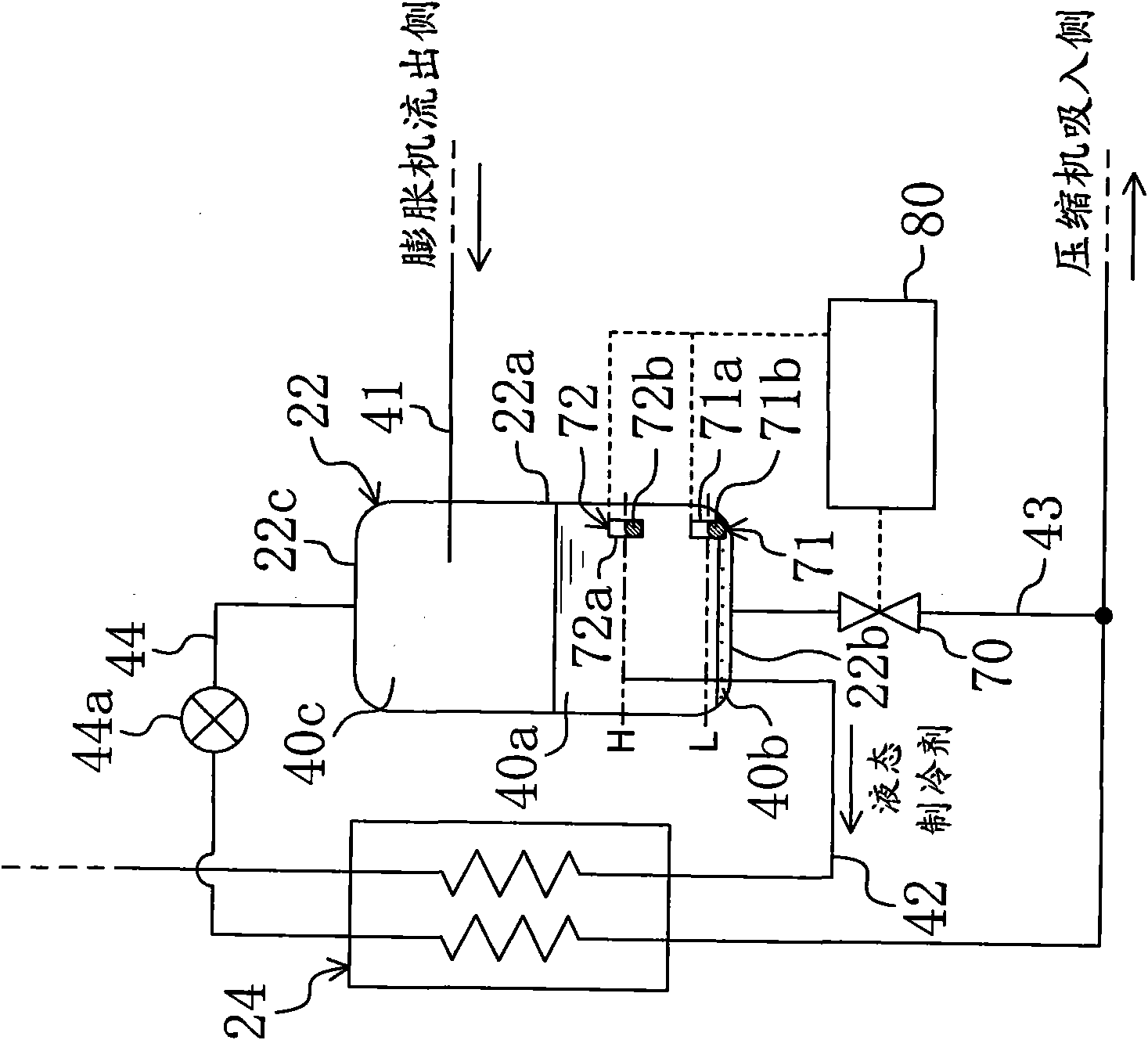

Refrigerating device

ActiveCN101646908AAvoid inhalationPrevent suction sideCompressorCompression machines with non-reversible cycleRefrigerantMechanical engineering

An opening / closing valve (70) is provided in an oil feed pipe (43). When a liquid refrigerant enters from an oil separator (22) into the oil feed pipe (43), the temperature of the liquid refrigerant depressurized by the opening / closing valve (70) is suddenly lowered. When the lowering amount of the temperature detected by a temperature sensor (73) exceeds a prescribed value, it is judged that theliquid refrigerant enters into the oil feed pipe (43), and the valve (70) is closed.

Owner:DAIKIN IND LTD

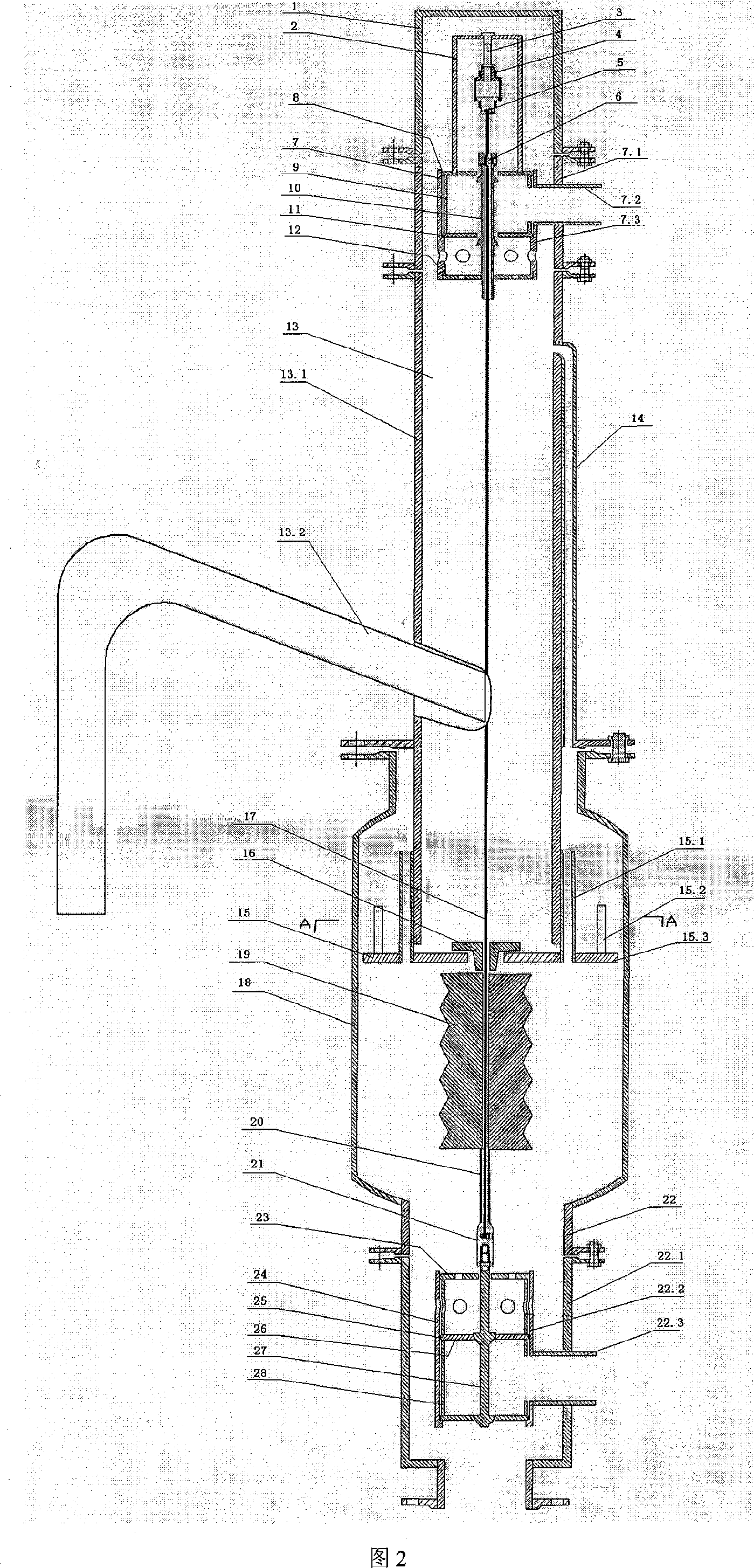

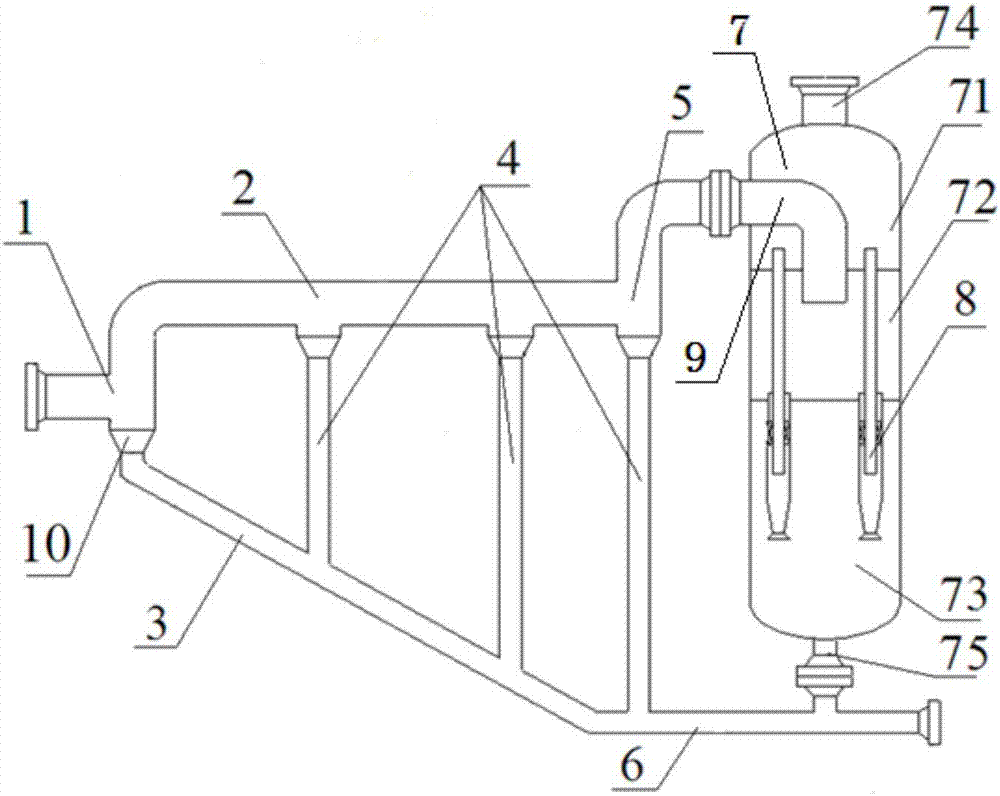

Self controlled high efficient gas and liquid separator

InactiveCN101053723AEfficient separationSeparators work efficientlyReversed direction vortexDispersed particle separationVapor–liquid separatorProduct gas

The invention relates to a self-control gas-liquid separator, especially to a control and separation integral self-control high efficiency gas-liquid separator. The embodiment is to connect to the gas valve (7) of said gas conditioning unit through the lower end of the spring (1) in which a bracket (2) is mounted. The bracket (2) vertically hangs a liquid level transmitting control unit, and basipetally impenetrates the said gas conditioning unit and gas-liquid separating unit in turn. The beneficial effect is that: control-separate one-piece design of the self-control gas-liquid separator, whose control unit uses self-operated control principle and whose separating unit gives priority to hydrocyclone Separation process and assists with gravity separation, the efficiency for gas-liquid separating is high, and the effect of separation is excellent; the reasonable structure makes it easily to manufacturing activity and have a low manufacturing and using cost without maintenance and have a long longevity; compared with conventional gravity separator matching to the self-control system, the gas-liquid separating technological process is largely simplified and the cost can save larger than 70 percent at the same time.

Owner:房师礼

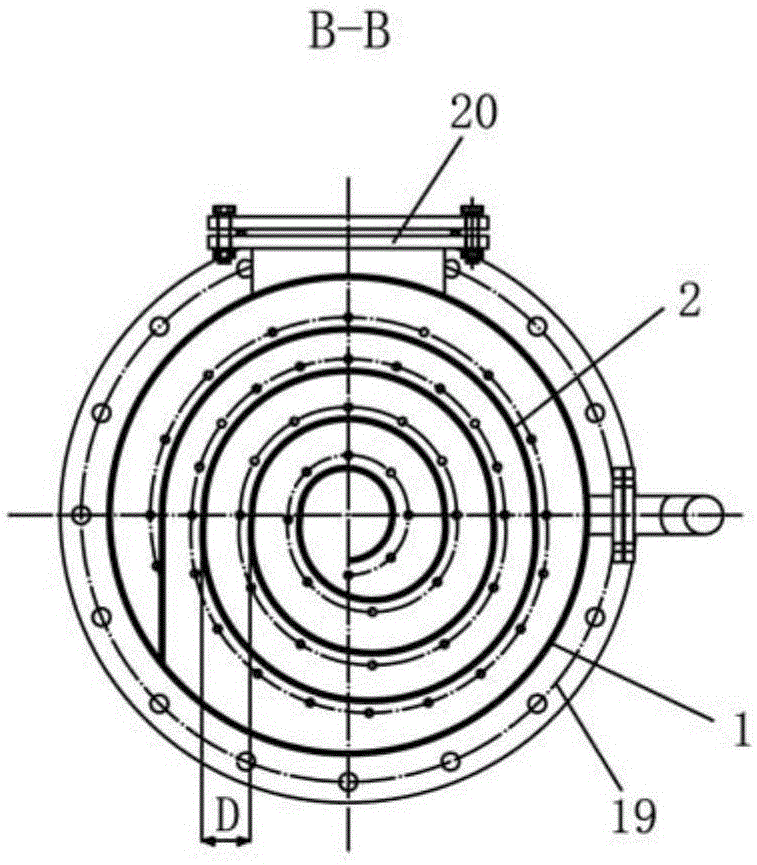

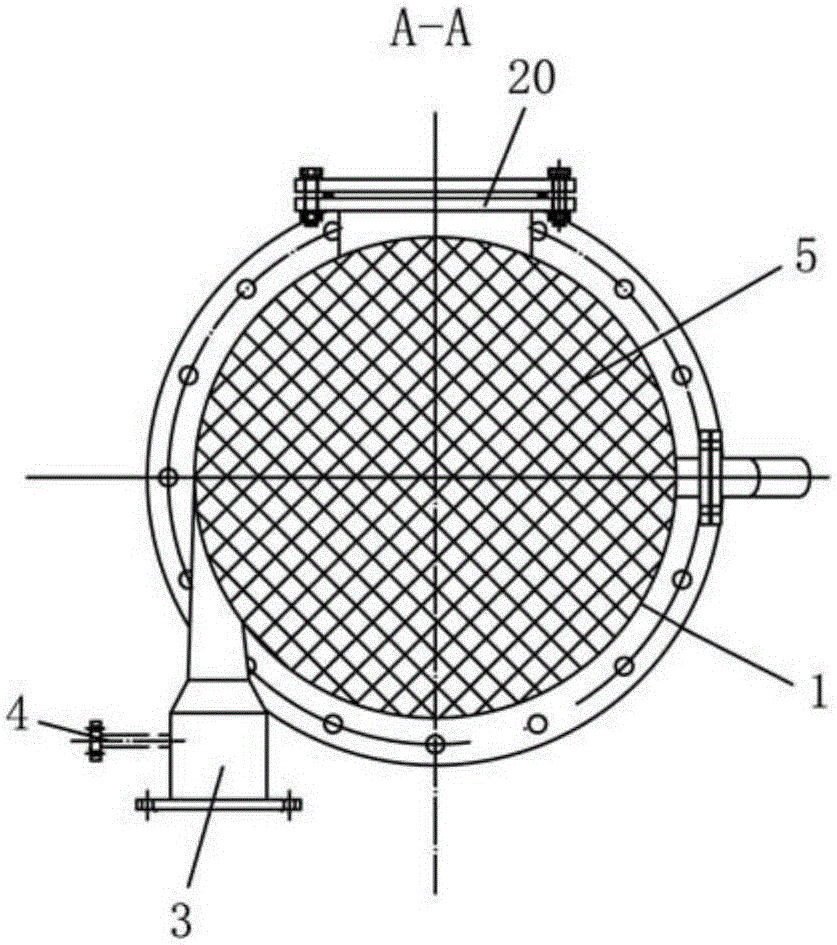

Gas-liquid separator

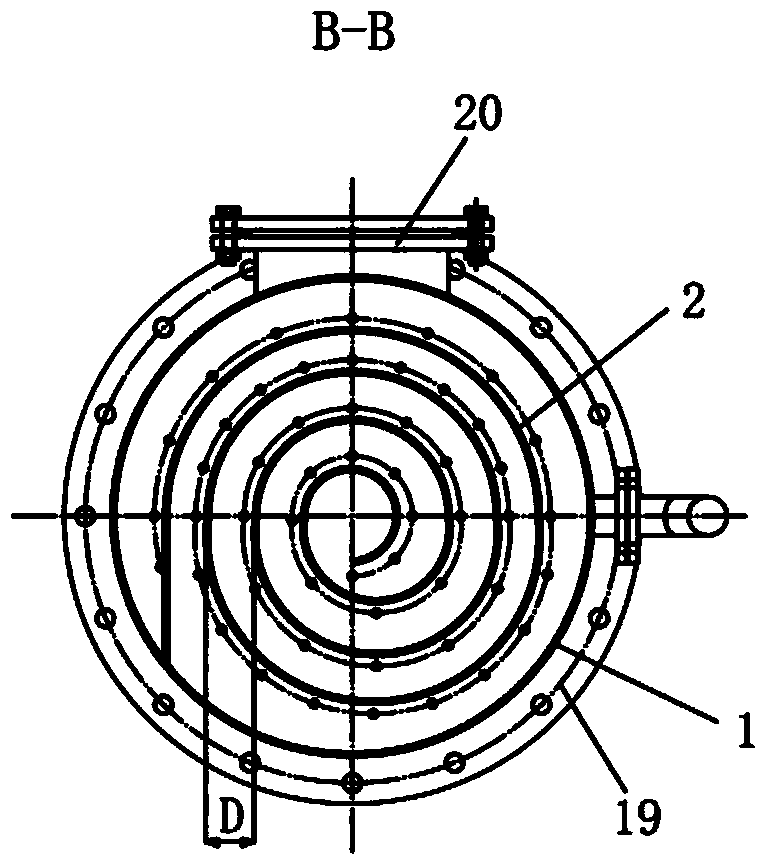

ActiveCN103977665AExtended service lifeNo cloggingCombination devicesVapor–liquid separatorCyclonic separation

The invention discloses a gas-liquid separator which comprises a barrel body, a cyclone separation assembly, a screen mesh part and a liquid discharge assembly, wherein the outer wall of the barrel body is connected with a gas inlet pipe along the horizontal tangential direction; the upper end of the barrel body is connected with a gas outlet pipe; the cyclone separation assembly is arranged in the barrel body, and comprises a spiral plate which extends to the center from the inner wall of the barrel body in a spiral way so as to form a spiral channel; the gas inlet pipe is communicated with the spiral channel; the screen mesh part is arranged in the barrel body and above the cyclone separation assembly; the liquid discharge assembly is arranged in the barrel body and under the cyclone separation assembly, so that the separated liquid can be discharged. The gas-liquid separator is capable of efficiently completing gas-liquid separation.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

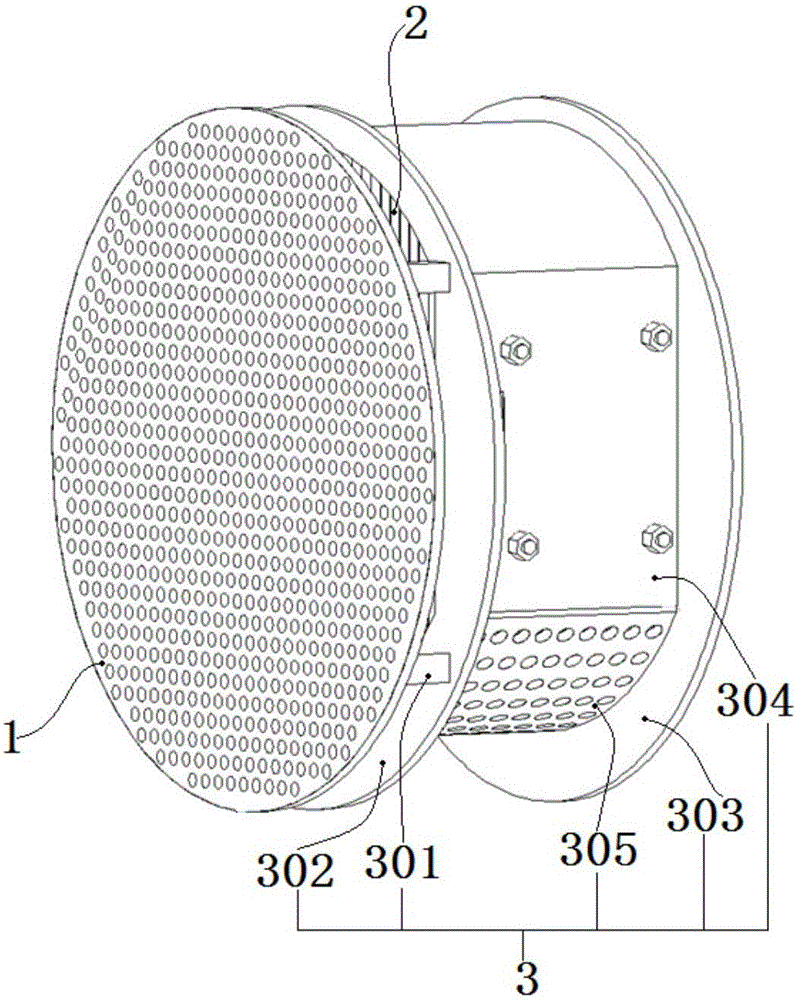

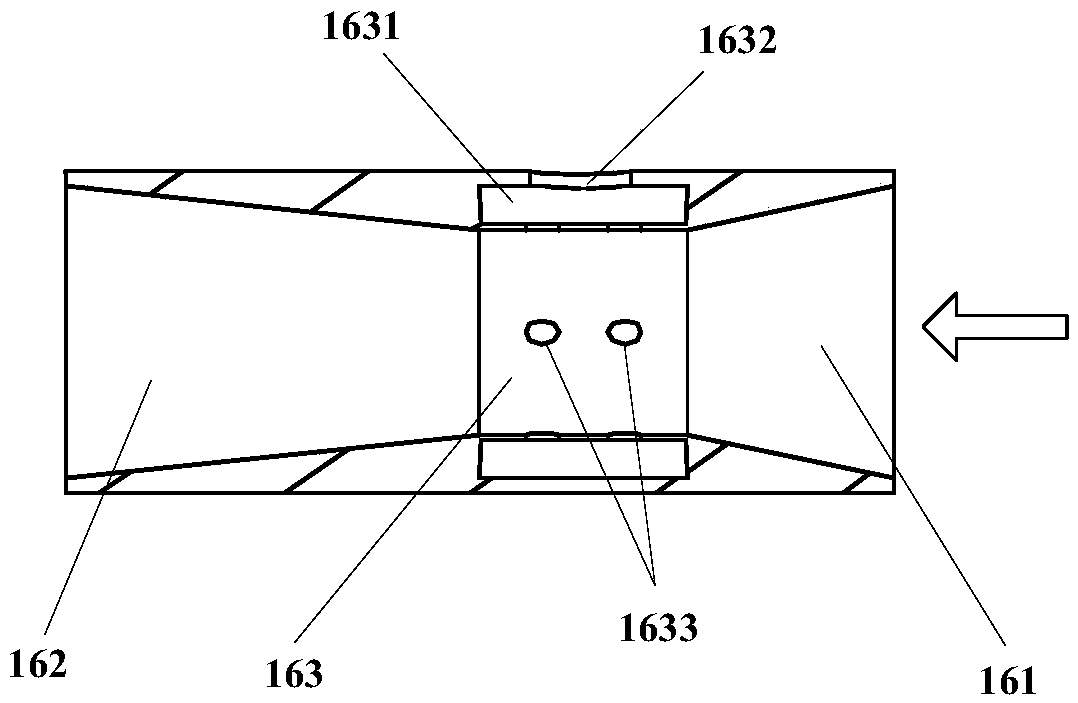

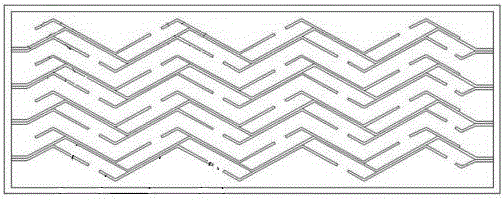

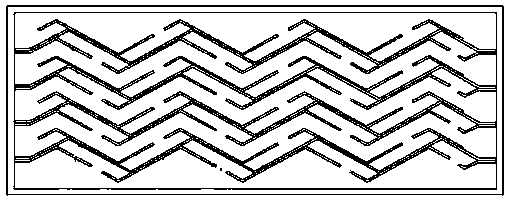

Blade type gas-liquid separating device

InactiveCN106268050AAdjustable spacingImprove gas-liquid separation efficiencyDispersed particle separationVena contracta diameterBlade pitch

The invention discloses a blade type gas-liquid separating device, and belongs to the technical field of gas-liquid separating equipment. The blade type gas-liquid separating device comprises a uniform flow orifice plate, a blade module and a housing module, wherein the uniform flow orifice plate is a circular plate provided with uniformly distributed flow dividing holes, the uniform flow orifice plate and the blade module are fixed through the housing module, a gas-liquid mixture is separated by the uniform flow orifice plate and the blade module, the blade module comprises a plurality of stepped triangular blades, distance rings and a horizontal supporting rod, each stepped triangular blade comprises a fold line-shaped main wave plate and a Z-shaped assistant wave plate, part of the top side of the fold line-shaped main wave plate is connected with part of the top side of the Z-shaped assistant wave plate, a lower V-shaped groove and an upper reversed V-shaped groove can be formed, the lower V-shaped groove and the upper reversed V-shaped groove are provided with an air vent respectively, a through hole is formed in the top side of each stepped triangular blade, a distance ring is arranged between every two neighboring stepped triangular blades, the horizontal supporting rod penetrates through the distance rings and the through holes, and two ends of the horizontal supporting rod are fixed on the housing module. The blade type gas-liquid separating device disclosed by the invention has the characteristics of uniform distribution of scattered air flow, regulation availability of blade pitch, high gas-liquid separating efficiency and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

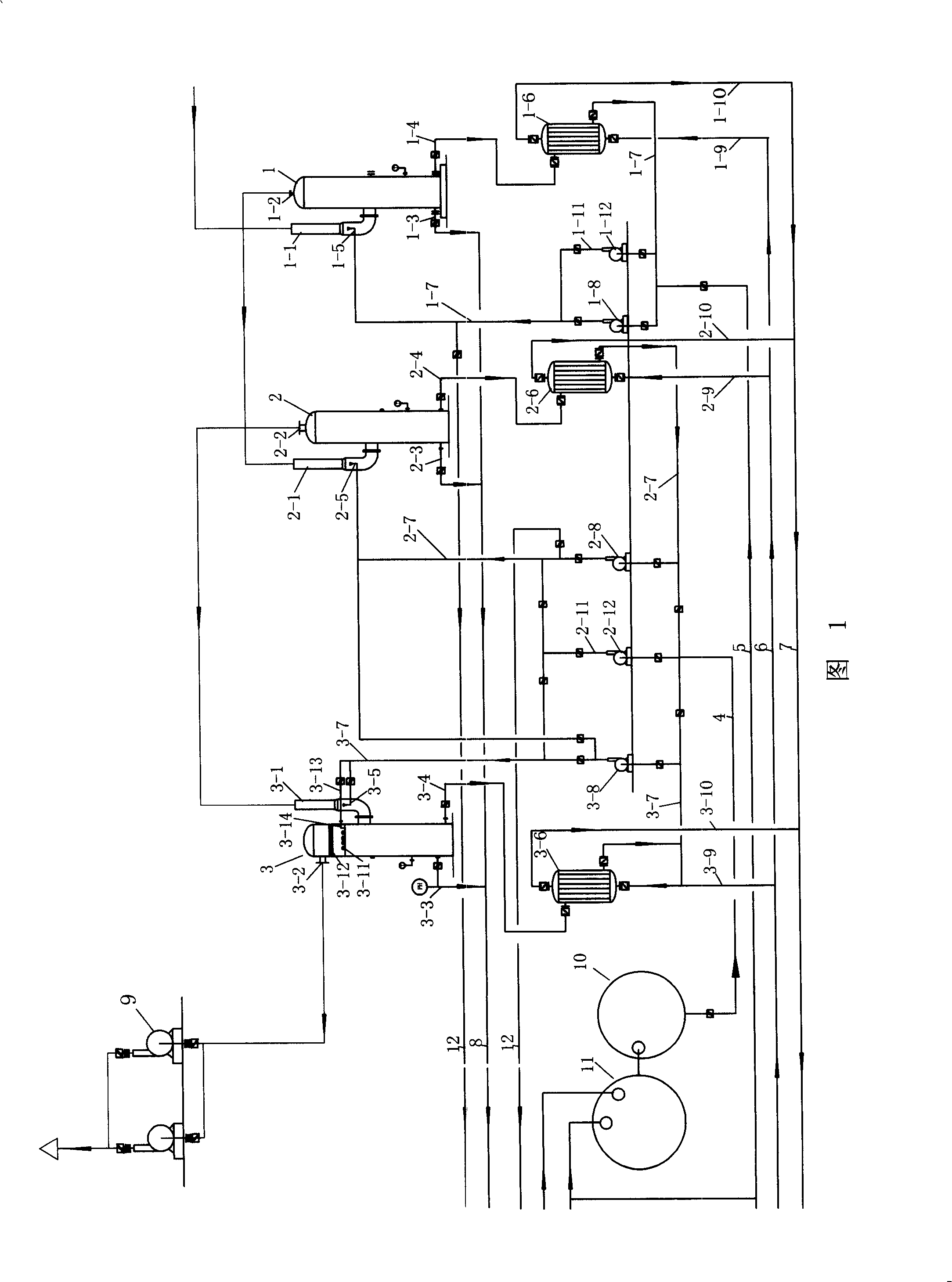

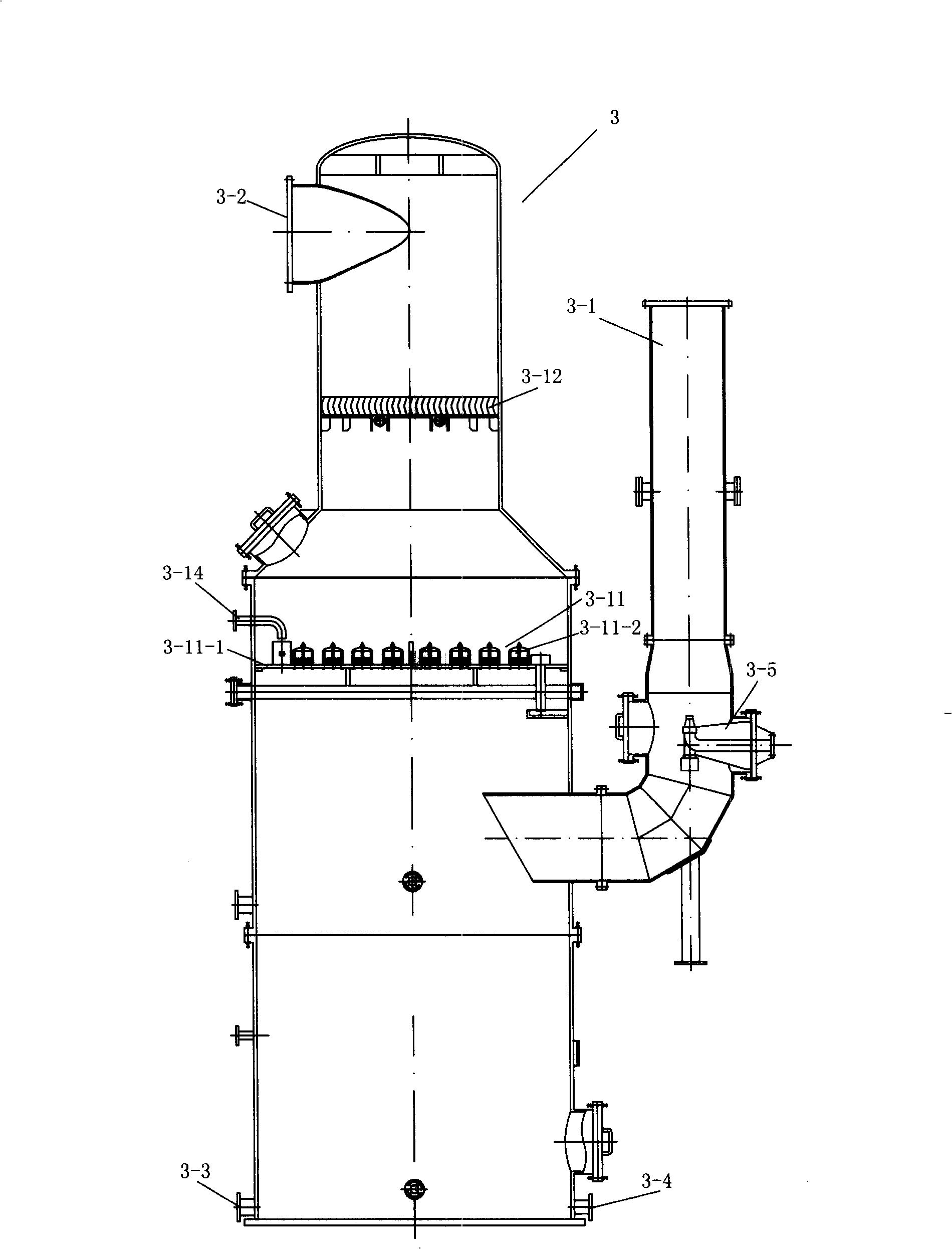

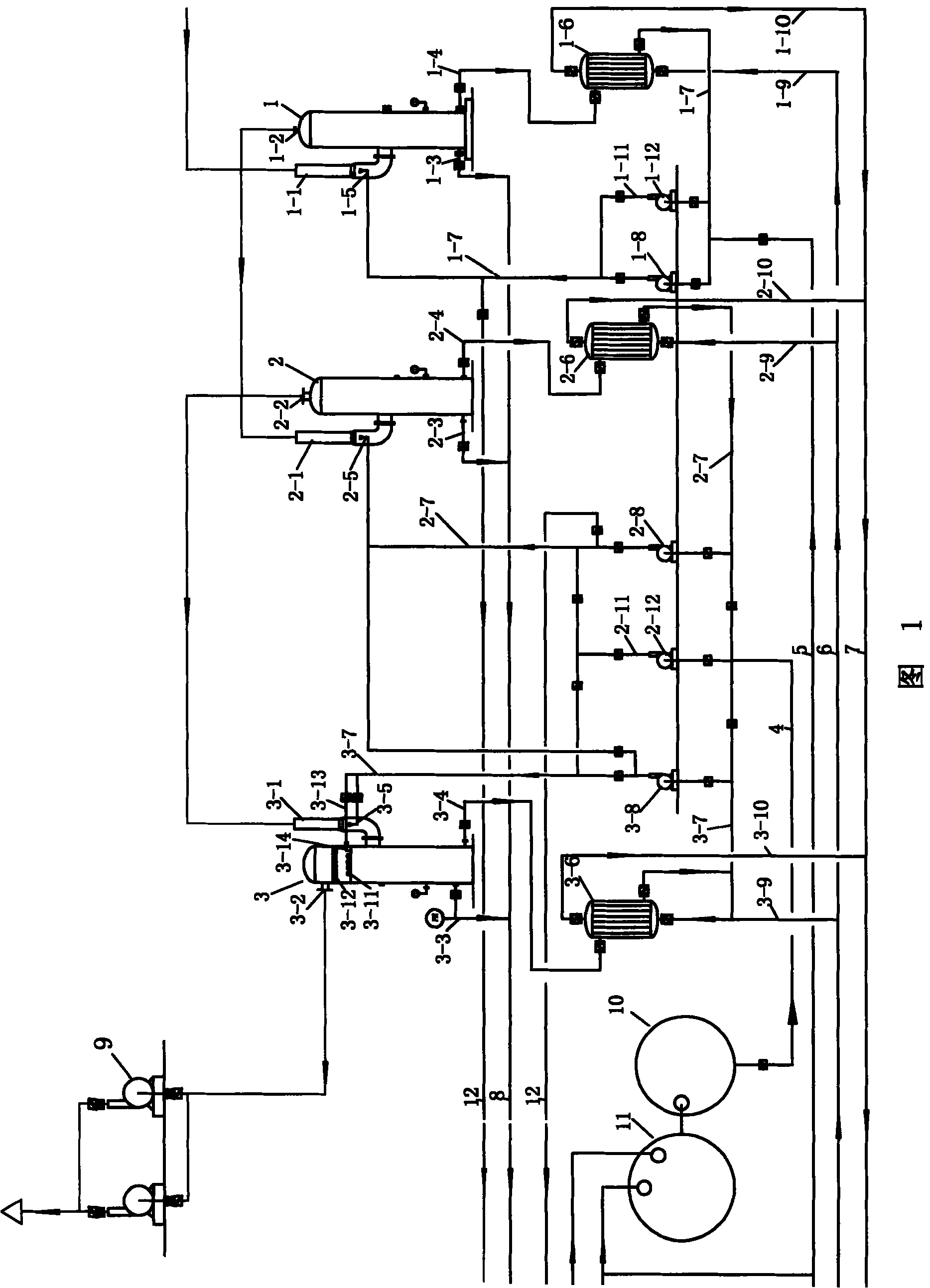

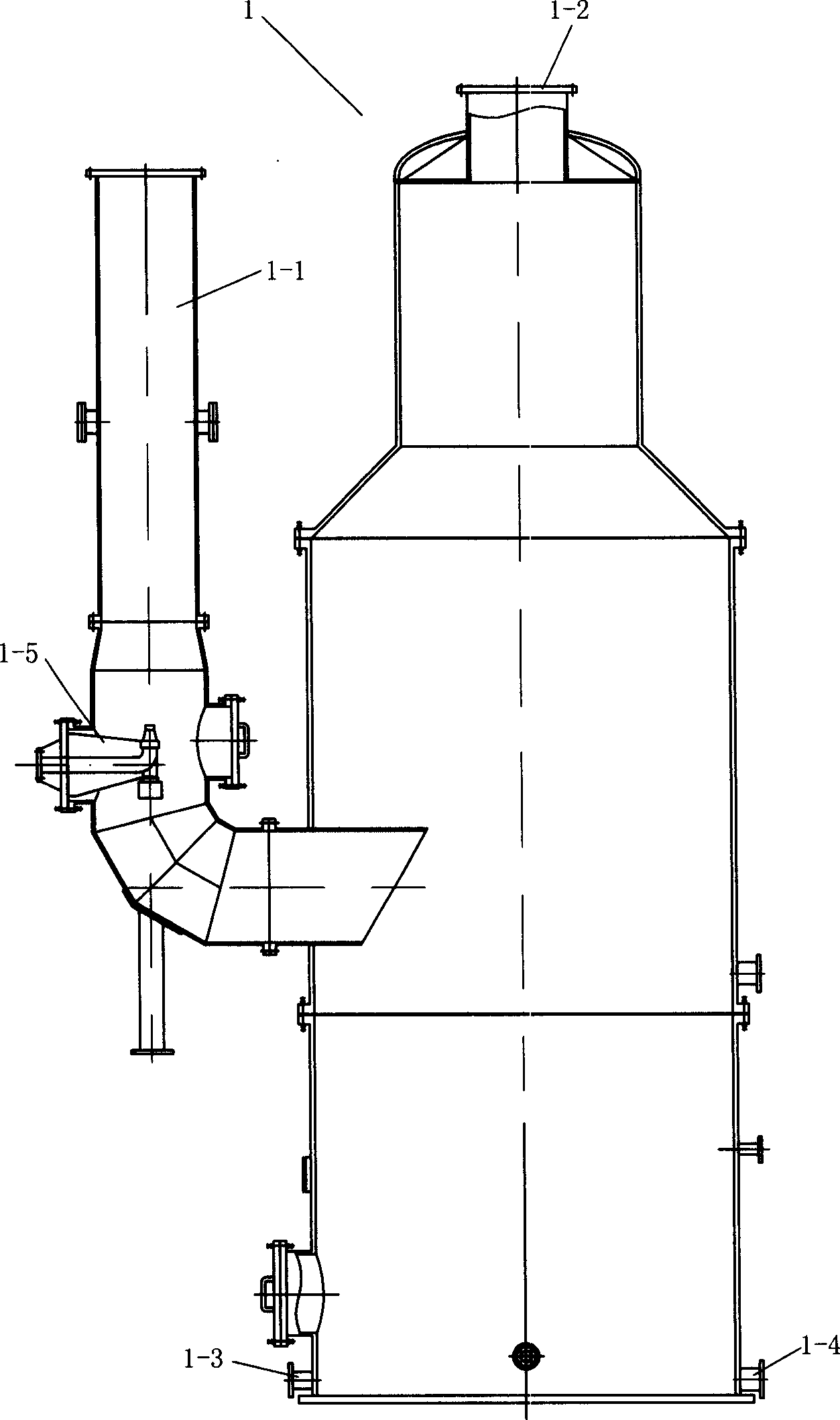

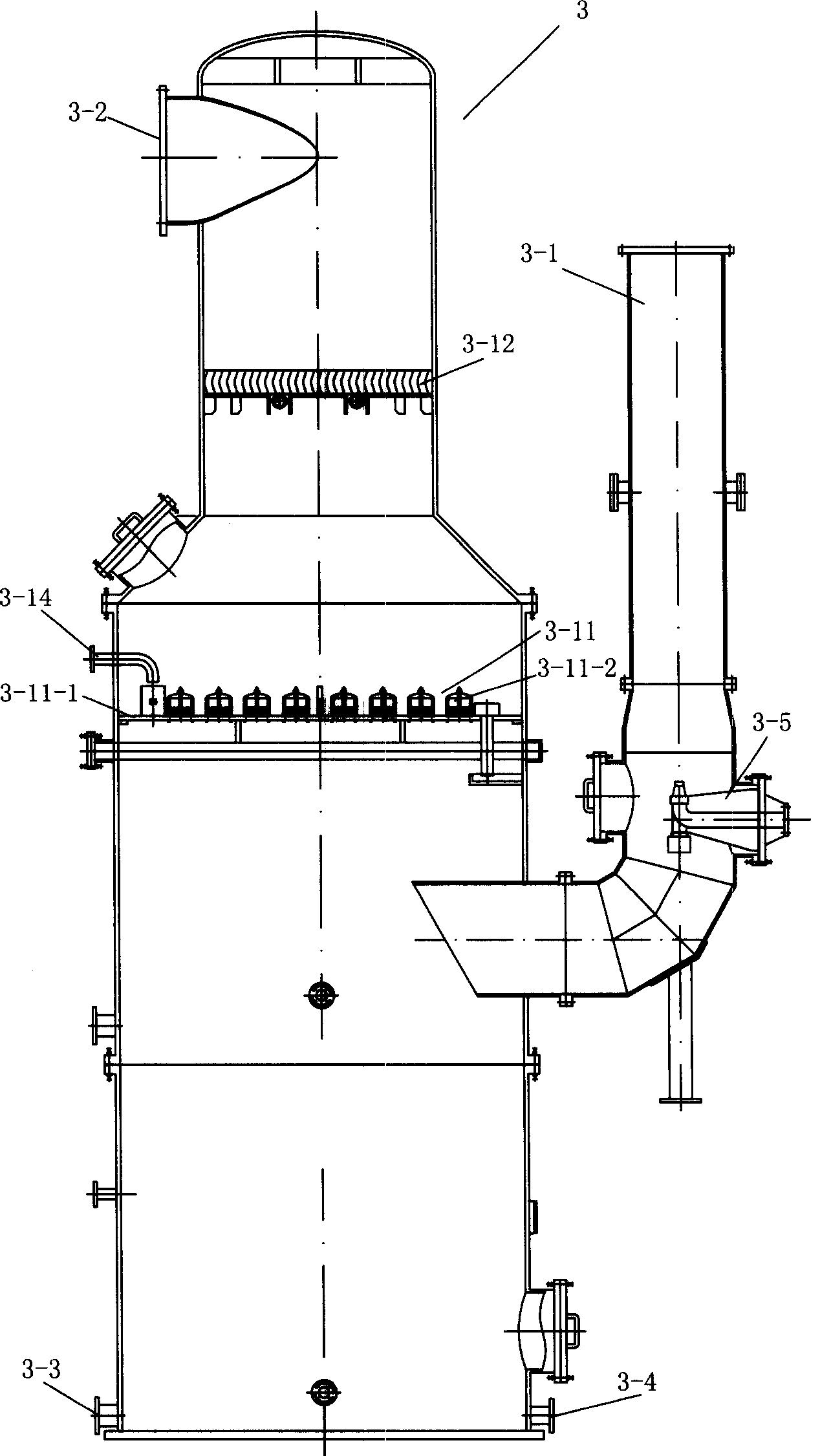

Waste gas treatment system

InactiveCN101254395AEasy to updateIncrease contact areaDispersed particle separationSpray nozzleTower

The invention discloses an off-gas handling system with a primary washing tower, a secondary turbulent flushing tower and a tertiary turbulent flushing tower, wherein, the primary washing tower, the secondary turbulent flushing tower and the tertiary turbulent flushing tower are respectively equipped with a first, a second and a third heat exchangers, and the system also has an alkali liquor main pipe, a water inlet, a cooling upper water main pipe, a cooling backwater main pipe and a discharge main pipe; the primary washing tower, the secondary turbulent flushing tower and the tertiary turbulent flushing tower is respectively provided with a liquid membrane foam area, and harmful waste gas passes through the liquid membrane foam areas of the primary washing tower, the secondary turbulent flushing tower and the tertiary turbulent flushing tower in order to be purified. As the waste gas passes through the three strongly turbulent liquid membrane foam areas, the invention achieves the effect of high efficient washing. As the gas-fluid exchange is not carried out in the towers, the structures of the towers are simple, the manufacturing and the maintenance are convenient, and the height of the towers can be greatly reduced. The consumption of the raw material can be greatly reduced, and the investment can be reduced. The circulation solution sprayed out by a spraying head is spiral shaped and is fully contacted with the harmful waste gas for absorption, and the spray nozzle is unlikely to be blocked because of the large size.

Owner:徐全海

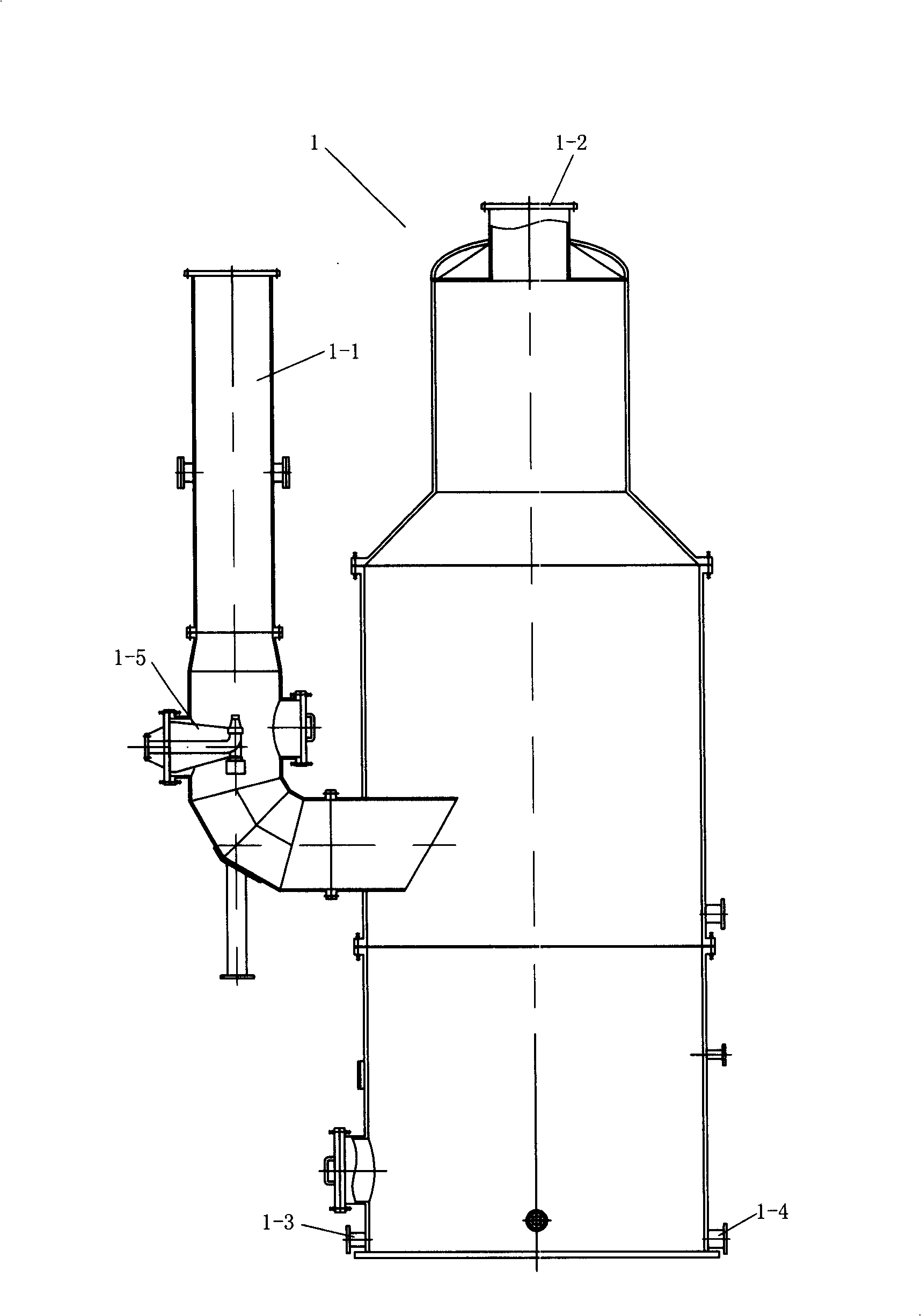

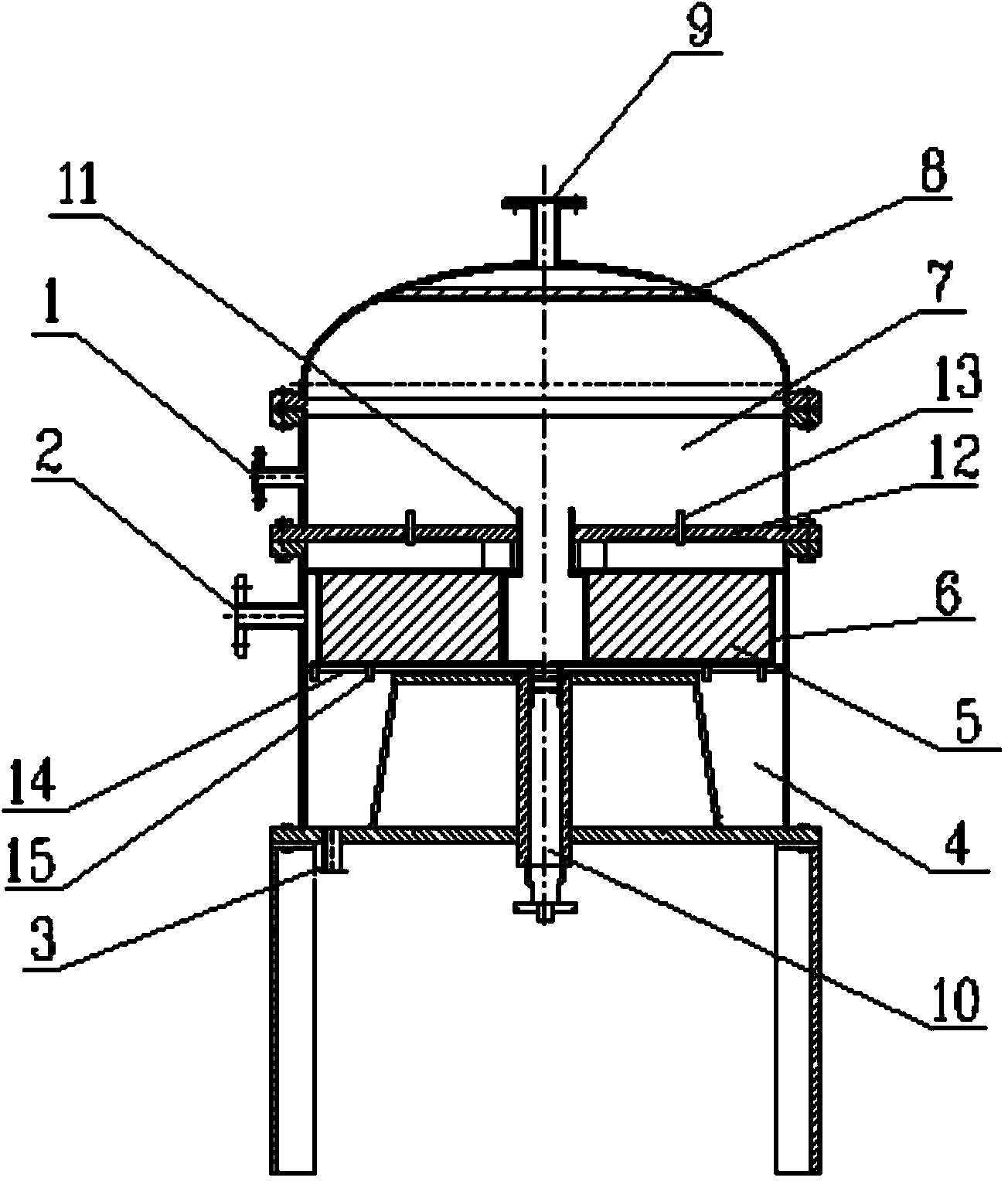

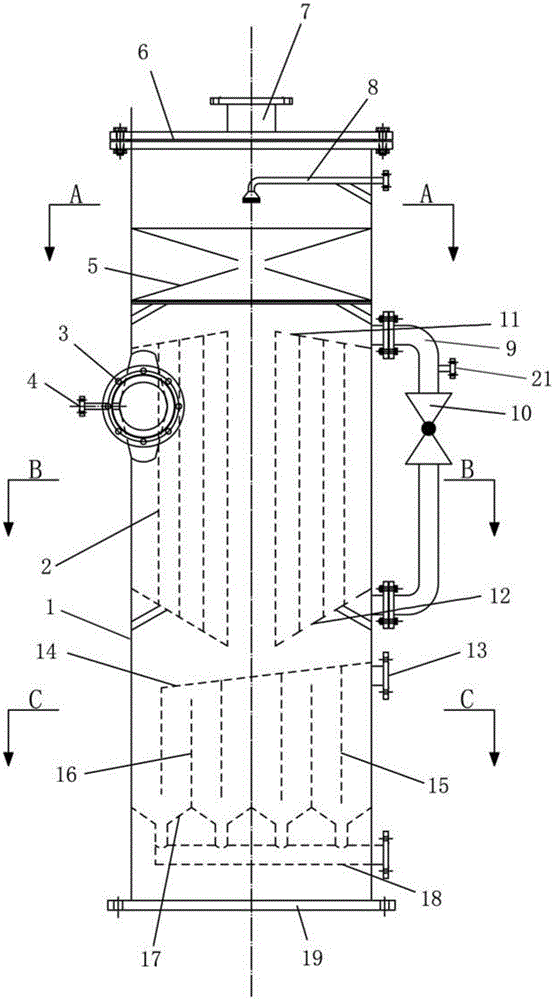

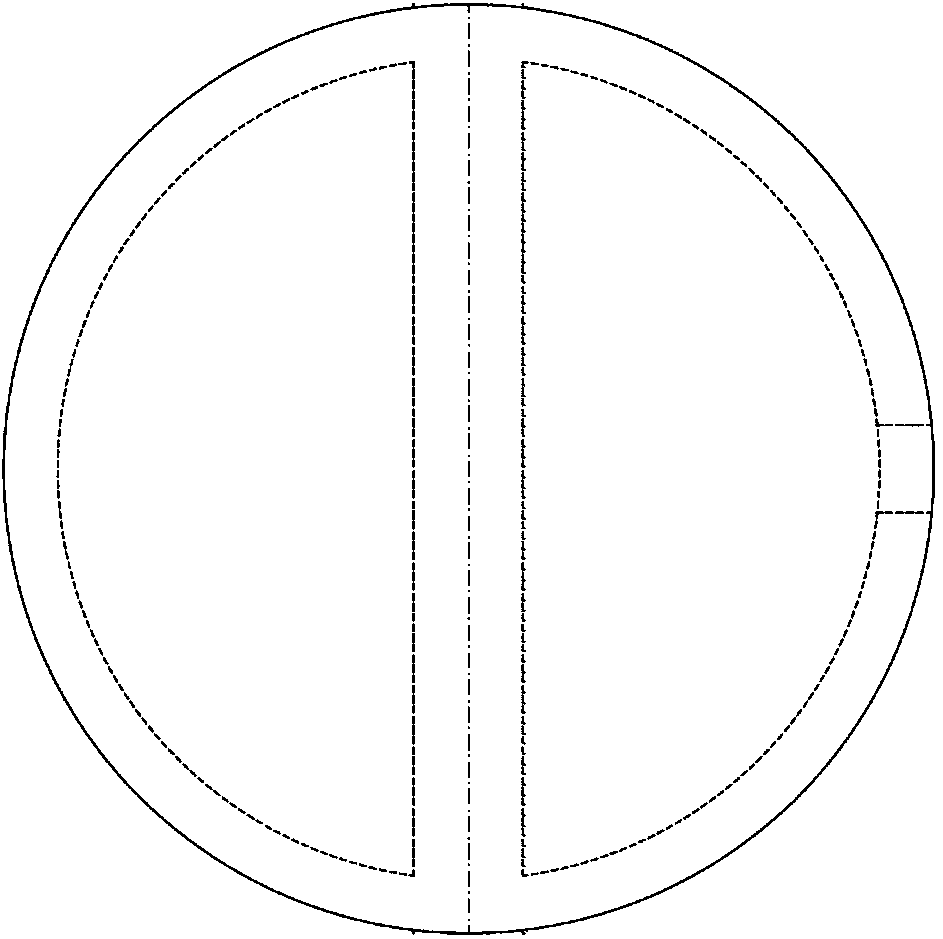

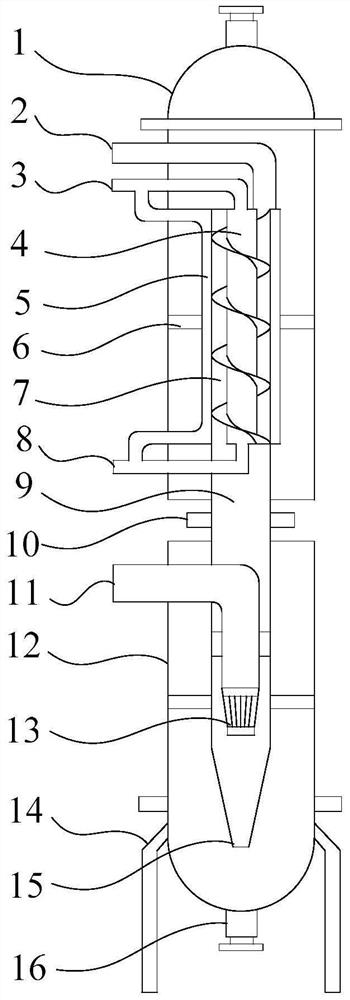

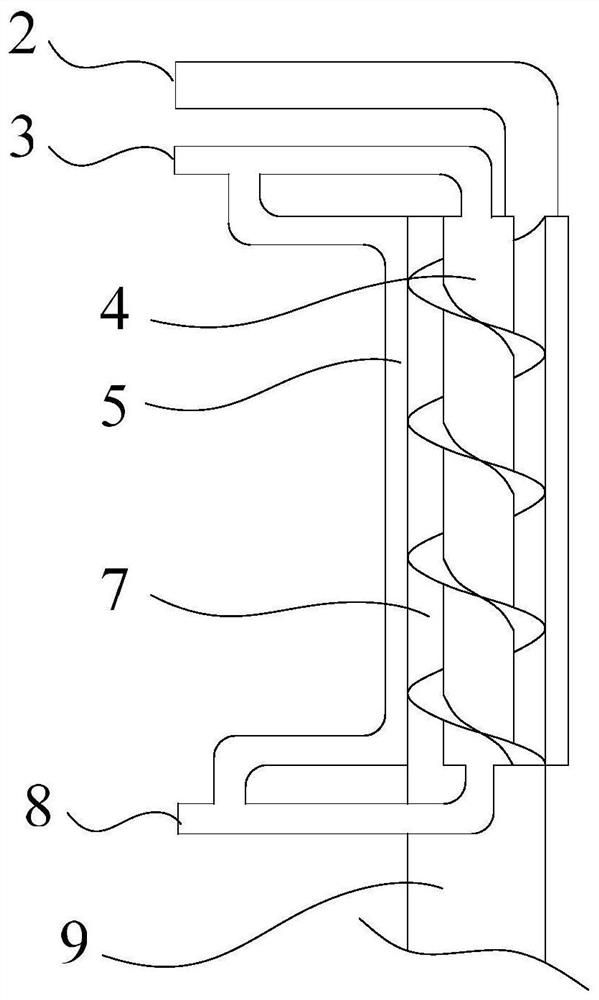

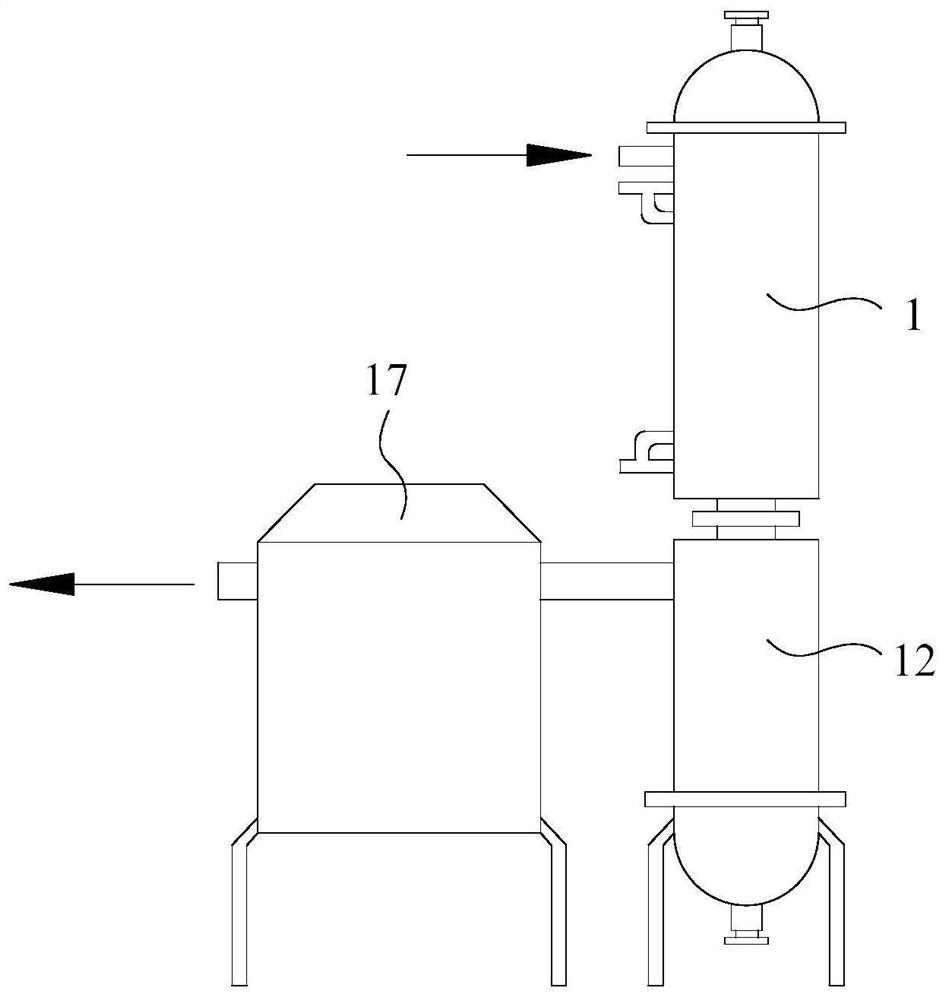

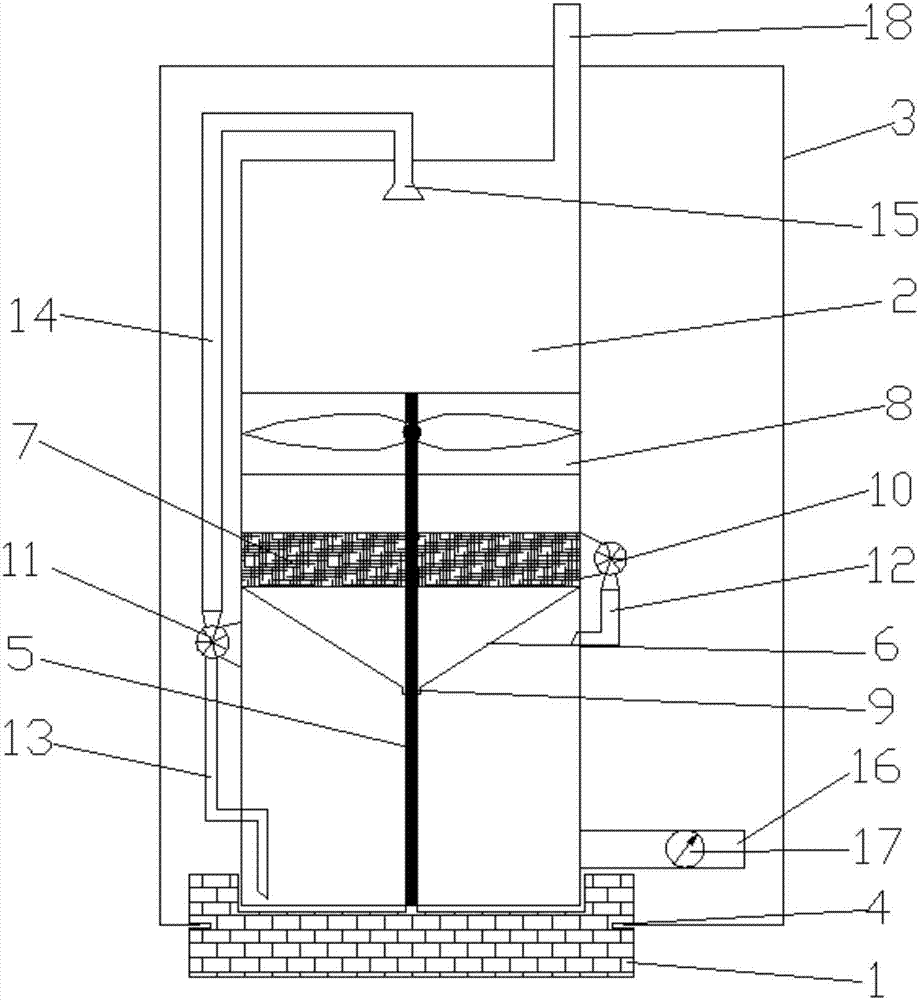

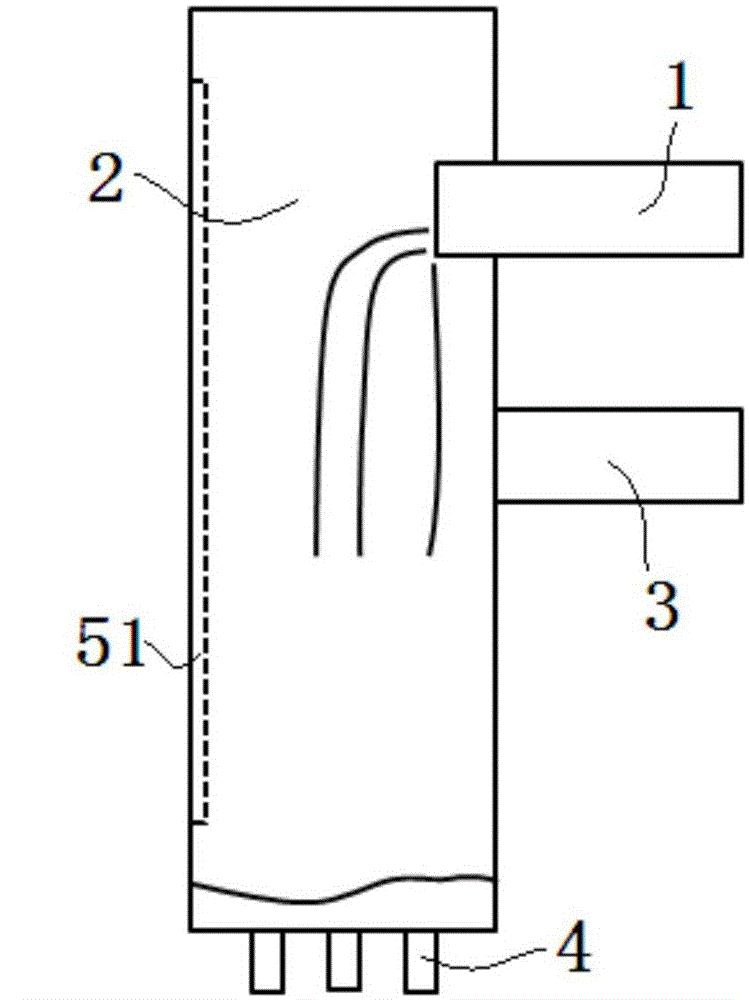

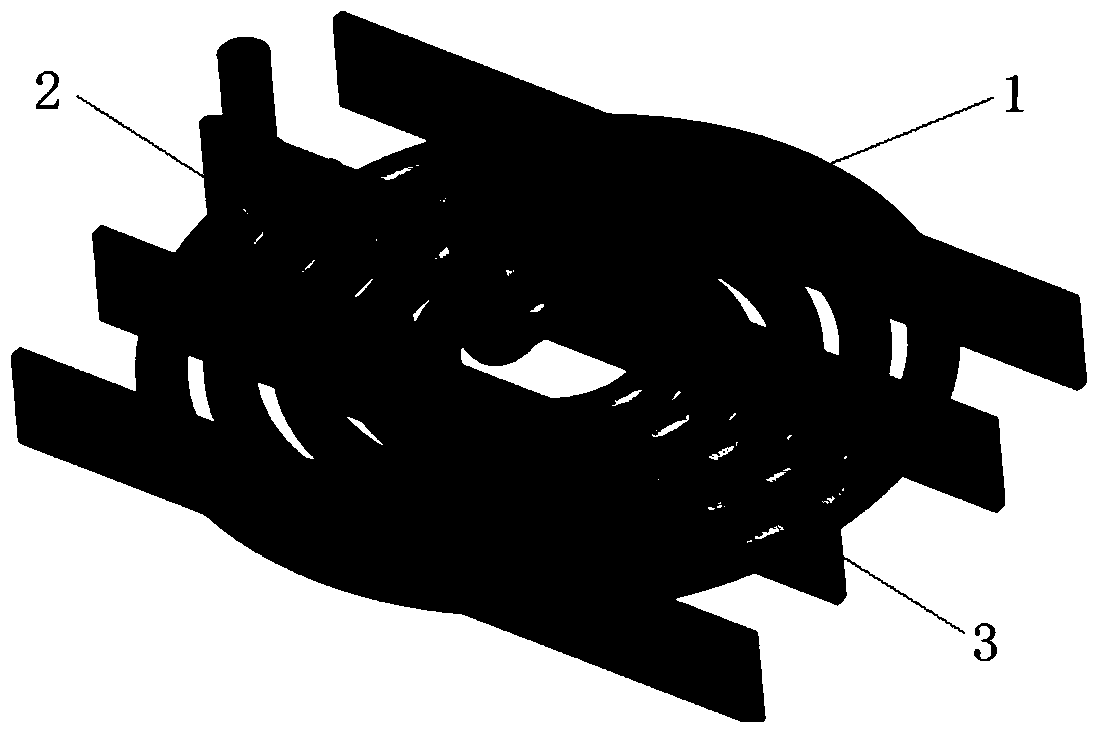

Raw oil associated gas supergravity separation device

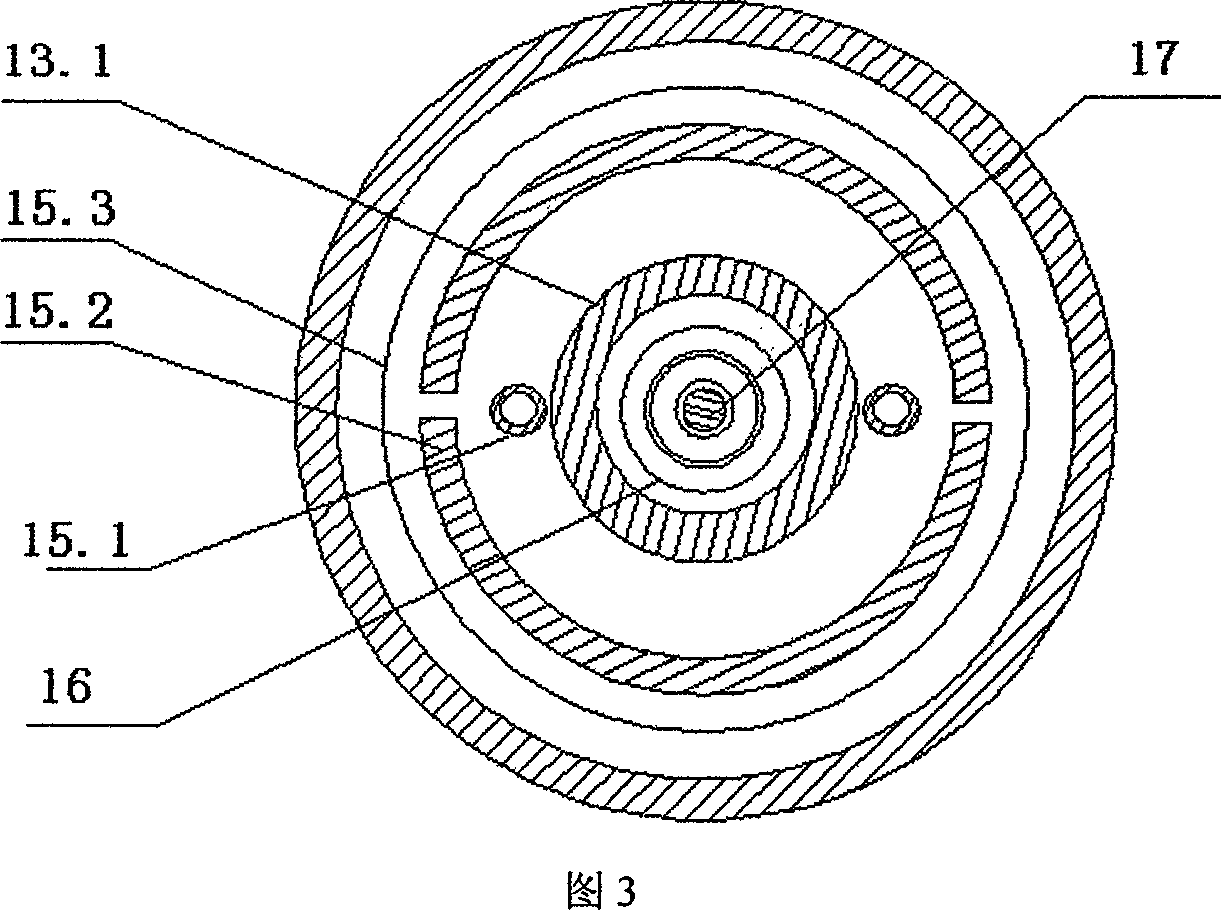

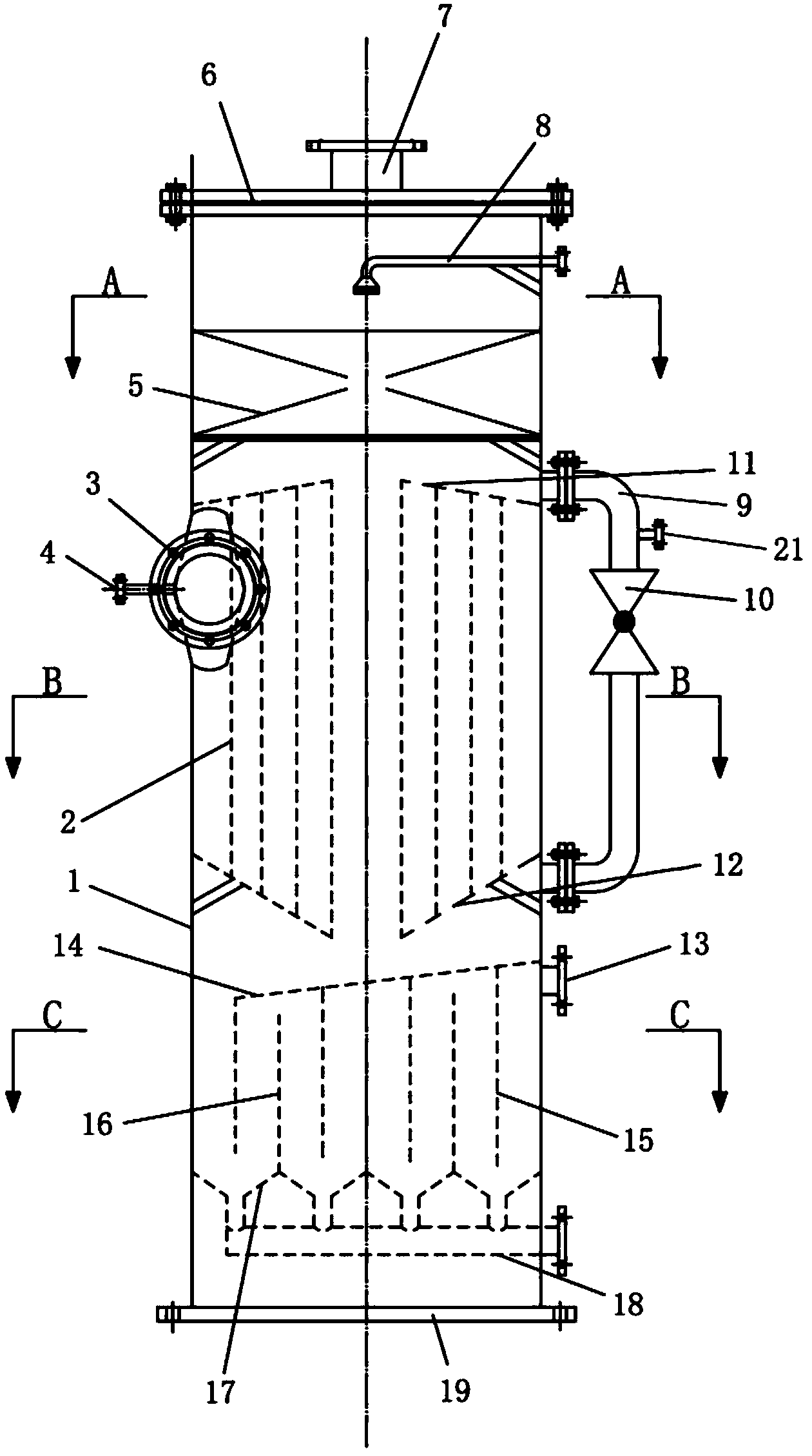

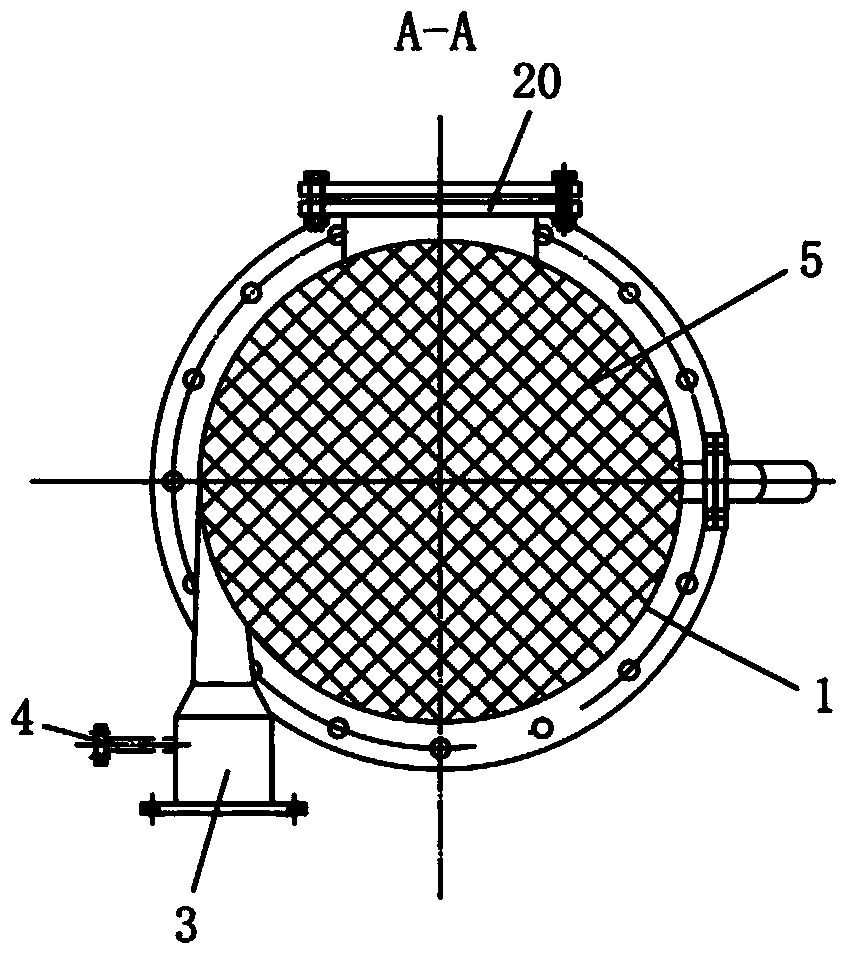

ActiveCN103657265AImprove gas-liquid separation efficiencySmall sizeGaseous fuelsDispersed particle separationDrive shaftEngineering

The invention discloses a raw oil associated gas supergravity separation device which comprises a shell, wherein a resolved gas outlet 9 is formed in the top of the shell; a demister 8 is arranged on the upper part of the shell; a baffle 12 is arranged on the middle part of the shell; a hole is formed in the middle part of the baffle and is connected with a liquid phase diversion pipe 11; a gas overflow pipe 13 is arranged on the baffle; a supporting plate 14 is arranged on the middle lower part in the shell; a liquid drainage pipe 15 is arranged on the supporting plate; a transmission shaft 10 penetrates through the middle part of the supporting plate and is connected with the lower surface of the middle part of a rotary bed 6 with a filler 5; an annular liquid phase collection bin 4 is arranged on the lower part of the supporting plate; a liquid phase outlet 3 is formed in the bottom wall of the shell; a space above the baffle is a resolving bin 7; a raw oil multi-phase fluid inlet 1 is formed in the tangent direction of the side wall of the shell; a standby inert resolved gas inlet 2 is formed in the side wall of the shell. The raw oil associated gas supergravity separation device is high in gas-liquid separation efficiency, can save the space and realize skid-mounting and is favorable for small-oil-field work on an offshore platform and dispersive small-oil-field work.

Owner:国恒信(常州)检测认证技术有限公司 +2

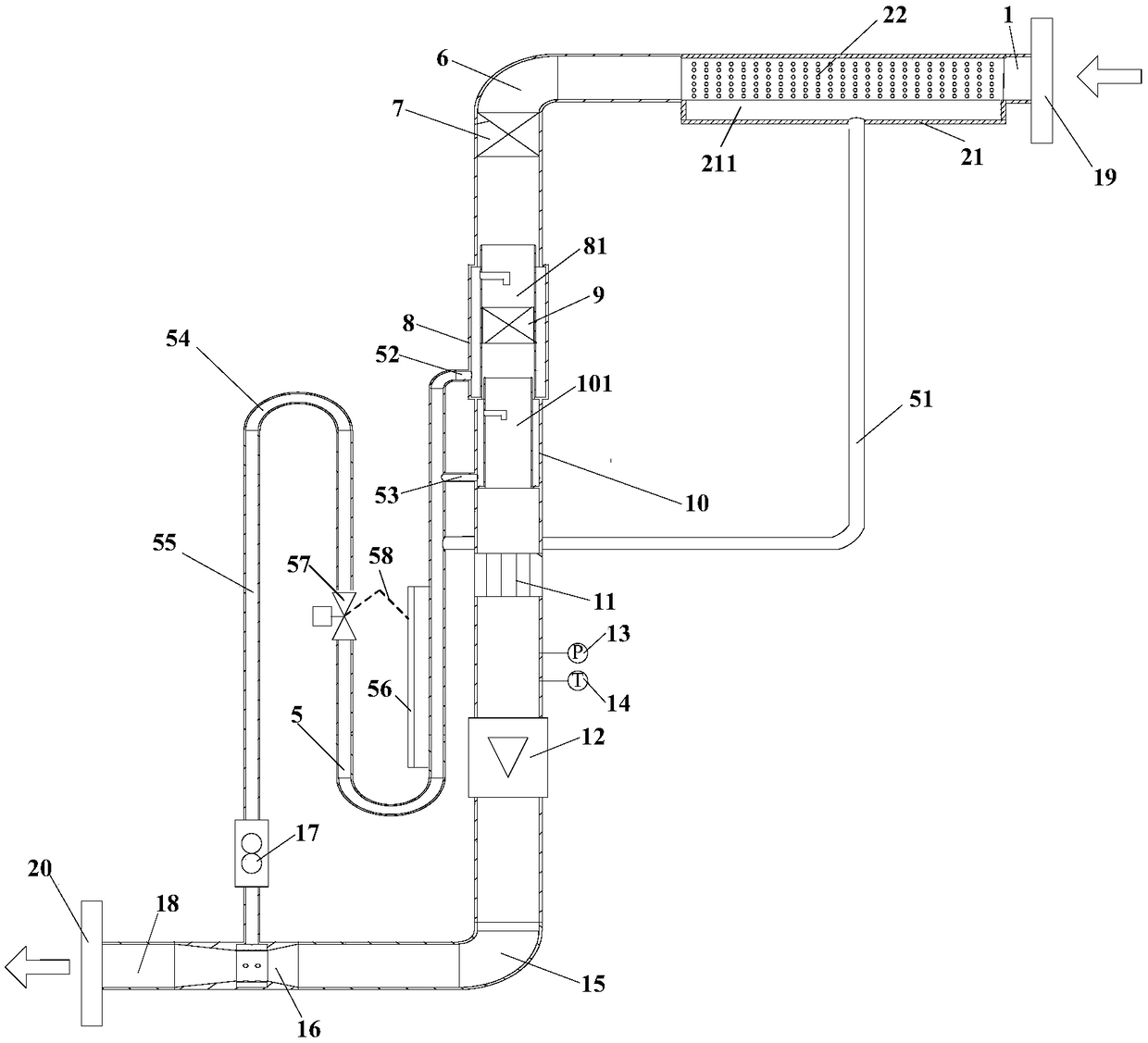

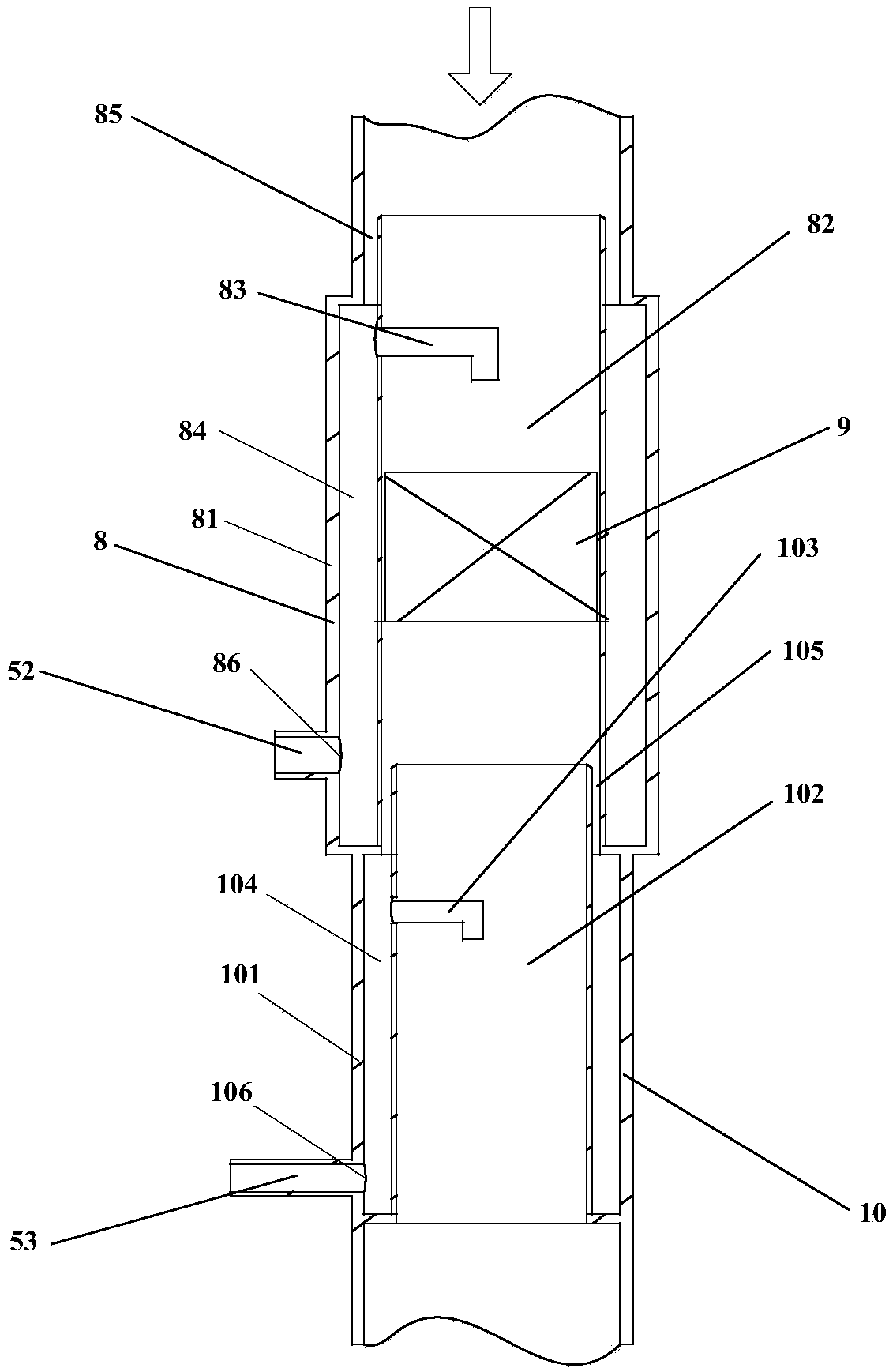

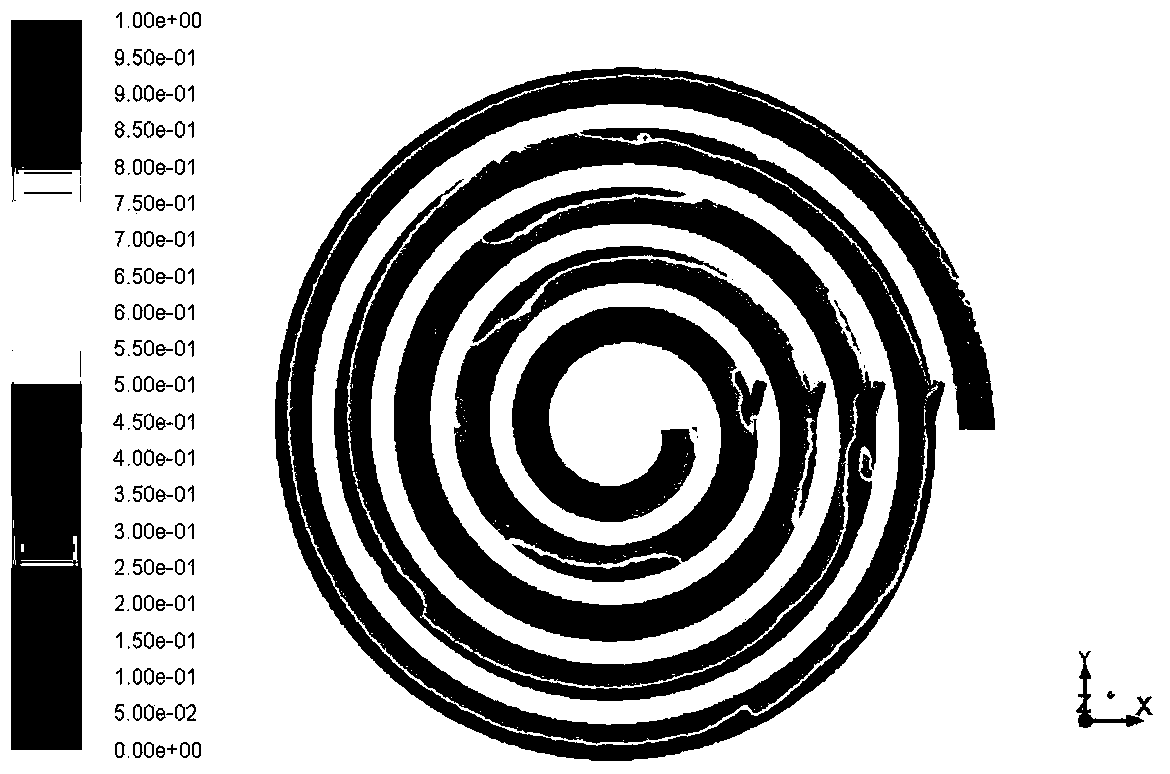

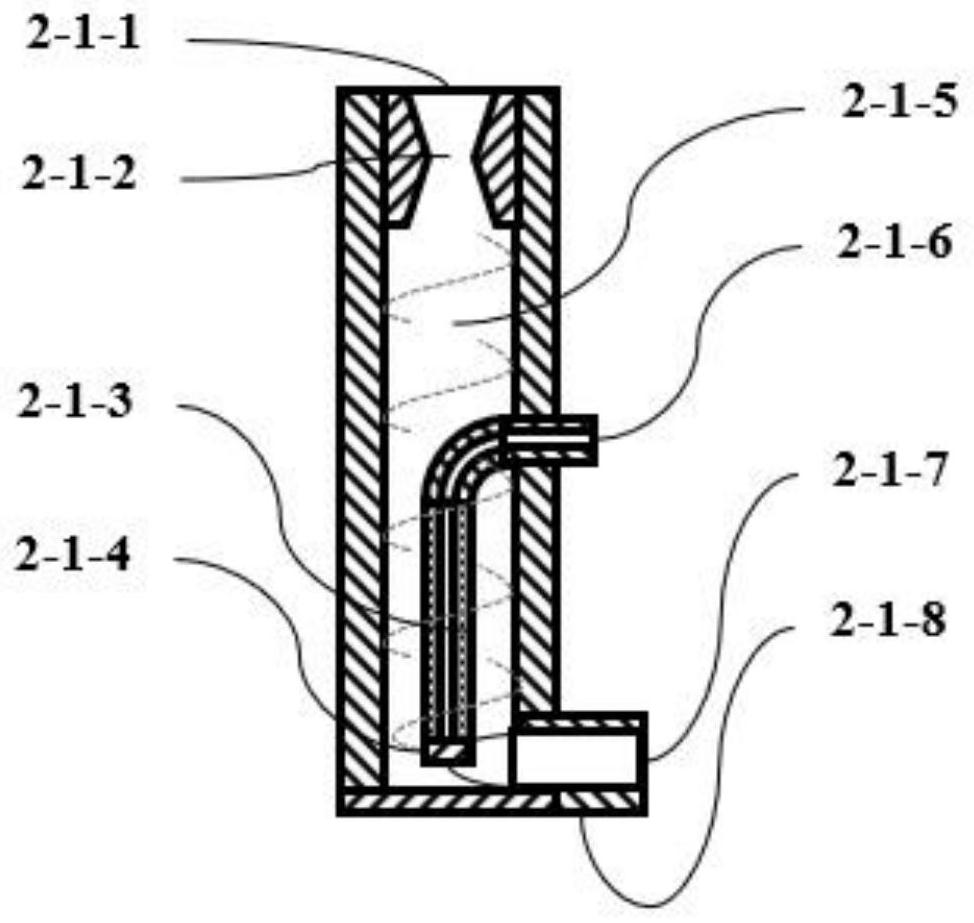

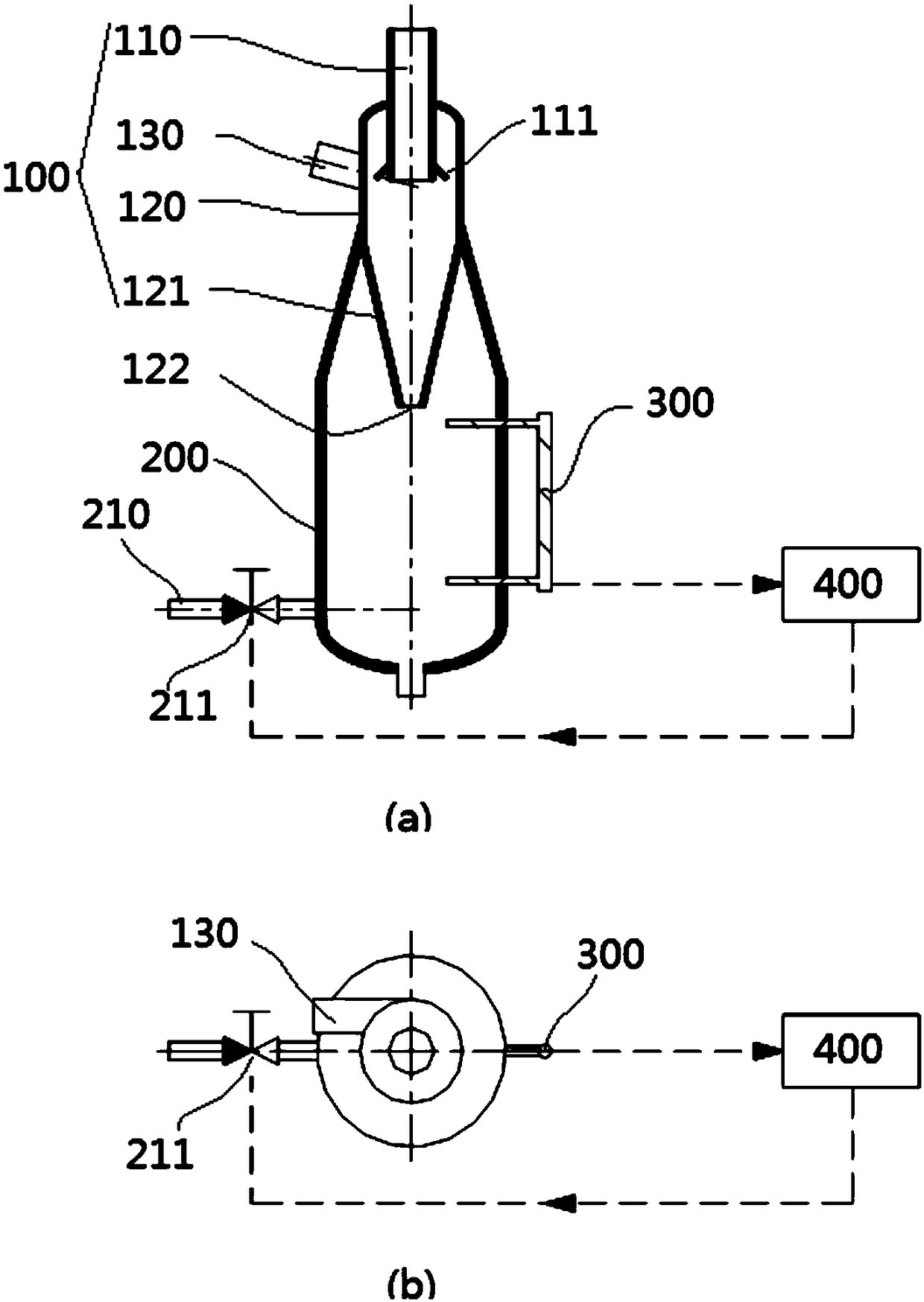

Z-type natural gas moisture real-time measuring device and method based on in-pipe phase separation

PendingCN109141563AAchieve separationGuaranteed accuracyVolume flow measuring devicesCycloneMeasurement device

The invention provides a Z-type natural gas moisture real-time measuring device based on in-pipe phase separation. The device mainly consists of a gas-liquid coarse separation system, a two-stage cyclone, a two-stage pipeline type compact gas-liquid separator, a derotator, a gas flowmeter, a temperature sensor, a pressure sensor, a U-shaped liquid collecting pipe, a liquid flowmeter and an ejection type gas-liquid mixer. The measuring method of the device provided by the invention is to achieve complete gas-liquid separation by using the multi-phase flow tube internal phase separation technology, in combination with the gravity separation and by means of multiple separation steps, and then to measure the flow rates of the gas phase and the liquid phase in natural gas moisture by using a single-phase flowmeter. By adoption of the Z-type natural gas moisture real-time measuring device provided by the invention, the separation efficiency of gas and liquid in the moisture can be greatly improved, the gas-liquid measurement accuracy is ensured, meanwhile the volume of a separator is greatly reduced, and the instantaneity of moisture measurement is improved. In addition, the moisture measuring device and method involved in the invention have the advantages of wide applicable flow parameter range, high safety performance and low manufacturing cost, and are very suitable for popularization and application in engineering.

Owner:YANGTZE UNIVERSITY

Gas-liquid separator

ActiveCN103977665BExtended service lifeNo cloggingCombination devicesVapor–liquid separatorCyclonic separation

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

A gas-liquid separator

ActiveCN104368214BImprove stabilityImprove gas-liquid separation efficiencyCombination devicesGaseous fuelsVapor–liquid separatorCyclonic separation

The invention provides a novel gas-liquid separator comprising a liquid storage cavity, and a cyclone separation section and a deep gas-liquid separation section which are arranged at the top of the liquid storage cavity and are communicated with the liquid storage cavity, wherein a base is arranged at the bottom of the liquid storage cavity, a gas-liquid separator inlet is formed in the cyclone separation section, and a cyclone column is arranged in the cyclone separation section; a separator outlet is formed in the deep gas-liquid separation section, a blade type separation box is arranged on the inner end surface of the separator outlet, the lower end of the blade type separation box is connected with a blade type separation box liquid discharge pipe which is communicated with the liquid storage cavity, the other end of the blade type separation box, relative to the separator outlet, is provided with a wire mesh demister, and the wire mesh demister is communicated with the blade type separation box; and a production liquid discharge opening is also formed in the bottom of the liquid storage cavity. The novel gas-liquid separator provided by the invention can be used for greatly improving the operation stability of gas fields, and re-purification of gas is achieved so as to ensure that gas to be purified is subjected to deep gas-liquid separation; and the purpose of increasing the gas-liquid separation efficiency of a multi-stage baffle plate liquid removal component can be achieved.

Owner:PETROCHINA CO LTD

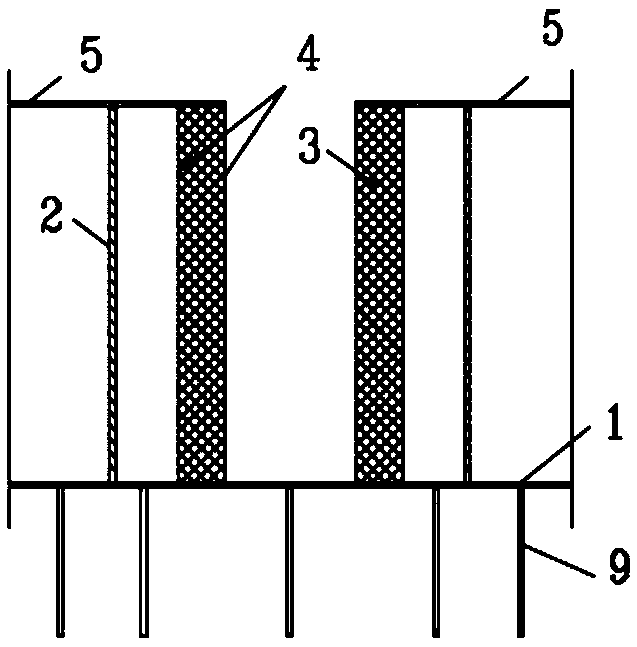

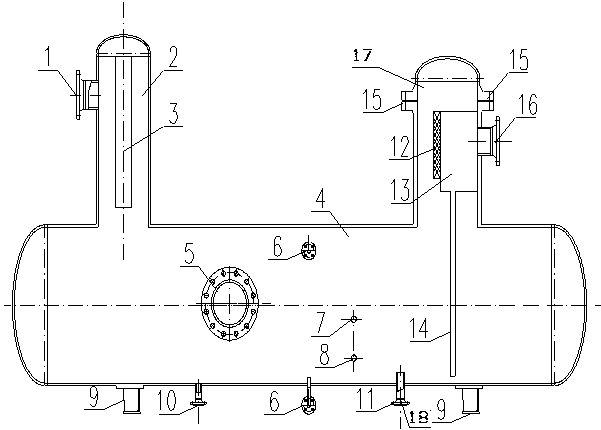

Liquid separation header

ActiveCN103743284AImprove gas-liquid separation efficiencyGood gas-liquid separation efficiencyDispersed particle separationHeat exchanger casingsEngineeringNet shape

The invention discloses a liquid separation header which comprises an incoming flow branch pipe, a header, a liquid discharging core and an outflow branch pipe. The incoming flow branch pipe and the outflow branch pipe are installed on an outer side wall of the header, the liquid discharging core is installed in the header, and a liquid catching sector is arranged on an inner wall of the header. A plurality of grooves longitudinally arranged along the header and the surface with scattered protruded points or an uneven net-shaped covering layer are arranged in the liquid catching sector. The liquid separation header has the advantages that the amount of liquid flowing out along the outflow branch pipe is reduced, header inner disturbance causing reduction of liquid separation efficiency is restrained, and gas-liquid separation efficiency of the liquid separation header is improved; a process is good, almost no manufacturing cost is increased, the gas-liquid separation effect of the liquid separation header can be improved well, and the liquid separation header is high in economy and popularization value.

Owner:GUANGDONG UNIV OF TECH

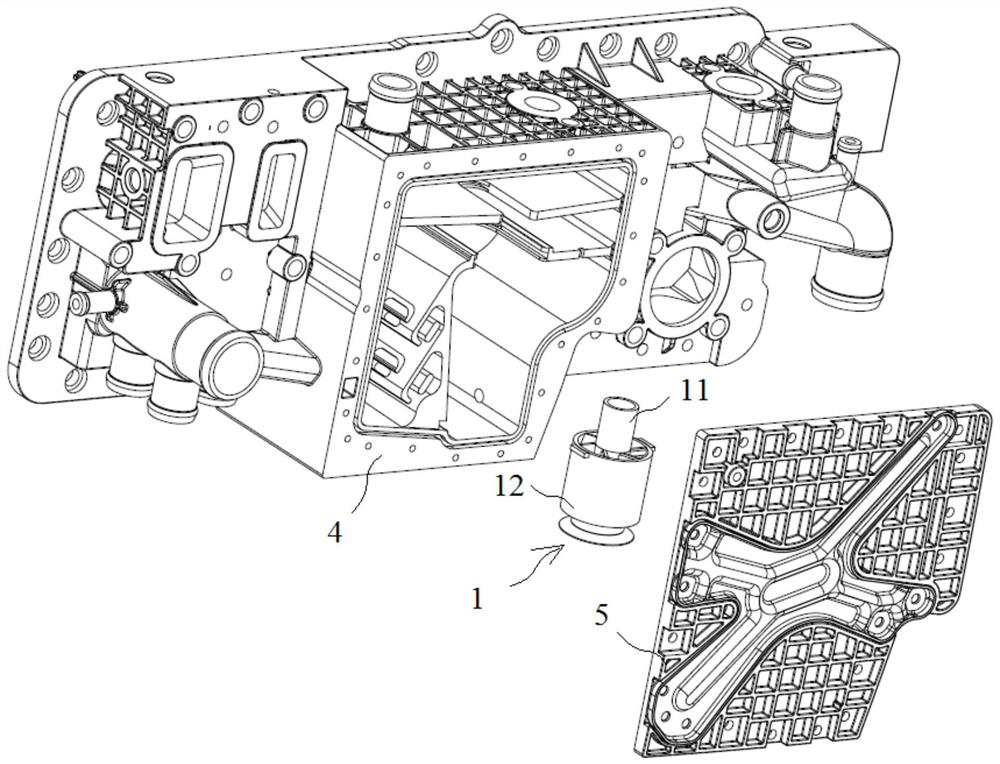

Heat exchange and separation integrated cyclone separation device

PendingCN113351385AImprove heat transfer effectImprove gas-liquid separation efficiencyReversed direction vortexCycloneThermodynamics

The invention provides a heat exchange and separation integrated cyclone separation device. The cyclone separation device comprises a shell, the shell is provided with an air inlet, an air outlet and an oil-gas mixture channel communicating with the air inlet and the air outlet; a heat exchange device for conducting heat exchange on an oil-gas mixture and an axial flow type cyclone separator are further arranged in the shell; the oil-gas mixture channel penetrates through the heat exchange device to lead to the cyclone separator, the oil-gas mixture channel is provided with a spiral flow channel in the heat exchange device, and the spiral flow channel is used for guiding the oil-gas mixture to spirally flow so as to be consistent with the airflow vortex direction of the cyclone separator. The heat exchange device and the separator are sequentially arranged in the cyclone separation device, high-temperature oil gas can be cooled and then separated, the spiral flow channel is formed in the inner cavity of the heat exchange device, the heat exchange area of the high-temperature oil-gas mixture is increased, and the heat exchange efficiency is improved; the spiral flow channel guides the airflow into a spiral shape to enter the axial flow type cyclone separator for multi-stage separation, and the high-temperature gas-liquid separation effect is effectively enhanced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

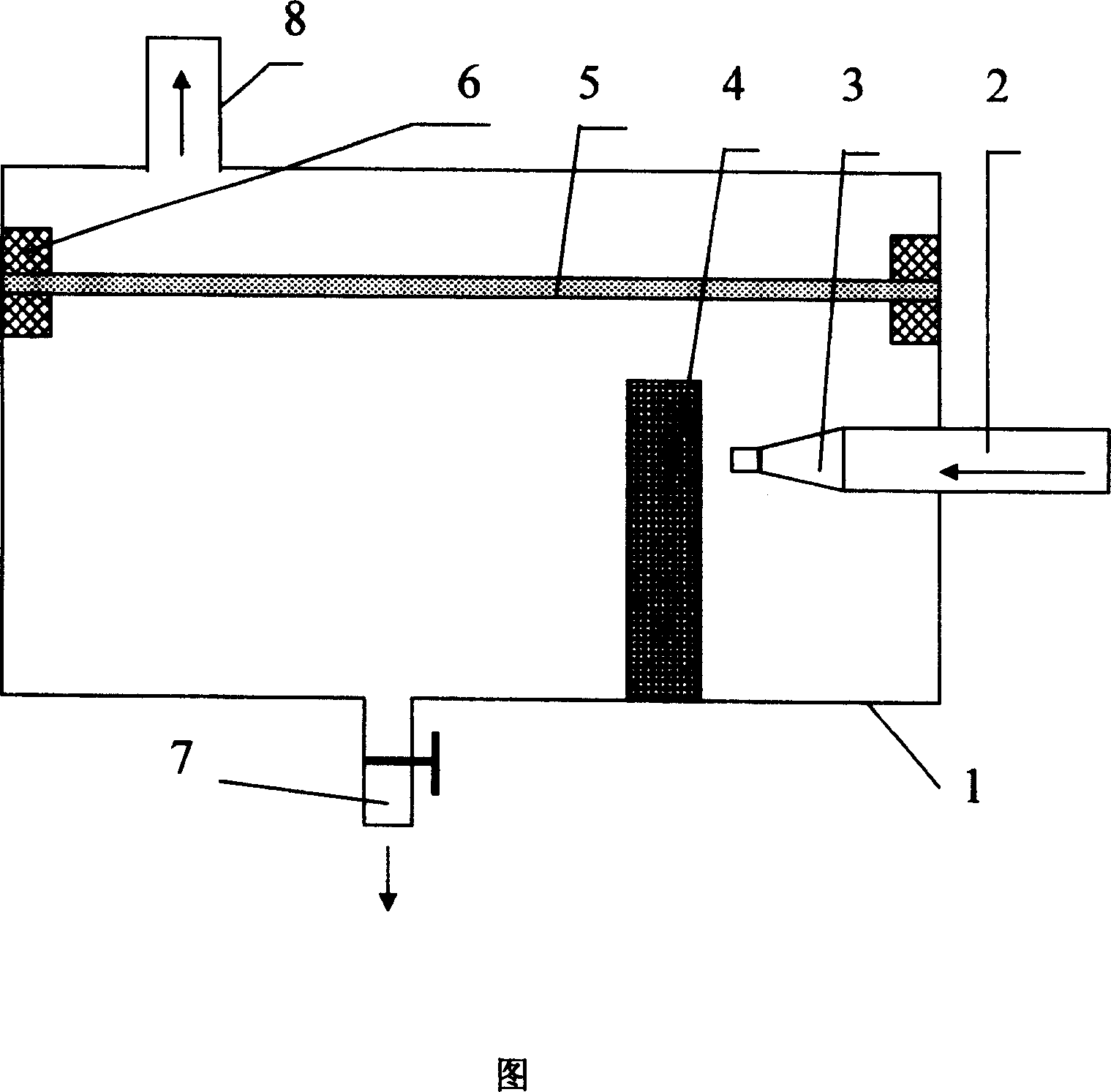

Gas-liquid separator for separating droplet from gas and its separating method

This invention concerns gas-liquid separation device and its method to separate micro-droplet from gas. Assemble one gas inlet pipe in one end wall of sealed container with nozzle; fix multihole retention felt pad on bottom wall of container before the nozzle front 0.5~10mm; there is micropore filter membrane pressed and sealed by edge in container; set gas outlet on top wall of container; set liquid outlet with one-way valve for intercepting liquid on downside wall of container front of pad; use two-class separation way with first class high speed spray absorption and interception and second class filter. The invention overcomes shortcomings of low efficiency and short life, and ensures the treated gas to satisfy require.

Owner:HEBEI UNIV OF TECH

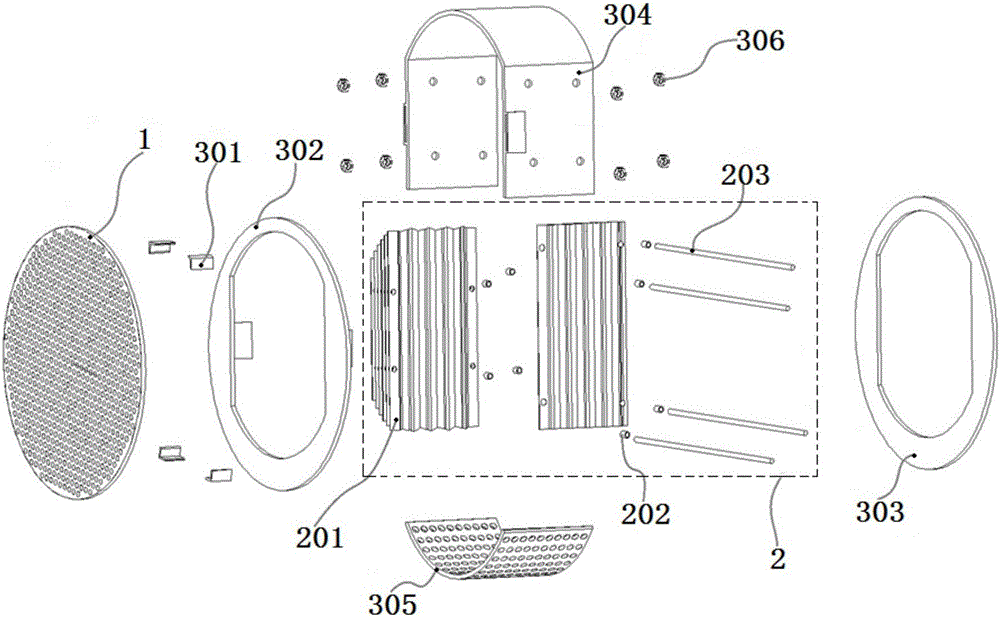

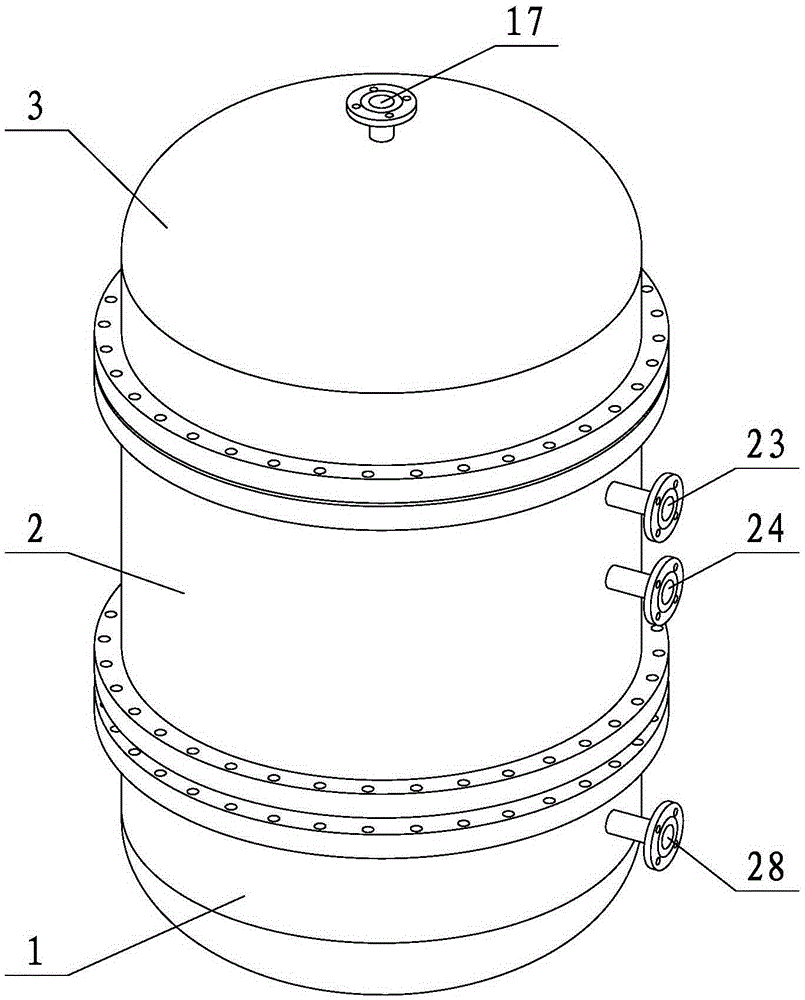

Condensation-type gas-liquid separation apparatus

InactiveCN105597480AHigh heat transfer efficiencyImprove gas-liquid separation efficiencyDispersed particle separationVapor condensationHeat pipe heat exchangerHeat transfer efficiency

The invention relates to a gas-liquid separation device, and more specifically discloses a condensation-type gas-liquid separation apparatus. The condensation-type gas-liquid separation apparatus is mainly composed of a lower shell cover part, a tank body part, an upper shell cover part, a transverse separating plate part, metal wire mesh strip parts, fixing plate parts, and heat pipe heat exchanger parts. When a refrigerant flows through a tank body upper chamber, heat energy of condensation sections of the heat pipe heat exchanger parts is absorbed by the refrigerant, so that the temperature of the condensation sections of the heat pipe heat exchanger parts is reduced; when a mixed gas flows through a tank body lower chamber, heat energy of the mixed gas is absorbed by the metal wire mesh strip parts, metal felt sleeves, and the condensation sections of the heat pipe heat exchanger parts together, so that gas in the mixed gas to be separated is changed into liquid drops via condensation, the liquid drops come together to become a condensate, and the condensate is discharged via a liquid outlet pipe; heat transfer efficiency is increased by the liquid drops absorbed by the metal felt sleeves, and the metal wire mesh strip parts take part in entire condensation and despumation processes of the mixed gas; reblending of a high concentration gas obtained via removing of the condensate with the mixed gas is not caused, so that gas liquid separation efficiency is increased.

Owner:江西金林化工有限公司

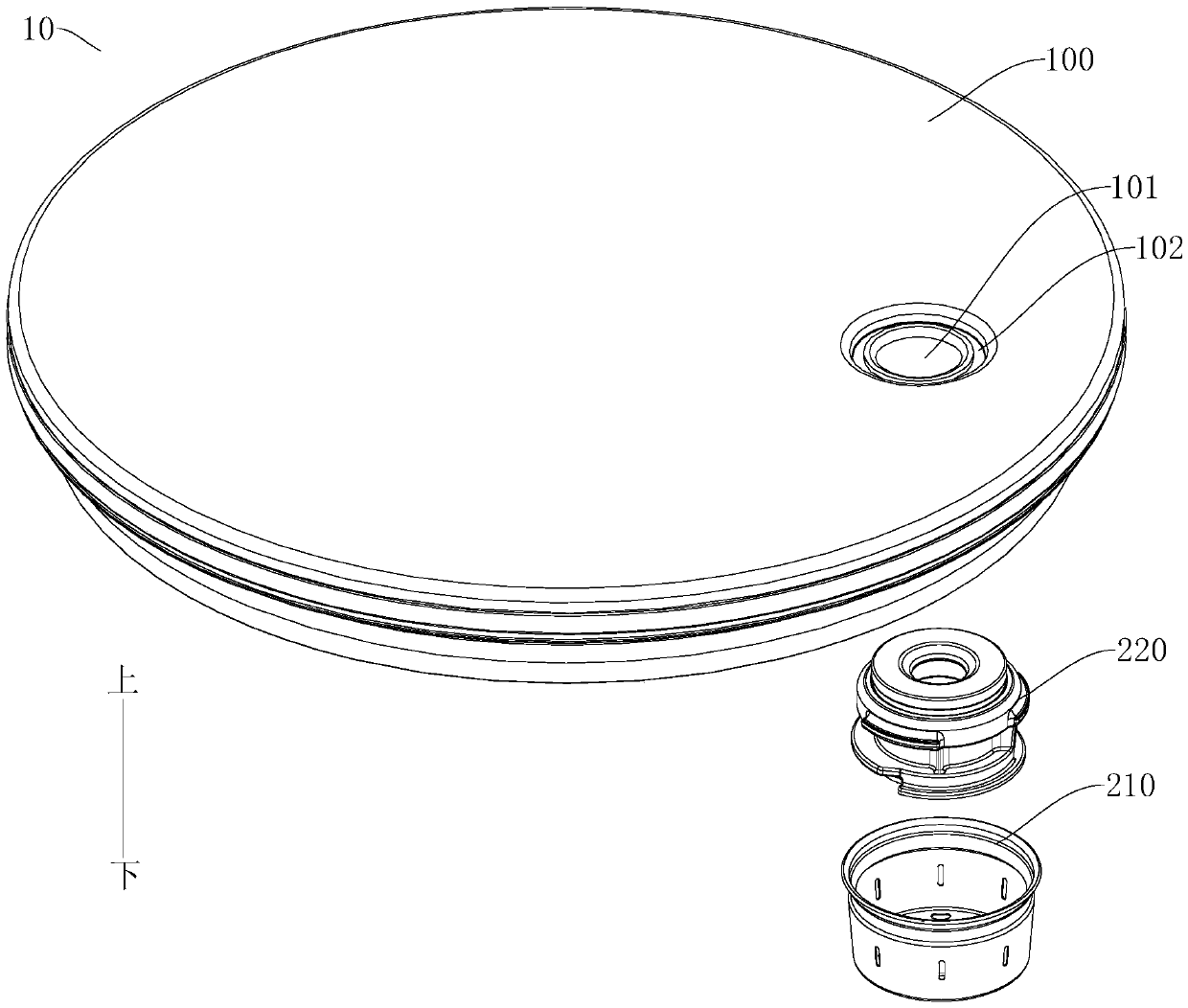

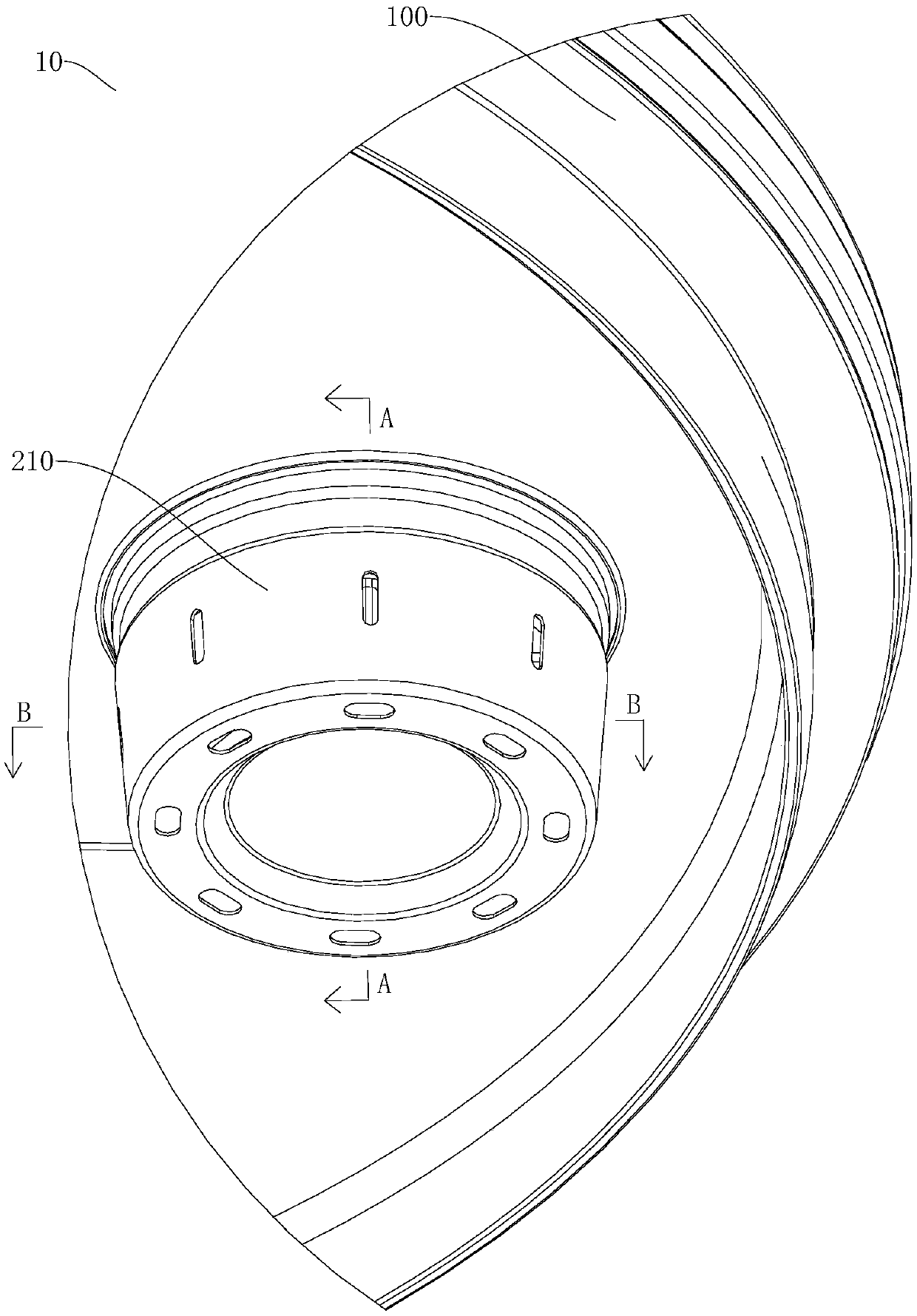

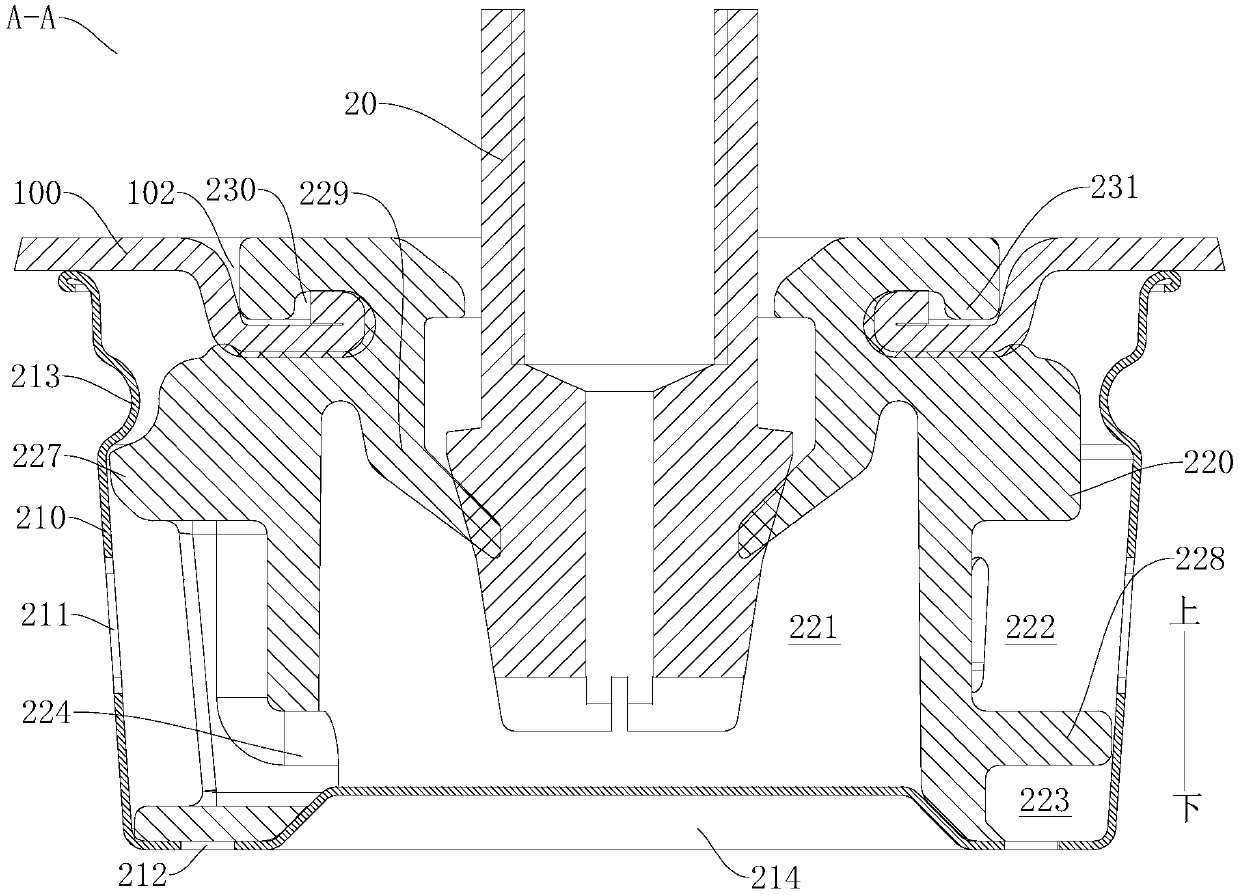

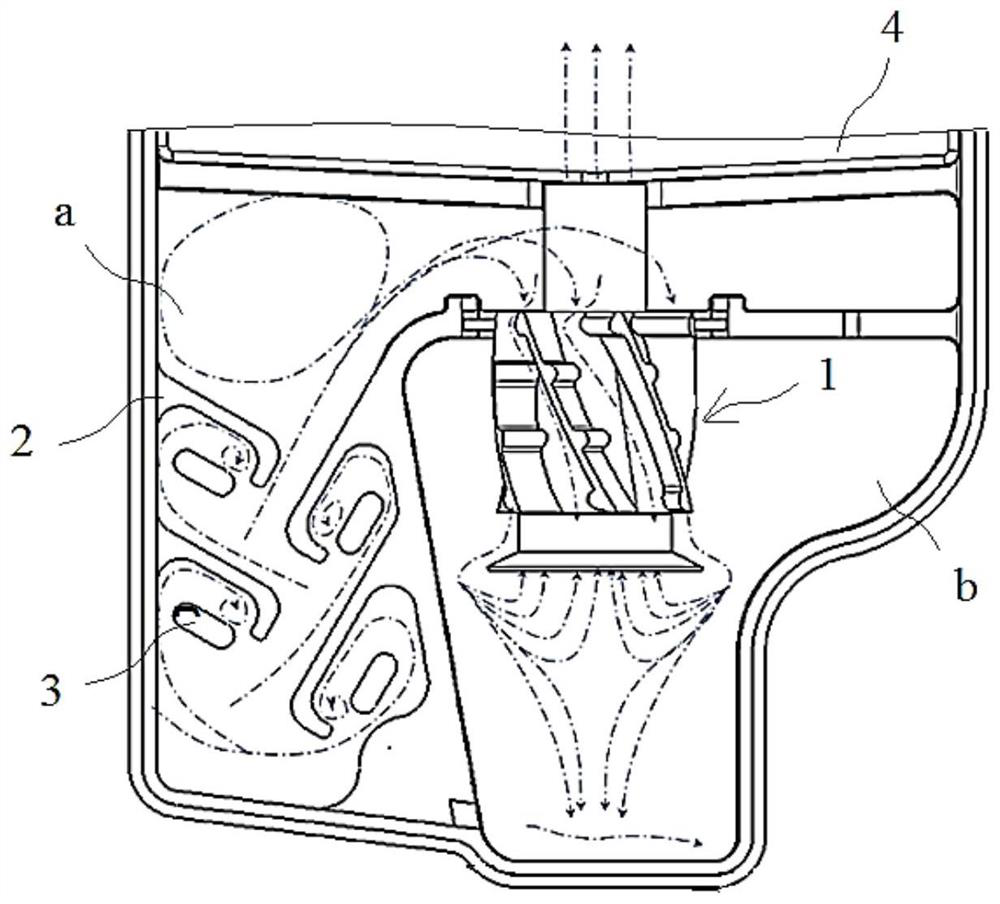

Foam breaking device for cooking utensil, pot cover and cooking utensil

ActiveCN110613332AImprove separation efficiencyGood foam breaking and spill preventioBoiling over preventionPressure-cookersCentrifugal forceWaste management

The invention discloses a foam breaking device for a cooking utensil, a pot cover and the cooking utensil. The pot cover of the cooking utensil is provided with an exhaust channel. The foam breaking device comprises a body, the body is suitable for being connected with the pot cover; the body is internally provided with an air passing cavity suitable for being communicated with the exhaust channeland an open-ring-shaped or closed-ring-shaped foam breaking flow channel surrounding the air passing cavity. The body is provided with a foam inlet hole communicating with the foam breaking flow channel and a cooking cavity of the cooking utensil, and an air inlet communicating with the foam breaking flow channel and the air passing cavity. A gas-liquid mixture in the cooking cavity is suitable for entering the foam breaking flow channel from the foam inlet hole and flowing in the circumferential direction of the foam breaking flow channel so as to break foam under the action of centrifugal force and gas-liquid separation is achieved, and gas formed through gas-liquid separation is suitable for entering the air passing cavity from the air inlet. According to the foam breaking device for the cooking utensil, the gas-liquid separation efficiency is high, and the foam breaking, overflowing preventing, exhausting and pressure reducing effects are good.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

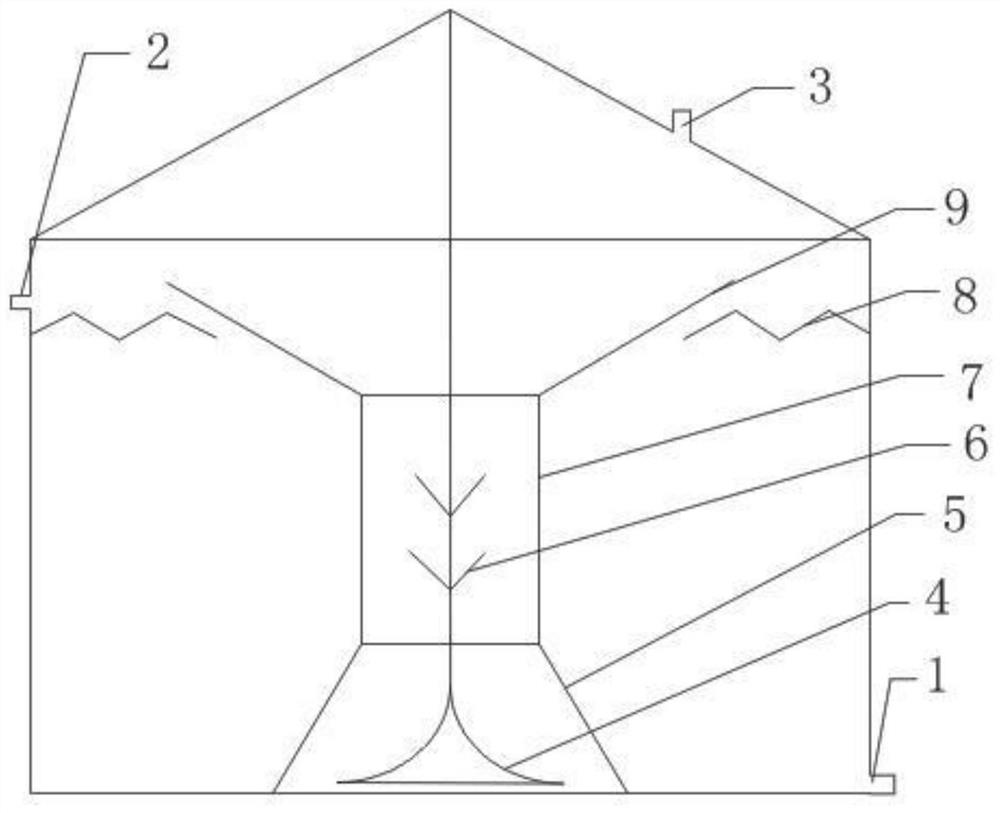

Combined type coal tar recycling equipment and coal tar recycling method thereof

InactiveCN107254333AImprove separation efficiencyHas the effect of energy saving and emission reductionChemical industryTar working-up by water removalCyclonic separationHigh pressure

The invention discloses combined type coal tar recycling equipment and a coal tar recycling method thereof. The combined type coal tar recycling equipment comprises a pedestal, a rotating cylinder and a protective cover, wherein the upper surface of the pedestal is connected with the rotating cylinder in a clamping manner through a groove; the side walls of the pedestal are connected with the protective cover in a clamping manner through clamping slots; the pedestal is provided with a rotating shaft extending into the rotating cylinder; the shaft wall of the rotating shaft is connected with a dropping funnel, a filtering layer and a turbofan in a sleeving manner in sequence from bottom to top; an air negative pressure machine and an oil pump are arranged on the outer wall of the rotating cylinder; the air negative pressure machine is connected with a negative pressure pipe; the oil pump is connected with a liquid extraction pipe and a spraying pipe; the spraying pipe is connected with a high pressure spraying head; the rotating cylinder is provided with a liquid discharging pipe and a gas feeding pipe. The coal tar recycling method comprises a centrifugal separation method, a cyclone separation method and a coal tar mutual adsorption and separation method. By combination with the centrifugal separation method, the cyclone separation method and the coal tar mutual adsorption and separation method, the combined type coal tar recycling equipment is high in gas-liquid separation efficiency; furthermore, by use of high temperature in raw coke oven gas, the combined type coal tar recycling equipment has the effects of saving energy and reducing discharging.

Owner:贵州森林木业有限公司

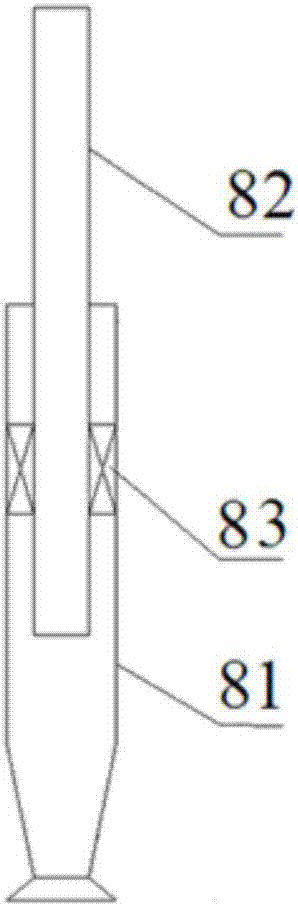

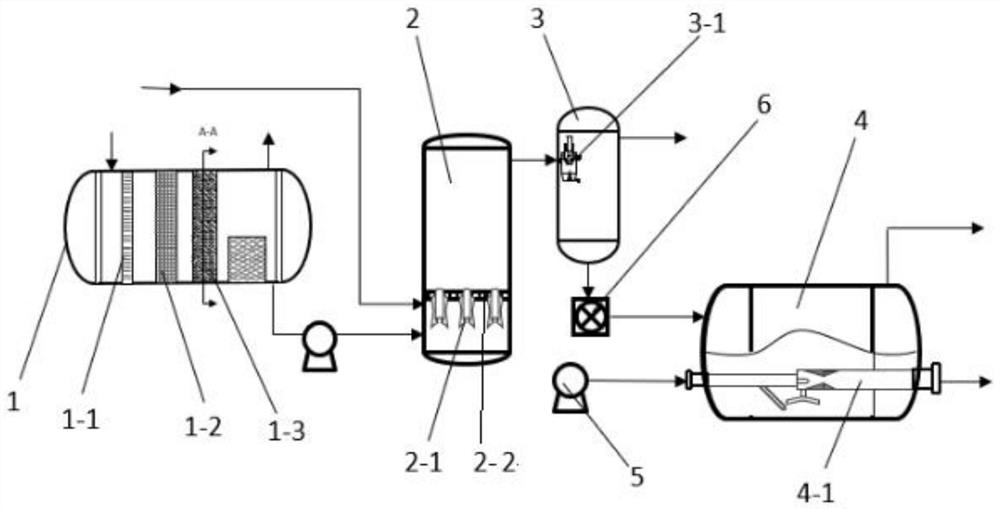

Underwater separation device with pre-separation pipeline and underwater separation method thereof

InactiveCN106964200AImprove gas-liquid separation efficiencyImprove efficiencyDispersed particle separationGaseous fuelsEngineeringPre-charge

The invention discloses an underwater separation device with a pre-separation pipeline and an underwater separation method. The device comprises the pre-separation pipeline and a centrifugal separator, wherein the pre-separation pipeline comprises a main gas phase pipe, an inclined liquid phase pipe and liquid falling pipes; the main gas phase pipe comprises an inlet condensate section, a horizontal section and an outlet condensate section which are connected in sequence; the inlet condensate section extends downwards relatively to the horizontal section; the outlet condensate section extends upwards relatively to the horizontal section; the inclined liquid phase pipe is arranged below the main gas phase pipe in an inclined manner; the inlet end of the inclined liquid phase pipe is communicated with the bottom of the inlet condensate section; the liquid falling pipes are respectively arranged between the bottom of the horizontal section and the inclined liquid phase pipe and between the bottom of the outlet condensate section and the inclined liquid phase pipe; the centrifugal separator comprises a pressure vessel tank and a plurality of centrifugal separation pipes; the pressure vessel tank is divided into a gas discharging chamber, a gas inlet chamber, and a liquid discharging chamber; the plurality of centrifugal separation pipes for communicating the gas discharging chamber and the liquid discharging chamber; and a gas discharging opening of the outlet condensate section is communicated with the gas inlet chamber.

Owner:CHINA NAT OFFSHORE OIL CORP +1

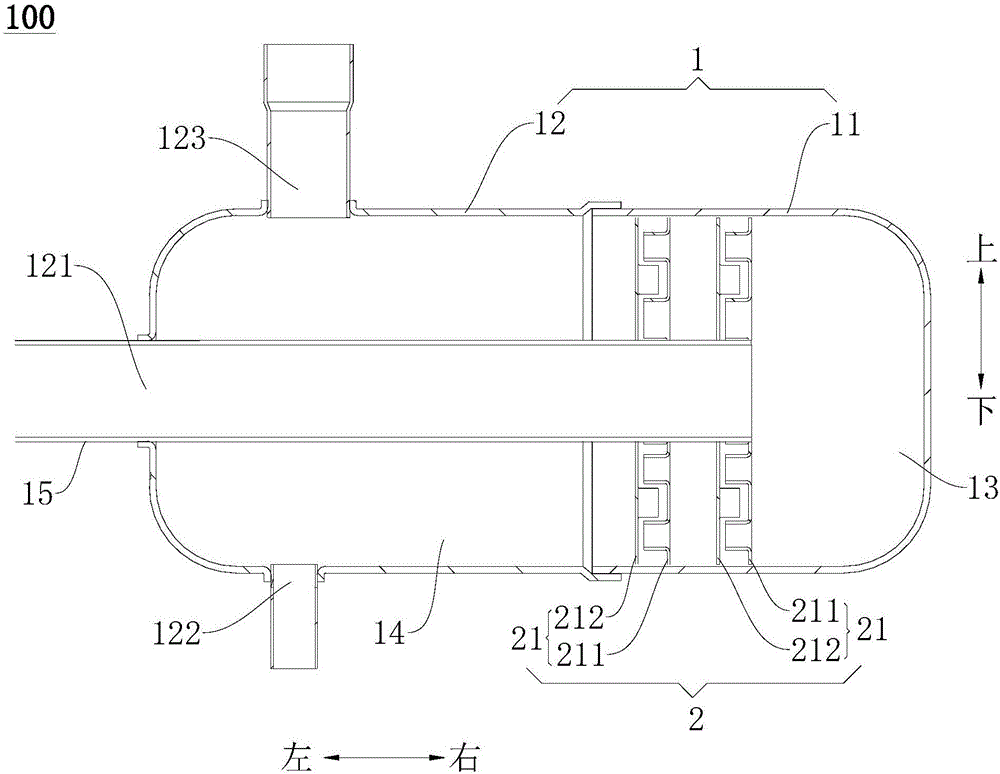

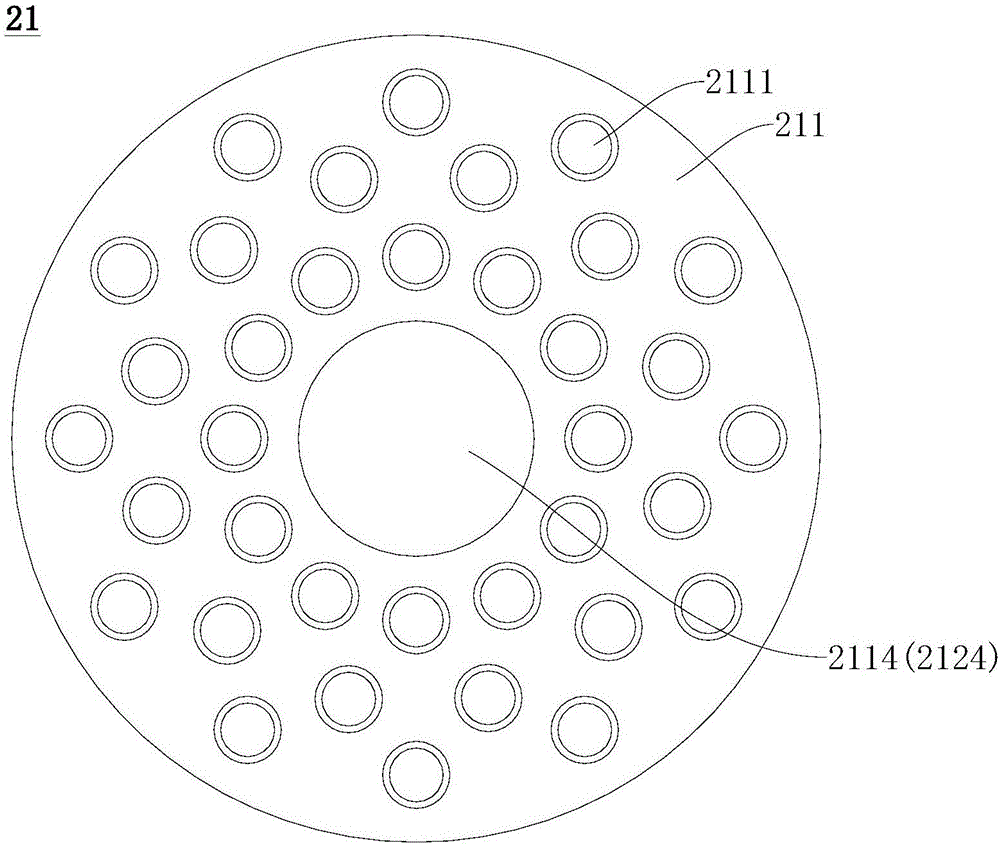

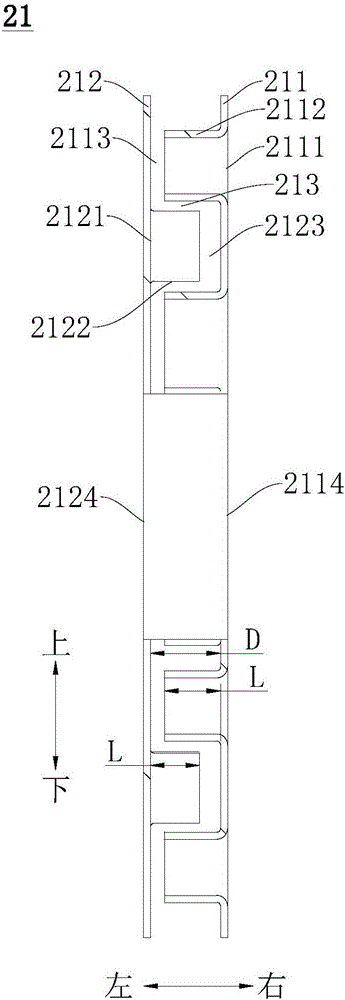

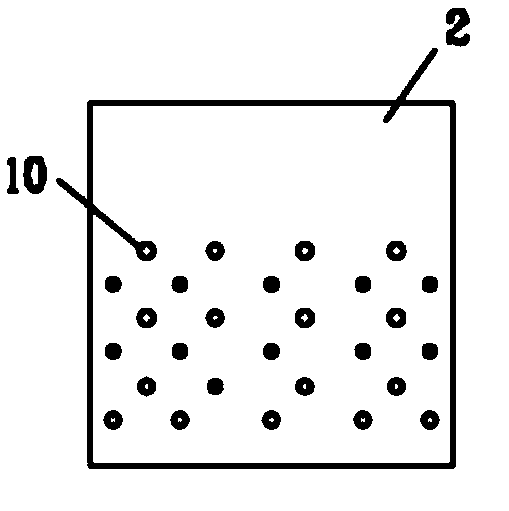

Gas-liquid separator and refrigerating system provided with same

PendingCN106766428AImprove gas-liquid separation efficiencySimple structureRefrigeration componentsVapor–liquid separatorProduct gas

The invention discloses a gas-liquid separator and a refrigerating system provided with same. The gas-liquid separator comprises a housing and a separating assembly for performing gas-liquid separation on fluid. The housing is provided with an inlet, a liquid outlet and a gas outlet; the separating assembly is arranged in the housing for dividing an inner cavity of the housing into a first chamber and a second chamber; the inlet communicates with the first chamber; the liquid outlet and the gas outlet communicate with the second chamber; the separating assembly comprises at least one separating part; the separating part comprises a first separating plate and a second separating plate which are opposite to each other and are spaced; the first separating plate and the second separating plate are connected with the inner wall of the housing; the first separating plate is closer to the first chamber relative to the second separating plate; a plurality of first through holes are formed in the first separating plate; a plurality of second through holes are formed in the second separating plate; and the first through holes and the second through holes are arranged in a staggered mode relative to each other. The gas-liquid separator disclosed by the invention is simple in structure and is good in separating effect.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

A liquid header

ActiveCN103743284BImprove gas-liquid separation efficiencyGood gas-liquid separation efficiencyDispersed particle separationHeat exchanger casingsEngineeringNet shape

The invention discloses a liquid separation header which comprises an incoming flow branch pipe, a header, a liquid discharging core and an outflow branch pipe. The incoming flow branch pipe and the outflow branch pipe are installed on an outer side wall of the header, the liquid discharging core is installed in the header, and a liquid catching sector is arranged on an inner wall of the header. A plurality of grooves longitudinally arranged along the header and the surface with scattered protruded points or an uneven net-shaped covering layer are arranged in the liquid catching sector. The liquid separation header has the advantages that the amount of liquid flowing out along the outflow branch pipe is reduced, header inner disturbance causing reduction of liquid separation efficiency is restrained, and gas-liquid separation efficiency of the liquid separation header is improved; a process is good, almost no manufacturing cost is increased, the gas-liquid separation effect of the liquid separation header can be improved well, and the liquid separation header is high in economy and popularization value.

Owner:GUANGDONG UNIV OF TECH

Gas-liquid separation assembly, alkali liquor regeneration tower and alkali liquor regeneration method

ActiveCN111085108AImprove gas-liquid separation efficiencyImprove the separation effectDispersed particle separationPhysicsExhaust gas

The invention relates to a gas-liquid separation assembly for an alkali liquor regeneration tower. The assembly comprises a bottom plate, a baffle plate, a silk screen separation piece and a top plate, the top plate and the bottom plate are arranged in parallel at intervals; the baffle plate is arranged between the top plate and the bottom plate, the top end and the bottom end of the baffle plateare fixedly connected with the top plate and the bottom plate correspondingly, so that the space between the bottom plate and the top plate is divided into a gas inlet area and a distribution area, first through holes are distributed in the bottom of the gas inlet area, so that the gas inlet area is in fluid communication with the space below the bottom plate through the first through holes; a second through hole is formed in the baffle plate, so that the gas inlet area is in fluid communication with the distribution area; the silk screen separation piece is arranged at an outlet of the distribution area, so that the distribution area is communicated with external fluid of the gas-liquid separation assembly through the silk screen separation piece; a liquid guide pipe is arranged on the lower surface of the bottom plate, the top end of the liquid guide pipe penetrates through the bottom plate, and the bottom end of the liquid guide pipe is a free end. The gas-liquid separation assemblycan improve the gas-liquid separation efficiency of alkali liquor regeneration tail gas and disulfide and reduce the content of disulfide in the tail gas.

Owner:SINOPEC ENG +1

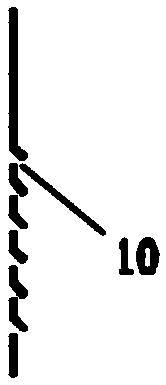

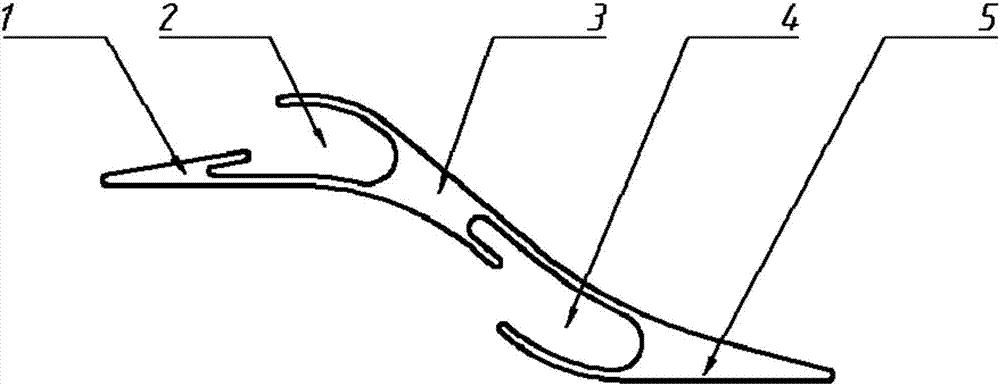

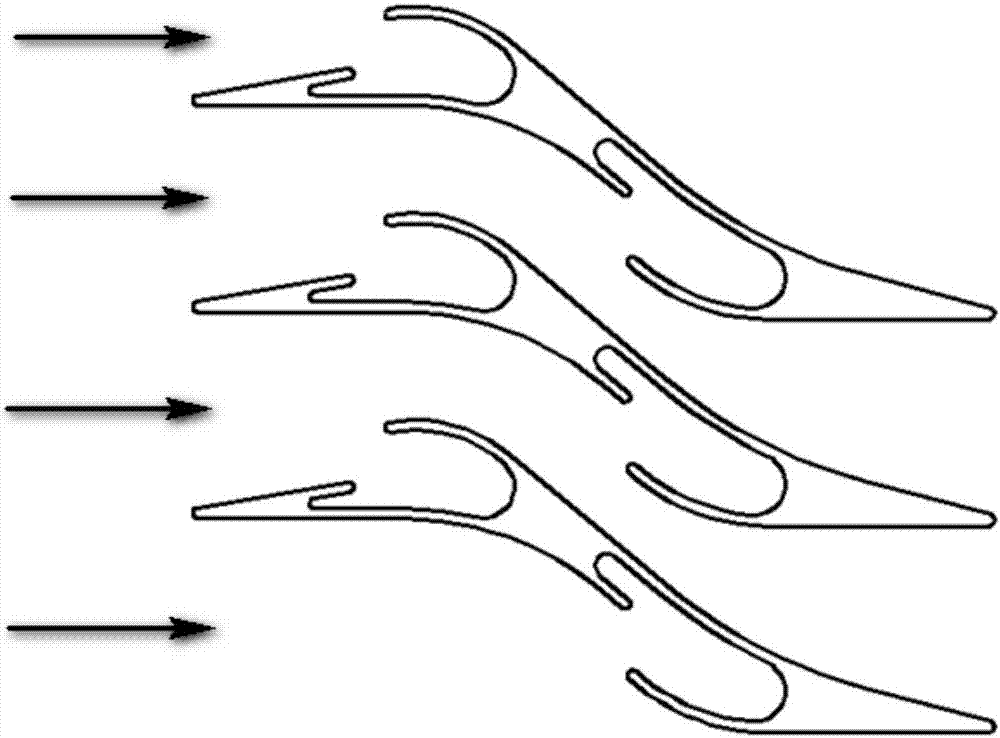

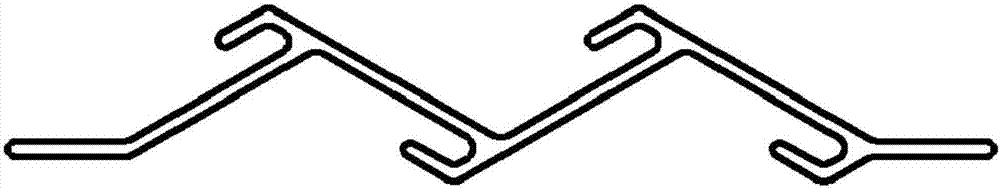

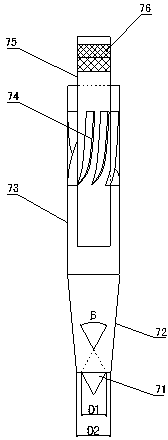

A high-speed air intake filter device inertia stage blade

ActiveCN105781745BReduce total pressure lossImprove gas-liquid separation efficiencyTurbine/propulsion air intakesFriction lossFiltration

The invention aims at providing an inertial-stage blade for a high-speed air inflow filtration device. The section of the inertial-stage blade is in a streamline type and is composed of two flow guide segments, two drainage grooves and a transitional segment for connecting the two drainage grooves. Outside structures of the two drainage grooves and all the parts are in transition through large-radius arcs, so that the flow resistance losses are reduced. The inlet area and volume of each drainage groove are large, and the drainage capacity is high under the high air flow speed condition. The front flow guide segment and the rear flow guide segment are each in a triangular shape, the air inflow edge of the front flow guide segment and the air outflow edge of the rear flow guide segment are in round-corner transition, and therefore the influences caused by air flow separation are reduced. By the adoption of the inertial-stage blade for the high-speed air inflow filtration device, the high air and water separation efficiency can be kept under the high-speed air inflow condition, meanwhile, the low total pressure loss level is kept, and the blade has the beneficial effects of being suitable for the high flow circulation speed condition, simple in structure, convenient to machine, low in cost and the like.

Owner:HARBIN ENG UNIV

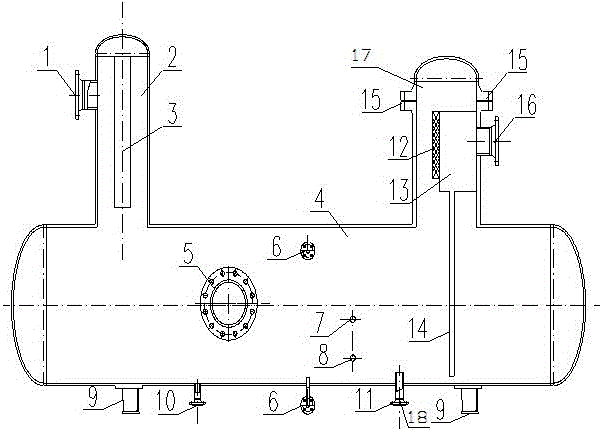

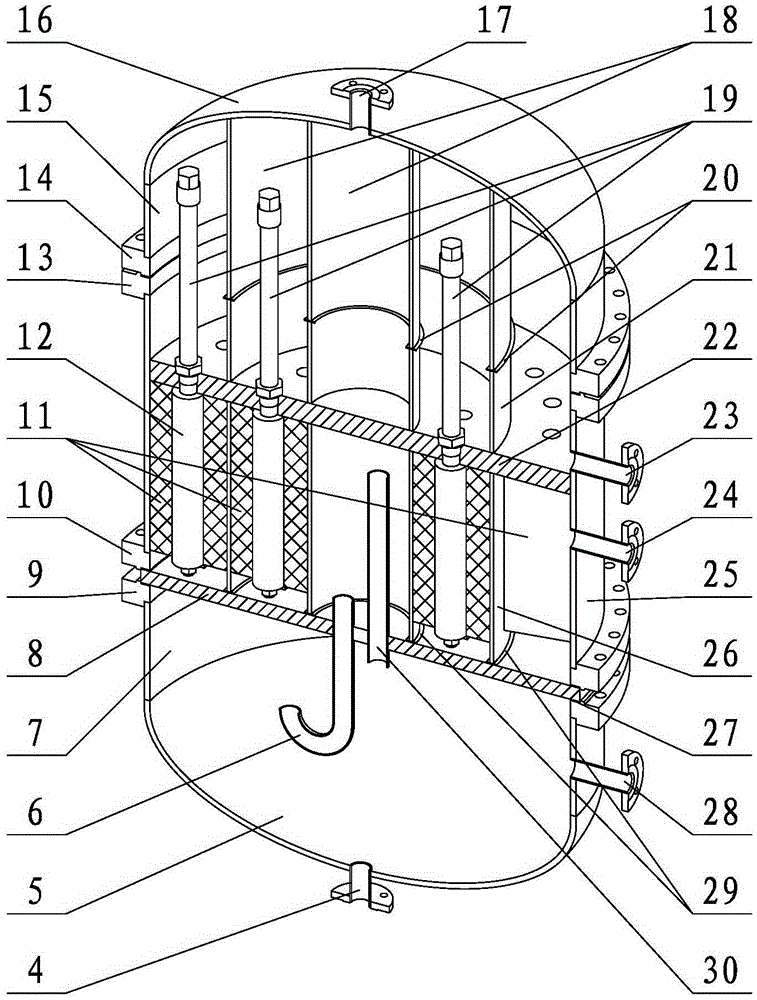

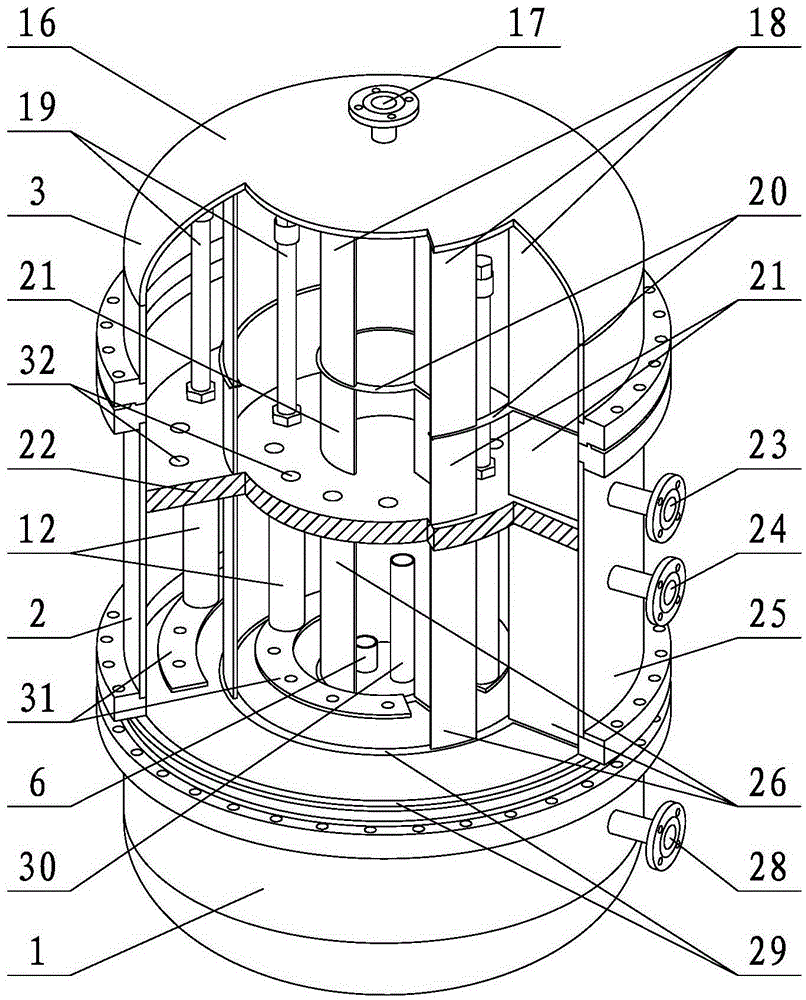

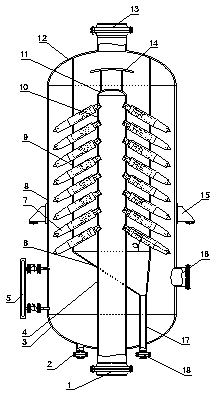

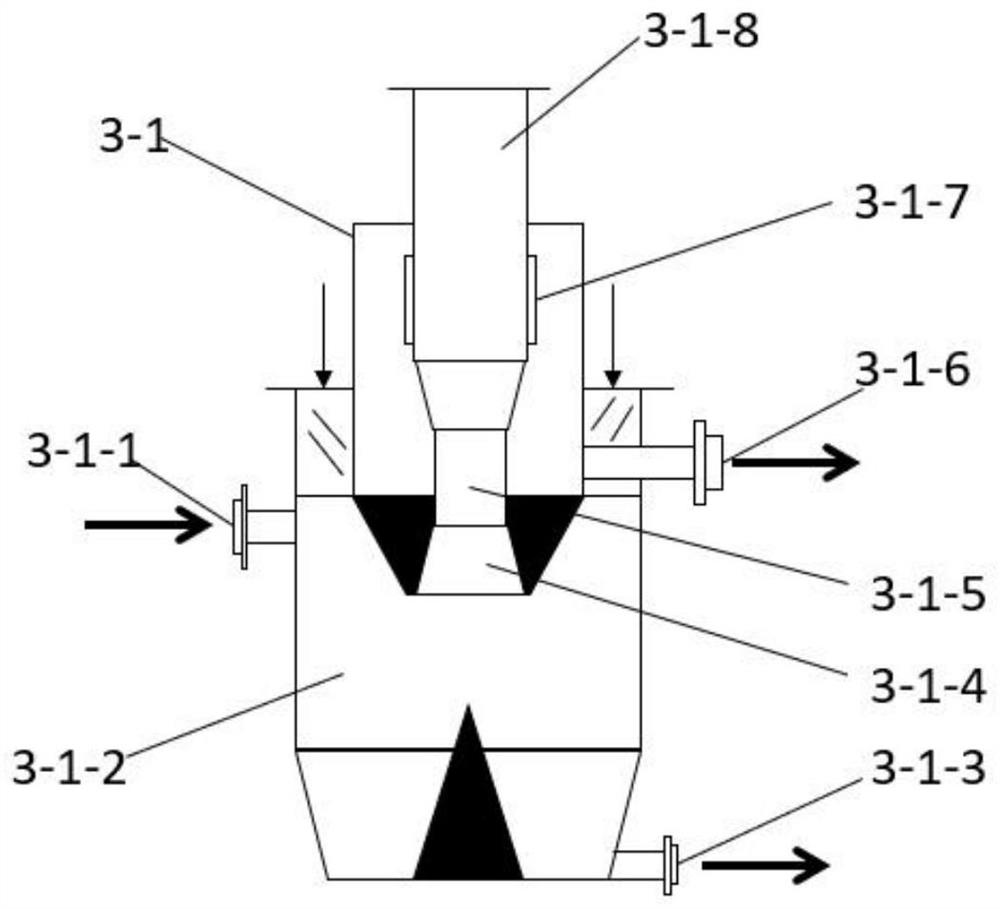

A large gas-liquid separator

ActiveCN105311906BAchieve continuous separationLarge gas volumeCombination devicesCycloneEngineering

The invention discloses a large-scale gas-liquid separator, which comprises an outer shell with an upper head and a lower head, the upper head is provided with an air inlet, the lower head is provided with an exhaust port, a main The outer cylinder of the liquid port and the gravity settlement drain, the outer cylinder is provided with a middle cylinder and an inner cylinder, and the middle cylinder and the inner cylinder separate the interior of the outer cylinder into three independent chambers body, the cavity between the middle cylinder and the inner cylinder communicates with the air inlet and the gravity sedimentation drain, the inner cavity of the inner cylinder communicates with the exhaust port, and the cavity between the middle cylinder and the inner cylinder There are a plurality of cyclones arranged obliquely, and the upper and lower ends of the cyclones protrude and are arranged in the cavity between the middle cylinder and the outer cylinder. The invention has good separation effect of gas-liquid mixture and good continuous separation performance, and is especially suitable for gas-liquid separation with pressurized gas, large processing gas volume, low resistance and high separation efficiency.

Owner:上海卓旋化工科技有限公司

Waste gas treatment system

InactiveCN101254395BEasy to updateIncrease contact areaDispersed particle separationSpray nozzleWaste treatment

The invention discloses an off-gas handling system with a primary washing tower, a secondary turbulent flushing tower and a tertiary turbulent flushing tower, wherein, the primary washing tower, the secondary turbulent flushing tower and the tertiary turbulent flushing tower are respectively equipped with a first, a second and a third heat exchangers, and the system also has an alkali liquor mainpipe, a water inlet, a cooling upper water main pipe, a cooling backwater main pipe and a discharge main pipe; the primary washing tower, the secondary turbulent flushing tower and the tertiary turbulent flushing tower are respectively provided with a liquid membrane foam area, and harmful waste gas passes through the liquid membrane foam areas of the primary washing tower, the secondary turbulent flushing tower and the tertiary turbulent flushing tower in order to be purified. As the waste gas passes through the three strongly turbulent liquid membrane foam areas, the invention achieves the effect of high efficient washing. As the gas-fluid exchange is not carried out in the towers, the structures of the towers are simple, the manufacturing and the maintenance are convenient, and the heights of the towers can be greatly reduced. The consumption of the raw material can be greatly reduced, and the investment can be reduced. The circulation solution sprayed out by a spraying head is spiral shaped and is fully contacted with the harmful waste gas for absorption, and the spray nozzle is unlikely to be blocked because of the large size.

Owner:徐全海

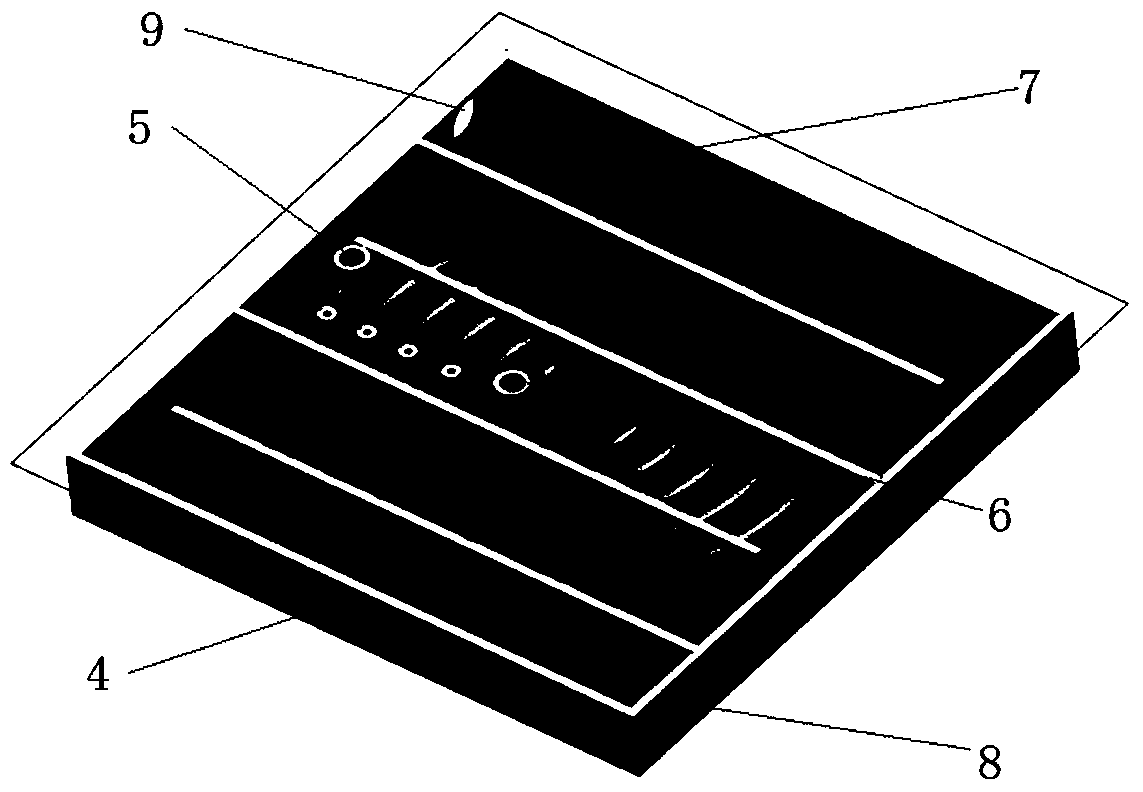

A micro radiator and fuel cell system with gas-liquid separation function

ActiveCN106898800BImprove gas-liquid separation efficiencyAchieve warm-upFuel cell heat exchangeWater management in fuel cellsFuel cellsAcute angle

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A device and method for wet oxidation treatment of sulfur-containing organic wastewater

ActiveCN111362451BImprove protectionFast oxidationWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesSludgeSulfide

The invention provides a device for wet oxidation treatment of sulfur-containing organic waste water, which comprises a coalescence oil removal unit, an oxidation reaction unit, a cyclone degassing unit and a closed mud discharge unit. The invention provides a method for wet oxidation treatment of sulfur-containing organic wastewater by using the above-mentioned device. Firstly, the sulfur-containing organic wastewater is subjected to high-efficiency degreasing treatment, and then the sulfide is chemically oxidized by the air oxidation method, and the reaction product enters the cyclone degreasing process. The gas device performs deep gas-liquid separation, and the sludge is discharged through the mud discharge device. The device and method of the invention improve the oxidation rate, enhance the treatment capacity, reduce secondary pollution, and can recover useful substances, and can be widely used in the field of waste water treatment.

Owner:EAST CHINA UNIV OF SCI & TECH +1

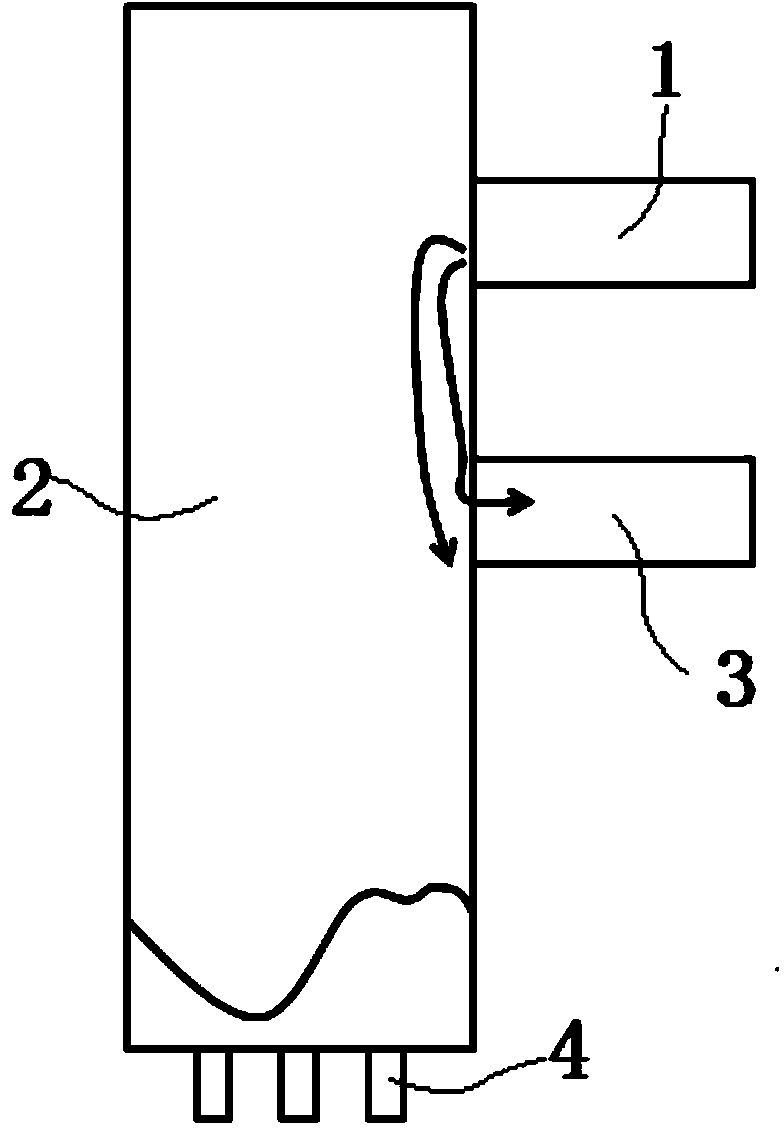

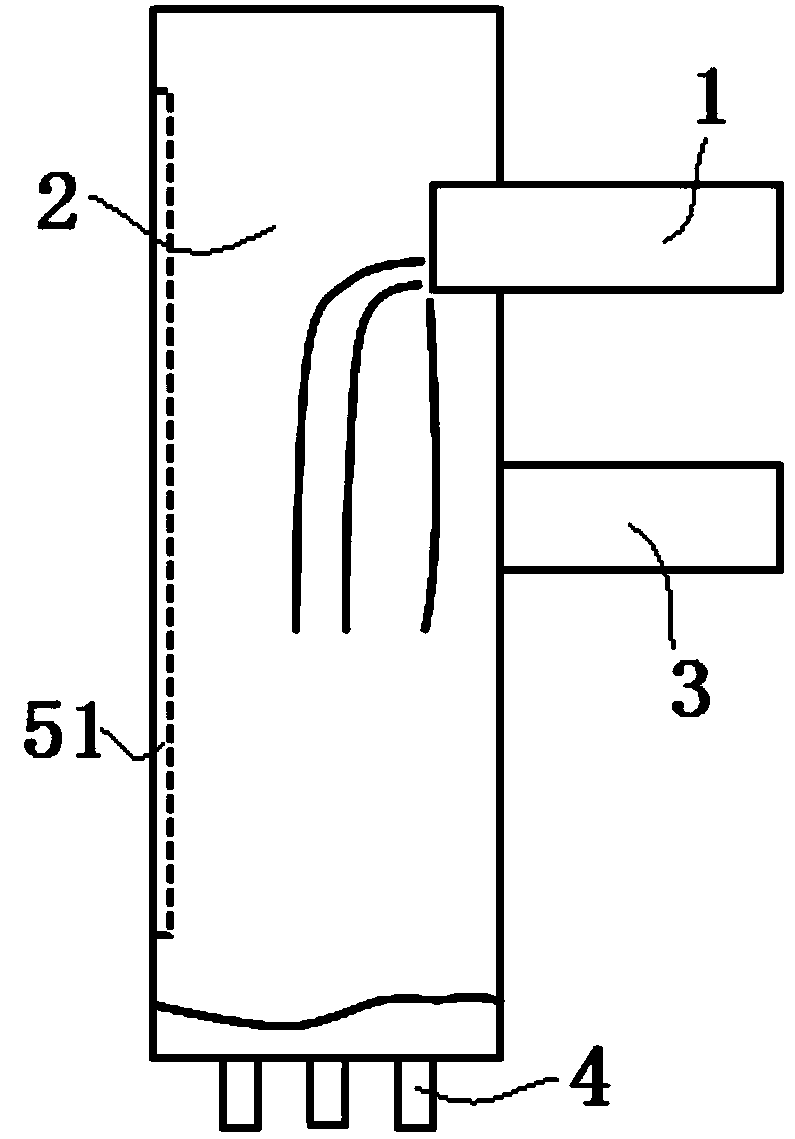

Novel gas-liquid separator

ActiveCN104368214AImprove stabilityImprove gas-liquid separation efficiencyCombination devicesGaseous fuelsVapor–liquid separatorCyclonic separation

The invention provides a novel gas-liquid separator comprising a liquid storage cavity, and a cyclone separation section and a deep gas-liquid separation section which are arranged at the top of the liquid storage cavity and are communicated with the liquid storage cavity, wherein a base is arranged at the bottom of the liquid storage cavity, a gas-liquid separator inlet is formed in the cyclone separation section, and a cyclone column is arranged in the cyclone separation section; a separator outlet is formed in the deep gas-liquid separation section, a blade type separation box is arranged on the inner end surface of the separator outlet, the lower end of the blade type separation box is connected with a blade type separation box liquid discharge pipe which is communicated with the liquid storage cavity, the other end of the blade type separation box, relative to the separator outlet, is provided with a wire mesh demister, and the wire mesh demister is communicated with the blade type separation box; and a production liquid discharge opening is also formed in the bottom of the liquid storage cavity. The novel gas-liquid separator provided by the invention can be used for greatly improving the operation stability of gas fields, and re-purification of gas is achieved so as to ensure that gas to be purified is subjected to deep gas-liquid separation; and the purpose of increasing the gas-liquid separation efficiency of a multi-stage baffle plate liquid removal component can be achieved.

Owner:PETROCHINA CO LTD

Gas-liquid separation device for boat

PendingCN108579220AReduce noiseImprove stealth performanceDispersed particle separationCycloneGas phase

The invention discloses a gas-liquid separation device for a boat. The gas-liquid separation device comprises a gas liquid cyclone unit, a liquid storage unit and a control unit, wherein a gas phase outlet, a gas liquid mixed inlet and a first liquid phase outlet are formed in the gas liquid cyclone unit from top to bottom; the liquid storage unit is positioned under the gas liquid cyclone unit and is communicated with the first liquid phase outlet; the lower part of the liquid storage unit is provided with a second liquid phase outlet; a control valve is arranged on the second liquid phase outlet; a liquid level sensor is arranged on the liquid storage unit so as to sense the liquid level in the liquid storage unit; the control unit is in communication connection with the control valve and the liquid level sensor, and controls the opening and closing state and / or the opening degree of the control valve according to the liquid level data feedback of the liquid level sensor, so that theratio of the gas phase space to the liquid phase space in the gas-liquid separation device for the boat can be maintained at the value around the set value. The device has the advantages that the installation is compact; the noise of an exhaust system can be reduced; the whole boat acoustic stealth capability is improved; the gas-liquid separation efficiency of the exhaust system can be improved;the downstream exhaust compressor can be protected to realize the long-time continuous and reliable operation.

Owner:SHANGHAI MICROPOWERS

Internal circulation bioreactor

ActiveCN109825423BIncrease mixing and mass transferImprove gas-liquid separation efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsImpellerSludge

The invention discloses an internal circulation bioreactor, comprising a feed pipe, a discharge pipe, an air collecting pipe, an impeller, a partition, a flow guiding device, a reactor body, a three-phase separator, and a fender. Under the action of the impeller and the flow guide device in the middle of the circulating bioreactor, the material in the partition is in a downward flow state, and driven by the blades on the impeller and the flow guide device, it enters the partition through the channel at the bottom of the partition External, and mixed with the material outside the partition and in an upward flow state, so that the material can achieve the effect of internal and external circulation mixing on the outside of the partition and downward on the inside of the partition, which improves the mass transfer efficiency and organic load. The residence time of the sludge and the quality of the effluent water are improved, and the scope of application of sewage treatment (such as low SS) is improved. At the same time, the gas-liquid separation of the biogas and the feed liquid is realized under the action of the three-phase separator on the upper part of the reactor body, which increases the transmission efficiency. Quality, improve gas production efficiency.

Owner:德沃(苏州)环境科技有限公司

Water distributor and water distribution system for fuel cell

PendingCN114405163AImprove gas-liquid separation efficiencySimple structureDispersed particle separationThermodynamicsFuel cells

The invention discloses a water segregator which comprises a separation cavity, and a baffling component is arranged in the separation cavity to form a baffling channel. A cyclone separation component (1) is further arranged in the separation cavity, and mixed fluid entering the separation cavity is subjected to gas-liquid separation through the baffling component and the cyclone separation component (1). The invention also provides a water distribution system for the fuel cell. The water separator is high in gas-liquid separation efficiency, simple in structure, small in size and convenient to manufacture, machine and install.

Owner:SHANGHAI HYDROGEN PROPULSION TECH CO LTD

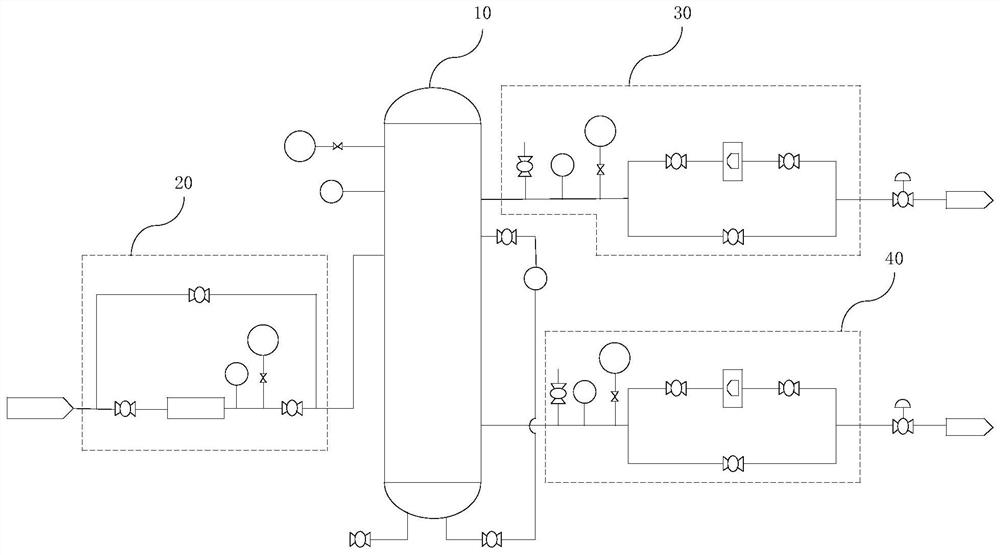

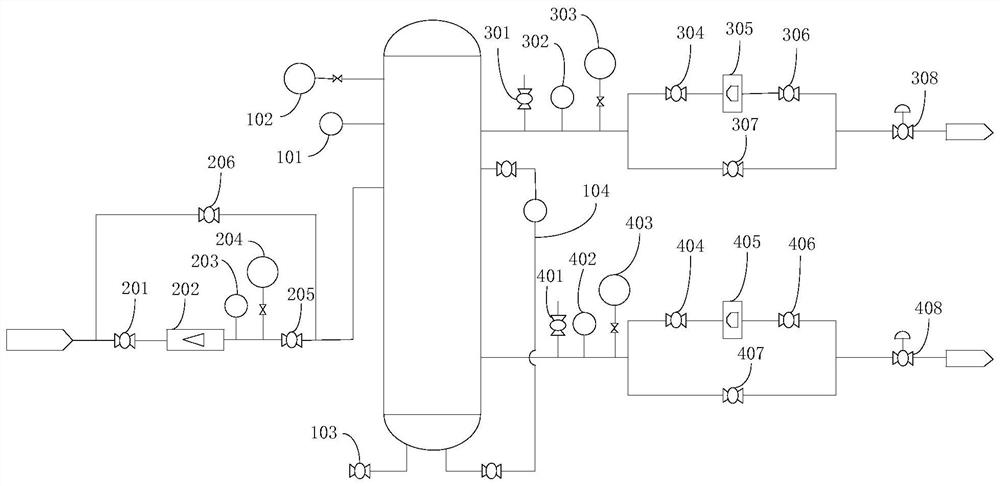

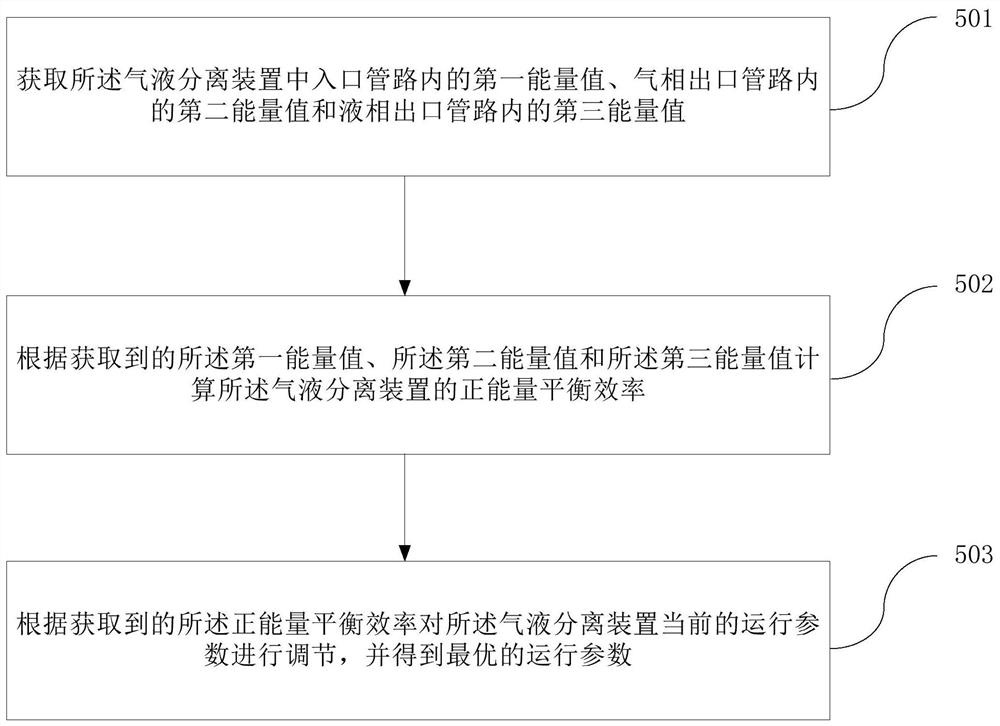

Gas-liquid separation device and consumption reduction method for gas-liquid separation device

ActiveCN112443310ASolve technical problems of energy inefficiencyImprove gas-liquid separation efficiencySurveyFluid removalFluid phaseHigh energy

The invention provides a gas-liquid separation device and a consumption reduction method for the gas-liquid separation device. The gas-liquid separation device is used for degassing treatment of crudeoil, and the gas-liquid separation device comprises a separator body, an inlet detection unit, a gas phase detection unit and a liquid phase detection unit; and the inlet detection unit, the gas phase detection unit and the liquid phase detection unit are respectively used for detecting state parameters of liquid or gas in an inlet pipeline, a gas phase outlet pipeline and a liquid phase outlet pipeline so as to optimize operation parameters in the separator body. The gas-liquid separation device and the consumption reduction method for the gas-liquid separation device solves the technical problems of low separation efficiency and high energy consumption of an oil-gas separator due to the fact that the existing oil-gas separator is difficult to perform separation operation according to optimal operating parameters.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com