A device and method for wet oxidation treatment of sulfur-containing organic wastewater

A technology of organic wastewater and wet oxidation, which is applied in chemical instruments and methods, oxidized water/sewage treatment, sustainable biological treatment, etc. and other problems, to achieve the effect of good degreasing protection effect, not easy to coke, and high gas-liquid separation efficiency.

Active Publication Date: 2022-06-03

EAST CHINA UNIV OF SCI & TECH +1

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

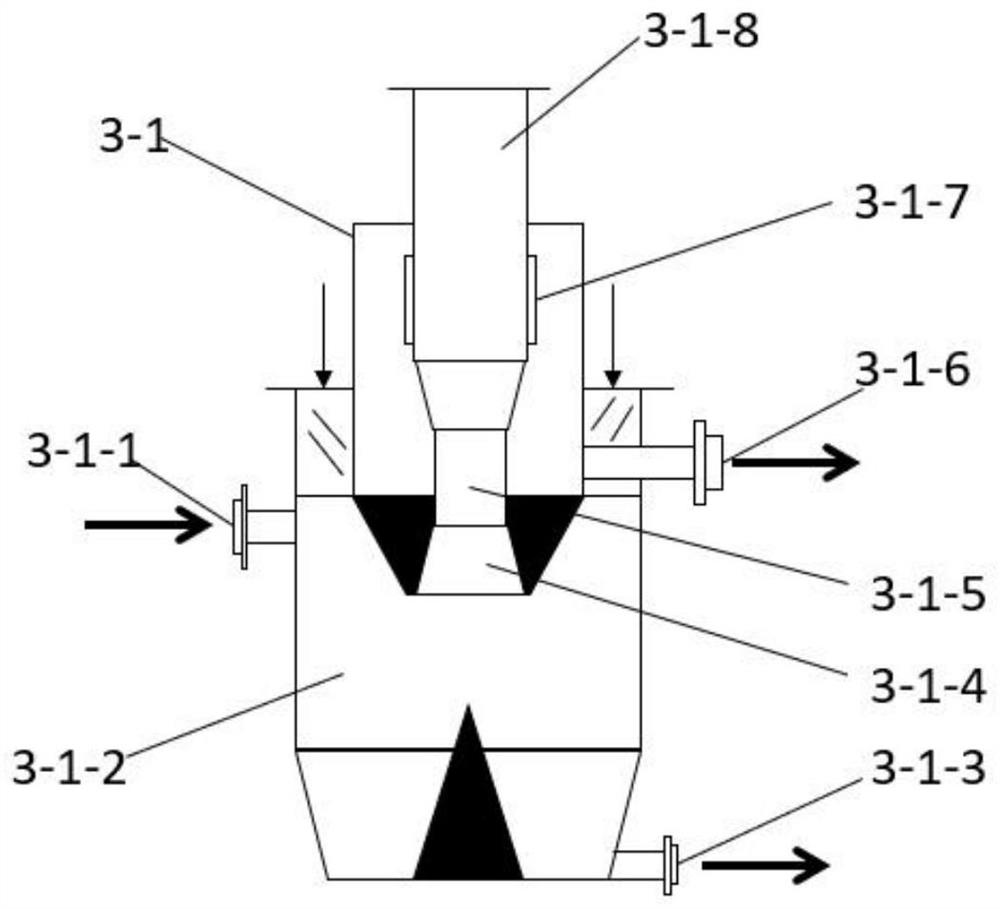

However, the smaller bubbles in the reaction product have a higher fluid followability. In the gas-liquid separation stage of the reaction product, the fine bubbles are difficult to peel off from the liquid phase, and the entrainment of the gas phase mist is serious.

In addition, due to the need to strictly control the gas-liquid contact time to avoid impurities and coking caused by excessive reaction, the volume of the gas-liquid separator should not be too large, which poses new challenges to the traditional sedimentation gas-liquid separation technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0063] The closed sludge discharge unit of the present invention can further add a parallel installation mode of sludge dischargers to increase the processing capacity. specific

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

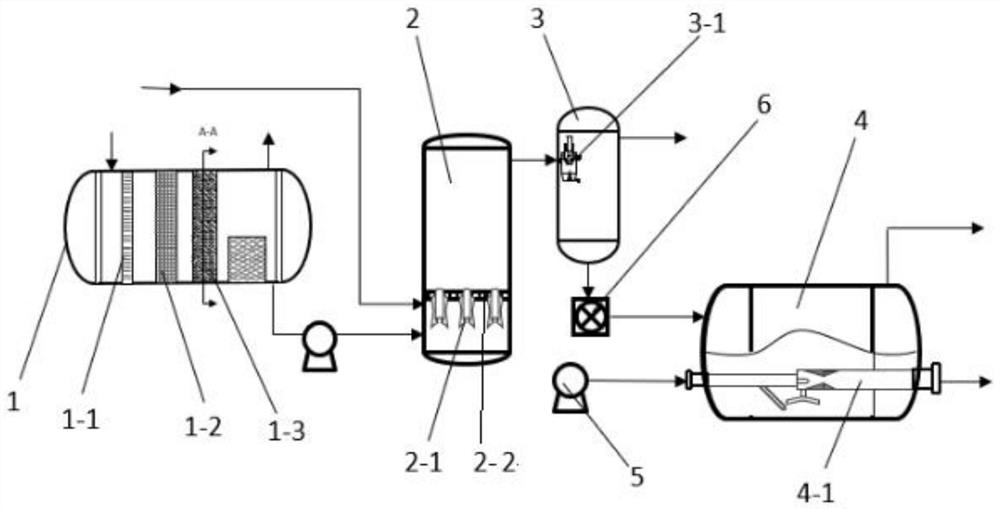

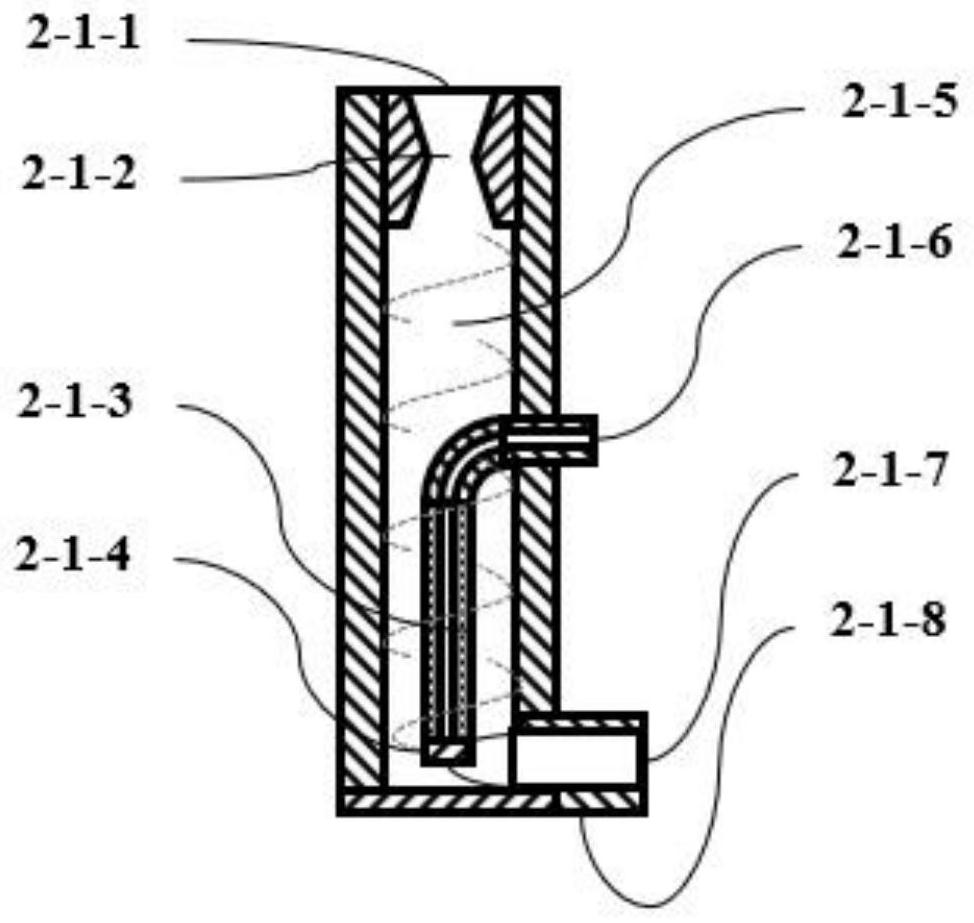

The invention provides a device for wet oxidation treatment of sulfur-containing organic waste water, which comprises a coalescence oil removal unit, an oxidation reaction unit, a cyclone degassing unit and a closed mud discharge unit. The invention provides a method for wet oxidation treatment of sulfur-containing organic wastewater by using the above-mentioned device. Firstly, the sulfur-containing organic wastewater is subjected to high-efficiency degreasing treatment, and then the sulfide is chemically oxidized by the air oxidation method, and the reaction product enters the cyclone degreasing process. The gas device performs deep gas-liquid separation, and the sludge is discharged through the mud discharge device. The device and method of the invention improve the oxidation rate, enhance the treatment capacity, reduce secondary pollution, and can recover useful substances, and can be widely used in the field of waste water treatment.

Description

A device and method for wet oxidation treatment of sulfur-containing organic wastewater technical field The invention belongs to technical field of wet oxidation, be specifically related to a kind of device of wet oxidation processing sulfur-containing organic waste water and method. Background technique Wet oxidation technology is medium and high pressure air oxidation (WetAir Oxidation, referred to as WAO) is a kind of treatment with high pressure. An important method for the removal of toxic, harmful, high-concentration organic wastewater. Under the conditions of 100-373 degrees Celsius and 0.5-10MPa, with oxygen in the air Gas is used as an oxidant, and the oxygen in the air is used to oxidize the sulfide in the waste lye into sodium thiosulfate or sulfate, eliminating the Malodorous odor; oxidize pollutants into inorganic substances or small molecular organic substances in the liquid phase, reduce the COD concentration in waste lye, It is suitable for COD ran...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F9/04C02F101/10C02F101/30

CPCC02F9/00C02F1/40C02F1/74C02F1/20C02F1/38C02F1/66C02F2101/101C02F2101/30Y02W10/10

Inventor 杨强许萧王俊杰王磊王志强孟敏李裕东

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com