Waste gas treatment system

A technology for waste gas treatment and this system, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of high production cost, tower height, short gas-liquid contact time, etc., and achieves convenient production and maintenance. The effect of height reduction and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

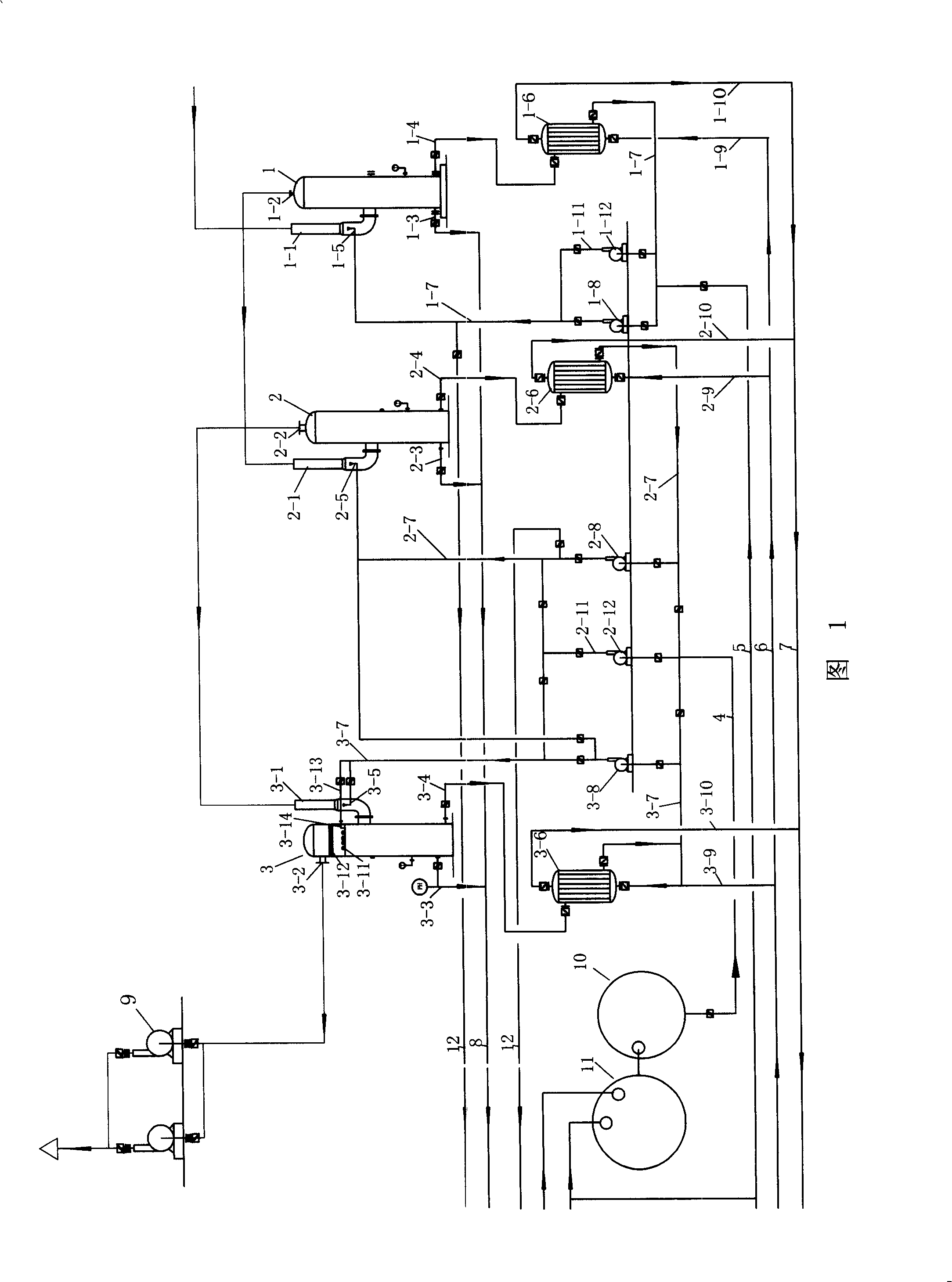

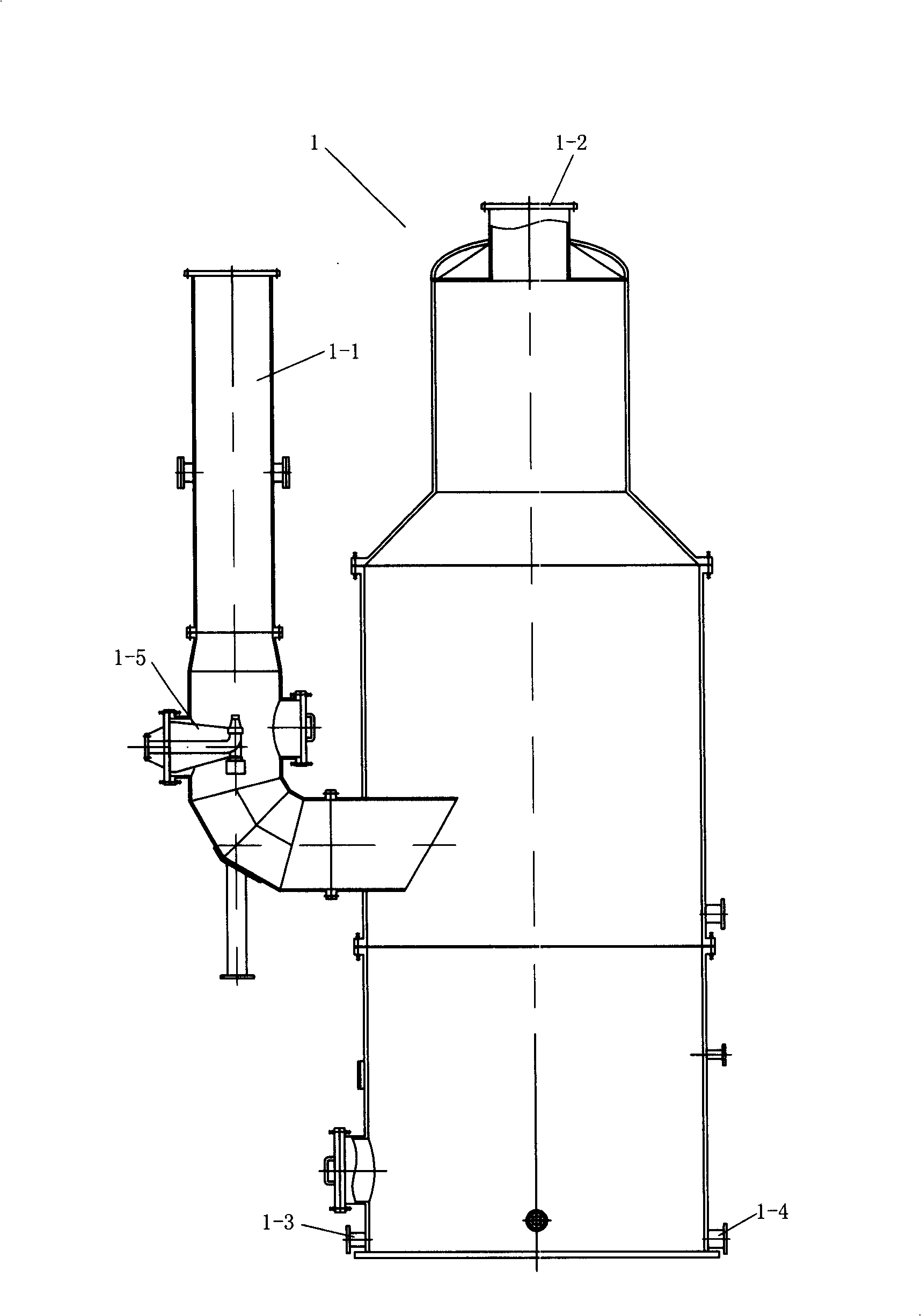

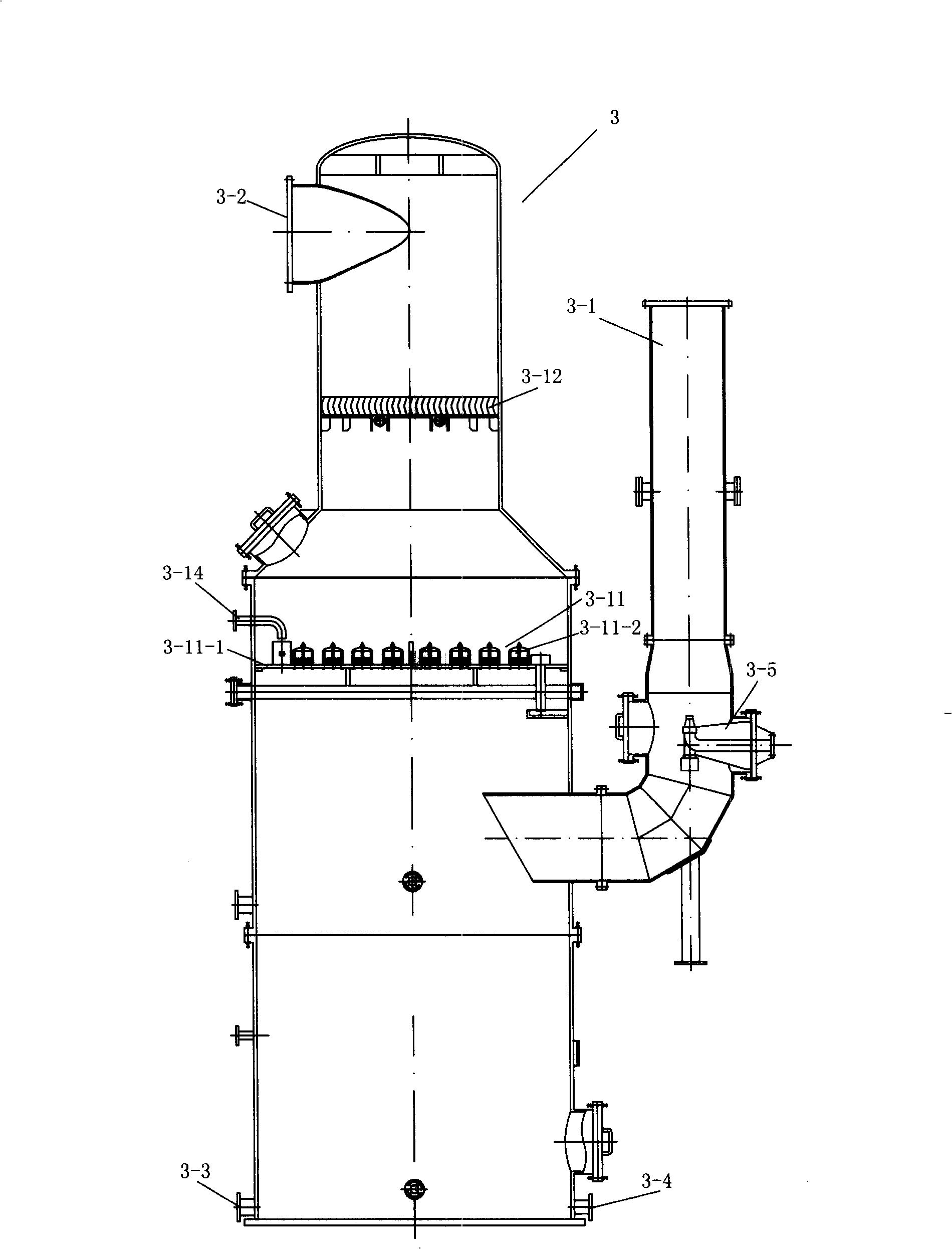

[0038] Referring to Fig. 1, the present invention has a first-stage washing tower 1, a second-stage turbulent tower 2 and a third-stage turbulent tower 3. Due to the exothermic reaction in the process of treating waste gas, the absorption efficiency of the tower decreases under high temperature conditions. Therefore, adding a heat exchanger can improve the absorption efficiency of the scrubber and turbulent tower, and at the same time reduce the temperature in the tower and reduce the impact on the tower. Material requirements, so the primary scrubber 1, secondary, and tertiary turbulence towers 2, 3 are equipped with No. 1, No. 2, and No. 3 heat exchangers 1-6, 2-6, and 3-6 respectively. In addition, the system Also have lye main pipe 4, water inlet pipe 5, cooling upper water main pipe 6, cooling return water main pipe 7, discharge main pipe 8, recovery treatment delivery pipe 12 and alkali distribution tank 10 and lye tank 9. The lye main pipe 4 links to each other with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com