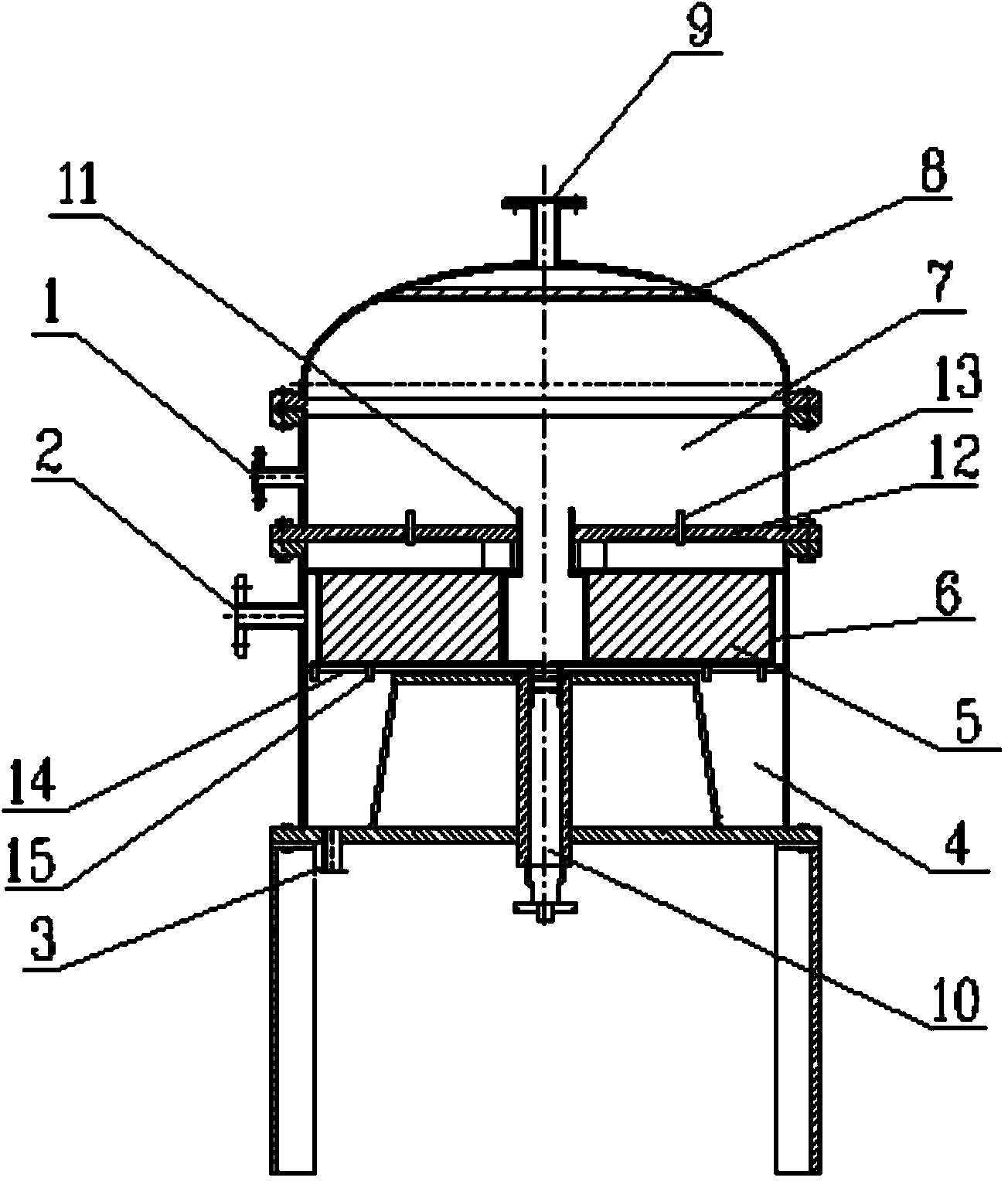

Raw oil associated gas supergravity separation device

A separation device and super-gravity technology, applied in separation methods, dispersed particle separation, gas fuel, etc., can solve the problems of low separation efficiency, difficult separation of heavy oil, huge separation equipment, etc., and achieve high gas-liquid separation efficiency and equipment size. zoom out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] It is also composed of a condenser, a decompression device, a liquid separation tank and a liquid level control system used in conjunction with the present invention, which were respectively installed in A oil field and B oil field for pilot tests, and materials from three wells were selected for treatment. A crude oil associated gas supergravity separation device has an inner diameter of the shell of 700mm, an outer diameter of the rotor (rotating bed) of 500mm, an inner diameter of the rotor of 220mm, a height of the rotor of 150mm, and a rotational speed of 1000rpm. See Table 1 and Table 2 for the two-phase flow rate, temperature and crude oil density of the mixed materials of the three wells in A oilfield and B oilfield.

[0018] Pilot test results:

[0019] For oilfield A, the pressure at the inlet and outlet of the analytical gas is 0.62Mpa, and the rotating bed speed is 600rpm. After the material treatment of the three wells, the gas volume of the crude oil is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com