Novel gas-liquid separator

A technology of gas-liquid separator and gas-liquid separation section, which is applied in the direction of separation method, dispersed particle separation, gas fuel, etc., and can solve the problems such as the reduction of liquid storage space of the separator, the large working range of the separator, and the failure to operate normally. Achieve the effect of improving gas-liquid separation efficiency and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

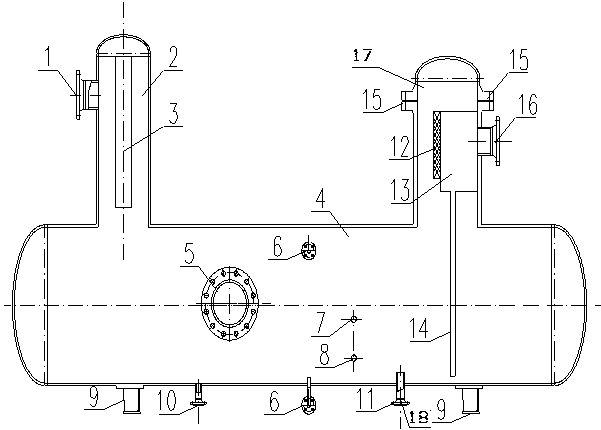

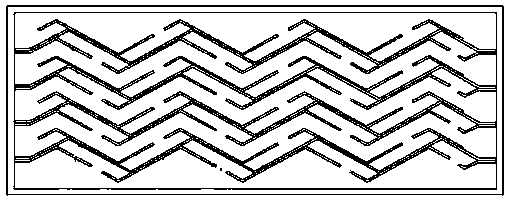

[0018] Such as figure 1 As shown, a new type of gas-liquid separator includes a liquid storage chamber 4, a cyclone separation section 2 and a deep gas-liquid separation section 17 that are arranged on the top of the liquid storage chamber 4 and communicate with it, and the bottom of the liquid storage chamber 4 is provided. There is a base 9, the cyclone separation section 2 is provided with a gas-liquid separator inlet 1, and the cyclone separation section 2 is provided with a cyclone column 3; the deep gas-liquid separation section 17 is provided with a separator outlet 16. The inner end surface of the separator outlet 16 is provided with a vane-type separation box 13, and the lower end of the vane-type separation box 13 is connected with a vane-type separation box drain pipe 14 which is connected to the liquid storage chamber 4. The vane-type separation box 13 is provided with wire mesh demister 12 with respect to the other end of separator outlet 16, and this wire mesh de...

Embodiment 2

[0024] On the basis of the above-mentioned embodiment 1, an inspection drain port 10, an inspection port 5 and a flange 15 are provided for the convenience of maintenance; the normal discharge of the separator is carried out through the drain port 11, and its automatic discharge is carried out through the liquid level measurement 6 , high liquid level switch 7, and low liquid level switch 8 are used to set the switch of the automatic liquid discharge valve; the liquid separated by the vane type separation box is connected to the liquid storage chamber through the liquid discharge pipe of the vane type separation box to prevent secondary entrainment. The liquid storage chamber 4 is also provided with a liquid level gauge interface 6 for installing a liquid level gauge, a high liquid level switch 7, a low liquid level switch 8, and an automatic liquid discharge valve 18 is installed in the production liquid discharge port 11. , the liquid level gauge interface 6, high liquid leve...

Embodiment 3

[0026] On the basis of the above-mentioned embodiment 2, the liquid storage chamber 4 is also provided with an inspection port 5 and an inspection drain port 10. The inspection drain port 10 is provided for the daily maintenance of the separator, and the drain port is flush with the bottom of the tube. , to ensure that all liquid is drained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com