A high-speed air intake filter device inertia stage blade

An inertial, high-speed technology, applied in the field of blades, can solve the problems of total pressure loss and flow velocity exceeding the limit, and achieve high gas-liquid separation efficiency, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

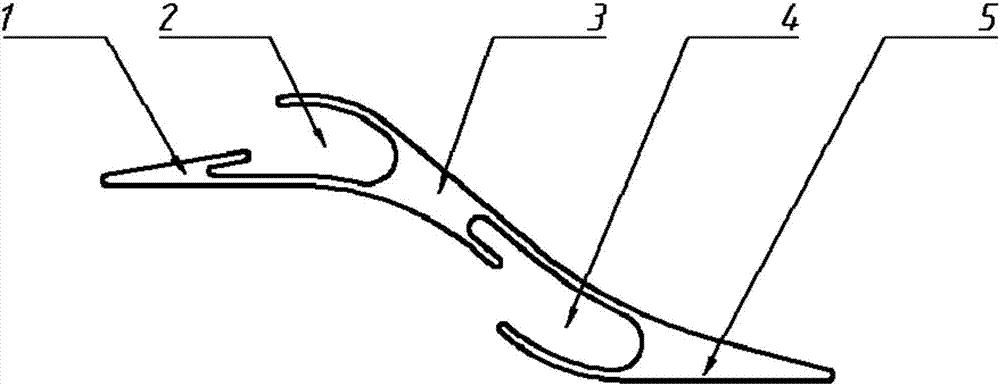

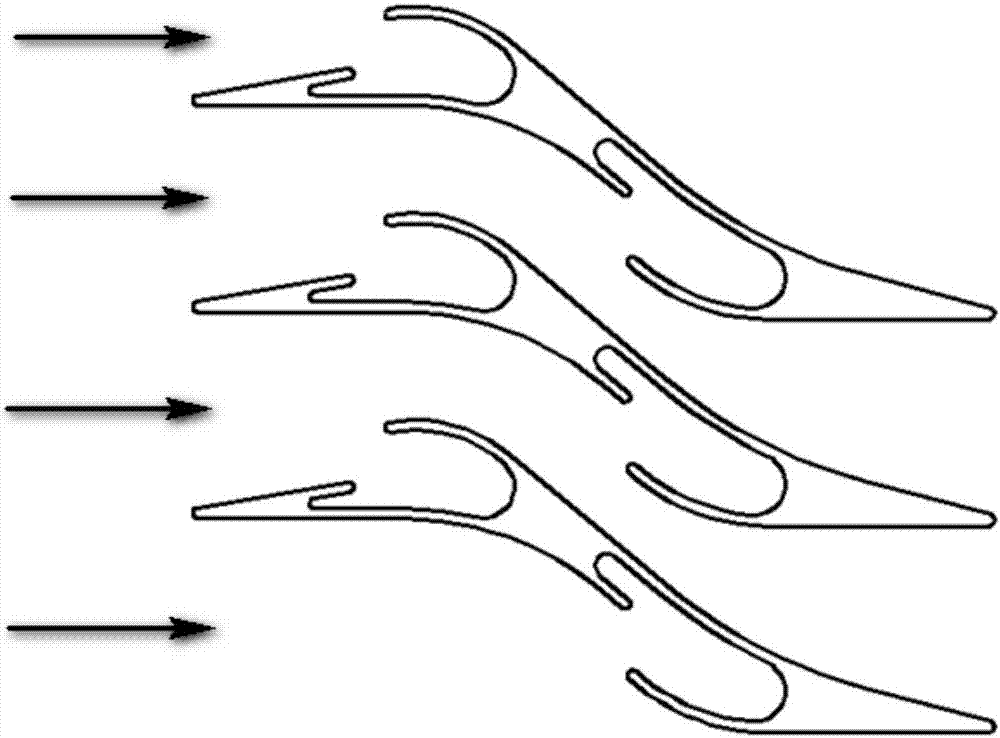

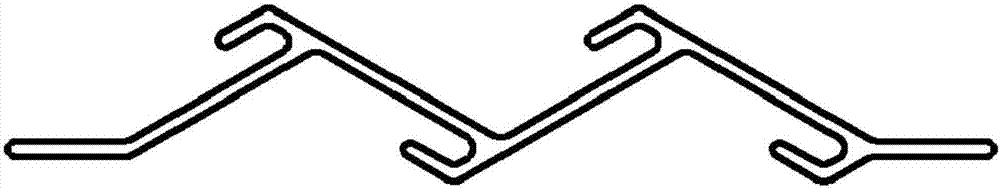

[0021] combine Figure 1~3 , each blade is composed of two diversion sections, two drainage grooves and a transition section connecting the two drainage grooves, the specific structure is:

[0022] (1) The outside of the two hydrophobic grooves is a large-diameter arc, and the inside is composed of straight lines at both ends and four arcs with different diameters. The adjacent parts are tangent and have a smooth transition. The transition between the inside and the outside is Use a small diameter semicircle.

[0023] (2) Both the front diversion section and the rear diversion section are triangular.

[0024] (3) In order to suppress the separation of airflow, the inlet edge of the front diversion section and the outlet edge of the rear diversion section adopt circular arc transitions instead of straight edges with sharp edges and corners.

[0025] (4) For the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com