Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Improve cutting work efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

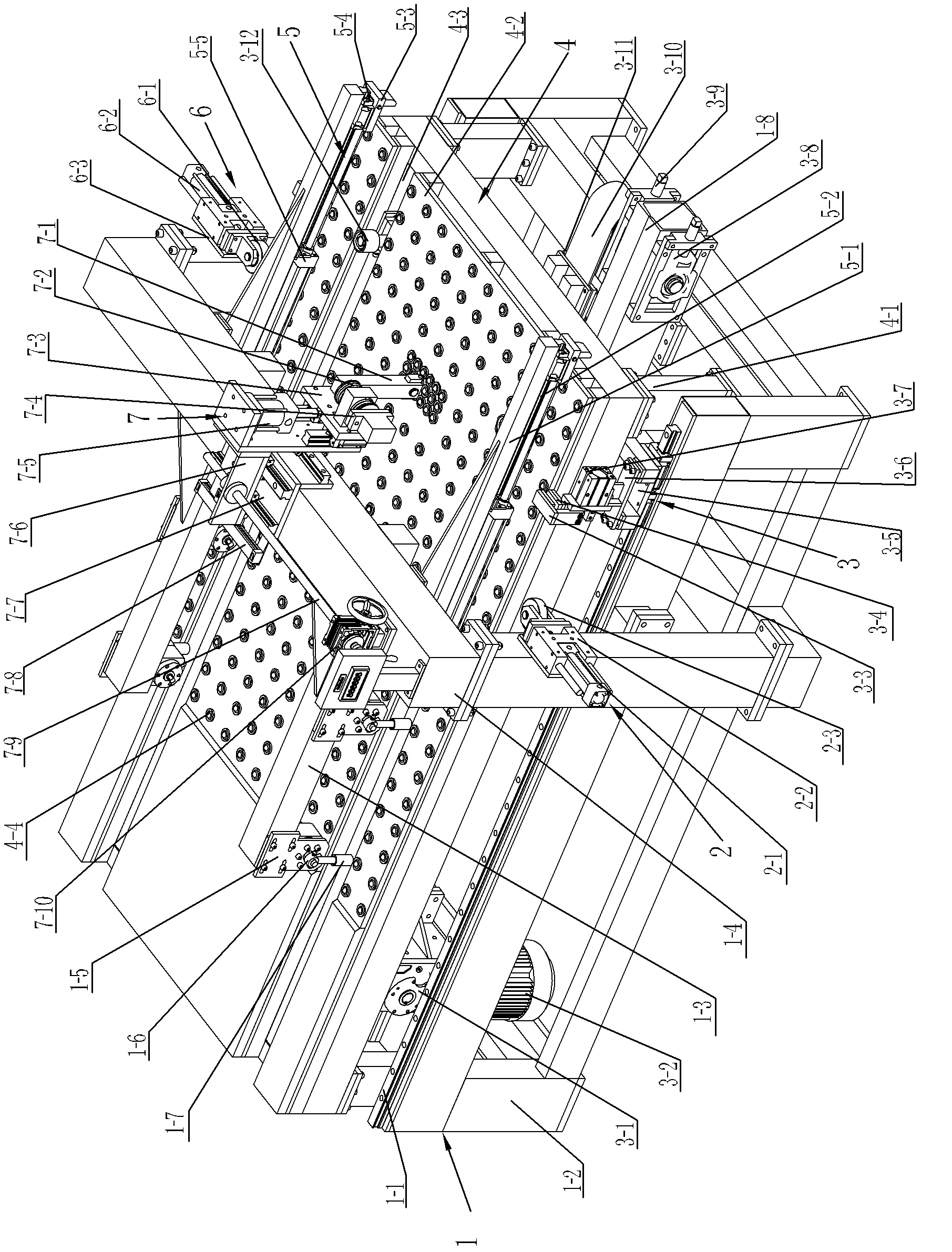

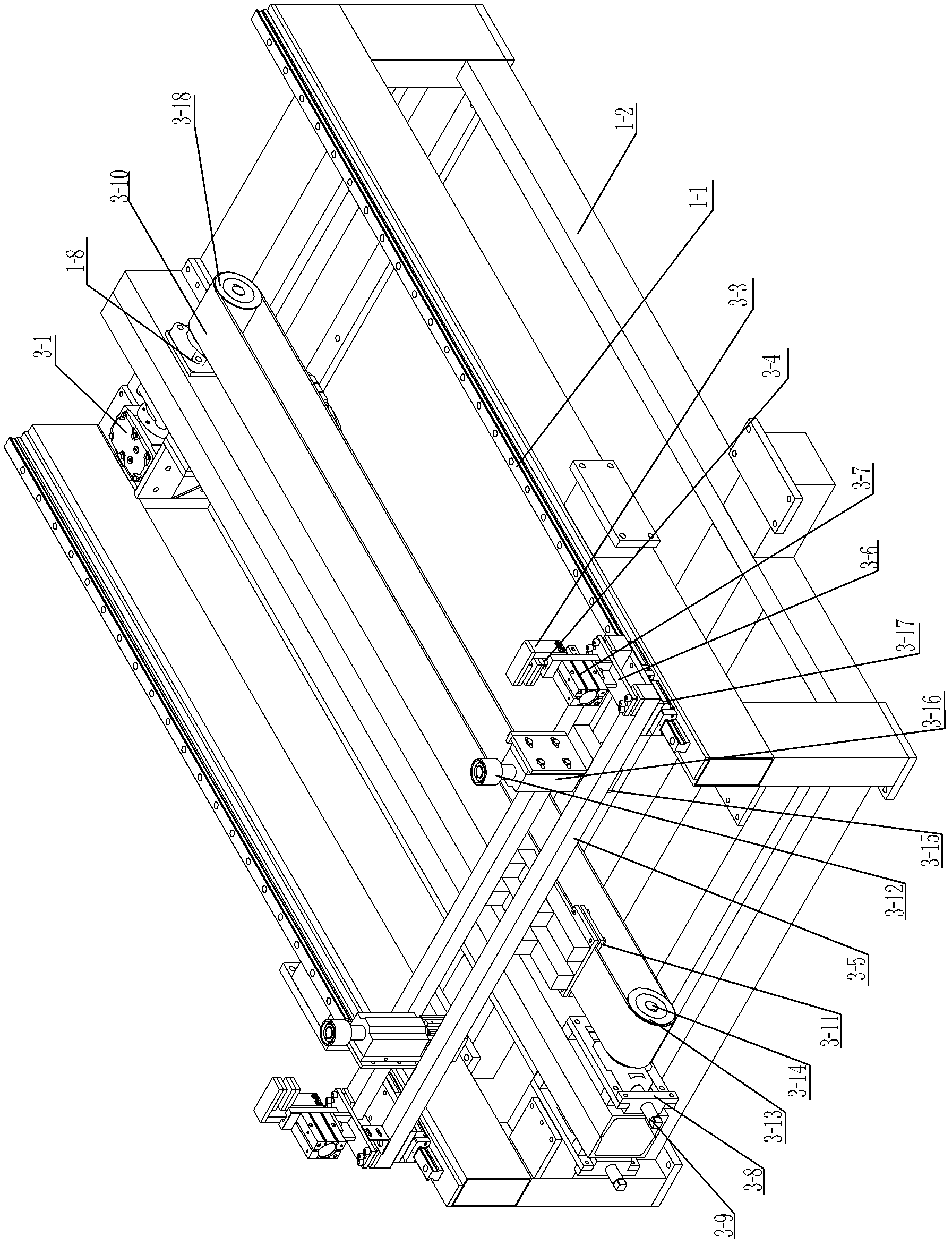

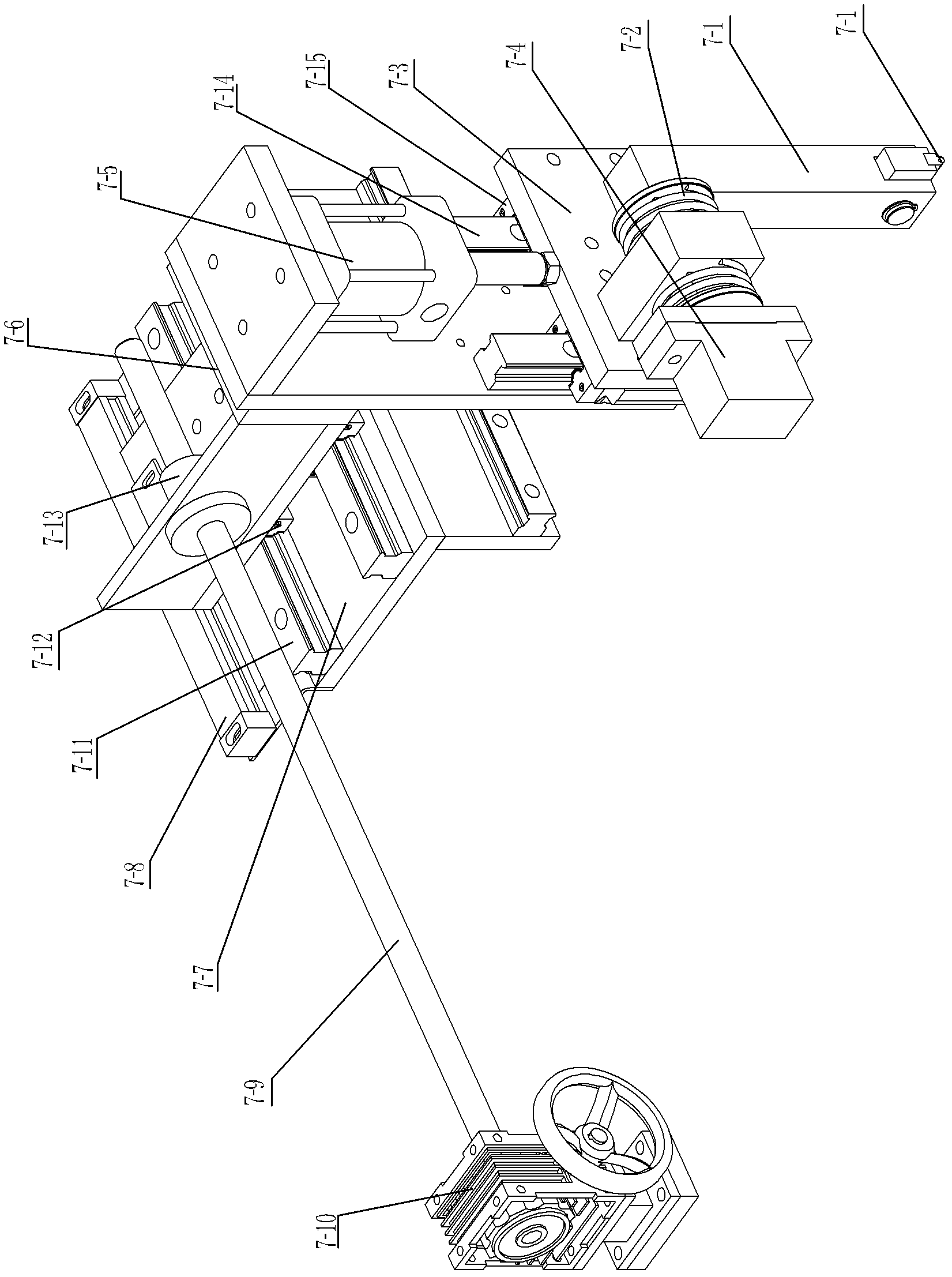

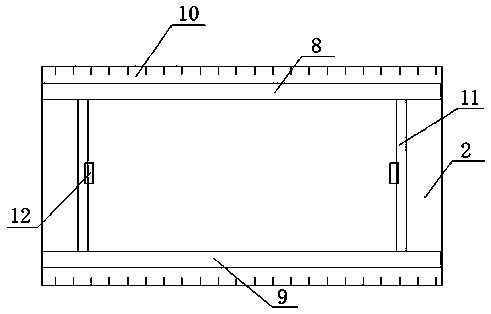

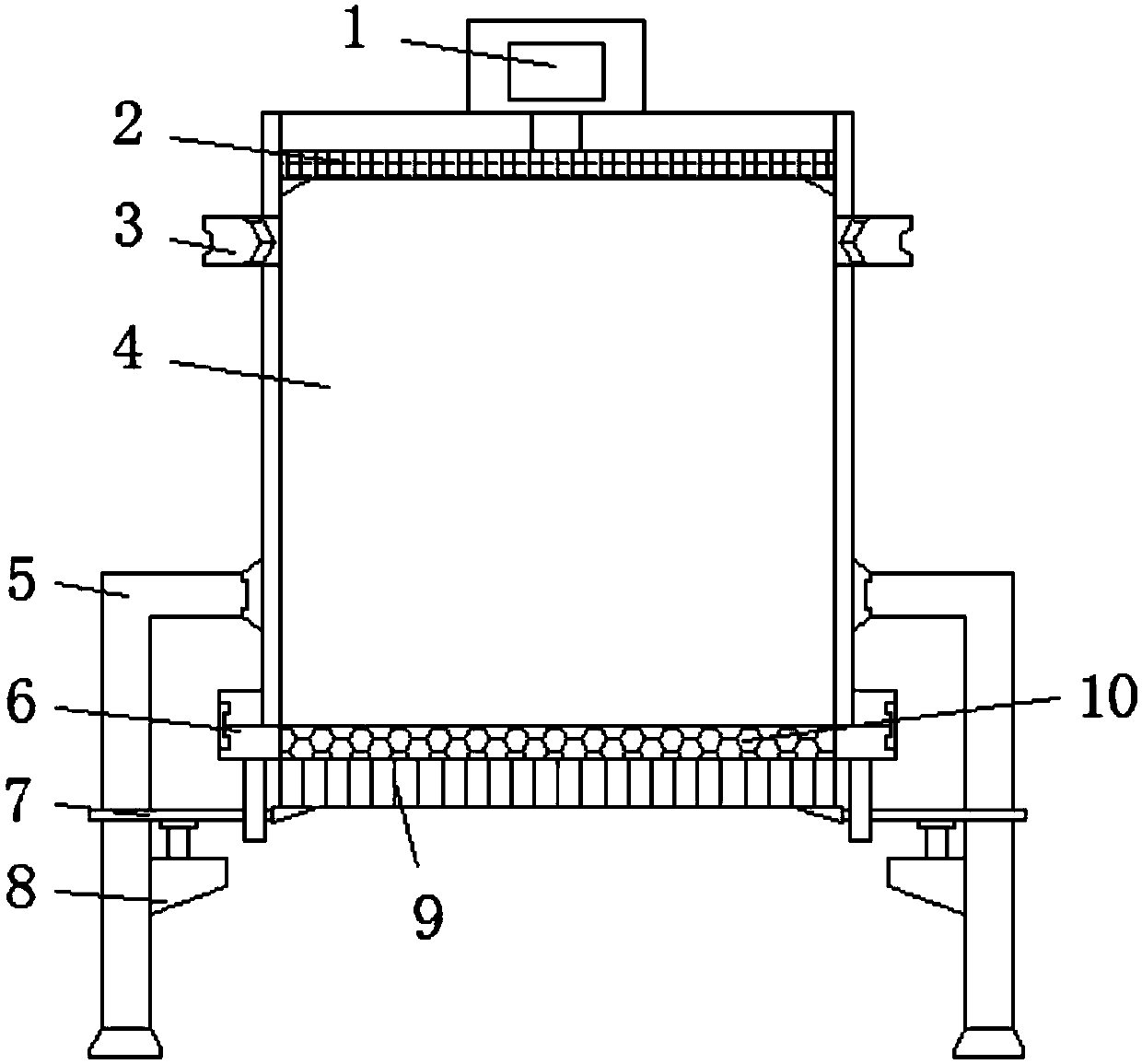

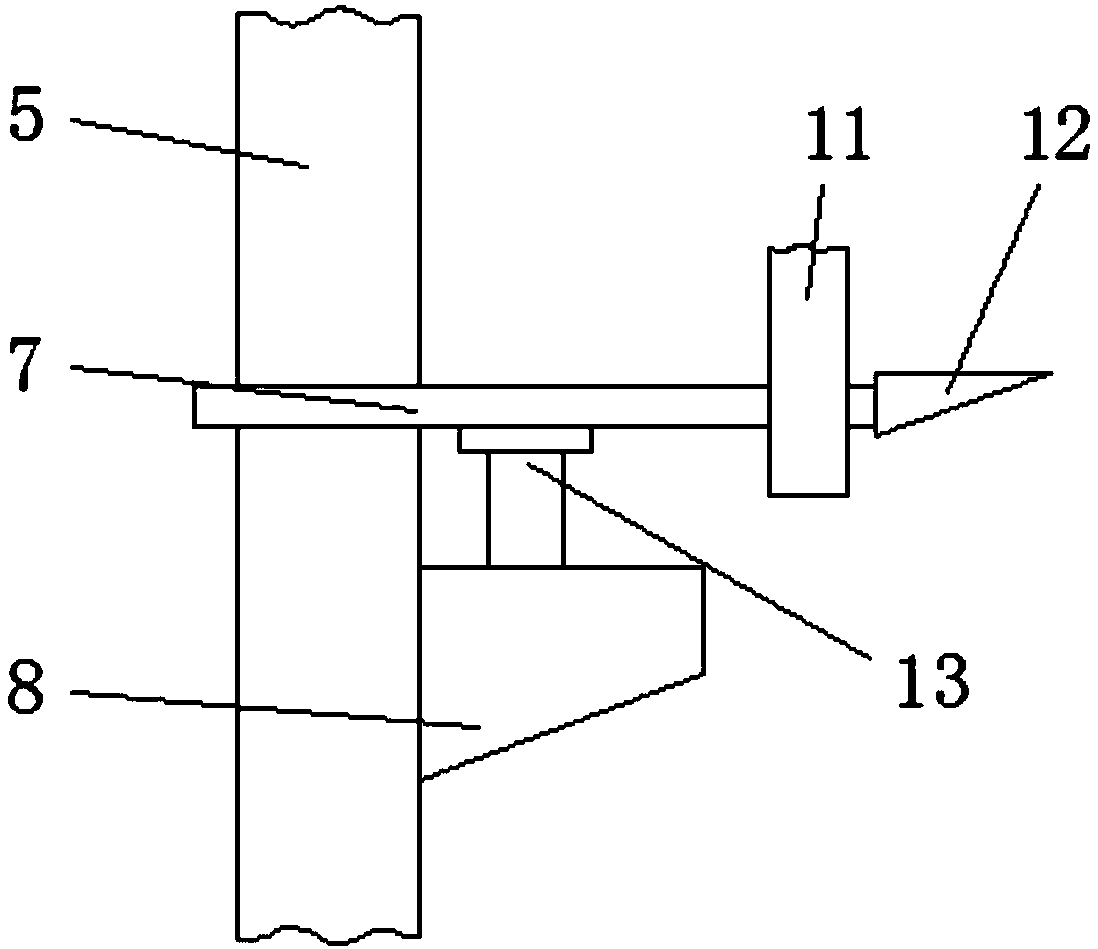

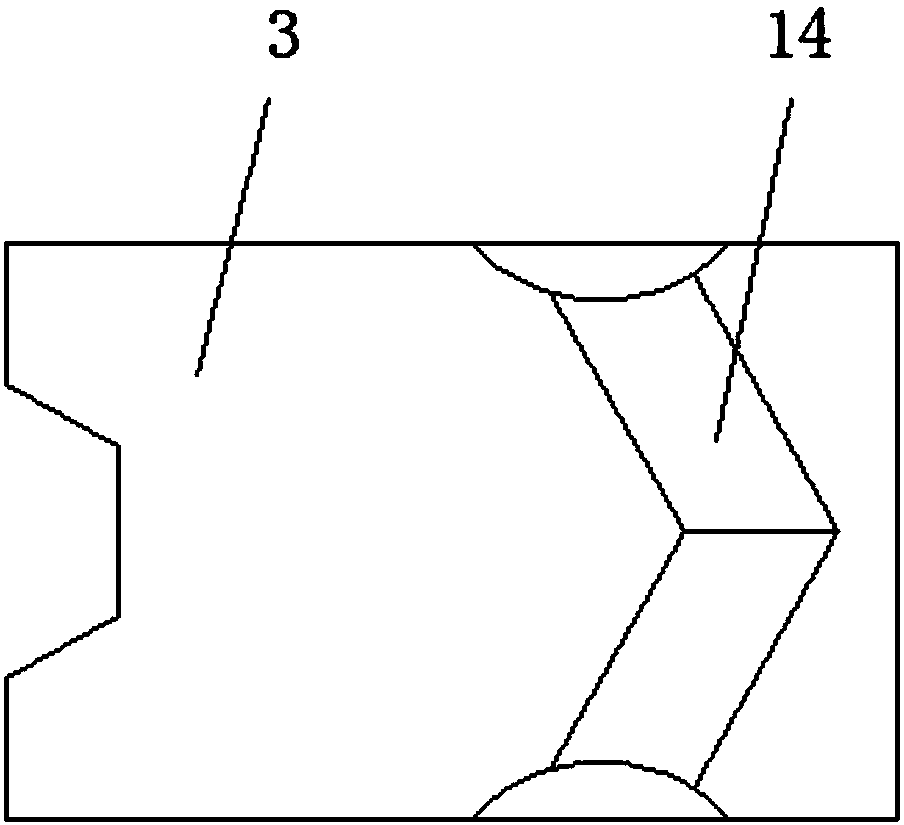

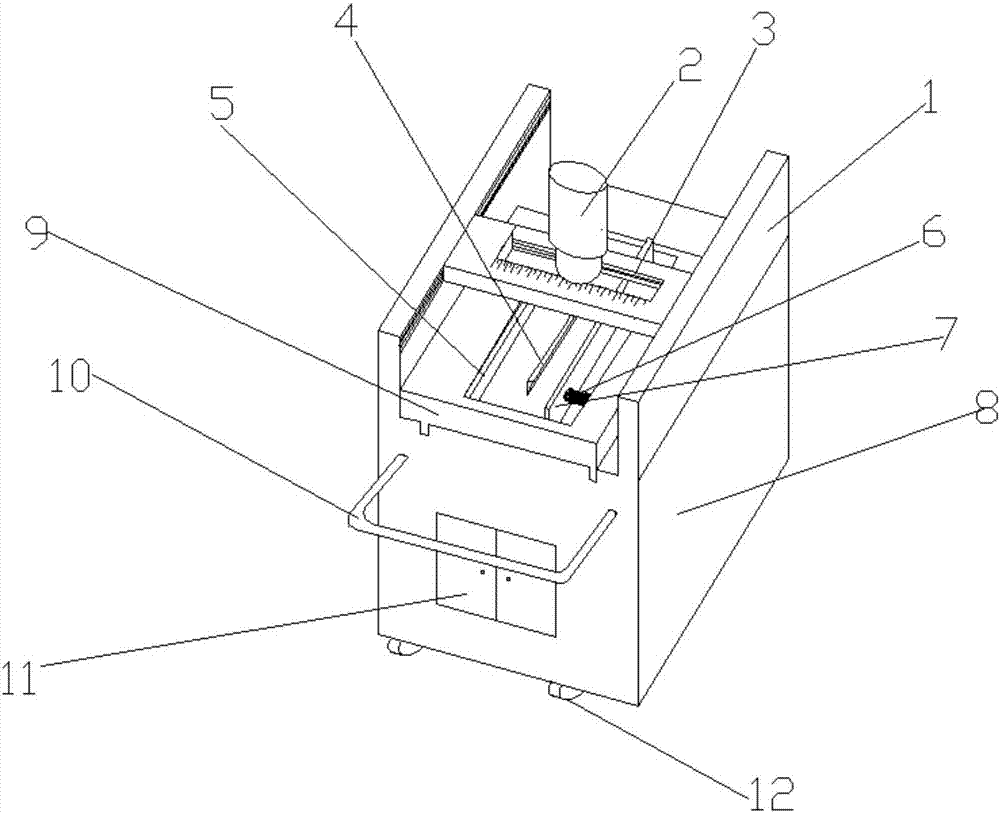

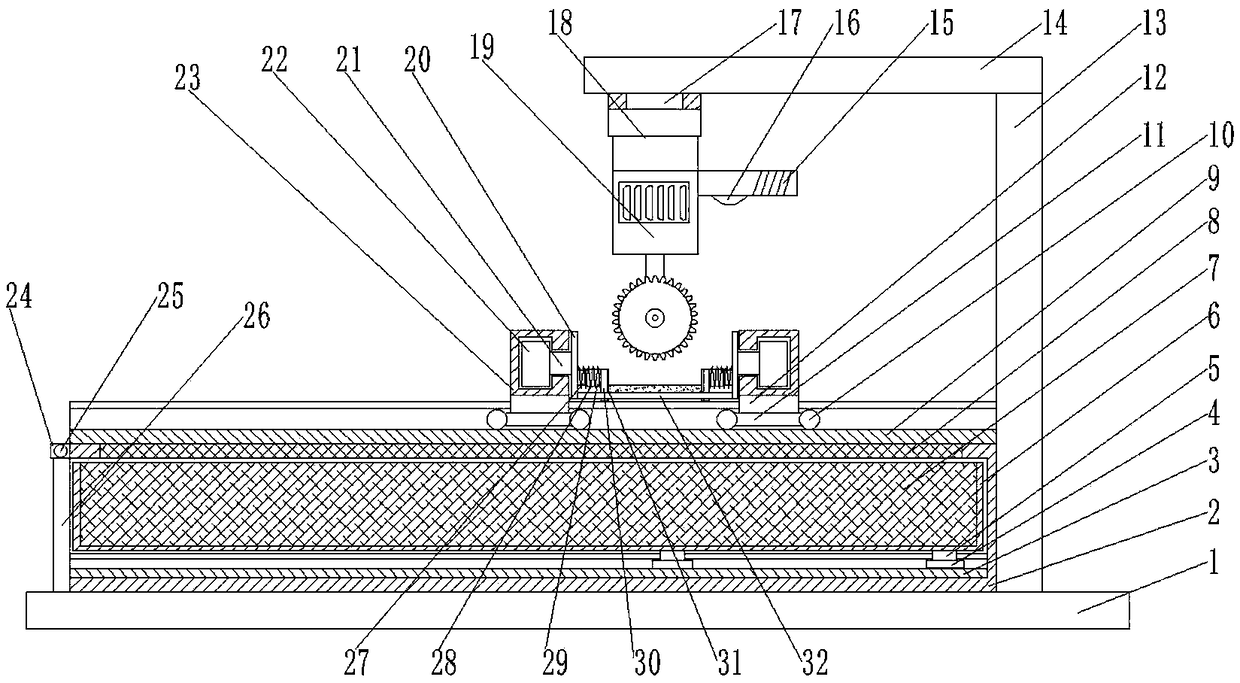

Feed pre-positioning method and device for molded plate

InactiveCN102350715AThe effect of accurate automatic positioningHigh degree of automationFeeding devicesClassical mechanicsStructural engineering

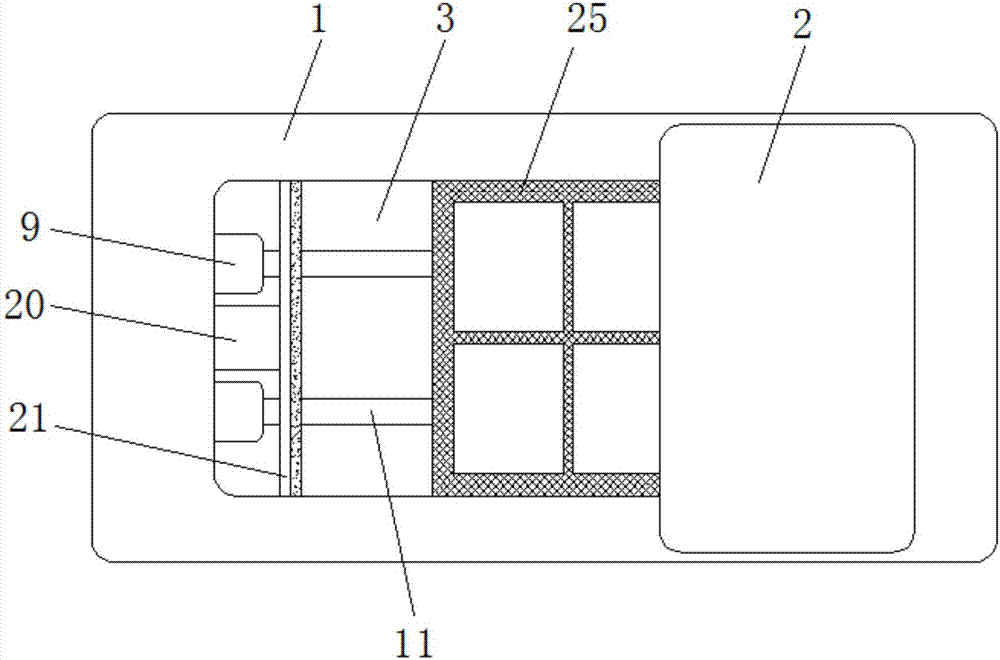

The invention relates to a feed pre-positioning device for a molded plate. The device comprises a frame mechanism, a working table, two pulling plate mechanisms, a lateral limiting mechanism, a lateral pushing mechanism, a vibration positioning mechanism and a supporting plate driving mechanism, wherein the frame mechanism comprises a supporting frame, a gantry frame and two upper longitudinal beams; the supporting frame has a framework structure; longitudinal driving guide rails are fixedly arranged on two sides of the top of the supporting frame respectively; the gantry frame is arranged across the supporting frame; the working table is fixedly arranged on the supporting frame; the two upper longitudinal beams are connected with the gantry frame; each upper longitudinal beam is longitudinally provided with at least two rotary cylinders in the backward and forward direction; the rotary cylinders are provided with rotary arms; a cross beam of the gantry frame is provided with at leasttwo pulling plate mechanisms and the vibration positioning mechanism; and the lateral limiting mechanism and the lateral pushing mechanism are arranged on two side beams of the gantry frame respectively. The device has the characteristics of rational structure, accurate positioning in a slot sheet, capability of increasing cutting yield, high universality and capability of clamping the sheet and driving the sheet to advance.

Owner:CHANGZHOU HUAWANG MECHANIC MFG CO LTD

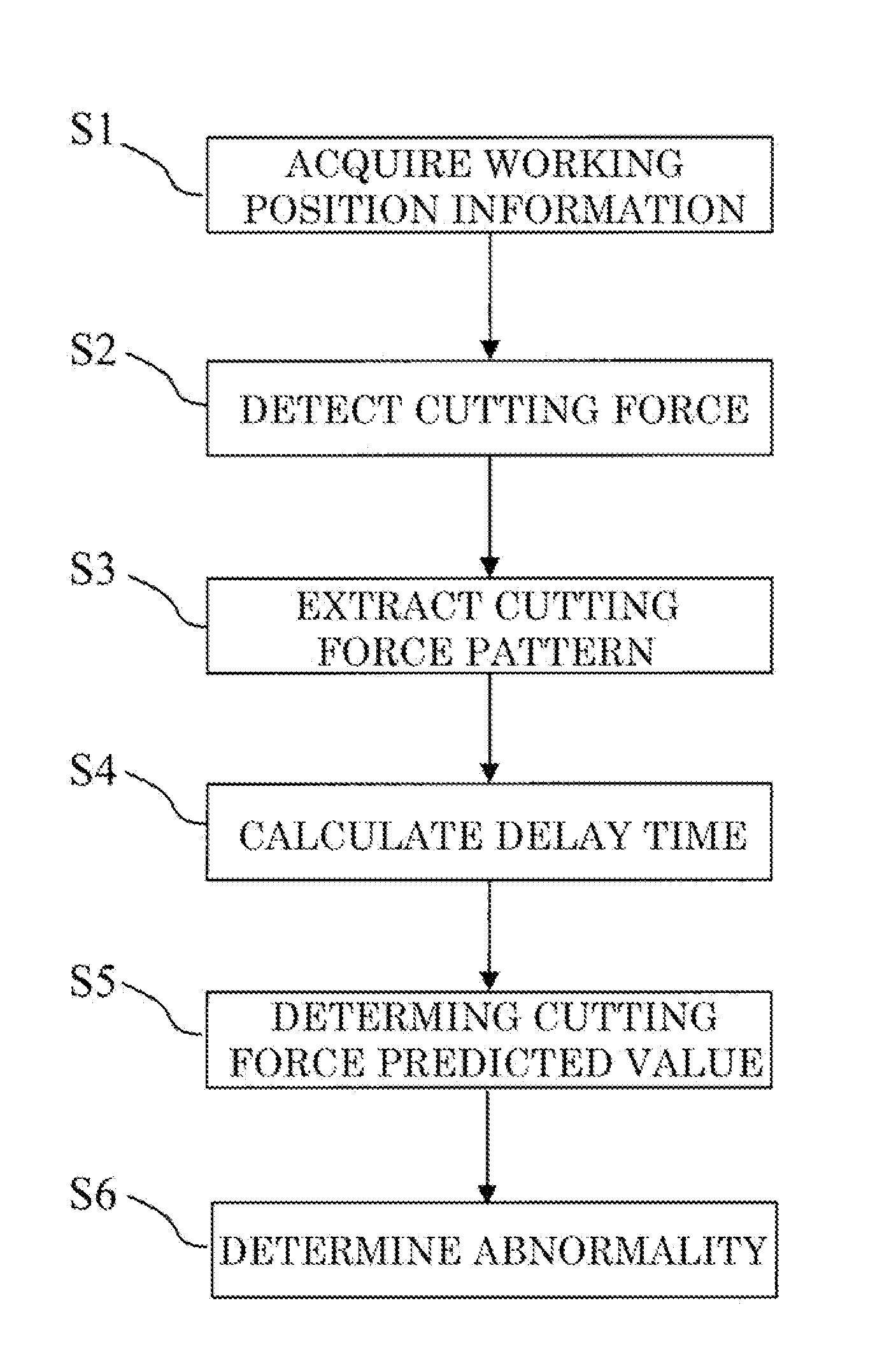

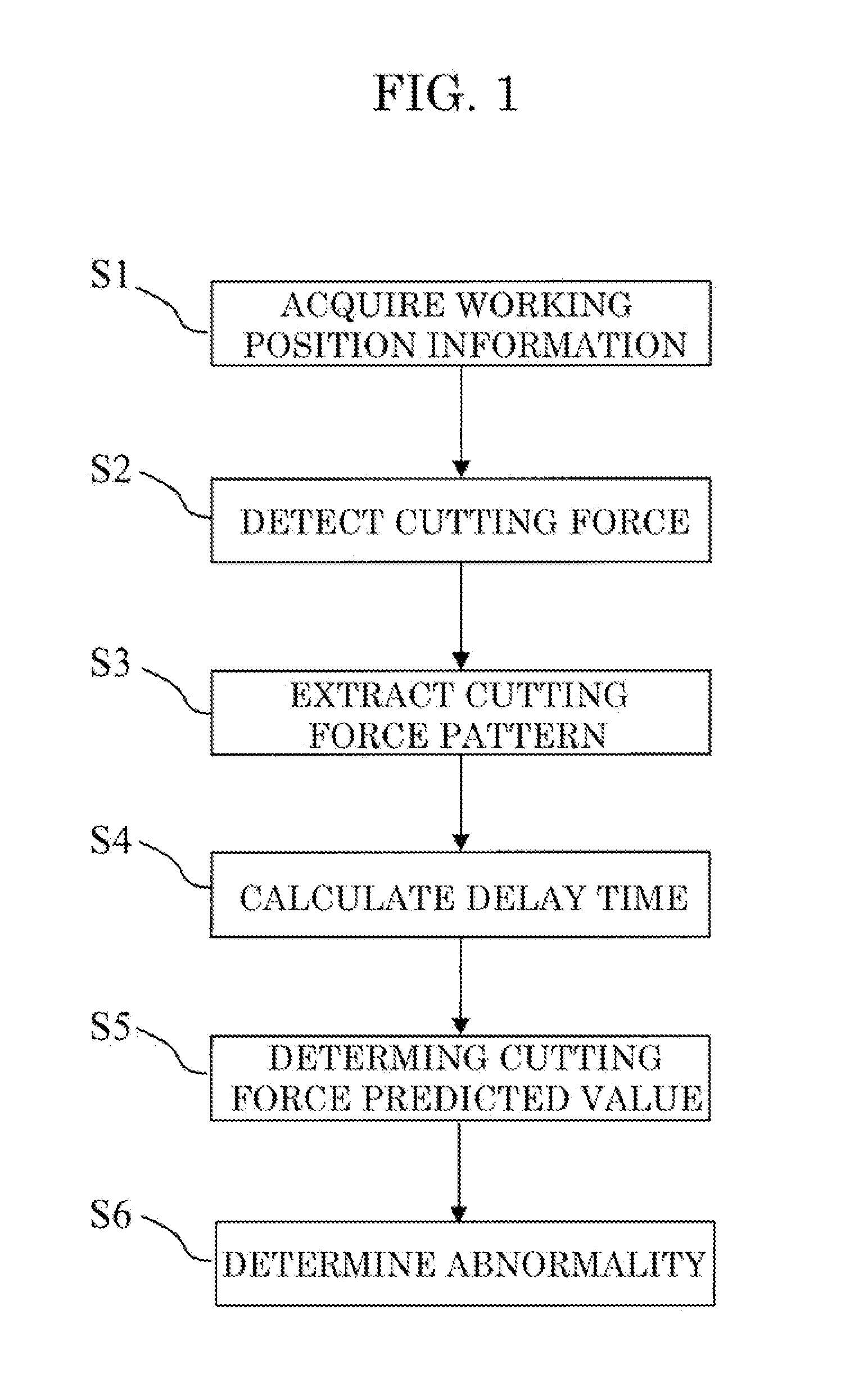

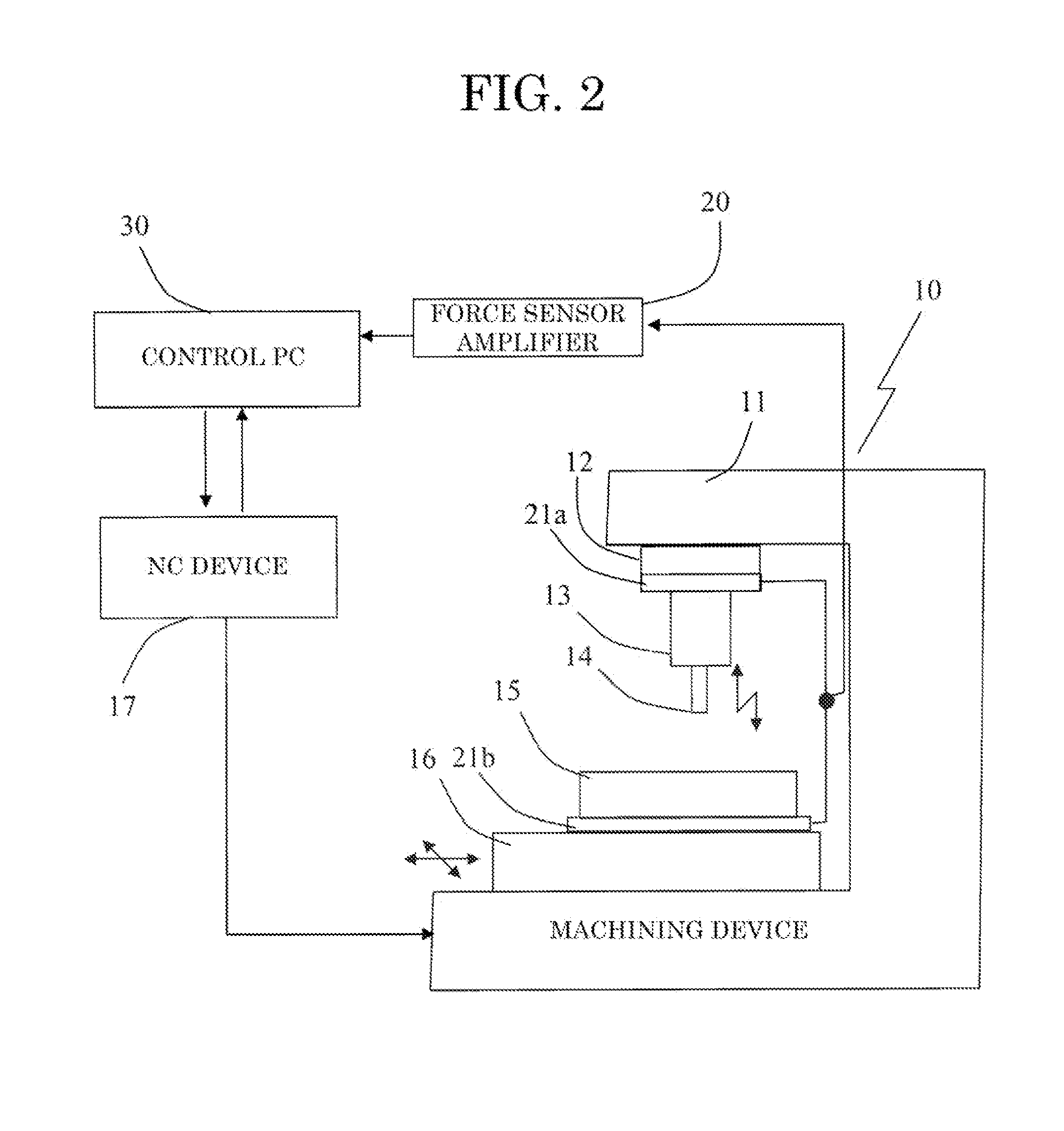

Working Abnormality Detecting Device and Working Abnormality Detecting Method for Machine Tool

InactiveUS20140123740A1Improve cutting work efficiencyLow production costProgramme controlMeasurement/indication equipmentsAnomaly detectionEngineering

Provided are a device and a method which determine a threshold value for detecting abnormality in a working path in which the cutting condition changes momentarily to thereby enable abnormality determination. Cutting force that becomes an abnormality determination value and threshold value information are previously calculated by cutting simulation, and a threshold value with which a comparison is to be made is determined from the position coordinates of a working machine which have been acquired during cutting and the measurement result of cutting force to thereby enable abnormality determination.

Owner:HITACHI LTD

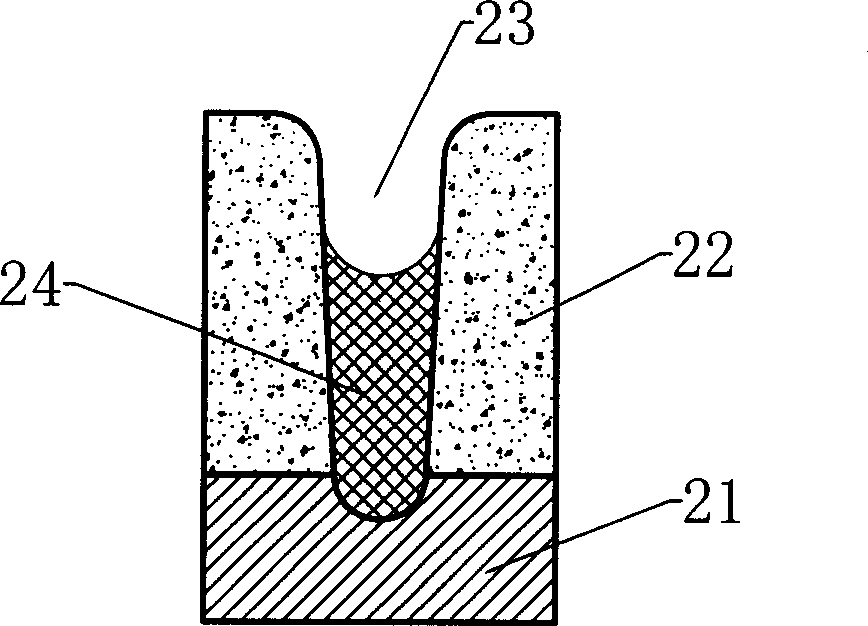

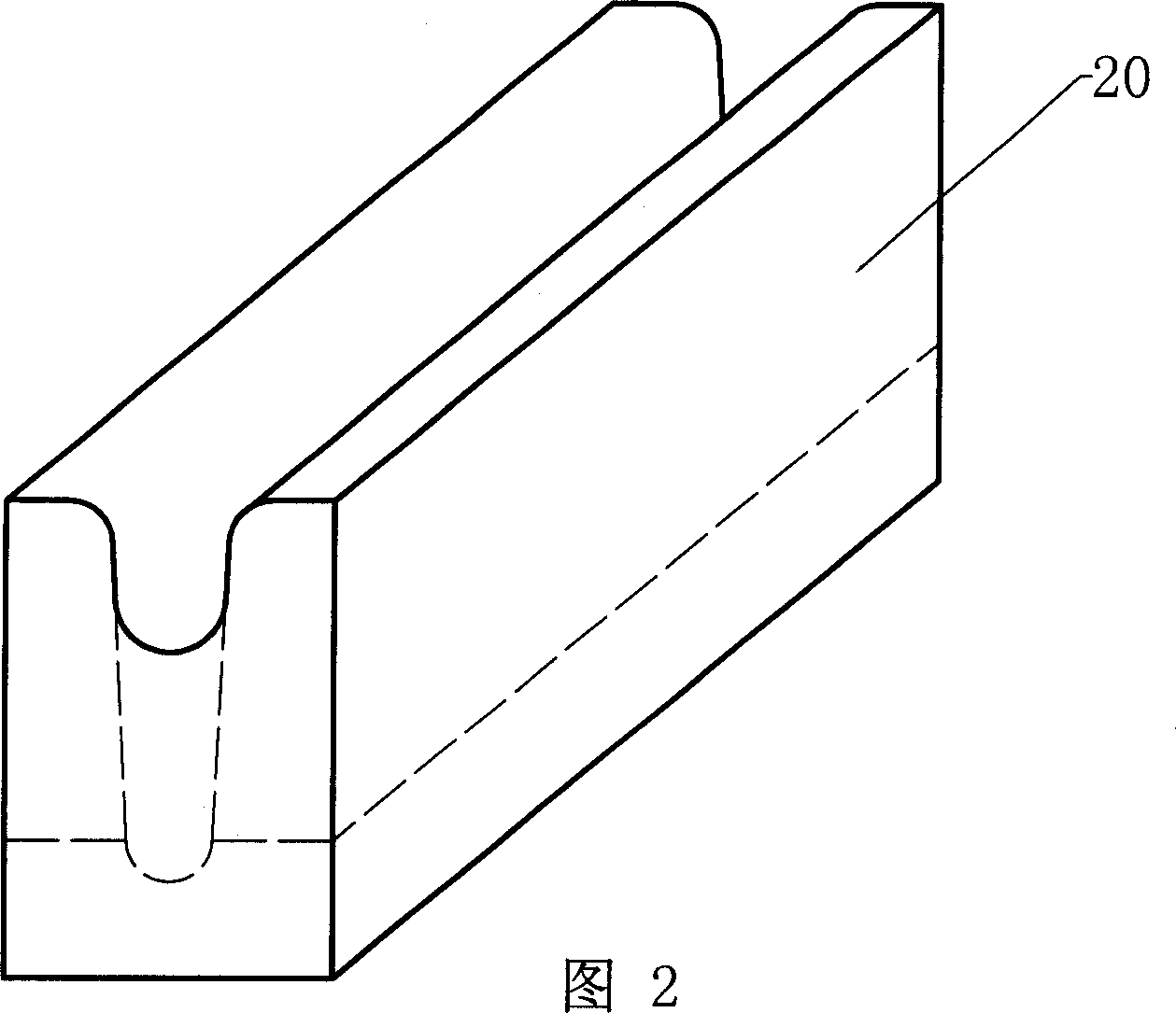

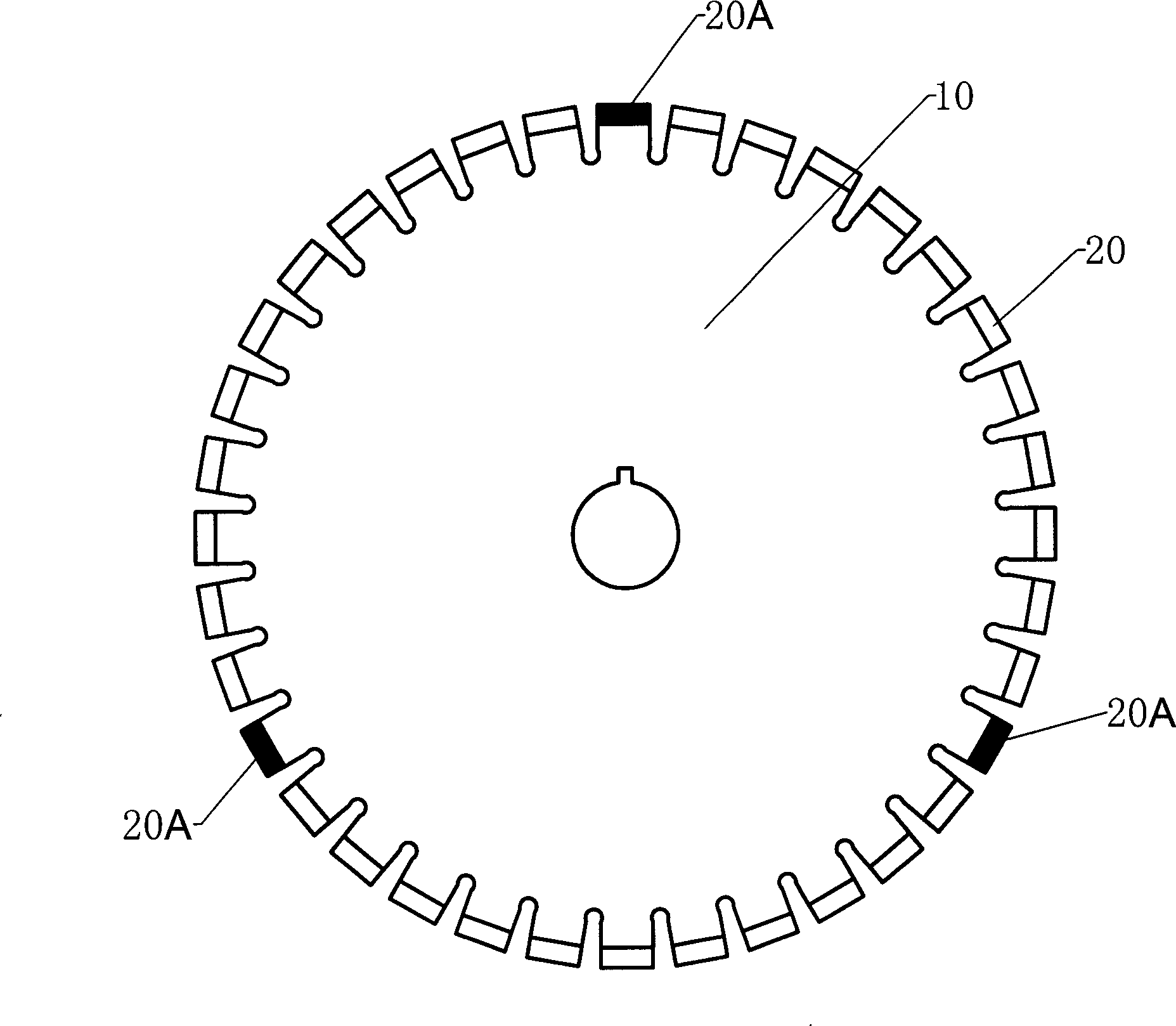

Diamond bits and saw disc therewith

InactiveCN1583388AImprove cutting work efficiencyReduce vibrationStone-like material working toolsGraphiteCeramic

A diamond cutter and its saw blade used for machining stone, ceramics, or glass are disclosed. Said diamond cutter is composed of steel base, metallic supporter, diamond, filing discharging slot and graphite on the bottom of said slot. Said diamond saw blade consists of the steel base and diamond cutters welded to said steel base.

Owner:JIEYANG HESHENG MACHINERY STONE

Aluminum alloy section cutting equipment

ActiveCN110315381ASimple and convenient cutting operationAdequate and effective fixationPositioning apparatusMetal working apparatusMaterials scienceAluminium alloy

The invention belongs to the technical field of aluminum alloy section processing equipment, and particularly relates to aluminum alloy section cutting equipment. The equipment comprises a rack and afeeding device used for conveying a aluminum alloy section, wherein a discharging plate, a mounting block and two L-shaped baffles are fixedly arranged at the top of the rack, the interior of the discharging plate communicates with the interior of the rack, and two sliding columns and two supporting rods are symmetrically arranged on the mounting block. According to the equipment, the cutting operation is simple and convenient, and the section is conveyed into the interior of the cutting equipment by the feeding device; through the design of a first material guiding roller and a second material guiding roller, the section can conveniently move in the equipment, and the phenomenon that moving is inconvenient due to the fact that friction is too large is avoided; cutting steps are simple andconvenient, so that the cutting working efficiency is improved; through matching of a limiting device and a reinforcing device, the section can be sufficiently and effectively fixed, so that the cutting precision of the section is improved; and meanwhile, through the design of a position structure of a cutting device is adopted,the safety of the equipment is improved.

Owner:南通金燃机械制造有限公司

Transverse and vertical cutting combined type dried bean curd slitting machine

InactiveCN105196333ARealize vertical slittingEasy to operateMetal working apparatusDry beanLinear motor

The invention discloses a transverse and vertical cutting combined type dried bean curd slitting machine. The transverse and vertical cutting combined type dried bean curd slitting machine comprises a rack, wherein a bean curd placing platform, a transverse cutting device, a vertical cutting device, a bean curd placing platform horizontal guide rail, a bean curd carrier plate and a first air cylinder are arranged on the rack; the transverse cutting device comprises a linear motor, a horizontal pressing plate and a transverse cutting steel wire; the vertical cutting device comprises a bean curd placing slot and a vertically cutting knife, bean curds are placed on the bean curd carrier plate during slitting, bean curd blocks are pressed downward by virtue of the horizontal pressing plate and are slit in layers along the transverse direction by virtue of a transversely cutting steel wire connected with a piston rod of a third air cylinder, after the bean curd blocks are transversely slit, the first air cylinder drives the two sides of the bean curd carrier plate to be pulled open, the bean curd blocks fall into the bean curd placing slot arranged below, and then a second air cylinder pushes the horizontal pressing plate to move down and depresses the bean curd blocks from the vertically cutting knife, so that vertical slitting on the bean curd blocks is realized. The transversely and vertically combined type dried bean curd slitting machine has the advantages that transversely cutting and vertically cutting operations are simple and the cutting working efficiency is high.

Owner:CHONGQING HONGXUAN FOOD CO LTD

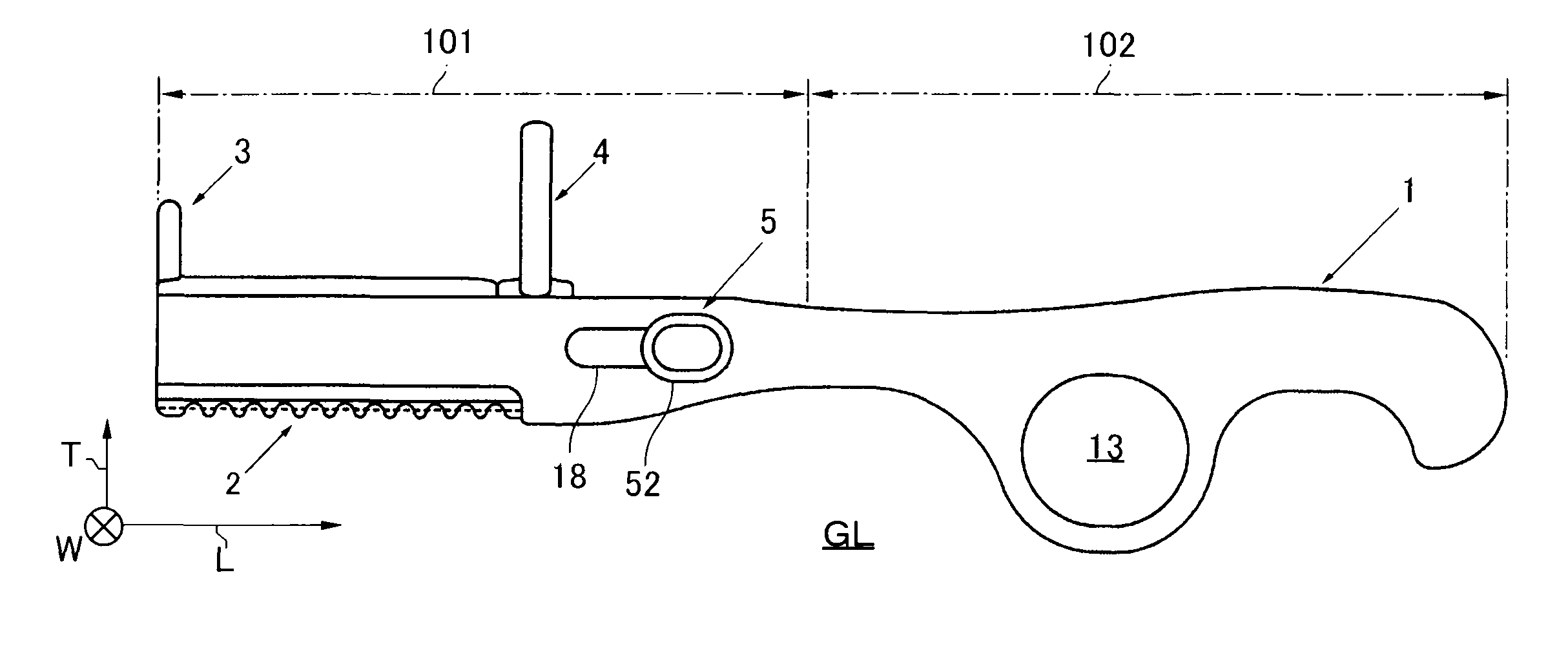

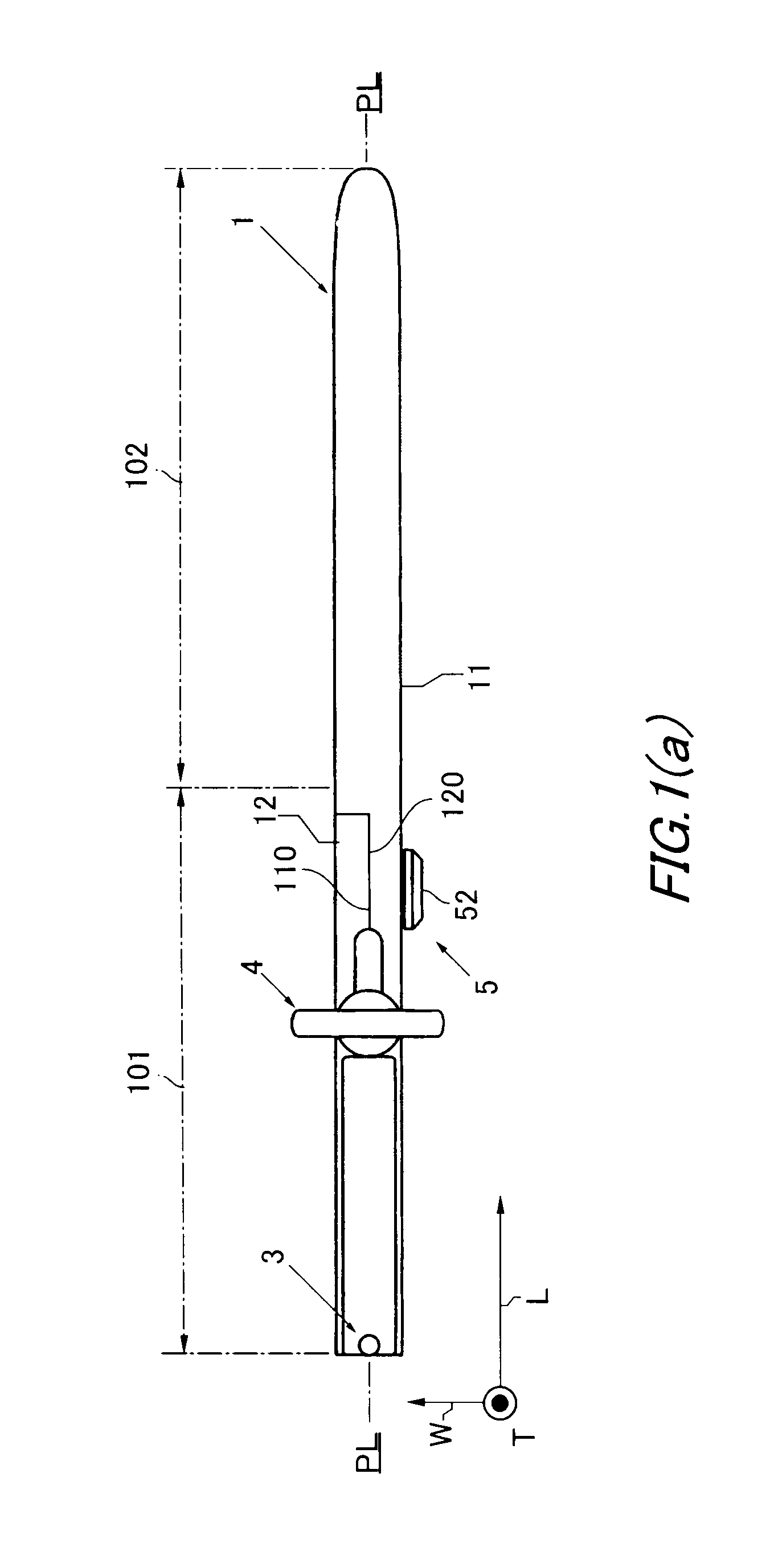

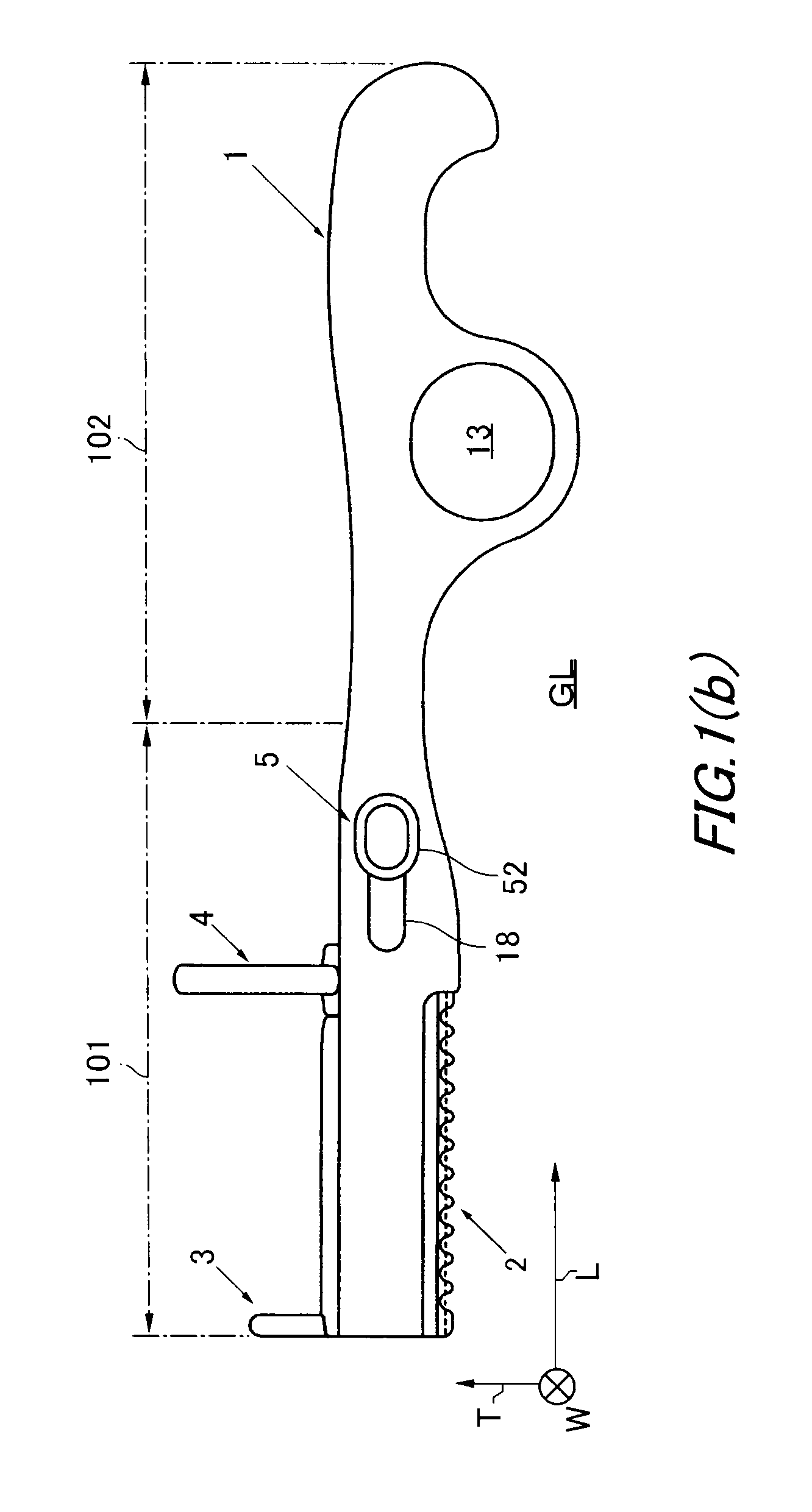

Multi-purpose hair cutter

InactiveUS8701291B2Improve work efficiencyImprove cutting work efficiencyHair combsMetal working apparatusEngineeringMechanical engineering

Owner:TOKYO RIKI

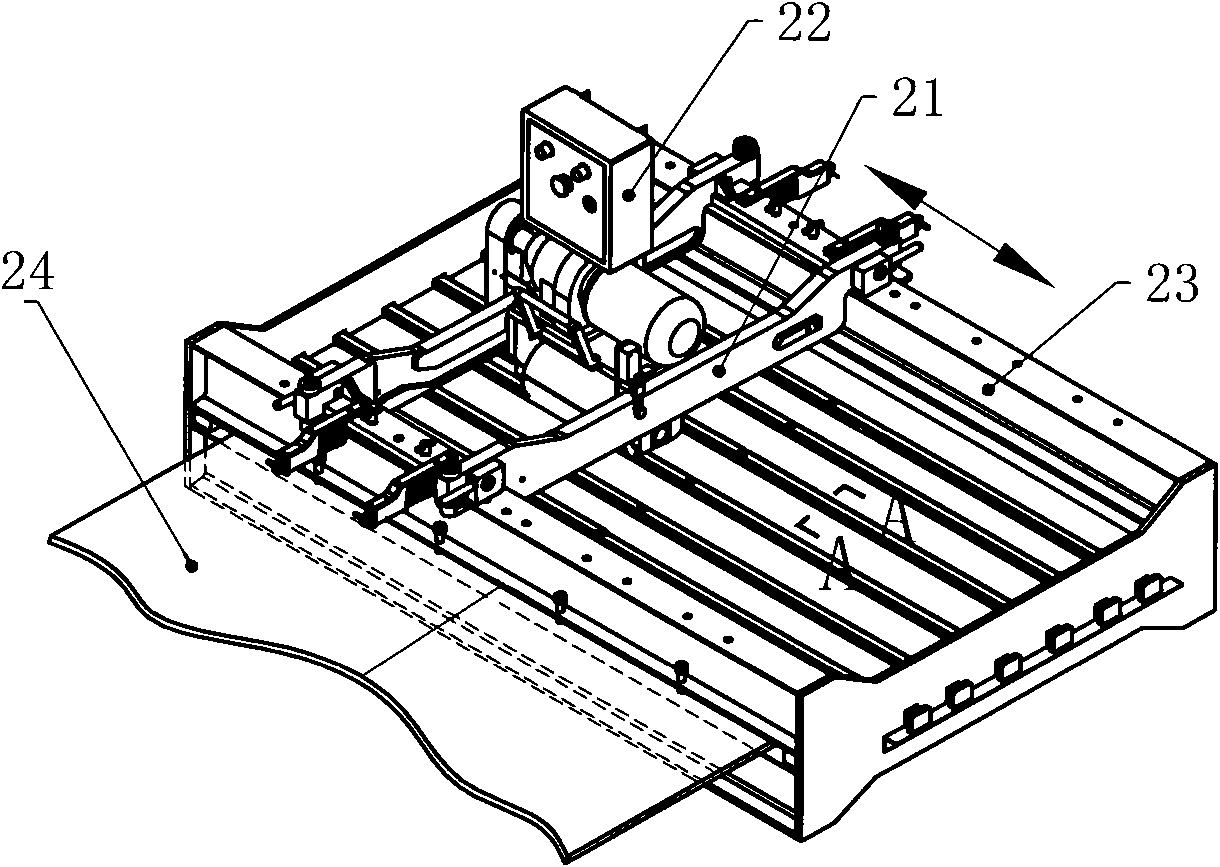

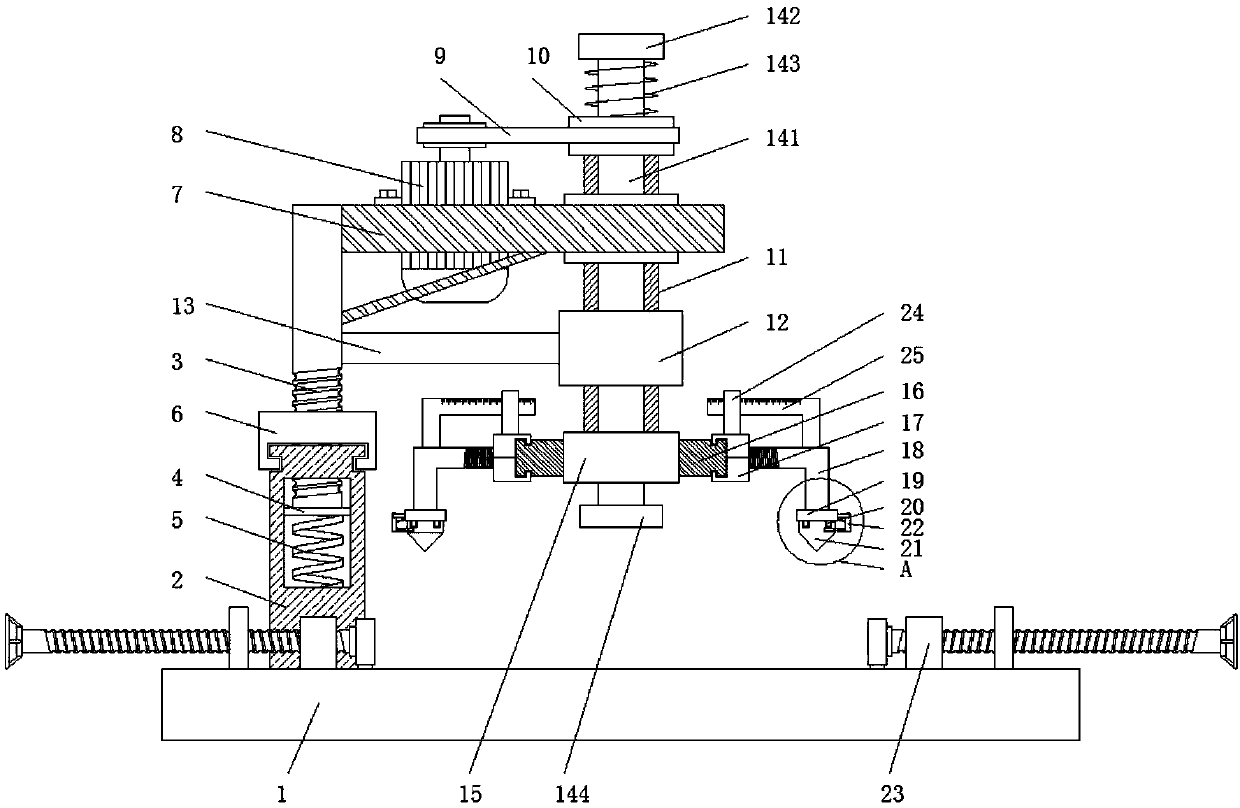

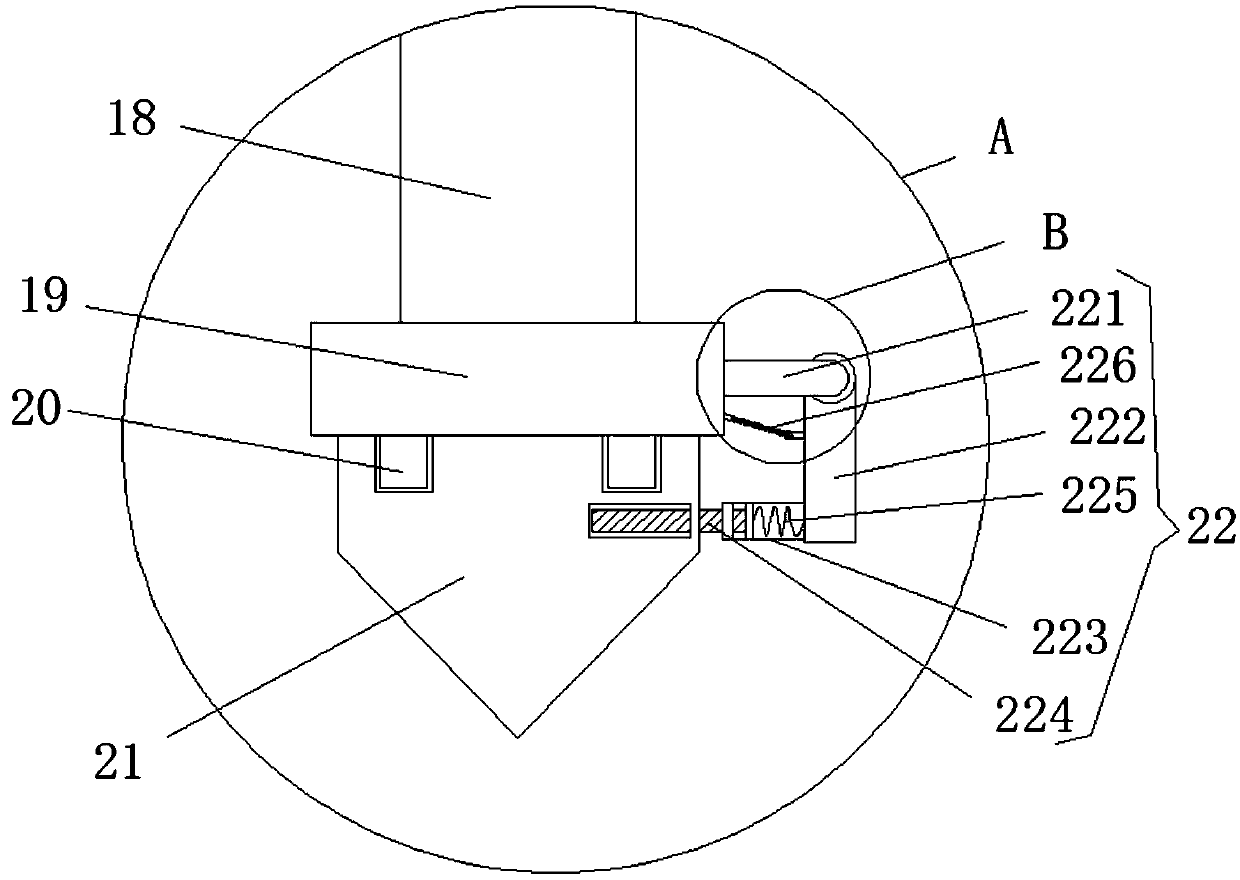

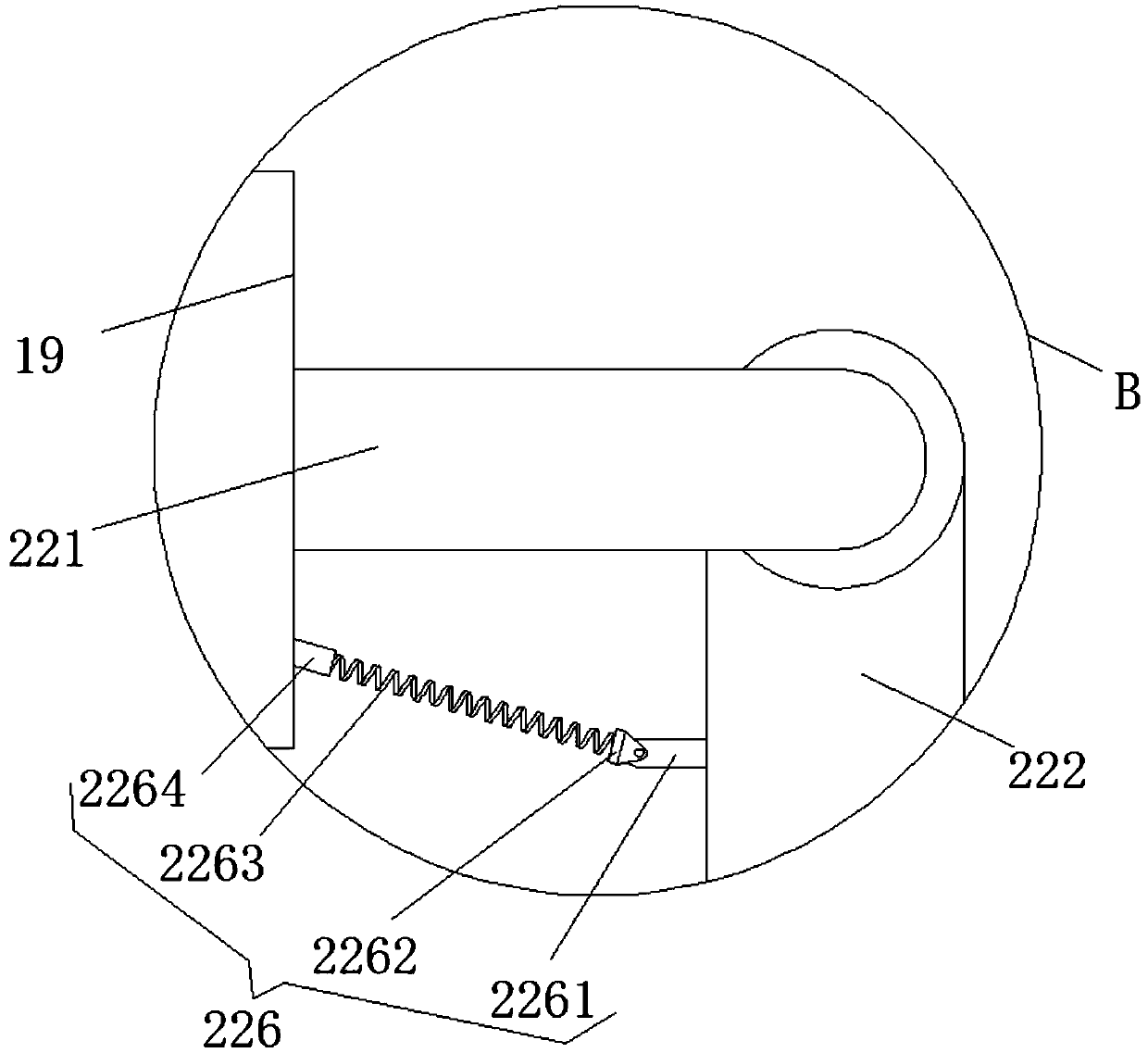

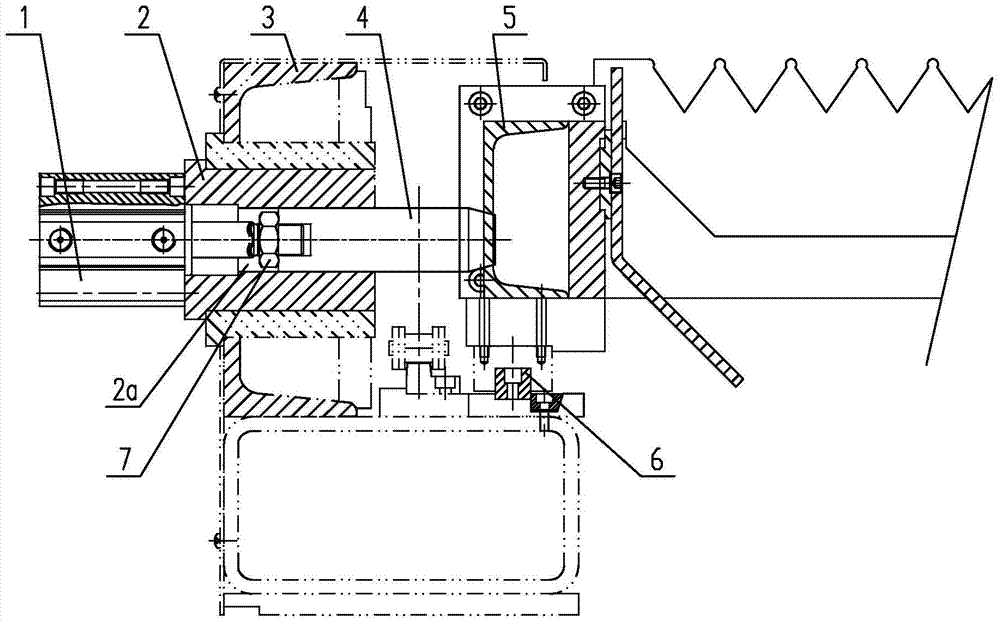

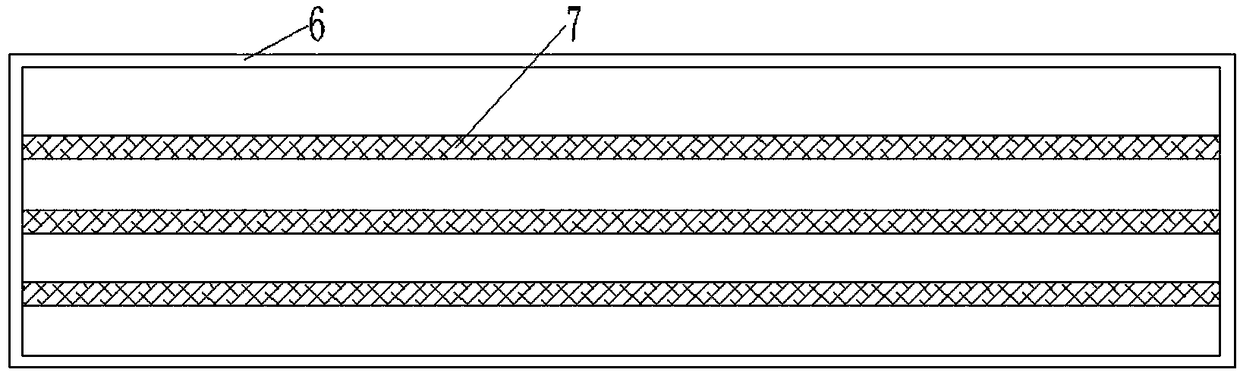

Whole-core conveyer belt tooth-shaped joint cutter

InactiveCN101913162AAchieve one-time cuttingQuality improvementMetal working apparatusSkill setsEngineering

The invention relates to a whole-core conveyer belt tooth-shaped joint cutter. At present, a conveyer belt is mostly connected by using a metal buckle so as to easily produce vibration and tear, obtain short service life and affect the production and safety of an enterprise. The invention aims to produce the whole-core conveyer belt tooth-shaped joint cutter. The structure of the cutter consists of a movable rail frame assembly (21) arranged on a base (23) and a movable tool rest assembly (15) arranged on the rail frame assembly (21) and is a detachable split connection structure. The cutter has the advantage that the cutter is widely applied to the industries of mines, power plants, cement plants, coking plants, docks and harbors and the like which use whole-core conveyer belts. The cutter improves the overall performance of whole-core conveyer belt tooth-shaped joint cutting operation, and avoids the previous problems of poor centering property, low cutting efficiency and poor whole-core conveyer belt connecting quality. The cutter has the advantages of multi-station and multi-blade precise cutting, split design, convenience for carrying, suitability for field operation, and no strict requirement for operator skills.

Owner:周鹏飞

Cutting device for wood decoration material for indoor decoration

The invention discloses a cutting device for a wood decoration material for indoor decoration. The cutting device comprises a cutting workbench, a cutting part fixing device and a protection device; supporting stand columns are fixedly installed at the bottom part of the cutting workbench, and a cutter wheel is fixedly installed at one end of the top part of the cutting workbench; and one end of the cutter wheel is connected to a cutter wheel rotating shaft, and the cutter wheel rotating shaft is in transmission connection with an output end of a cutting motor installed at the bottom part of the cutting workbench through a belt. The cutting device has the advantages that structure is reasonable and simple, the cutting efficiency and precision are high, and the energy-saving and environment-friendly effects are achieved; the moving track of a cutting part is guided and limited through a guide rail and the cutting part fixing device, so that cutting precision of the cutting device on thewooden cutting part is effectively improved, the labor intensity of workers is reduced, and the cutting working efficiency is improved; and wood chips scattered on the surface of the cutting part andthe cutter wheel can be blown away by a fan installed in a protection cover, so that the problem that the cutting efficiency is influenced due to the fact that the wood chips are scattered on the surface of the cutting part and the cutter wheel is solved.

Owner:钟灏

Intelligent cutting method for steel plate

InactiveCN105364159APrecise cuttingImprove cutting work efficiencyShearing machinesShearing machine accessoriesAutomatic controlSteel plates

The invention discloses an intelligent cutting method for a steel plate. The method comprises steps as follows: firstly, the steel plate is placed on a cutting working table and positioned by a clamp, after positioning, a cutting device is driven to move downwards until the cutting device is adjacent to the steel plate, then a camera arranged on the cutting device acquires an image of the steel plate, a controller controls the cutting device to move horizontally, meanwhile, the camera acquires an image of the steel plate and determines the cutting position of the steel plate, and finally, the controller starts the cutting device and controls the cutting device to move downwards continuously to cut the steel plate. According to the method, the steel plate is accurately positioned by the aid of the cutting working table, fixation of the steel plate during cutting is guaranteed, and cutting accuracy is guaranteed; besides, the controller is adopted for automatic control, and improvement of the cutting working efficiency is guaranteed.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

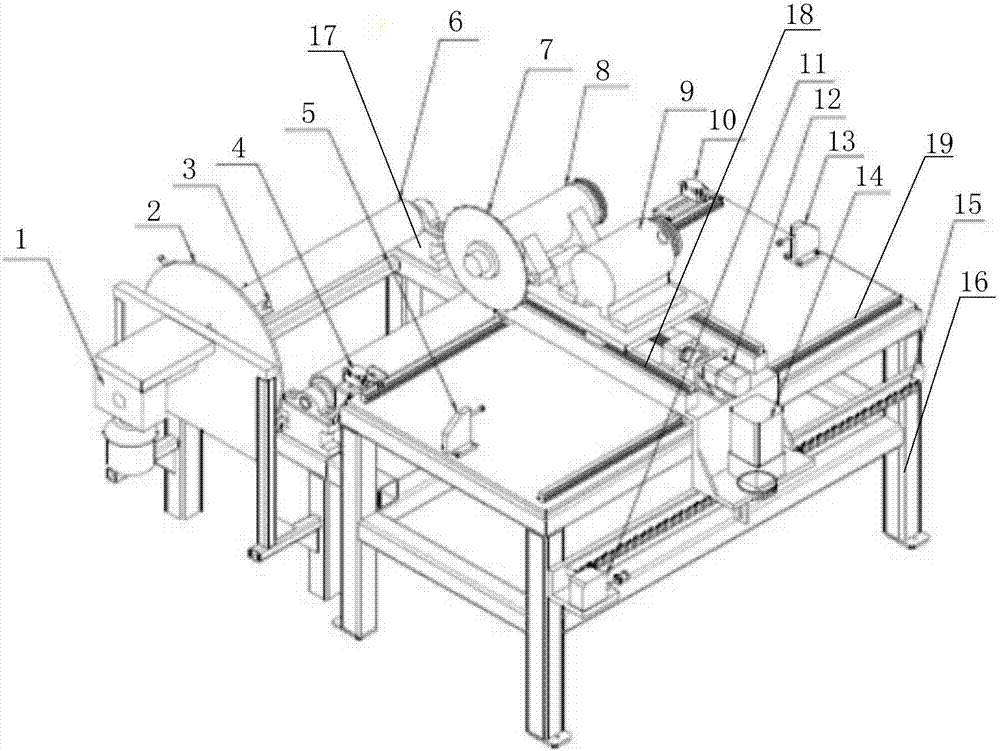

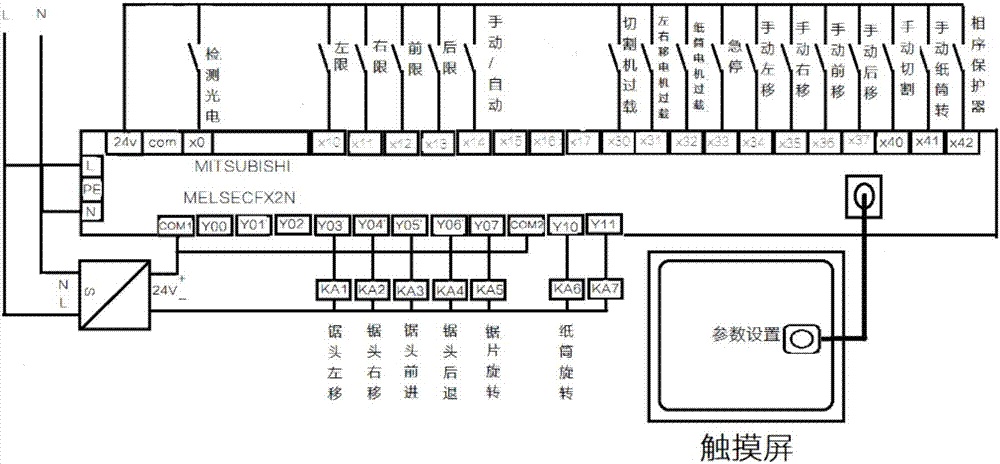

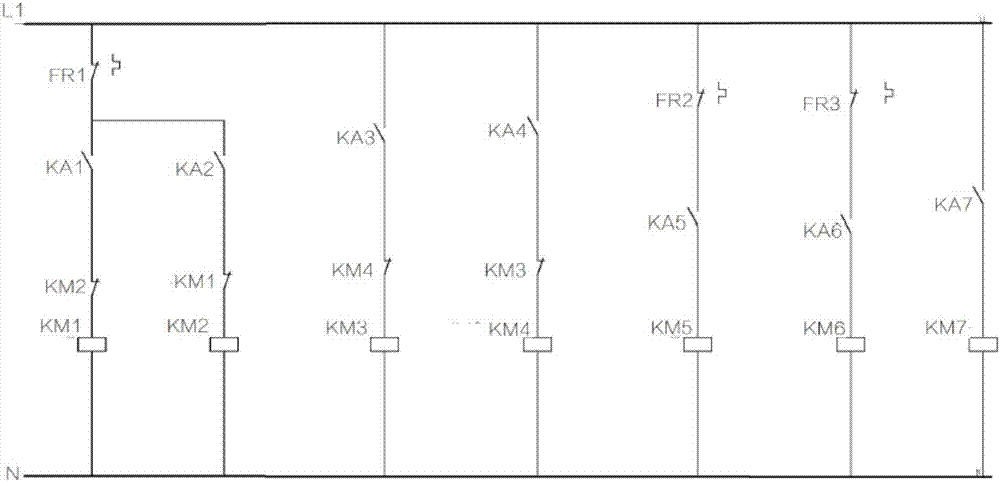

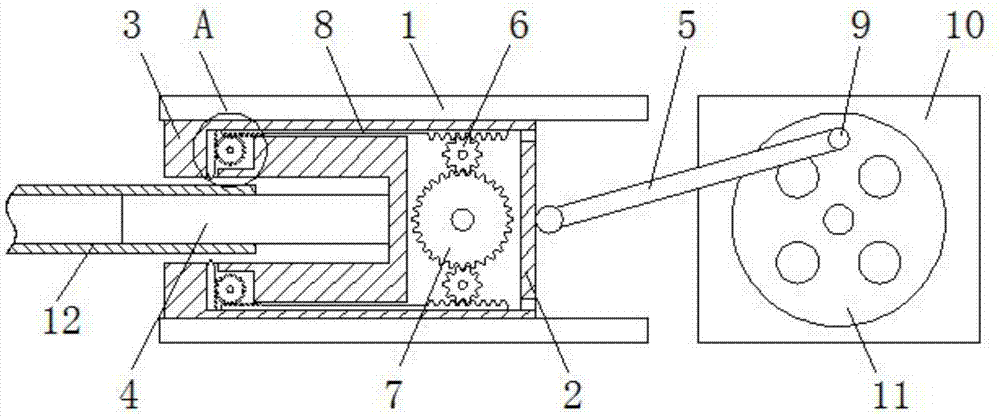

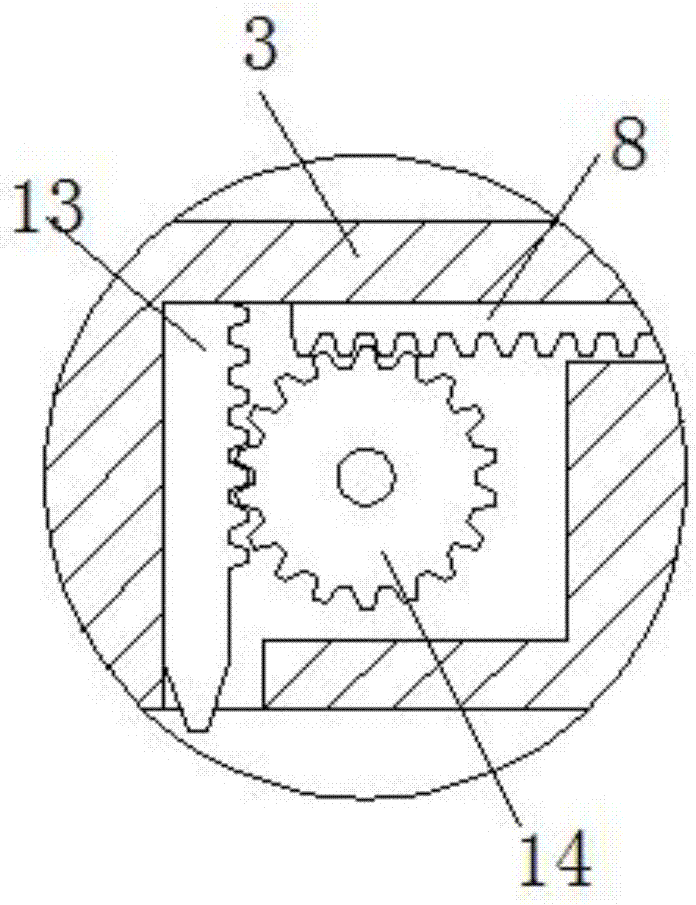

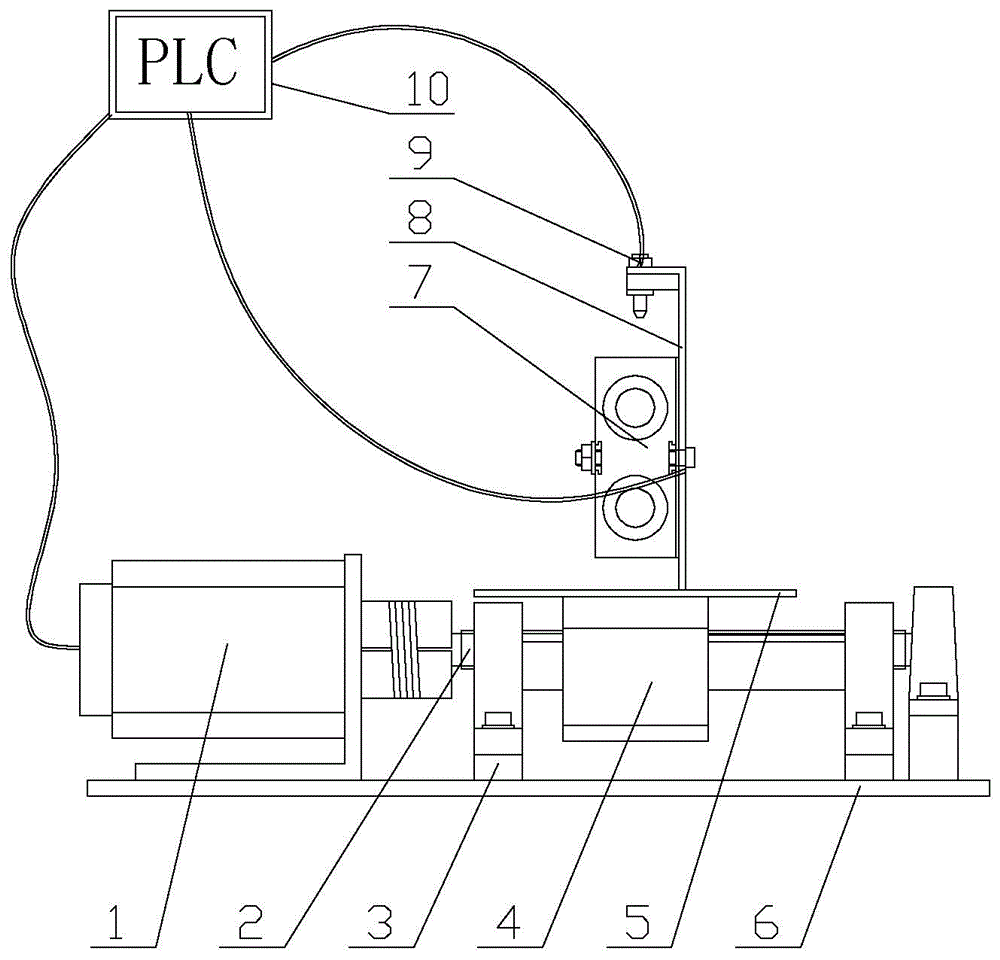

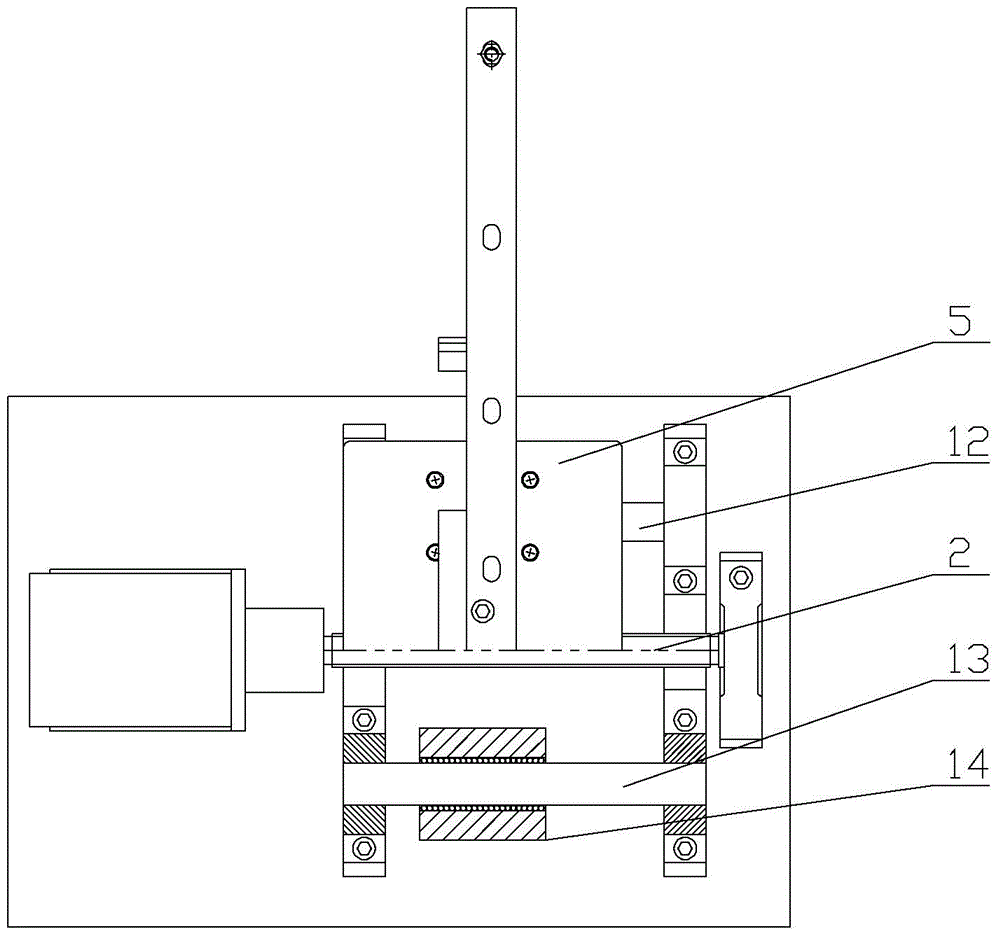

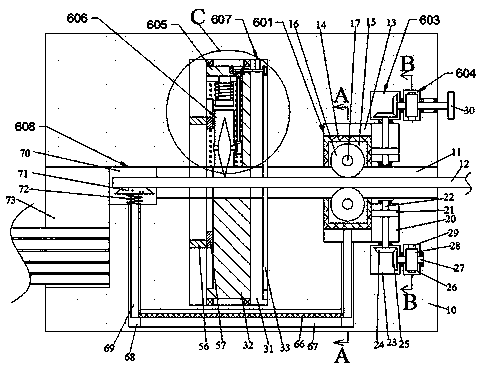

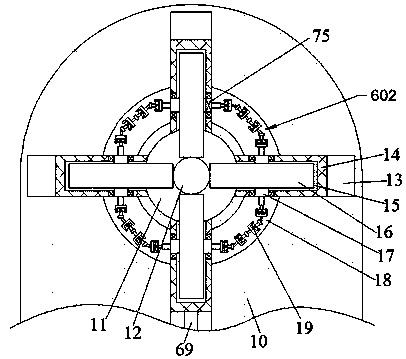

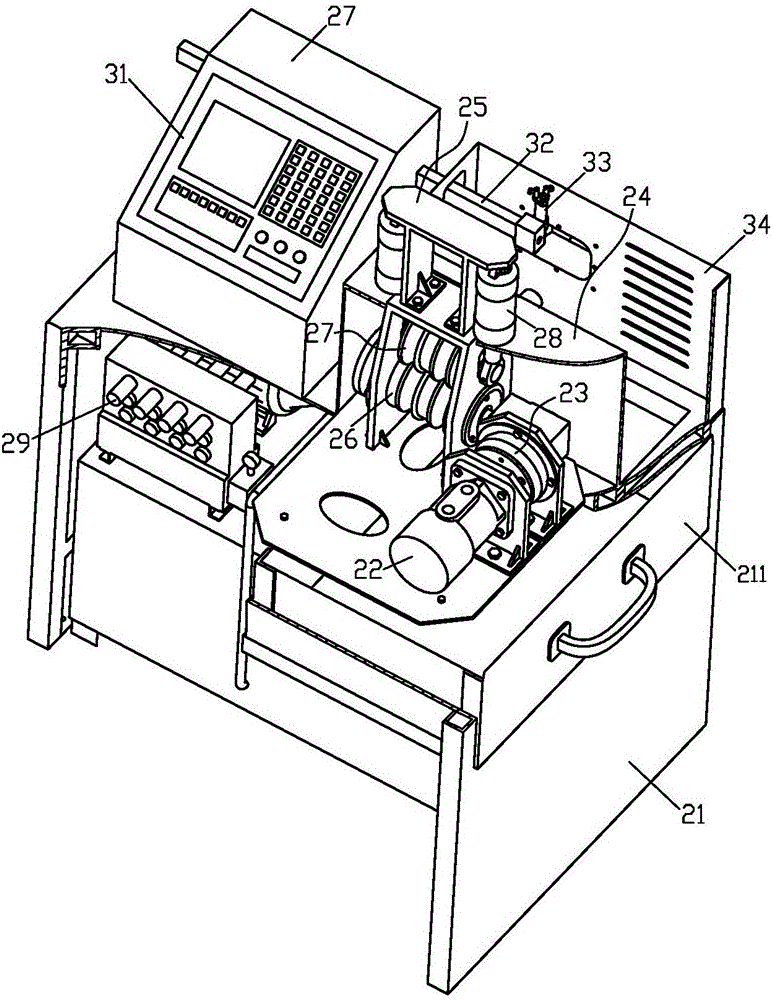

Integrated manual and automatic paper tube cutting device and cutting control method

InactiveCN107139244AImprove cutting accuracyRealize continuous cuttingMetal working apparatusElectric machineryPulp and paper industry

The invention provides an integrated manual and automatic paper tube cutting device which comprises a rotation power unit, a flange plate, a locking claw, a right limiting switch, a supporting roller, a saw web, a saw head, a cutting motor, a left limiting switch, an electro-optical distance measurement device, a saw head power unit, a sizing driving device, a transmission toothed rack, a rear rack, a front rack, a front-back moving rail and a left-right moving rail. According to the integrated manual and automatic paper tube cutting device and a cutting control method, a bracket roller and a paper tube center positioning flange are adopted to position and clamp a paper tube; the manual and automatic cutting manners can be switched over to realize continuous paper tube cutting, so that the paper tube cutting efficiency and cutting precision are effectively improved.

Owner:ANHUI BAOSTEEL STEEL DISTRIBUTION

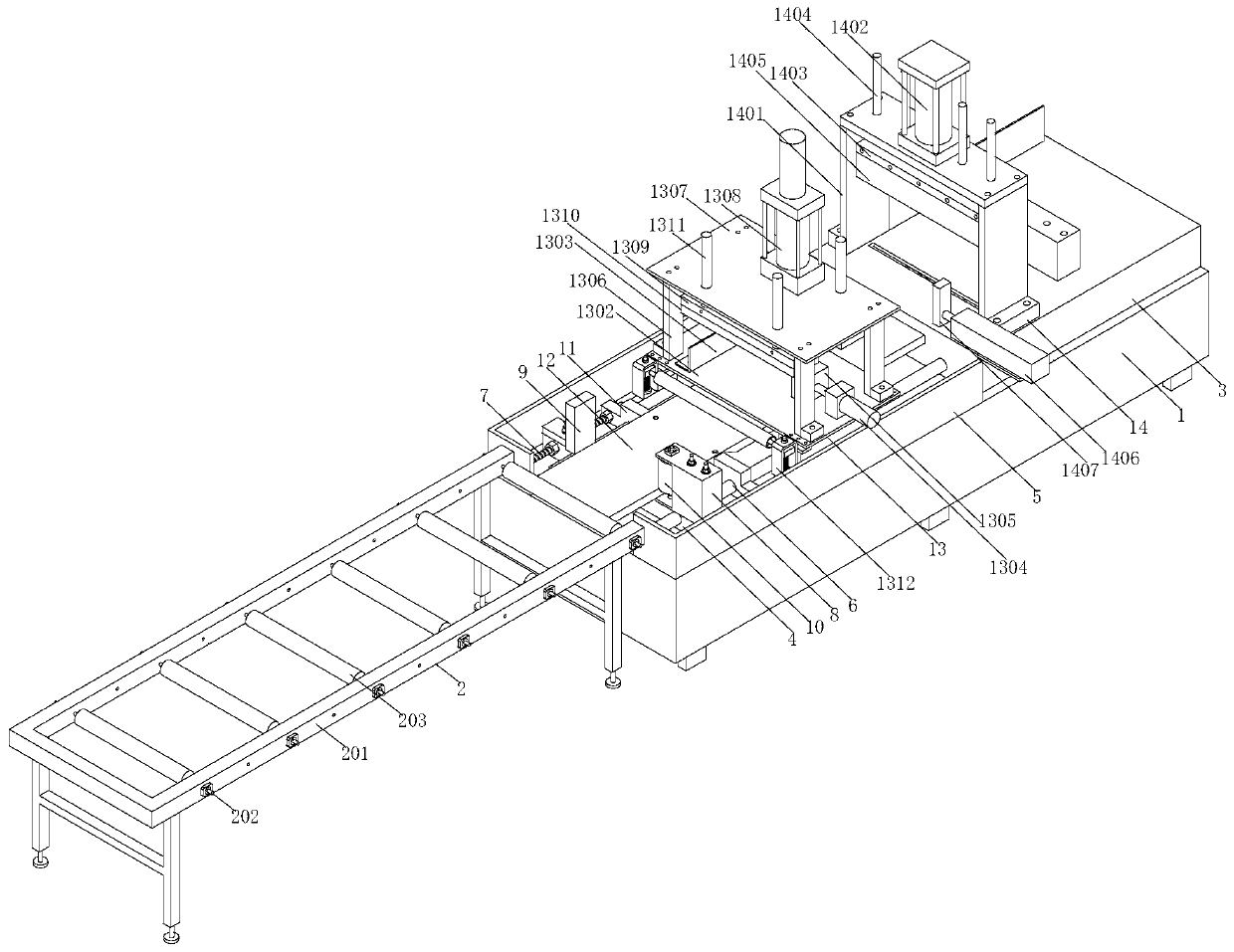

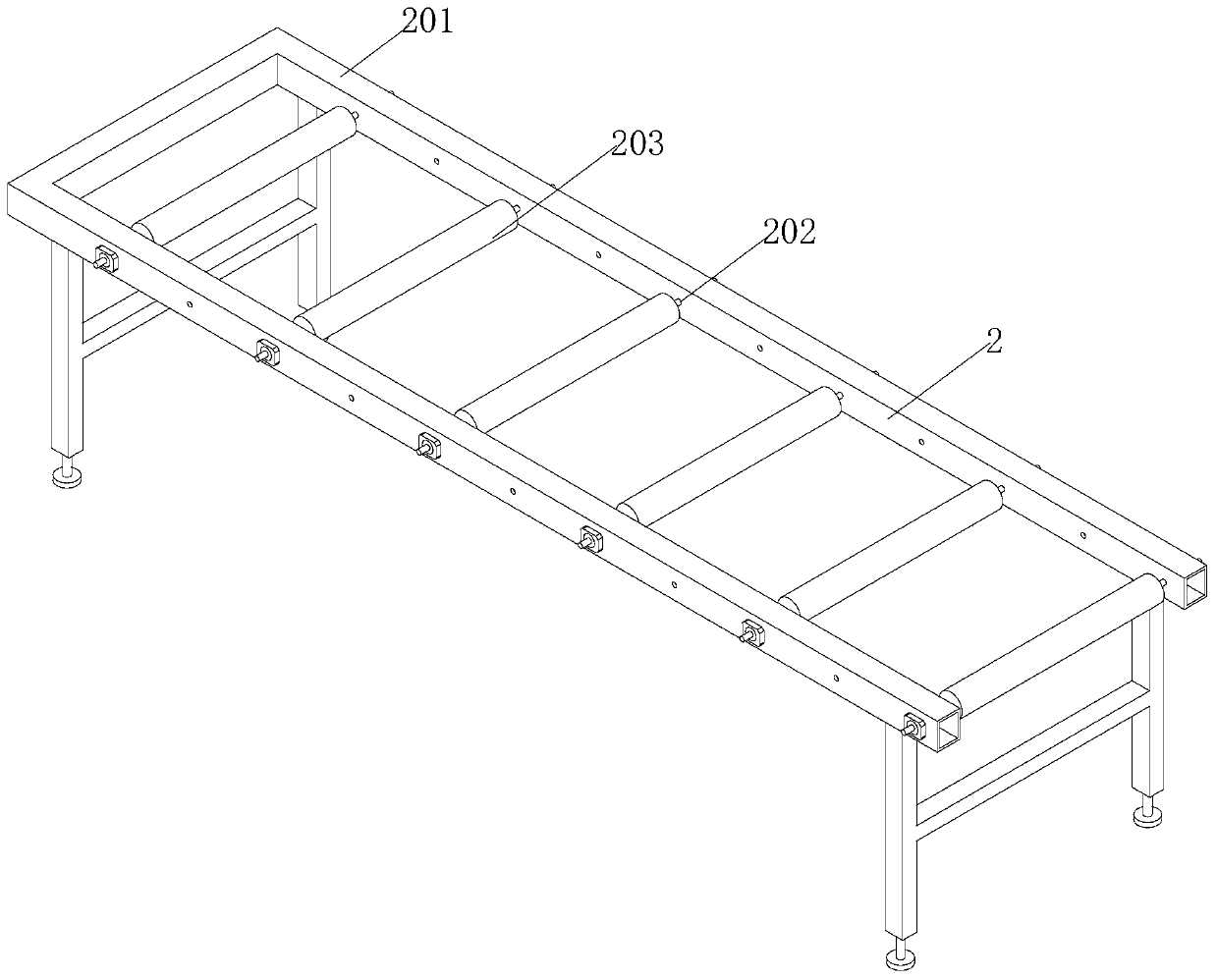

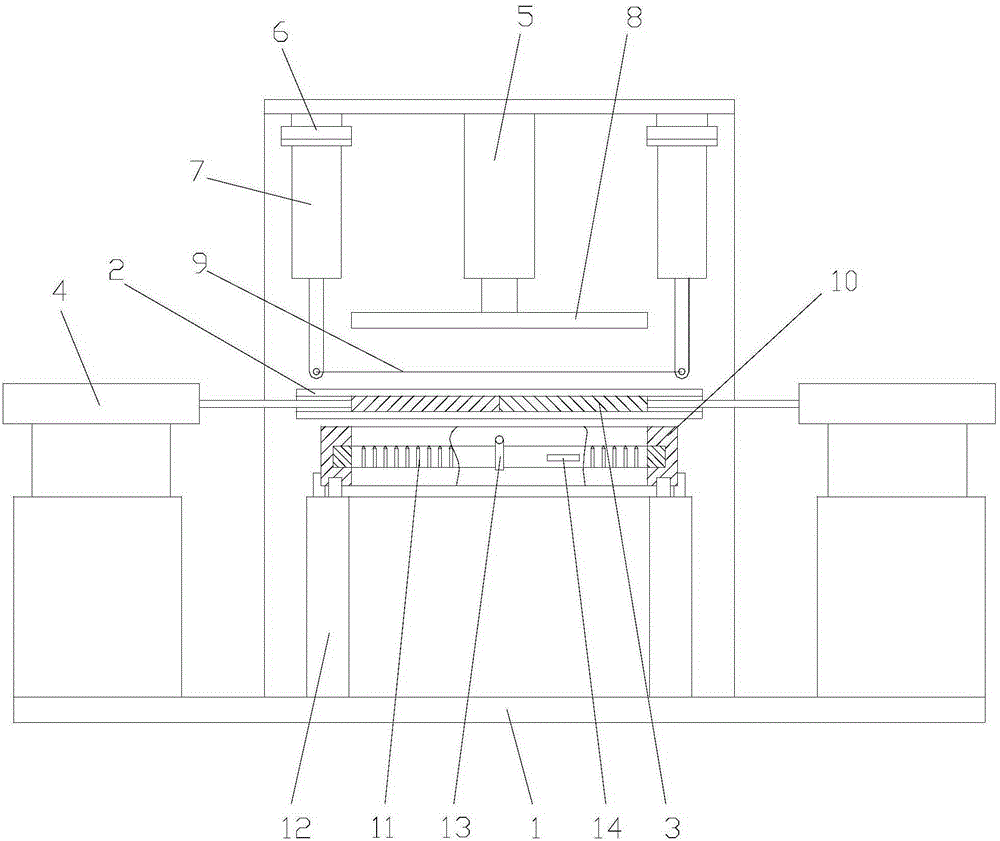

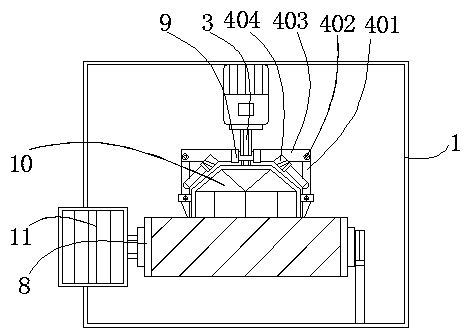

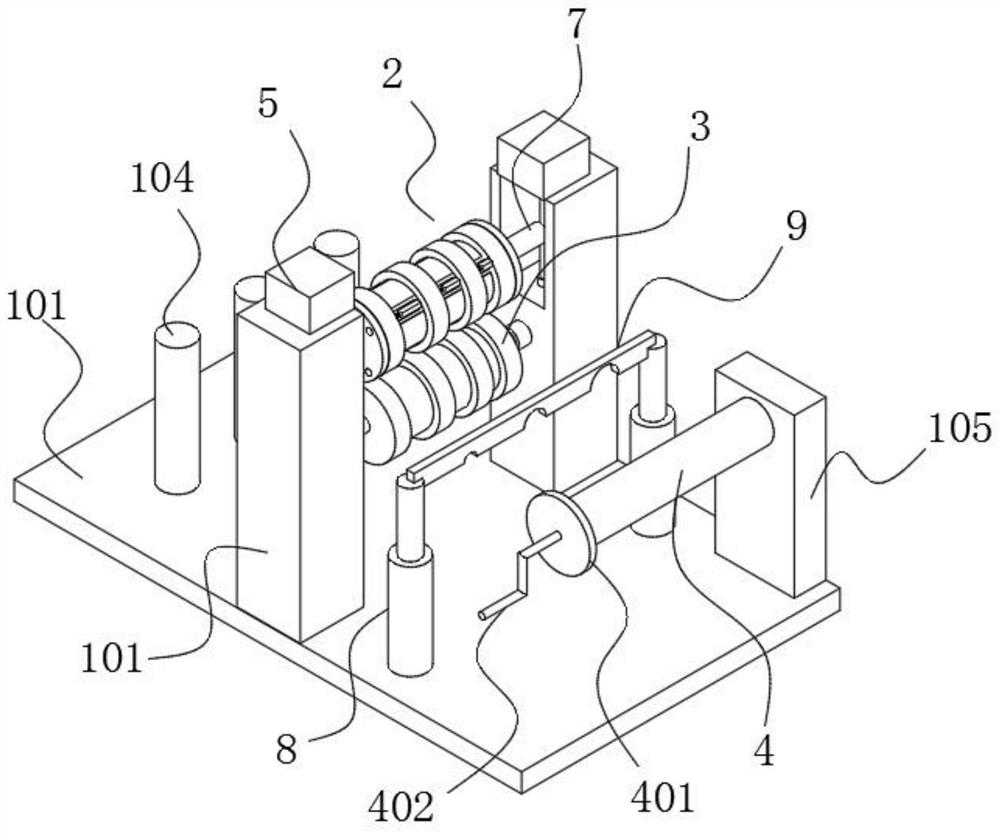

Petroleum casing collar automatic production line

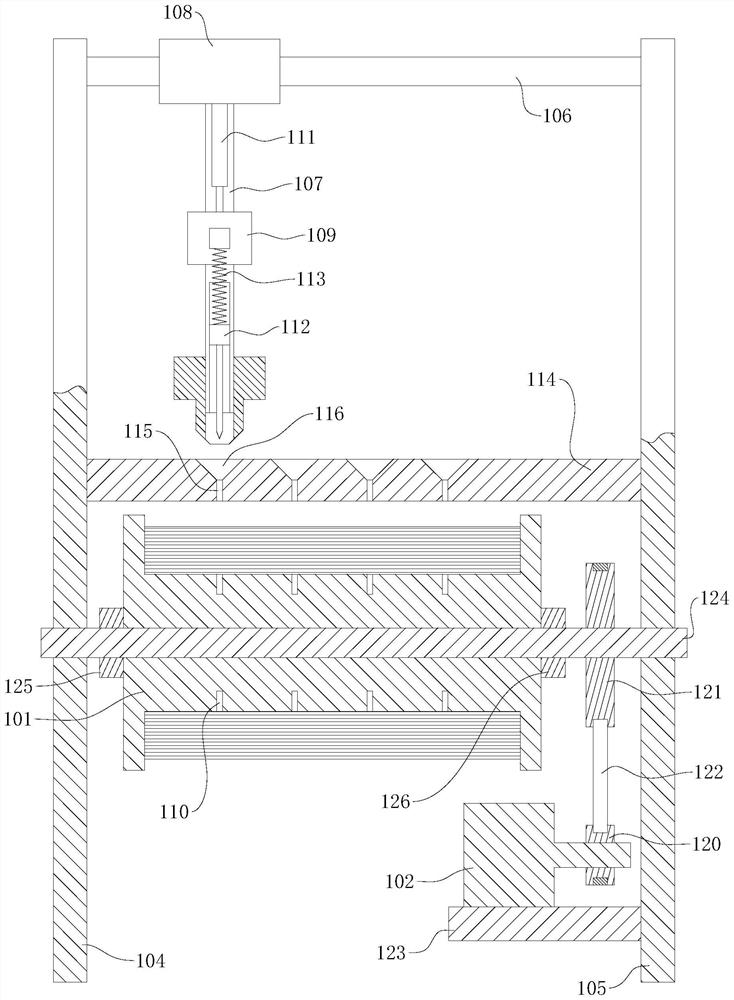

PendingCN109454467AGuaranteed stabilityConsistent positionOther manufacturing equipments/toolsProduction lineElectrical control

The invention discloses a petroleum casing collar automatic production line. The petroleum casing collar automatic production line comprises a long casing conveying device, a long casing cutting device, a marking device, a collar blank conveying device, a lifting device, a mechanical hand structure, a machining device and other multiple process devices; and the long casting cutting device, the marking device, the collar blank conveying device and the lifting device are connected through connection conveying plates. According to the petroleum casing collar automatic production line provided bythe invention, the mechanical devices cooperates with electrical control, the process that taking and conveying of a long casting, turning of the end surface and the outer circle of the long casting,cutting off of the long casing, marking of a collar blank, conveying of the collar blank between planes different in height, mechanical hand grabbing and machine tool machining are automatically and efficiently conducted is achieved, manpower is saved, and the production efficiency is improved.

Owner:SHANGHAI JIANGAO CNC MACHINE TOOLS

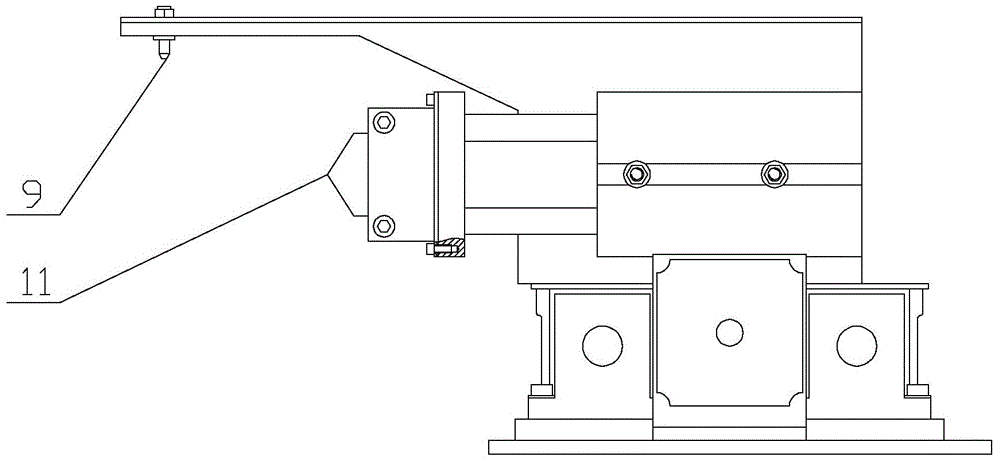

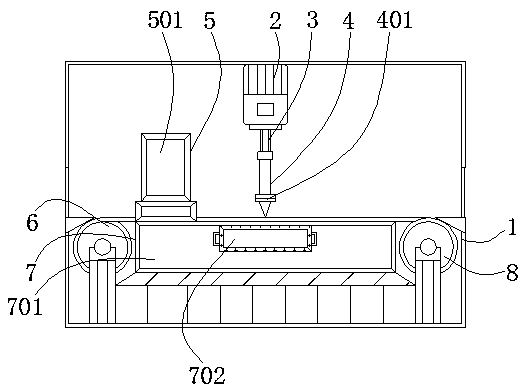

Mechanical dragging cutting equipment

InactiveCN107263142ARealize trailing continuous cuttingAvoid interferencePositioning apparatusMetal working apparatusEngineeringMechanical engineering

The invention discloses a mechanical traction cutting device, comprising a chute, the bottom end of the chute is provided with a support frame, and the support frame is fixedly arranged on the workshop floor, and an intermittent motor is provided on one side of the chute. And the intermittent motor is also installed on the support frame, the inside of the chute is provided with a sliding installation box, the driving end of the intermittent motor is equipped with a turntable, and the end of the side wall of the turntable away from the center of the circle is equipped with a rotating The side wall of the sliding installation box close to the intermittent motor side is rotatably connected with a connecting rod, and the connecting rod is rotatably connected with the rotating rod, and the side wall of the sliding installation box far away from the intermittent motor is symmetrically installed with There are two fixing seats, and an installation cavity is opened inside the sliding installation box. The invention has exquisite structure, is easy to operate, and skillfully realizes the traction type continuous cutting of the workpiece, avoids the interference between the workpiece and the driving mechanism, and will significantly improve the efficiency of the cutting work.

Owner:HEFEI YAOSHI TONGHUI TECH CO LTD

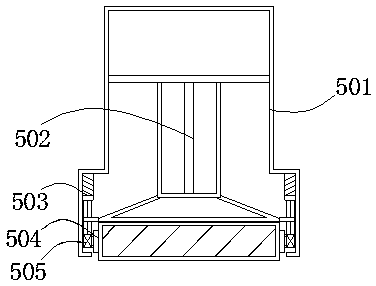

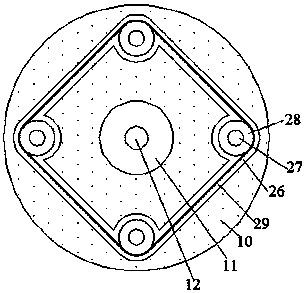

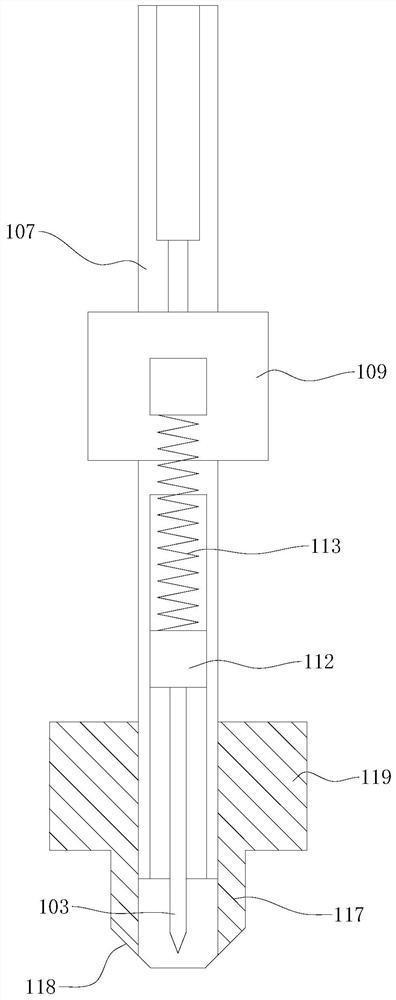

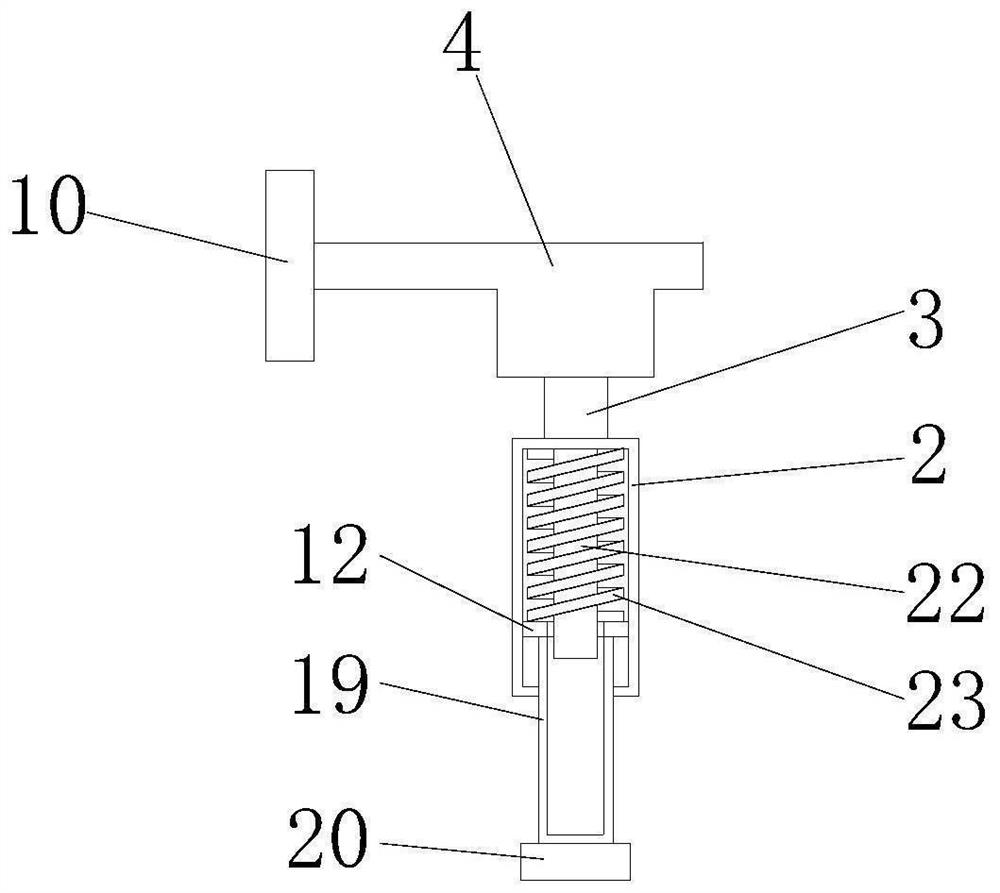

Ceramic tile rapid drilling device used for civil engineering

PendingCN109531833AQuick drillImprove work efficiencyWorking accessoriesStone-like material working toolsPunchingSlide plate

The invention relates to the technical field of building equipment, and discloses a ceramic tile rapid drilling device used for civil engineering. The ceramic tile rapid drilling device comprises a base, a supporting pillar is fixedly connected to one side of the top end of the base and movably sleeves a position-adjusting screw rod, the position-adjusting screw rod is located at the bottom end inside the supporting pillar and fixedly connected with a limiting sliding plate, and the bottom end of the limiting sliding plate is fixedly connected with one end of a support spring. According to theceramic tile rapid drilling device used for civil engineering, two symmetrically distributed drill bits are arranged, a driving motor is adopted for driving a rotating barrel to rotate to drive the drill bits on the two sides of an installing plate to rotate around the center of the rotating barrel at high speed, ceramic tiles below the installing plate are drilled to form round holes, after drilling is conduced by a certain depth and scratching is conducted, a punching rod is pressed to punch the ceramic tiles to form the round holes, accordingly, round hole drilling can be rapidly conductedon one part of each ceramic tile, and the working efficiency of decoration engineering with needed round hole face tile regions of bathrooms, kitchens and others is improved.

Owner:褚梦佳

Steel plate cutting tool

InactiveCN105500044APrecise cuttingImprove cutting work efficiencyPositioning apparatusMetal-working holdersSteel platesAutomatic control

The invention discloses a steel plate cutting tool which comprises a steel plate locating working platform, an inverted-L-shaped support frame arranged on the steel plate locating working platform, a moving guide rail arranged at the horizontal part of the inverted-L-shaped support frame, and a cutting device arranged on the moving slide rail, wherein the steel plate locating working platform comprises a base, support plates arranged on the base, and an upper guide rail and a lower guide rail oppositely arranged on the upper end surfaces of the support plates; the two ends of two locating rods are respectively connected on the upper guide rail and the lower guide rail in a sliding manner; clamps are oppositely arranged on the two locating rods; and a lifting cylinder, an electric cutting machine, sliding driving mechanisms of the two locating rods, and a sliding driving mechanism of the cutting device are connected with a controller. According to the steel plate cutting tool, a steel plate is accurately located through adopting the steel plate locating working platform, so that the fixation of the steel plate is guaranteed during the cutting process, and the cutting is guaranteed to be accurate; and besides, the automatic control is carried out through adopting the controller, so that the cutting efficiency is improved.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

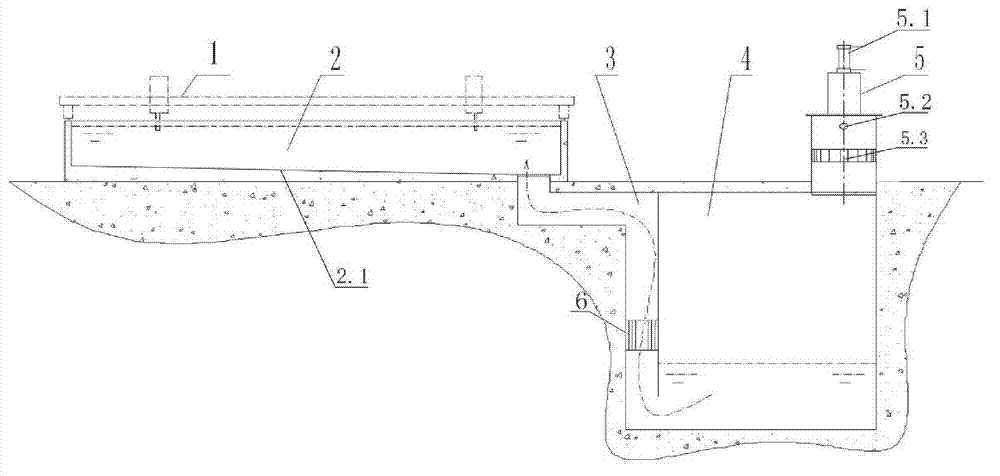

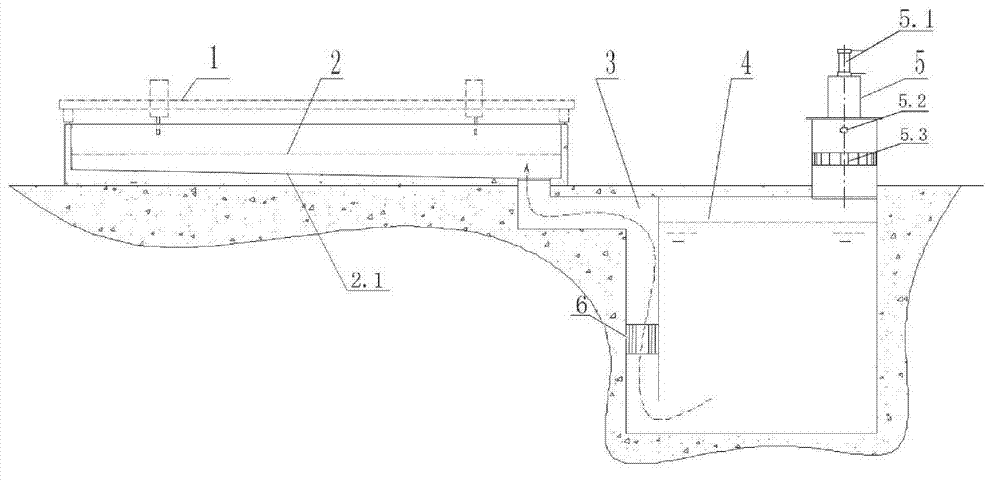

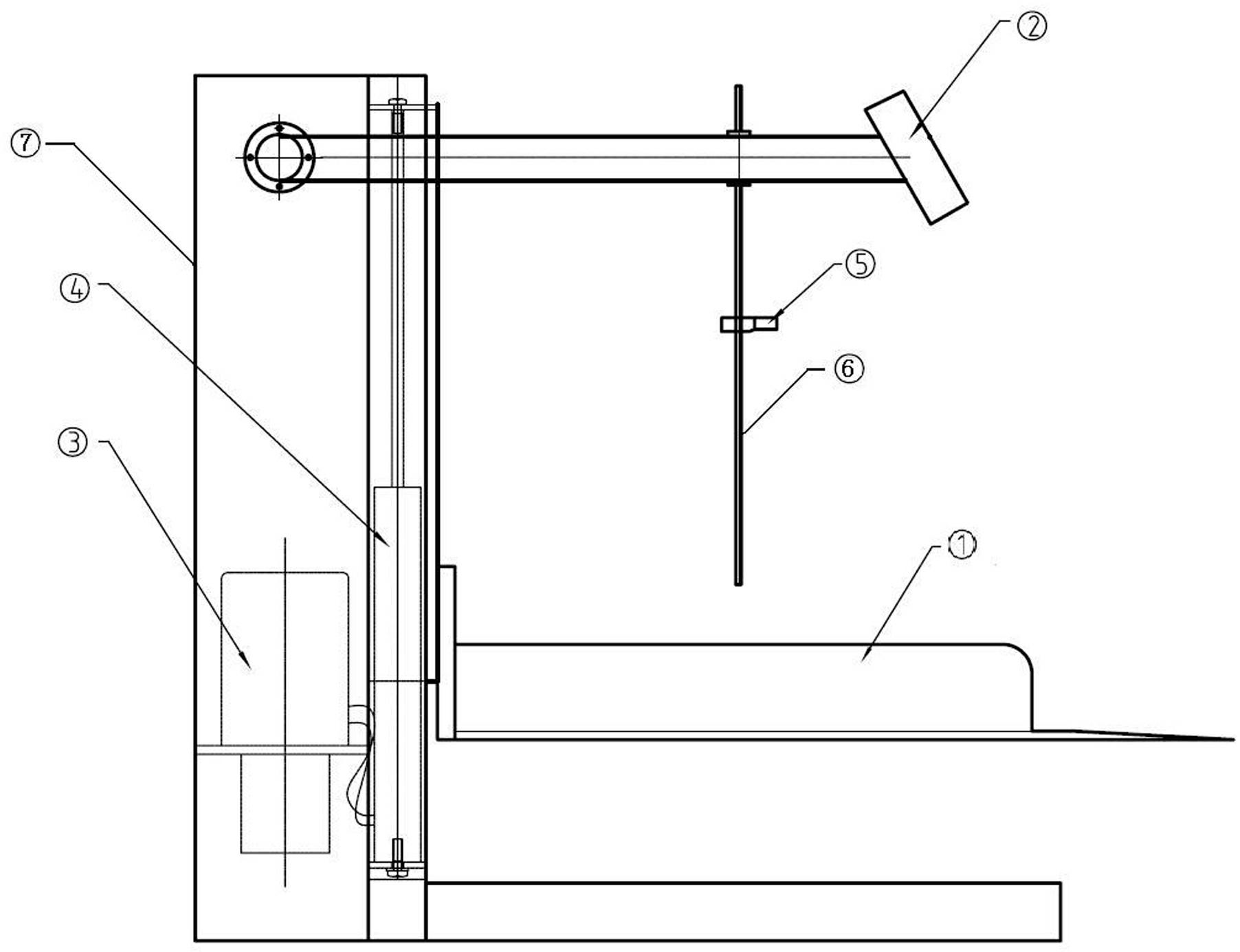

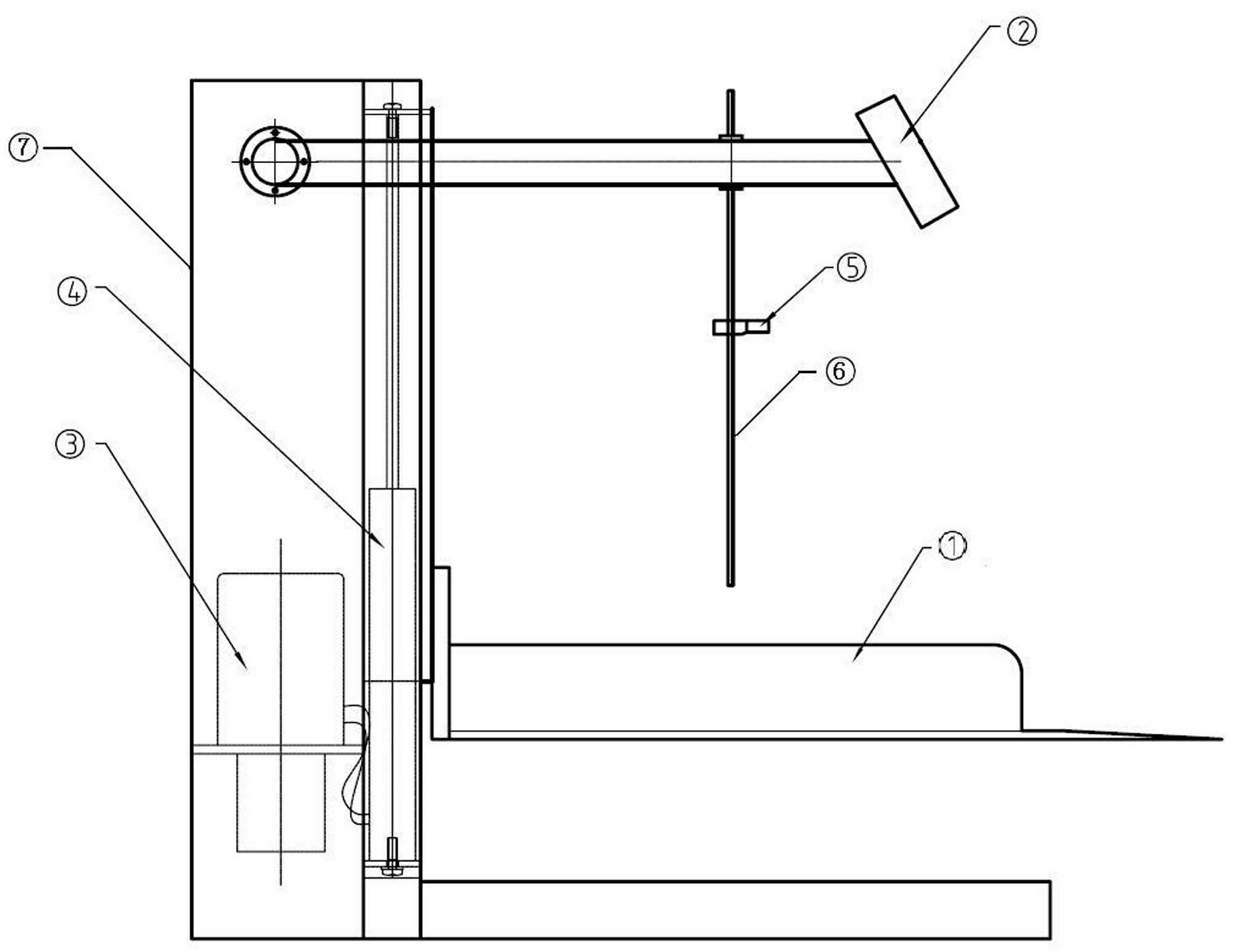

Numerical control plasma underwater cutting device

InactiveCN102728940ASimple structureImprove cutting work efficiencyPlasma welding apparatusUnderwaterMarine engineering

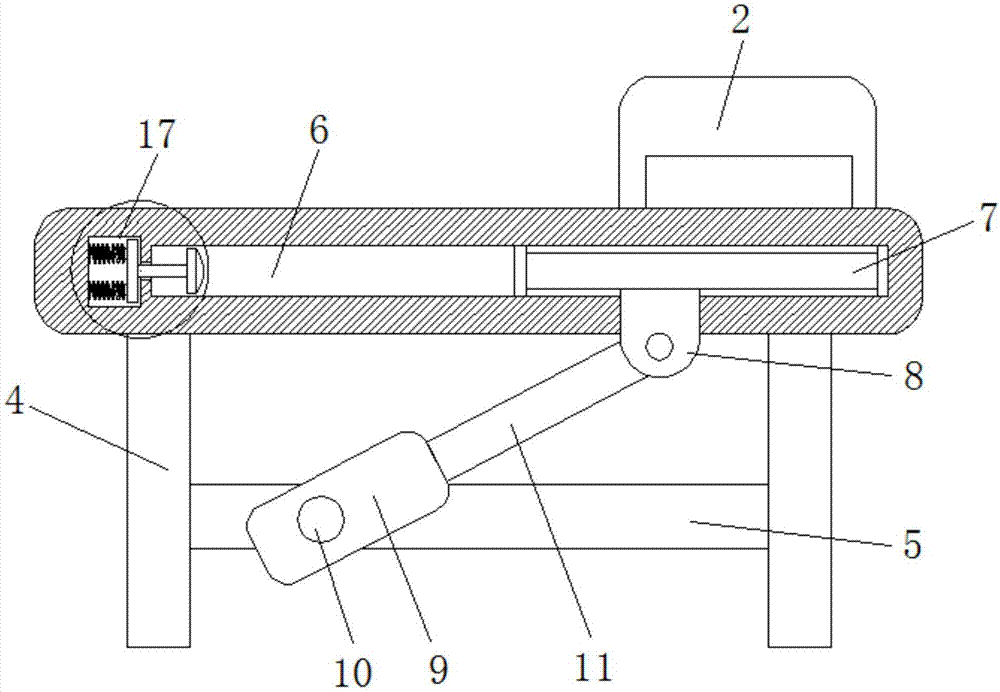

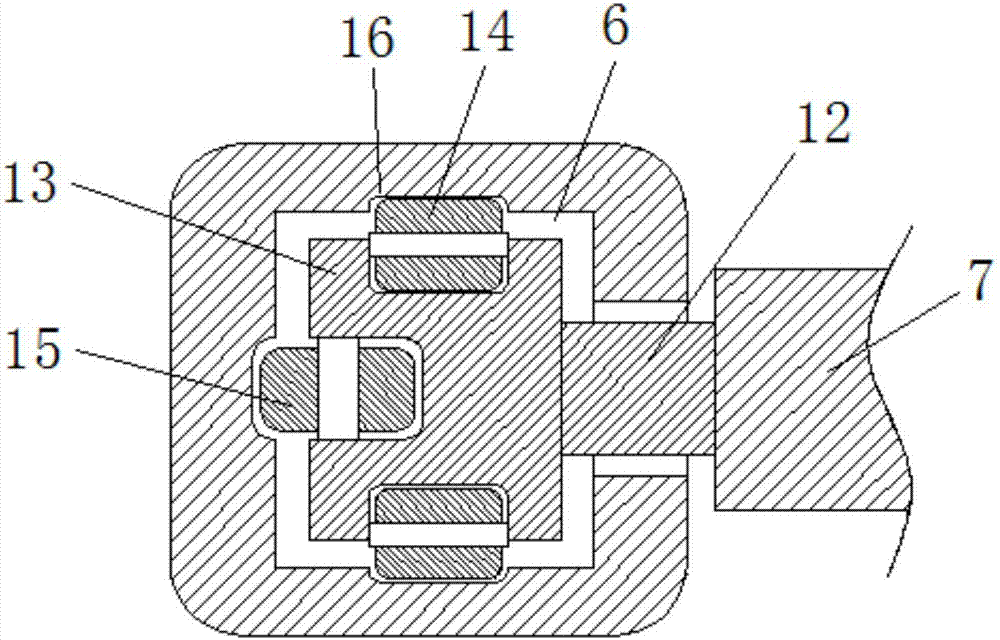

The invention discloses a numerical control plasma underwater cutting device, which comprises a numerical control plasma cutter (1), and a water pond (2). The numerical control plasma cutter (1) is arranged at the top of the water pond (2). The cutting device is characterized in that the water pond (2) is connected with a water tank (4) via a pipe (3), the top of the water tank (4) is lower than the bottom of the water pond (2), the water tank (4) is connected with a control pipe (5), the control pipe (5) includes an air compressor, an air inlet valve and a vent valve, and the control pipe (5) is connected with an operation board. The inventive device is simple in structure, and can rapidly raise or drop water level and improve cutting work efficiency.

Owner:中船桂江造船有限公司

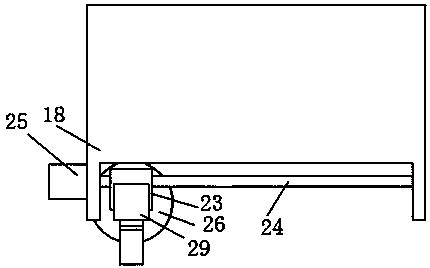

Edge sealing band cutting-off device

ActiveCN104552375ARealize automatic controlImprove cutting work efficiencyMetal working apparatusEngineeringElectrical and Electronics engineering

The invention discloses an edge sealing band cutting-off device which comprises a cutter, a cutter driving unit, a detection unit, a control unit and a sliding unit, wherein the detection unit is used for outputting a first alignment signal to the control unit when detecting a position to be cut off for the first time and outputting a second alignment signal to the control unit when detecting the position to be cut off for the second time in one cutting-off operation period; the control unit is used for outputting a conveying stop command to a gypsum board conveying table and outputting a start command to the sliding unit when receiving the first alignment signal and outputting a sliding stop command to the sliding unit and outputting a conveying cutting-off command to the cutter driving unit when receiving the second alignment signal. The edge sealing band cutting-off device can be applied to the technical field of edge sealing of a gypsum board, can realize the effect that the device can be automatically regulated to be aligned with the cut-off position, and realizes the accurate and rapid cutting-off operation; meanwhile, after cutting-off operation is completed, a residual edge sealing band is controlled within a range of 2mm.

Owner:BEIJING NEW BUILDING MATERIAL

Automatic elevation machine for paper cutter

The invention relates to an automatic elevation machine for a paper cutter, which is matched with the paper cutter to use, and comprises a machine body, an elevation platform which is arranged on the machine body, a hydraulic power device for driving the elevation platform to move and a photoelectric detection device for detecting the elevation height as well as a control operation panel for controlling the running of the entire machine, wherein both the hydraulic power device and the photoelectric detection device are connected with the control operation panel through a circuit, and the control operation panel is provided with a pressing operation switch. The automatic elevation machine can be matched with the paper cutter to use, the elevation height of the automatic elevation machine is adjusted according to the real requirement, the elevation machine automatically ascends to a set position after a paper pile is withdrawn, the elevation machine automatically descends to return on the original position after the paper pile is completely used, so the paper pile can be automatically maintained at a preset height position, the paper is convenient to load or unload, the heavy operation for moving the paper pile up and down can be avoided, the cutting work efficiency can be improved, and the potential of the program-controlled paper cutter can be adequately played; and the labor can be saved, the labor intensity can be reduced, the work efficiency can be greatly improved, and the automatic elevation machine has a simple structure, is safe and reliable and is convenient to operate.

Owner:YALONG PAPER PRODS KUSN

Mask paper anti-folding cutting device for mask processing

The invention discloses a mask paper anti-folding cutting device for mask processing and relates to the technical field of mask processing. The mask paper anti-folding cutting device comprises a mainbody and an anti-folding mechanism; a carrying mechanism is disposed at the bottom end of the inner side of the main body; the anti-folding mechanism is arranged on one side of the top of the carryingmechanism; the inner side of the anti-folding mechanism comprises a shell; a scraper blade is movably disposed at the top end of the interior of the shell; and second electric push rods are fixedly installed on the two sides of the inner wall of the shell. The mask paper anti-folding cutting device for mask processing has the beneficial effects that by arranging a pressing barrel, the second electric push rods, the shell, a first roller and a second roller, the pressing barrel and the shell form a lifting structure through the second electric push rods, when mask paper slides along a carryingtable, the mask paper passes through the anti-folding mechanism, the mask paper which is winded and tightened through the first roller and the second roller can be spread under the pressing action ofthe pressing barrel, and thus the phenomenon of folding of the mask paper is effectively prevented.

Owner:DONGGUAN XIANGFEI INTELLIGENT EQUIP TECH CO LTD

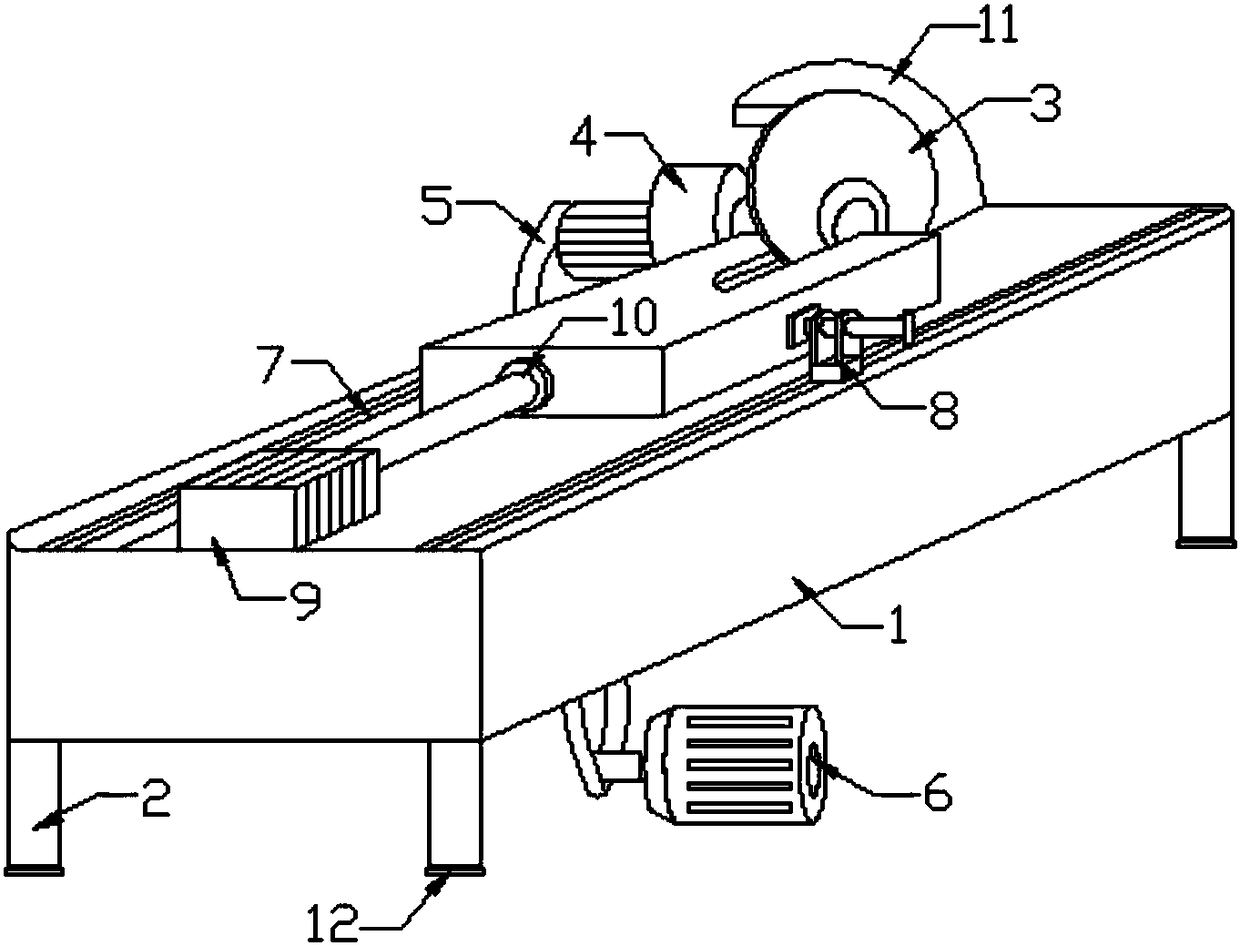

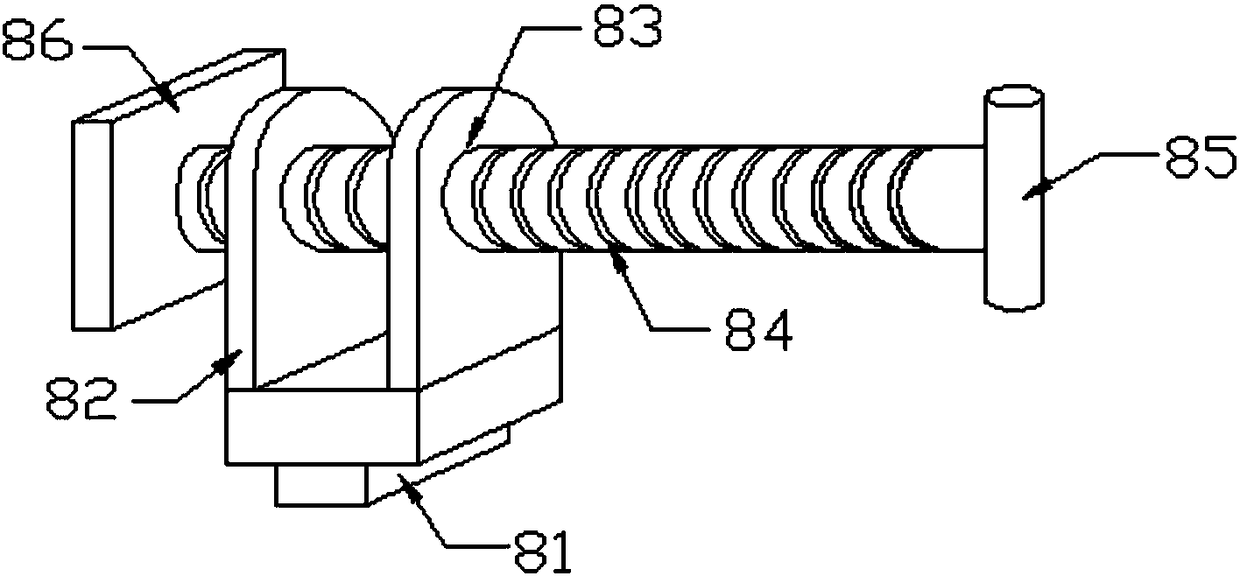

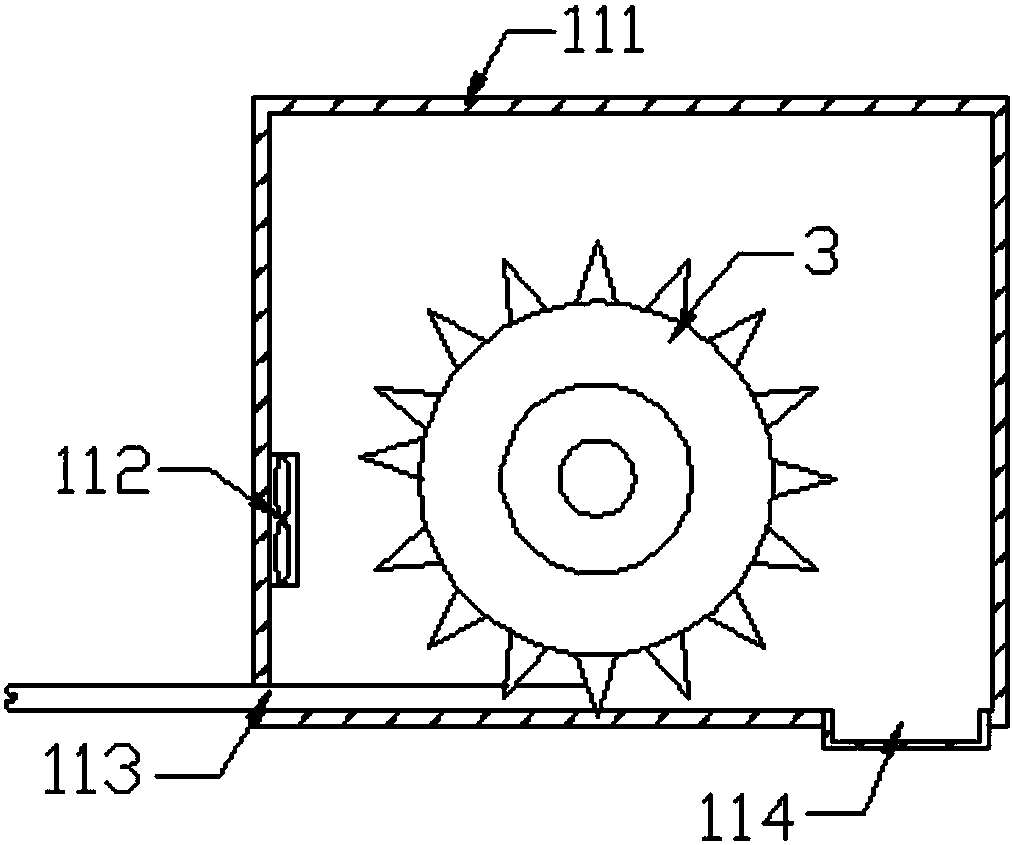

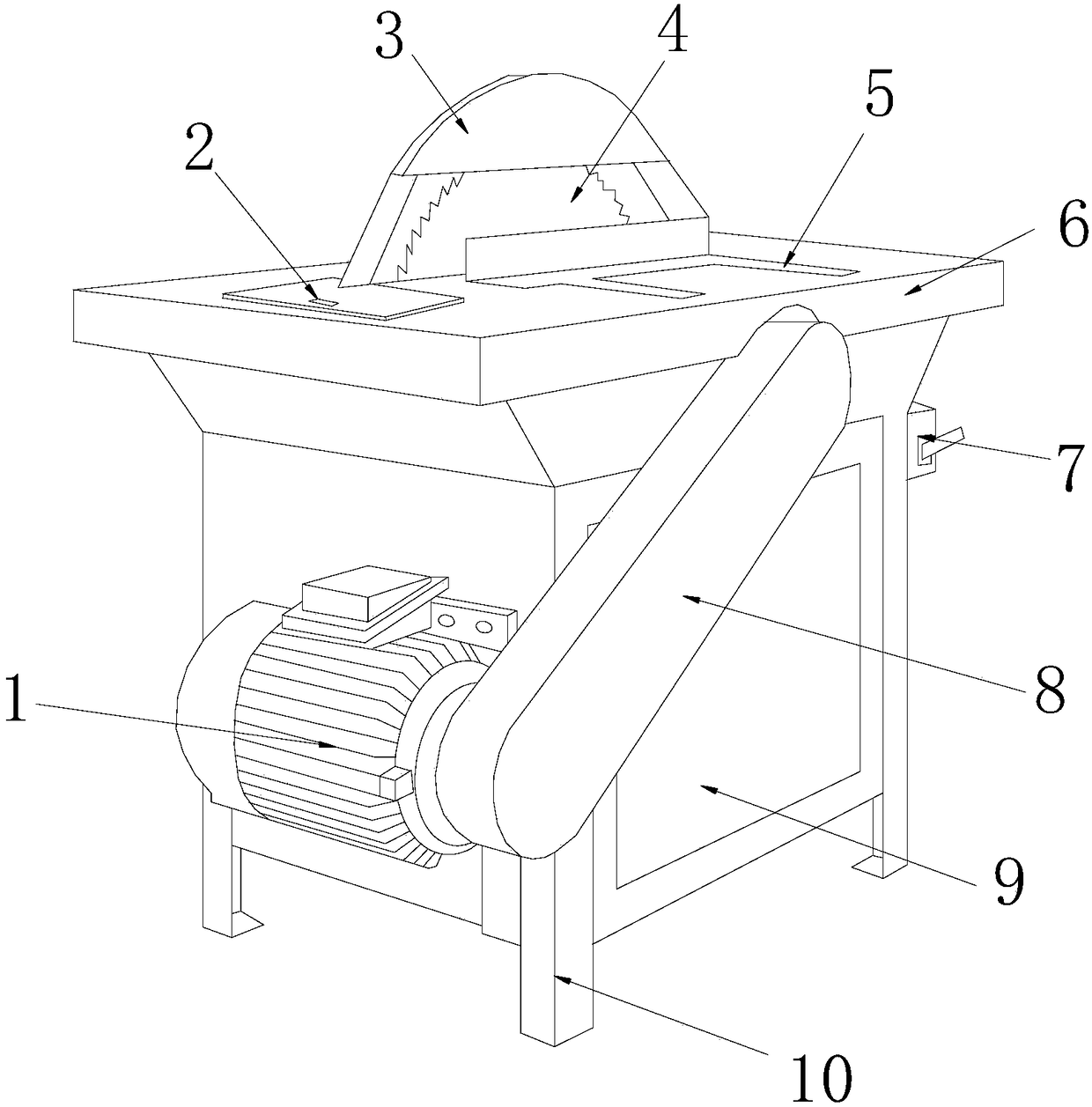

Plank cutting machine for furniture processing

InactiveCN108393968AImprove cutting work efficiencyProtect your healthCircular sawsControl switchPower transmission

The invention discloses a plank cutting machine for furniture processing. The plank cutting machine structurally comprises a cutting power machine, an induction material pushing device, a saw blade protection shell, a cutting saw blade, a chip inlet groove, an operation supporting platform, a power supply control switch, a power transmission belt, an equipment supporting machine frame and supporting protection stand columns. The rear end of the cutting power machine is rotationally arranged in the middle of the front end of the equipment supporting machine frame. The four ends of the outer surface of the equipment supporting machine frame are welded to the outer surfaces of the supporting protection stand columns. The plank cutting machine has the beneficial effects that the plank cuttingmachine is additionally provided with the induction material pushing device, thus, when the plank cutting machine is used for furniture plank cutting machining operation, planks can be pushed in timefor cutting in real time, when wood with small cutting size or length and width is cut by the plank cutting machine, the cutting operation efficiency of operators can be improved, the physical healthof the operators can be further protected, and the plank cutting machine is practical.

Owner:湖州南浔美瑞鑫家具有限公司

Steel wire cutter for building

The invention discloses a steel wire cutter for building. The steel wire cutter comprises a cutting machine body, wherein a conveying hole is formed in the cutting machine body, a steel wire is arranged in the conveying hole, a conveying device is arranged on the outer side of the conveying hole, the conveying device comprises four conveying wheels, the conveying wheels are in power connection through a transmission device, and a clamping and adjusting device is arranged on the right side of the conveying device, and can drive the conveying wheels to move oppositely. According to the steel wire cutter, the steel wire is conveyed, clamped and fixed through the four conveying wheels of a annular array, so that the position of the steel wire is stable in a cutting process, in the cutting process, a cutting knife rotates in the circumferential direction of the steel wire for annular cutting, the cutting knife rotates on the axis of the cutting knife and rotatably cuts the steel wire alongthe surface to the interior of the steel wire, the cutting speed is increased, the cutting working efficiency is high, and a counting device is arranged in the cutter.

Owner:DONGYANG LUOSU ELECTRONICS TECH CO LTD

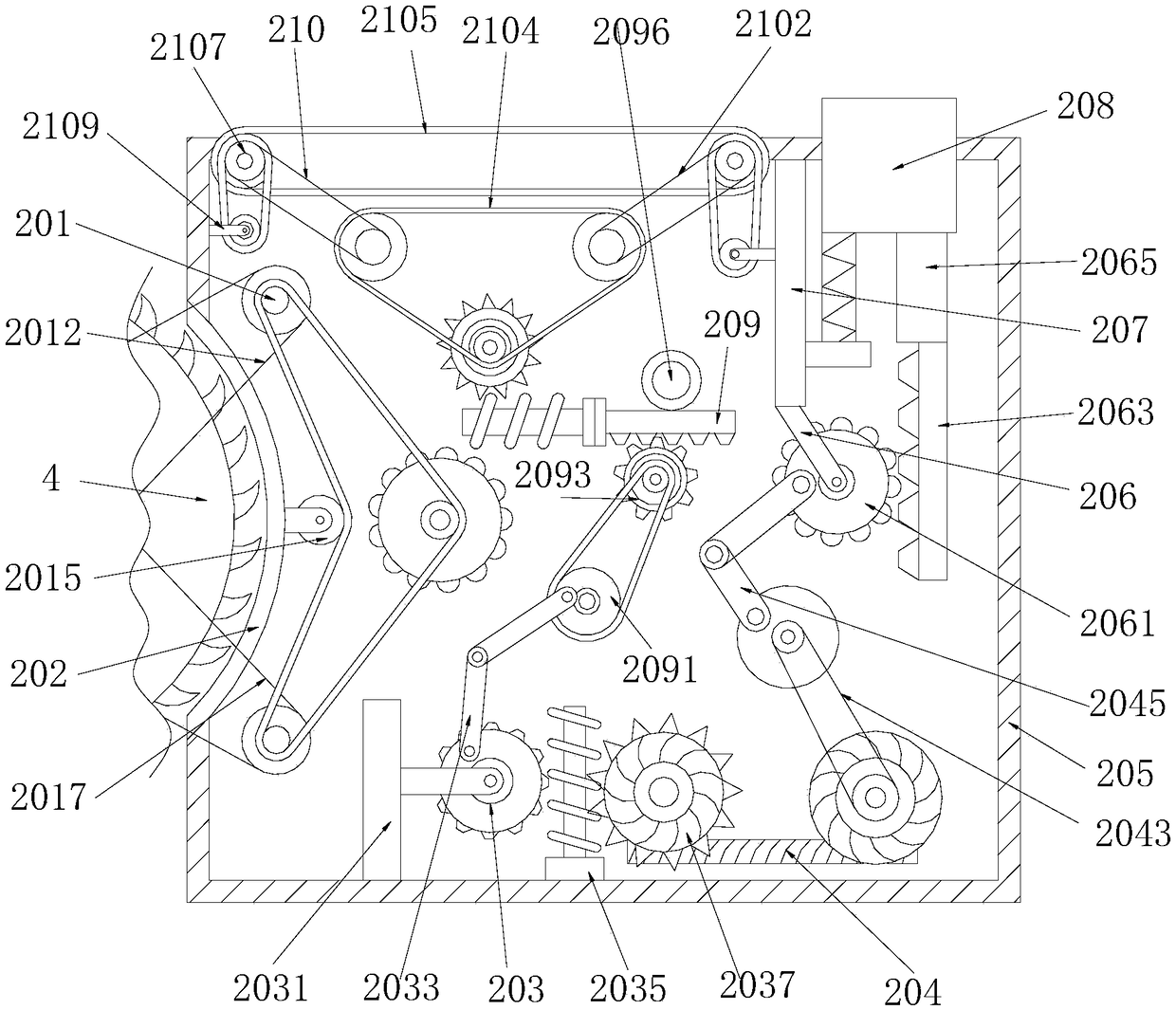

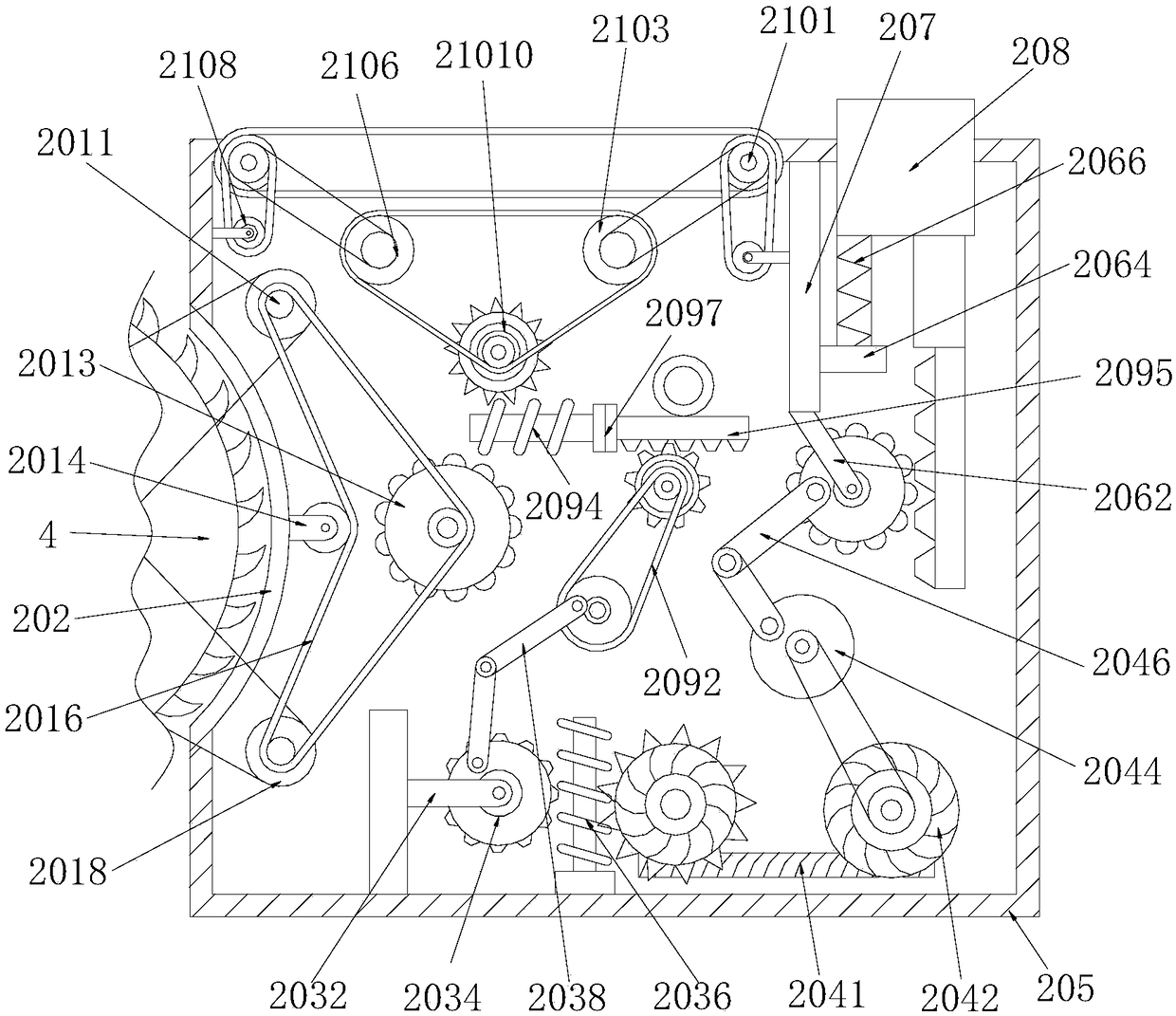

Straw particle forming device

InactiveCN107855075AImprove cutting work efficiencyExpand the scope of useBiofuelsSolid fuelsEngineeringSieve

The invention relates to a straw particle forming device, comprising a storage bin; a hydraulic cylinder is arranged in the center of the upper surface of the storage bin; the hydraulic cylinder is connected with a pushing plate in the storage bin by means of a hydraulic telescopic rod; feed pipes are respectively and symmetrically arranged at the two sides of the outer surface wall of the storagebin; the inner surface wall of each feed pipe is rotatablely connected with a one-way valve rod; the outer surface wall of the bottom of the storage bin is connected with a filter sieve plate in a buckling way by means of a clamping pin; two support frames are respectively arranged at the two sides of the storage bin, and a reinforcing block is welded on the inner surface wall of each support frame; the upper surface of each reinforcing block is provided with a balance plate; two limiting rods are respectively welded at the two sides of the lower surface of the filter sieve plate, and each limiting rod is internally provided with a bearing; a transmission rod is arranged in each bearing, and a cutting knife is arranged at the inner side of each transmission rod; two oil injection holes are respectively formed at the two sides of each bearing. The straw particle forming device is simple and reasonable in integral structural design, stable in connection between parts, flexible as well as convenient and fast in operation, and has higher practicality.

Owner:咸丰隆态生物科技有限公司

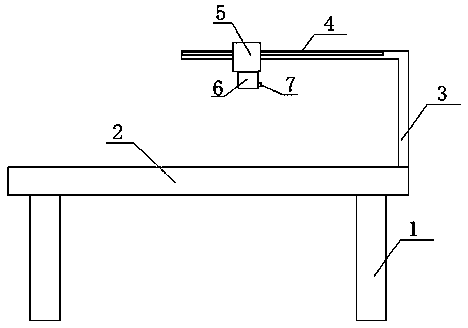

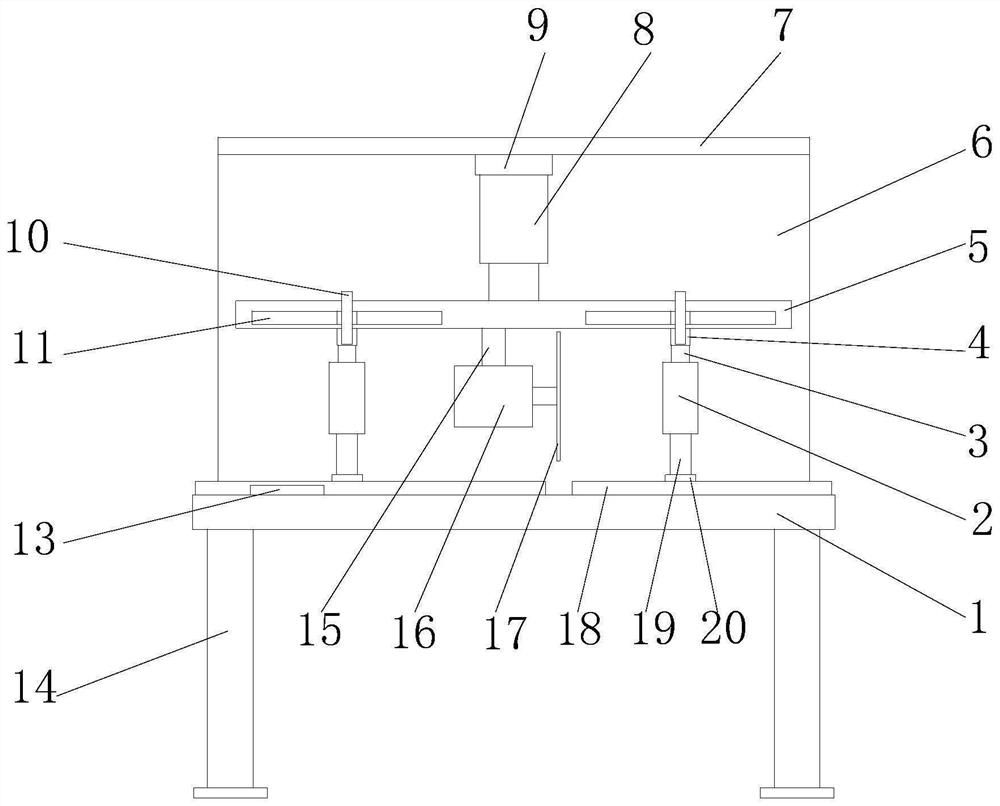

Feeding mechanism of cutting machine

InactiveCN107351169AAccelerate the rate of reciprocating motionReduce the necessary timeMetal working apparatusHydraulic cylinderReciprocating motion

The invention discloses a feeding mechanism of a cutting machine. The feeding mechanism comprises a working table, a cutting machine head, a rectangular hollow, supporting rods, a feeding plate and hydraulic cylinders, the rectangular hollow is formed in the middle of the working table, the cutting machine head is fixedly arranged at one end of the upper portion of the working table, sliding grooves are formed in the two sides of the part, in the rectangular hollow, of the working table, connecting rods are fixedly arranged on the two sides of the feeding plate respectively, the other ends of the connecting rods extend into the inner sides of the sliding grooves respectively, sliding blocks are fixedly arranged at the ends of the connecting rods, telescopic shafts of hydraulic cylinders are connected with hinged bases on the bottom surface of the feeding plate in a rotating mode respectively, and a buffering mechanism is arranged on the inner side of the end, away from the cutting machine head, of the working table. The sliding grooves are formed in the working table, the hydraulic cylinders can drive the feeding plate to reciprocate during stretching and retracting, the rate of reciprocation movement is increased for the feeding plate, necessary time for cutting work is shortened, and the working efficiency in cutting is effectively improved.

Owner:苏州圣凡自动化科技有限公司

Gilding film cutting machine

PendingCN113858317AExtended service lifeReduce frictionMetal working apparatusElectric machineryStructural engineering

The invention provides a gilding film cutting machine comprises a roller, a motor, a support frame and a blade, wherein the motor is fixed to the support frame; the roller is rotationally connected with the support frame; the blade is installed on the support frame; the motor is in transmission connection with the roller; the roller is horizontally arranged; the two ends of an axial guide rail are respectively and fixedly connected with a first vertical plate and a second vertical plate; an axial sliding seat is arranged on the axial guide rail; an axial sliding seat is in sliding connection with the axial guide rail in the direction parallel to the roller; the radial guide rail is vertically arranged; the upper end of the radial guide rail is fixedly connected with the axial sliding seat; a radial sliding seat is arranged on the radial guide rail; and the radial sliding seat is in sliding connection with the radial guide rail in the vertical direction; the blade is vertically arranged and is connected with the radial sliding seat; and a plurality of avoiding grooves are formed in the outer wall of the roller, are arranged around the central axis of the roller, and are arranged at equal intervals in the axial direction of the roller. When the blade cuts off the gilding film, the blade is inserted into the avoiding groove, friction between the blade and the outer wall of the roller is avoided, and the service life of the blade is prolonged.

Owner:扬州海克赛尔新材料有限公司

Sponge block cutter

InactiveCN106956303AImprove cutting work efficiencyAchieve fixationMetal working apparatusHydraulic cylinderControl engineering

The invention provides a sponge block cutter, and relates to the field of block cutting mechanical equipment. The sponge block cutter comprises a worktable, a work base, a push rod, a scroll wheel and a hydraulic cylinder sliding device, wherein a groove is formed in the worktable; the left side of the groove is provided with a turning plate and a sponge block outlet while the right side of the groove is provided with a sliding plate; the sliding plate is fixedly connected with the right side of the groove by an extensible rod; the worktable is connected with the sliding groove positioned on the work base by sliding blocks in a sliding manner; the hydraulic cylinder sliding device is connected with a sliding groove positioned on the inner side of each baffle plate by sliding blocks positioned on the two sides of the hydraulic cylinder sliding device; the sponge block outlet penetrates through the left-sided baffle plate; the hydraulic cylinder is connected with the sliding groove positioned on the hydraulic sliding device by the one-sided sliding block in a sliding manner; the lower part of the hydraulic cylinder is provided with a connection device; the hydraulic cylinder is fixedly connected with a cutter by a connection device; and the push rod is arranged in front of the work base. The sponge block cutter has the advantages of simple structure, high working efficiency, and capability of reducing production cost and freely moving.

Owner:安徽华诚海绵制品有限公司

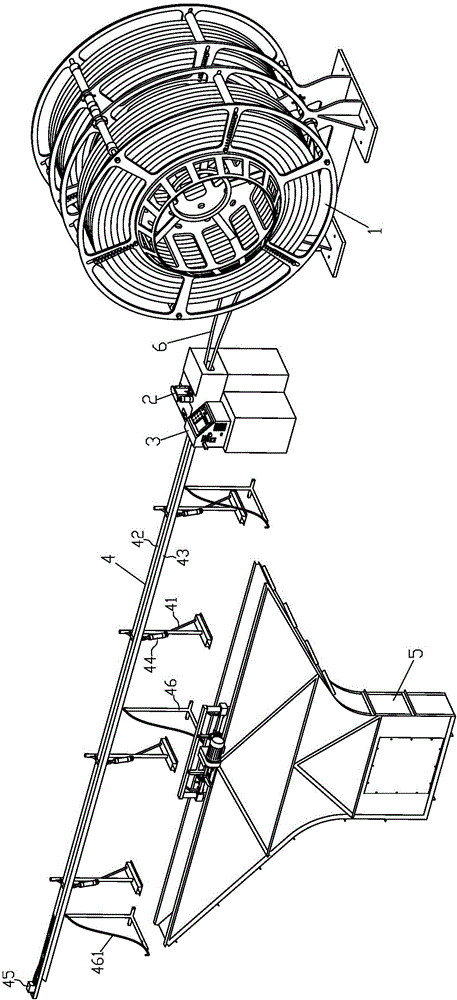

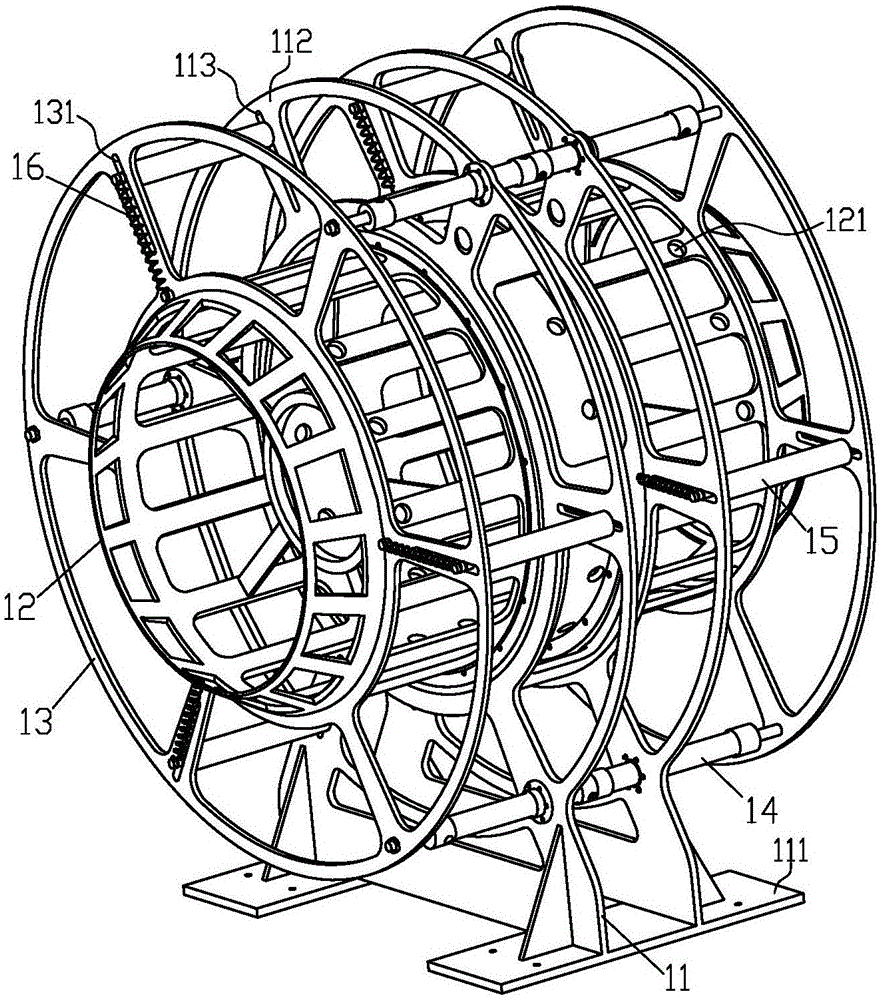

The automatic double anchor cable blanking bending all-in-one machine

ActiveCN106334943AImprove hoisting efficiencyEasy to fixOther manufacturing equipments/toolsHydraulic motorEngineering

The invention discloses an automatic double anchor cable blanking bending all-in-one machine, which comprises a horizontal pay-off disc, a traction device, a cutting device, a discharging device and a bending device. The horizontal pay-off disc is a horizontal pay-off disc with double structure arranged horizontally on the axis. The traction device and the cutting device are mounted on the same frame. The cutting device is located at the rear end of the traction device and is arranged close to the discharging device. The traction device is driven by the hydraulic motor, the cutting of the anchor cable is completed by the ion cutting gun, the opening of the sealing plate of the discharging device is driven by the discharging cylinder, and the length of the anchor cable to be discharged is defined by the stroke controller. The cable after discharging is bent by the bending device. In that invention, the two discs of anchor cables can be simultaneously carried out the discharging operation, the production efficiency is high, the traction, the cutting and the discharge of the anchor cable can be completed automatically, the single person can operate, the labor intensity is low, the structure is small, the device occupying space is small, the safety is high, the operation and maintenance is simple, and the device can be used for discharging and bending the anchor cable.

Owner:贾培英

Lamp strip cutting equipment for LED lamp production

InactiveCN112372694APrevent deviationFast cutting speedMetal working apparatusElectric machineEngineering

The invention discloses lamp strip cutting equipment for LED lamp production. A vertical plate is fixedly mounted at the top of a worktable; a top plate is fixedly mounted at the top of the vertical plate; a mounting base is fixedly mounted at the bottom of the top plate; an electric control telescopic rod is fixedly mounted in the mounting base; a lifting plate is fixedly mounted at an telescopicend of the electric control telescopic rod; a first connecting rod is fixedly mounted at the bottom of the lifting plate; an electric control motor is fixedly mounted at one end, far from the liftingplate, of the first connecting rod; and a cutter is fixedly mounted at a driving end of the electric control motor. Through the cooperation among the electric control telescopic rod, the electric control motor, the cutter and a pressing device, the mechanical cutting of LED lamp strips can be realized; in the cutting process, the pressing device firstly presses the LED lamp strips to fix the LEDlamp strips, so that the deviation phenomenon of the LED lamp strips in the cutting process is prevented; the cutting speed is fast; and only one worker is needed to operate, so that the cutting efficiency is improved, and the labor cost is saved.

Owner:CHONGYI JINGYI LIGHTING PROD CO LTD

Wood die comparison cutting device

InactiveCN109291157AStable positionWill not affect the cutting effectProfiling/shaping machinesEngineeringWood cutting

The invention discloses a wood die comparison cutting device. The wood die comparison cutting device comprises a workbench internally provided with an installing cavity. A partition plate is fixedly connected to the middle portion of the top face of the workbench. First rotation shafts are symmetrically arranged on the two sides of the partition plate. The two first rotation shafts are rotationally connected with a workbench table plate. The bottom ends of the two first rotation shafts penetrate through the workbench and extend into the installing cavity. The extending ends of the two first rotation shafts are fixedly in cup joint with driven gears. A first limiting plate and a second limiting plate are arranged at the two ends of a second lifting plate capable of freely ascending and descending, the two limiting plates can freely move in the opposite direction or the reverse direction, the cutting position of to-be-treated wood is determined according to the sample plate wood size, accordingly, the high-low and left-right positions of a cutting blade are flexibly adjusted, and cutting size precision maximization is guaranteed. The wood die comparison cutting device can conduct wood cutting with high-degree automation, the high error rate of manual operation is avoided, the work efficiency is improved, industrial production can be better enlarged, and the qualification rate canbe better increased.

Owner:华琳琳

Locating device of laser cutting platform

InactiveCN103567644AHigh positioning accuracyCompact structureLaser beam welding apparatusEngineeringLaser cutting

The invention relates to a locating device of a laser cutting platform. The locating device is characterized by comprising an air cylinder, a fixing base and a locating shaft. The fixing base is installed on the side of a rack, the air cylinder is installed on the outer side face of a locating base, a through hole is formed in the center of the fixing base, the locating shaft is arranged in the through hole and can axially slide, the rear end of the locating shaft is connected with the end of a piston rod of the air cylinder, the front end of the locating shaft is inserted into a locating hole in the cutting platform, and then the cutting platform is located. The locating device is simple and compact in structure, attractive in appearance, convenient to install, maintain and adjust, and accurate and reliable in locating, time and labor are saved, locating accuracy of the cutting platform can be improved, and cutting work efficiency is improved.

Owner:无锡洲翔成套焊接设备有限公司

Circuit board cutting device for electronic product production convenient to adjust cutting position

InactiveCN108943098AImprove cutting work efficiencyImprove cut qualityMetal working apparatusWorking environmentEngineering

The invention belongs to the technical field of electronic products, in particular to a circuit board cutting device for electronic product production convenient to adjust a cutting position, and solves the problem of complex structure, low stability, incapability of conveniently adjusting the cutting position and incapability of preferably meeting requirements in a traditional circuit board cutting device for electronic product production. The device comprises a base; the outer wall of the top of the base is connected with a collecting box through bolts; two connecting frames, symmetrically arranged, are welded at the top of the outer wall of one side of the collecting box; and the same rotating shaft is welded on the outer walls of one opposite sides of the two connecting frames. The device can adjust the cutting position on circuit boards rightly under a cutting machine, effectively improves the circuit board cutting efficiency in electronic product production, is more stable in clamping of the circuit boards, improves the worker efficiency and the circuit board cutting quality, prevents flying dust in production workshops, and effectively improves the working environment of thecircuit board cutting work.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

Feeding and cutting device for steel wire rope

The invention discloses a feeding and cutting device for a steel wire rope and relates to the technical field of steel wire rope cutting devices. The feeding and cutting device comprises a workbench,a cutting assembly, a limiting roll and a winding roller. The workbench is in rotary fit with the cutting assembly and the limiting roll. The winding roller is in rotary fit with the workbench. A motor is fixedly connected to the top of each support pillar. A lead screw is fixedly connected between the bottom face inside each mounting groove way and the output end of the corresponding motor. A connecting rod is in threaded transmission connection with the lead screws. The cutting assembly comprises an inner cutting roll and an outer roll sleeve. The inner cutting roll is in rotary fit with theouter roll sleeve and the connecting rod. According to the feeding and cutting device, the lead screws are driven by the motors to rotate so that the distance between the cutting assembly and the limiting roll can be adjusted; a guiding adjustment plate is driven by electric extending-and-contracting rods to tightly press the steel wire rope; the steel wire rope is cut off through the cutting assembly; a handle is rotated to wind the steel wire rope; and the steel wire rope is effectively prevented from being loosened or disordered.

Owner:合肥巨步机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com