Straw particle forming device

A particle forming and straw technology is applied in the field of straw particle forming devices, which can solve the problems of reducing the working range of the device, reducing the practicability, inconvenient disassembly, etc., and achieving the effect of improving the cutting work efficiency and increasing the use range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

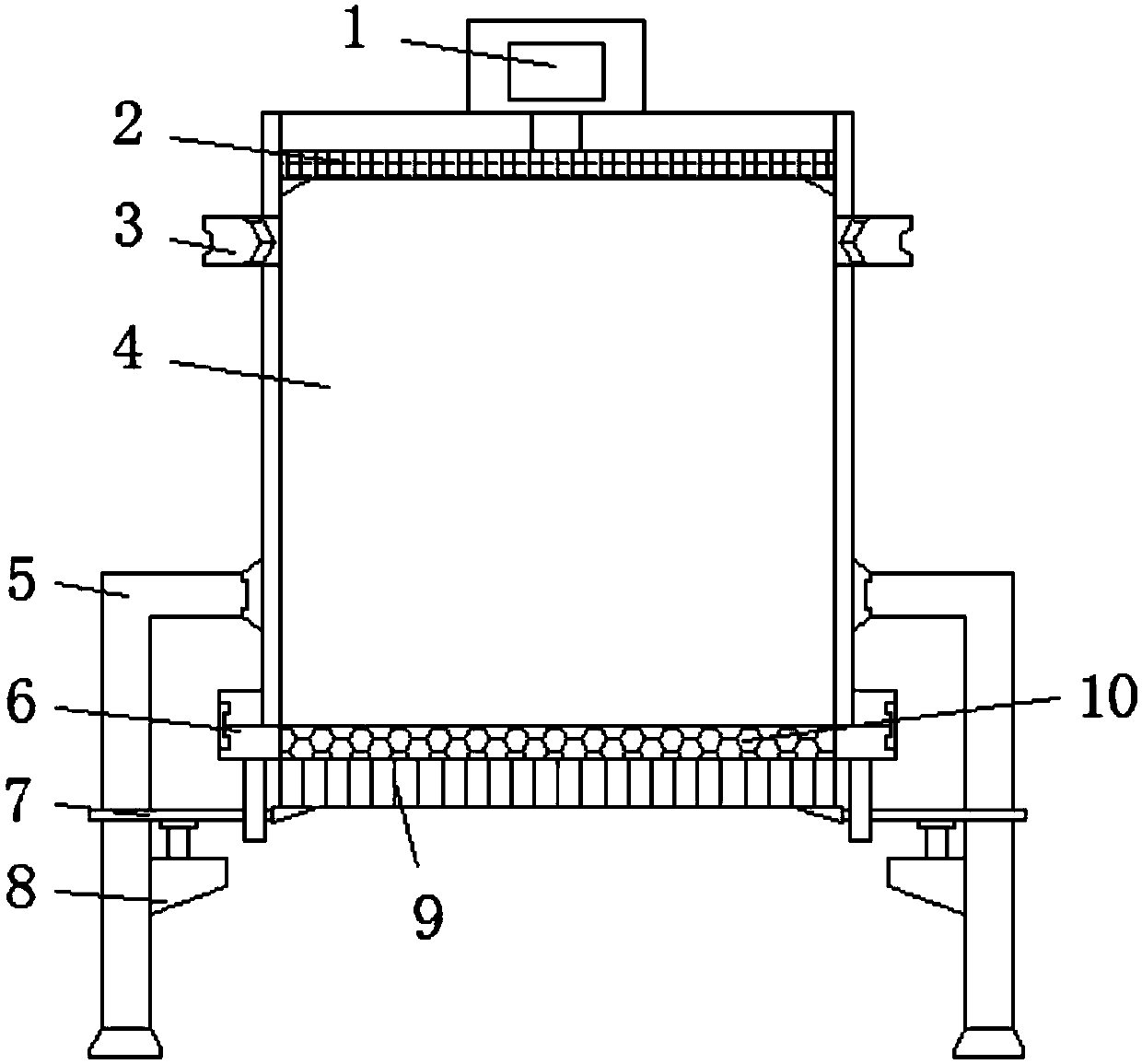

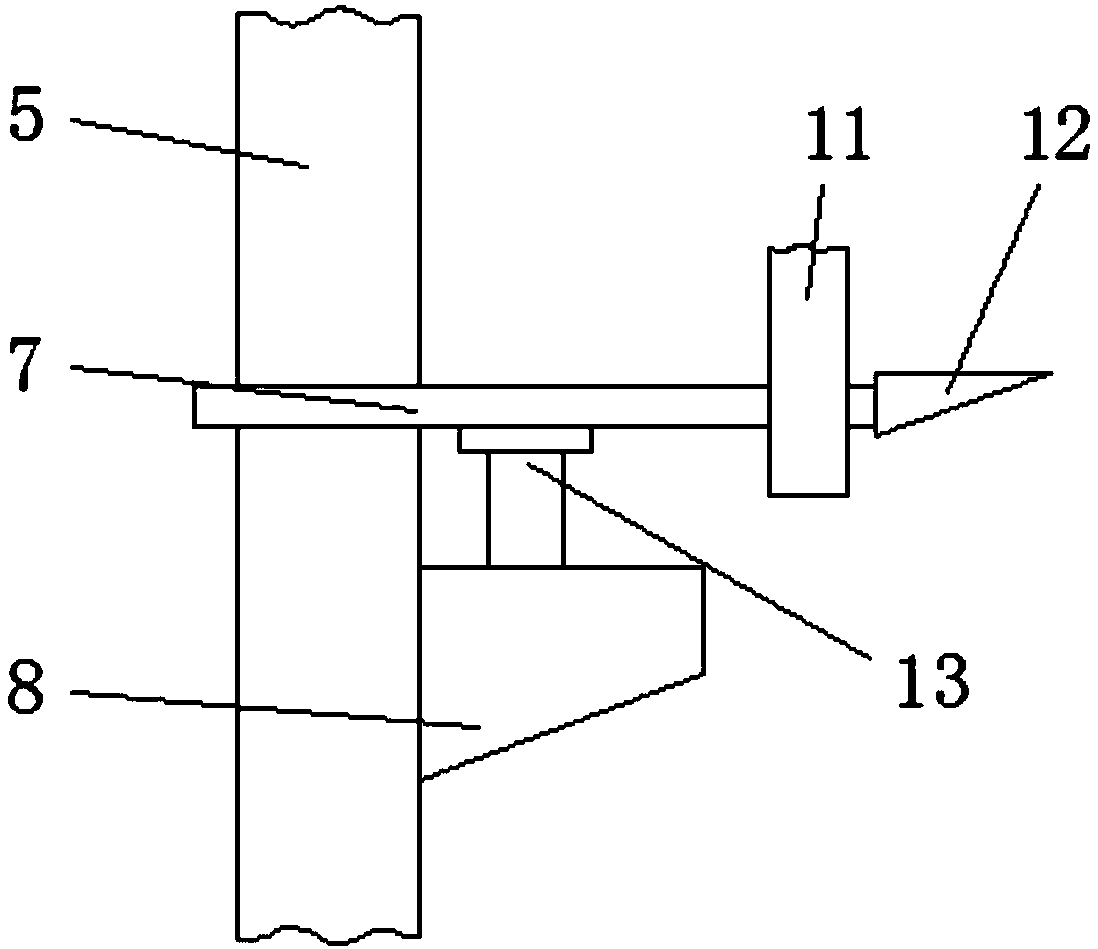

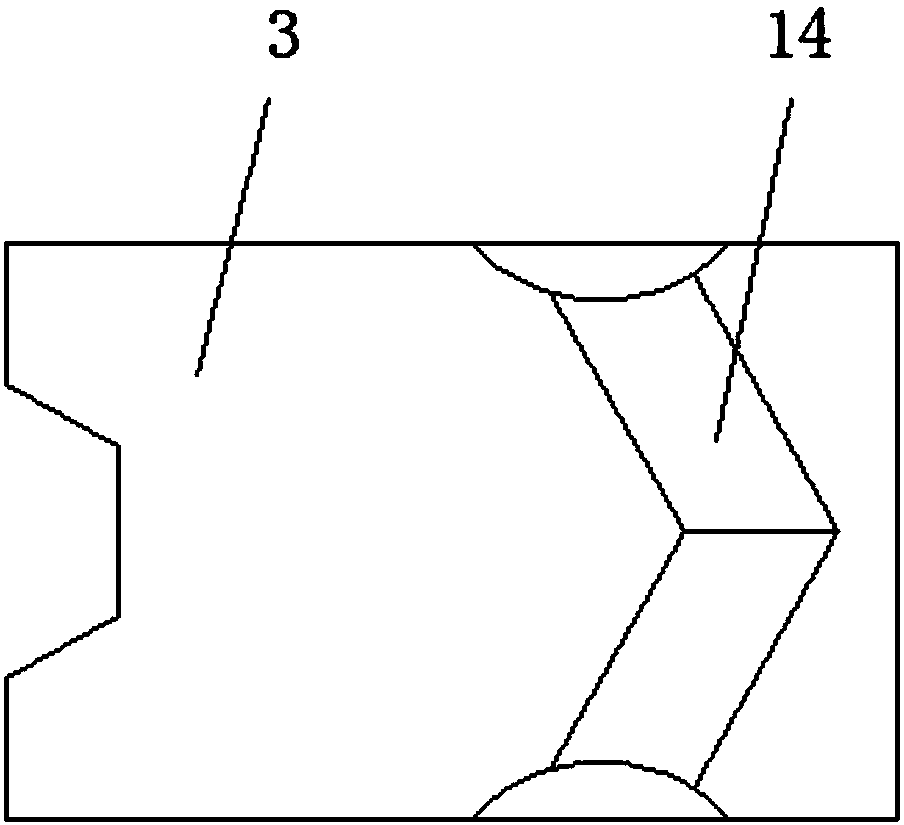

[0021] Reference Figure 1-4 , A straw pellet forming device, including a storage bin 4, a hydraulic cylinder 1 is arranged at the center of the upper surface of the storage bin 4, and the hydraulic cylinder 1 is connected with the pusher plate 2 in the storage bin 4 through a hydraulic telescopic rod to store The outer wall of the silo 4 is provided with feeding pipes 3 symmetrically on both sides, and the inner surface of the feeding pipe 3 is rotatably connected with a one-way valve rod 14. The outer wall of the bottom of the storage silo 4 is buckled with the sieve plate 10 through a bayonet 6 In connection, a discharge plate 9 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com